Uncoiling and wire drawing device

A technology of wire drawing and wire drawing liquid, which is applied in the direction of metal wire drawing, metal processing equipment, manufacturing tools, etc., can solve problems such as the reduction of wire drawing efficiency of steel wire drawing machines, the reduction of wire drawing efficiency of dry wire drawing machines, and the influence of wire drawing effects of steel wire drawing machines. Good wire drawing effect, easy to clean and handle, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

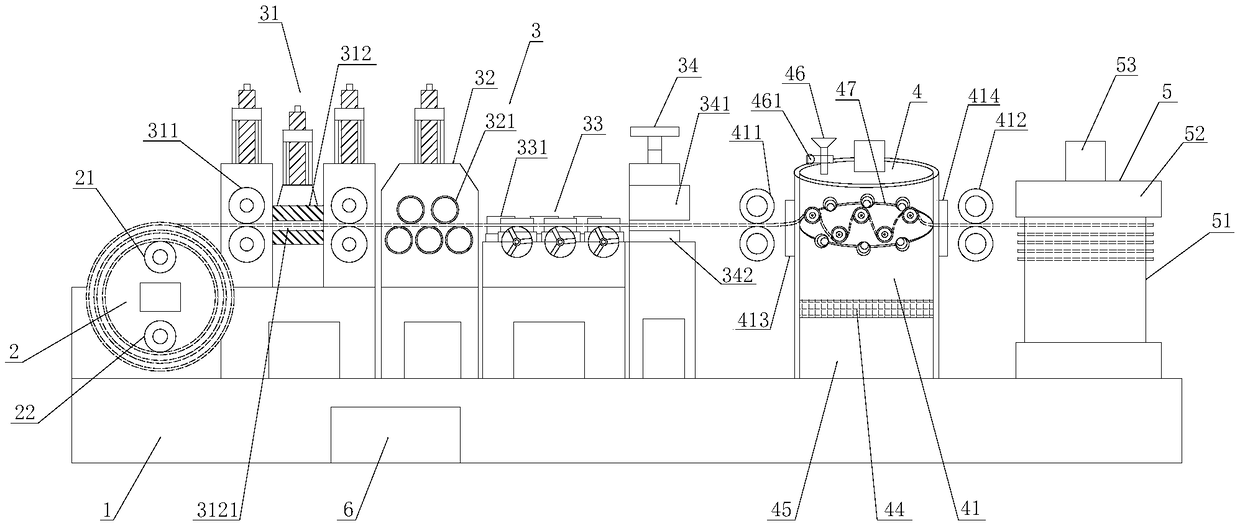

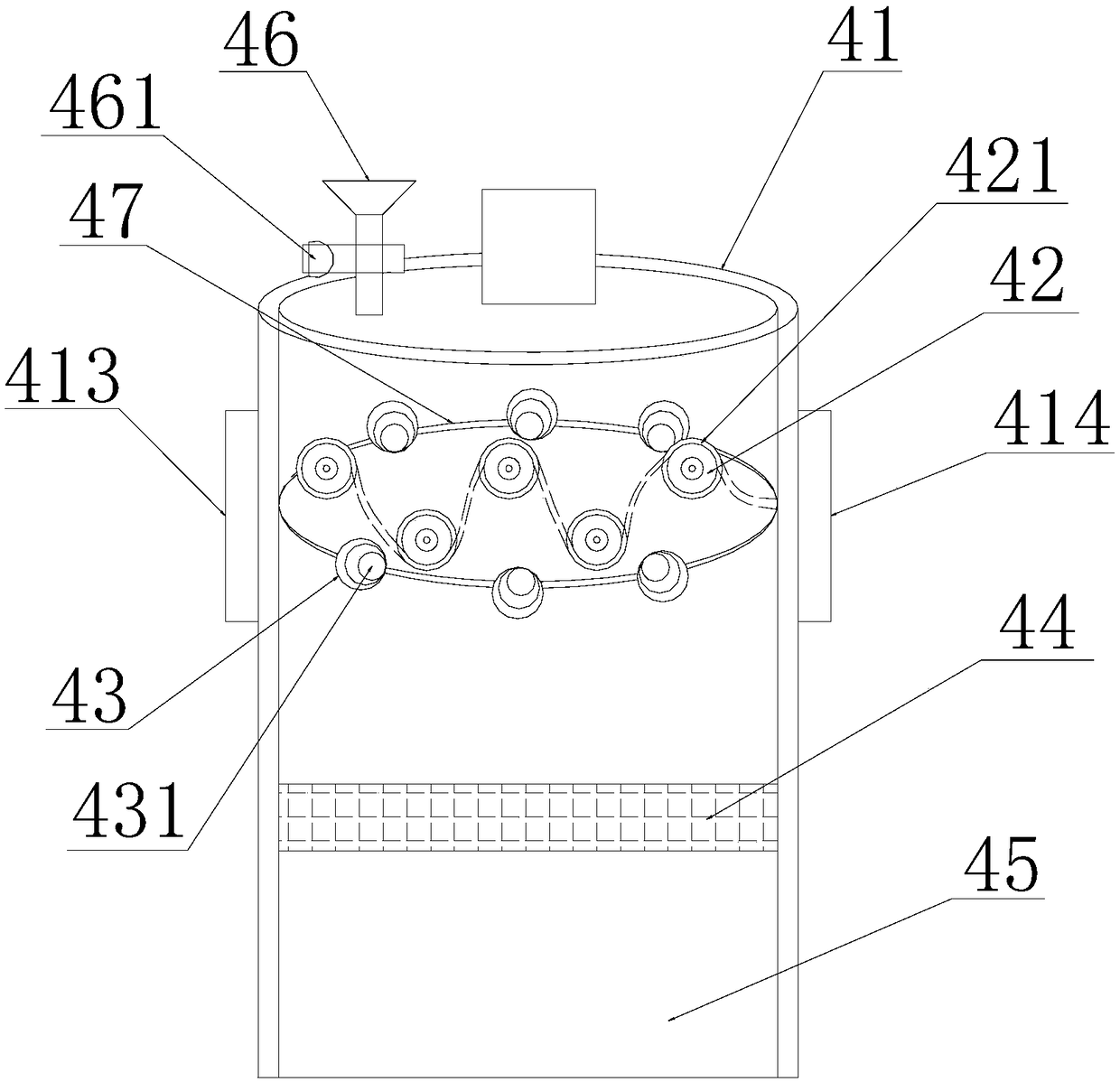

[0014] refer to figure 1 and figure 2 , an uncoiling wire drawing device of the present invention, comprising a base 1, a feeding rack 2, an uncoiling mechanism 3, a wire drawing mechanism 4, a wire take-up mechanism 5 and a control mechanism 6, and the base 1 is sequentially installed and fixed with Feeding rack 2, uncoiling mechanism 3, wire drawing mechanism 4, wire take-up mechanism 5, said base 1 is also provided with a control mechanism 6, said feeding rack 2, uncoiling mechanism 3, wire drawing mechanism 4, wire take-up mechanism 5 Linked to the control mechanism 6, the uncoiling mechanism 3 includes a first uncoiling part 31, a longitudinal straightening part 32, a horizontal straightening part 33 and a feeding part 34, and the first uncoiling part 31, the longitudinal straightening part 32, the horizontal straightening part The straight part 33 and the feeding part 34 cooperate with each other in order from left to right to transmit the wire to the wire drawing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com