Cold-drawing die of ribbed cladding pipe, production process and finished pipe thereof

A cladding tube and ribbed technology, which is used in nuclear engineering, wire drawing dies, manufacturing tools, etc., to achieve the effects of convenient manufacturing, low manufacturing cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] For the mold design in this process, the forming tool used in the present invention is a cold drawing die, including a cold drawing outer mold 1 for controlling the outer contour forming and a cold drawing core 2 for controlling the inner diameter.

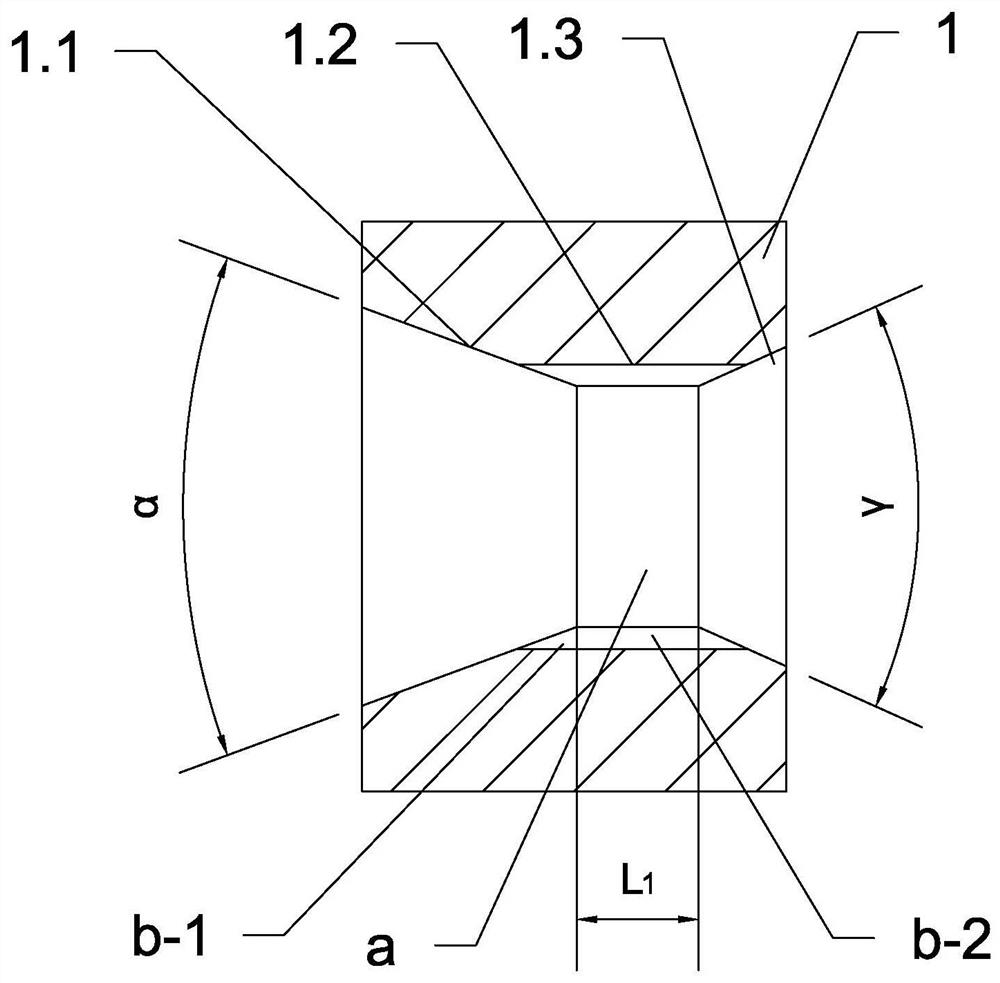

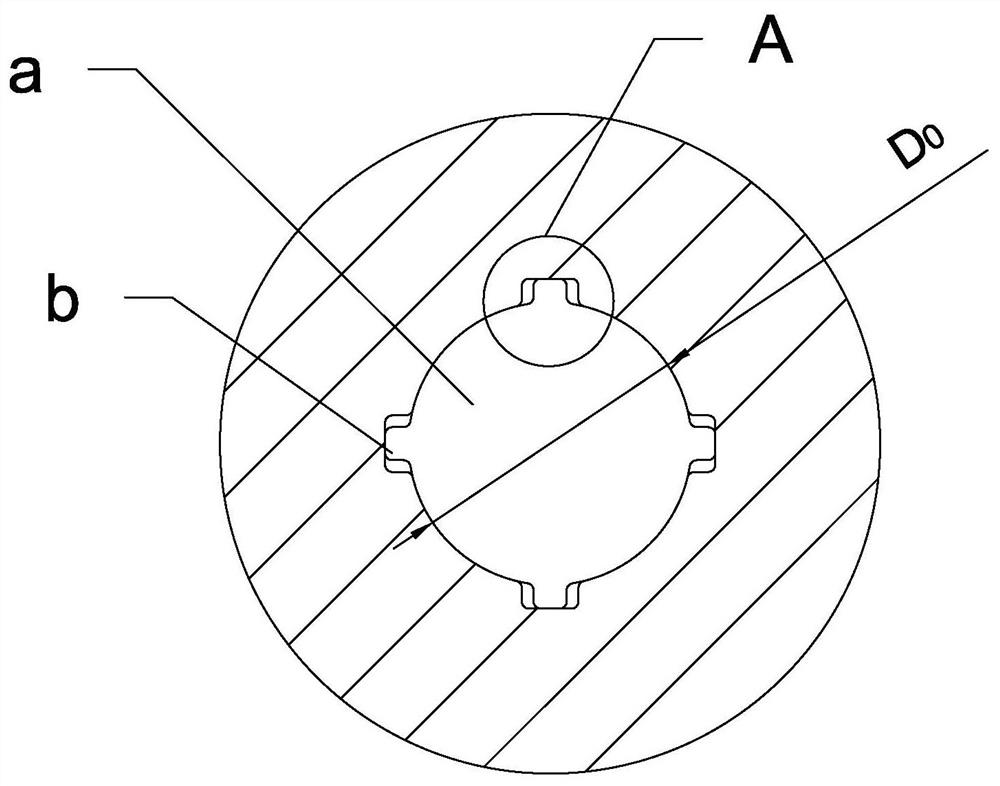

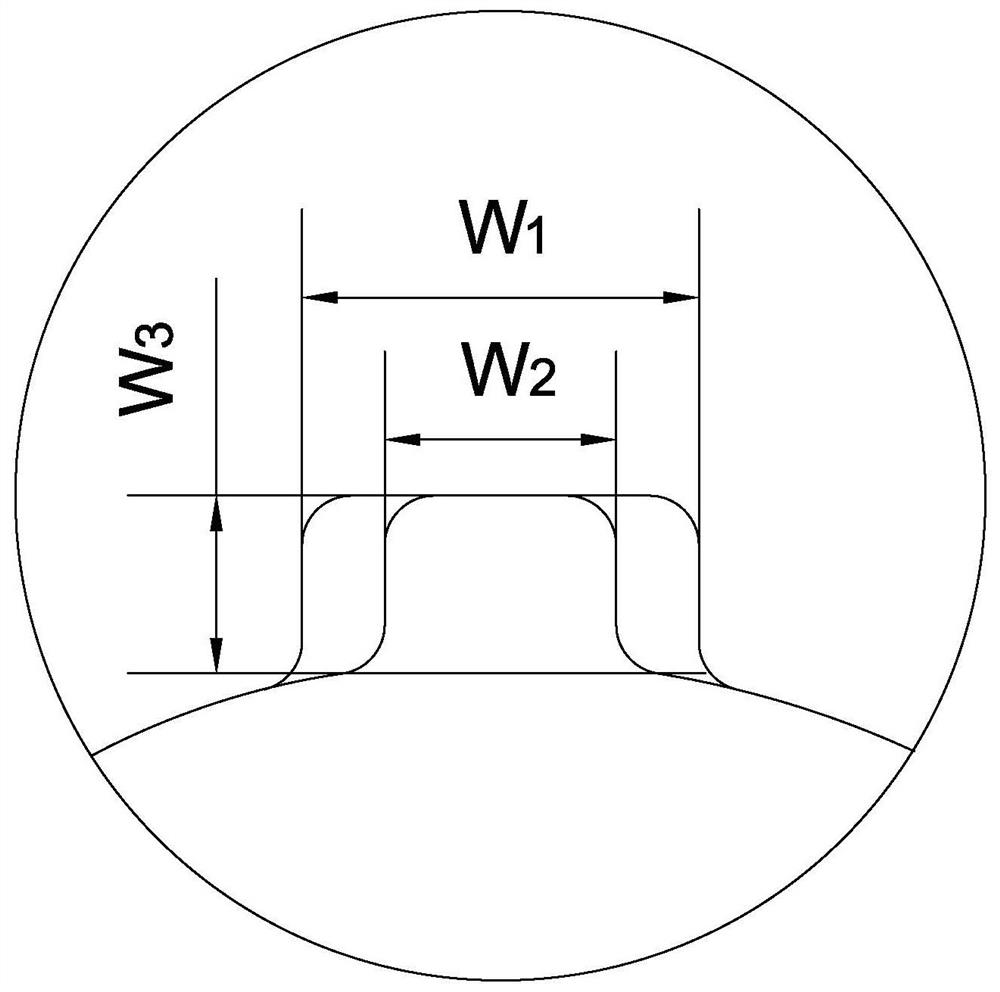

[0043] Cold drawn outer mold 1 design, refer to figure 1 , figure 2 and image 3, the cold-drawn outer mold 1 is a mold with a hollow area inside, and the hollow area is divided into three sections: the entrance section 1.1, the sizing section 1.2 and the exit section 1.3, and the sizing section 1.2 is formed by the outer diameter of the hole a and four sections of rib groove b, the inlet section 1.1 and outlet section 1.3 are both frustum-shaped grooves, the rib groove b is divided into two sections, the front section is the guide section b-1 and the rear end is the fixed-length section b-2 , the outline of the guide section b-1 gradually shrinks toward the direction of the fixed-length section b-2 until it completely m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com