Tension adjusting device for flat copper alloy wire processing

A tension adjustment device and tension adjustment wheel technology, applied in metal processing equipment, metal wire drawing, manufacturing tools, etc., can solve the problems of rigid structure, unadjustable tension, single function, etc., to avoid line bending, avoid structural rigidity, and facilitate the The effect of tension adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

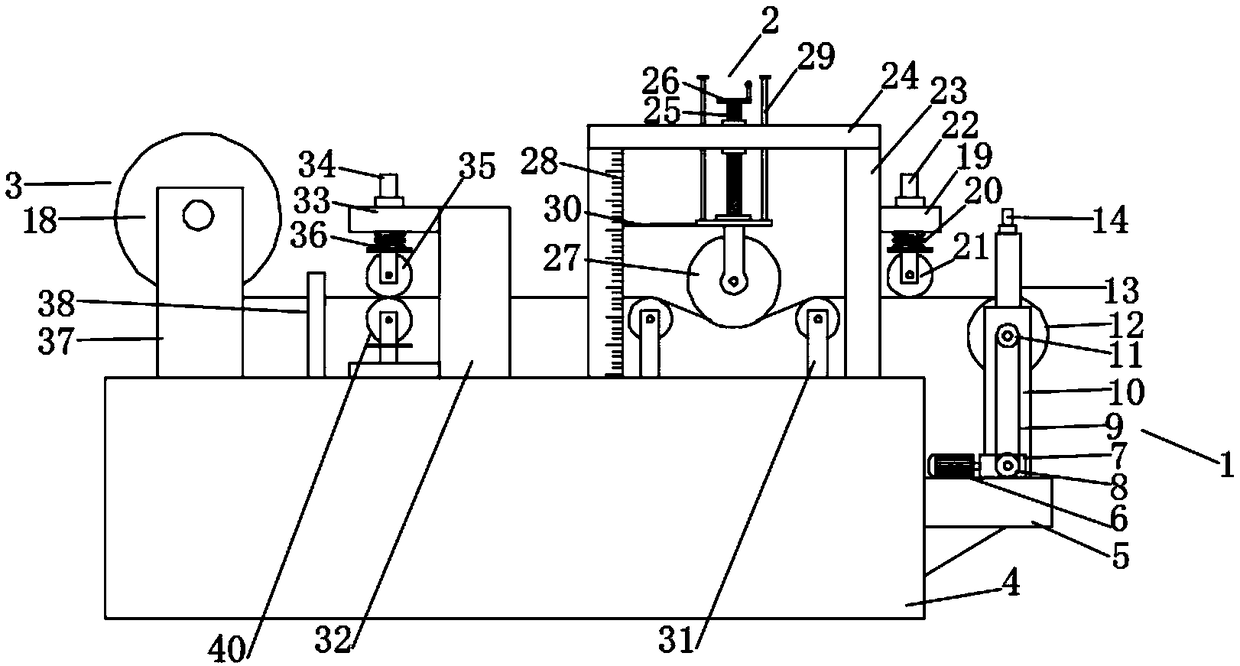

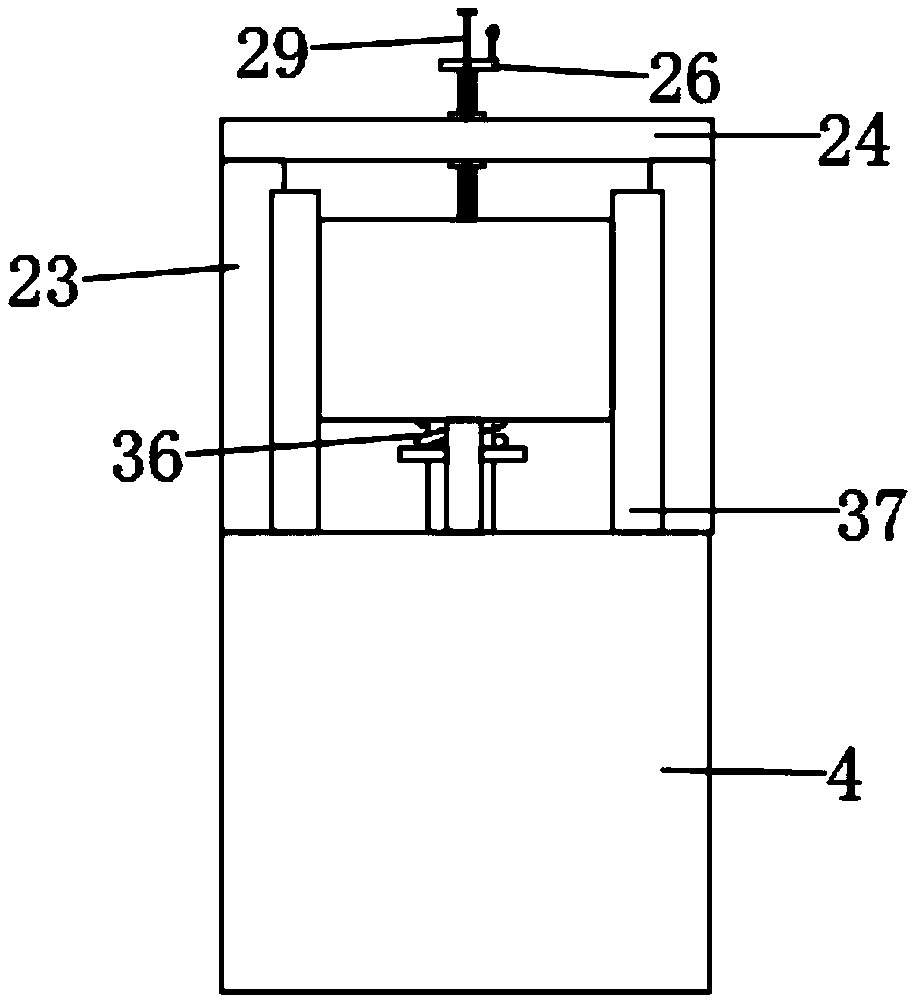

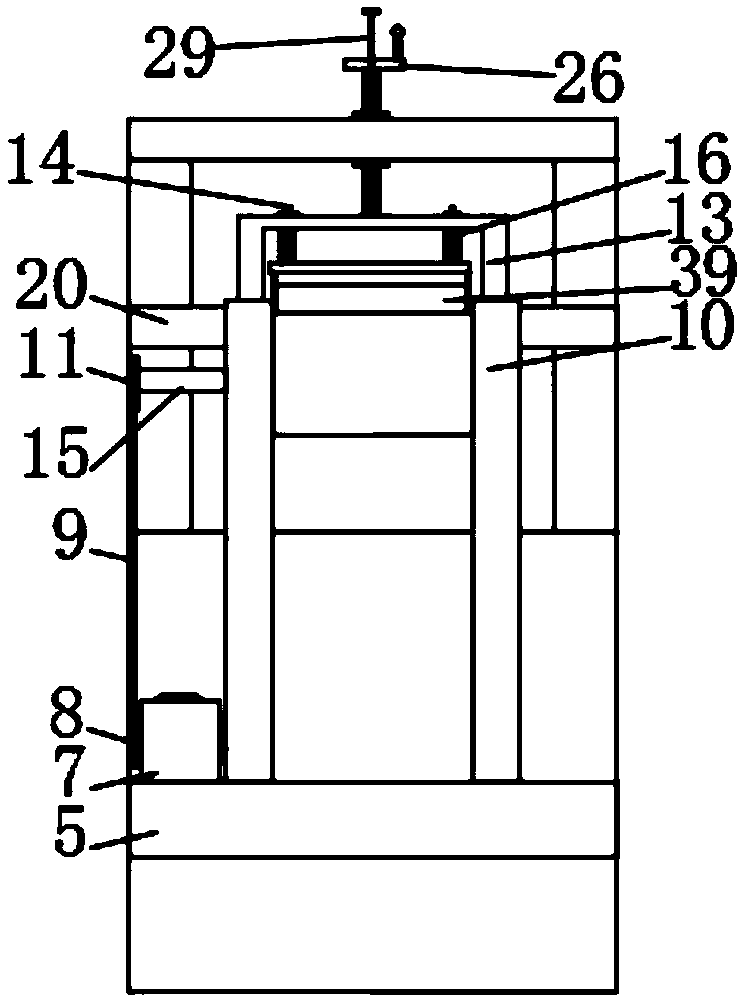

[0020] Such as Figure 1-4 As shown, this specific embodiment adopts the following technical solutions: a tension adjustment device for copper alloy flat wire processing, including a wire take-up mechanism 1, a tension adjustment mechanism 2, a wire release mechanism 3 and a workbench 4, the workbench 4 One end is fixedly connected with a take-up mechanism 1, the other end of the workbench 4 is provided with a pay-off mechanism 3, and a tension adjustment mechanism 2 is provided above the workbench 4 between the take-up mechanism 1 and the pay-off mechanism 3 , the take-up mechanism 1 is composed of a support plate 5, a motor 6, a reducer 7, a power wheel 8, a belt 9, a first support plate 10, a driven wheel 11, a take-up roller 12, a bracket 13, a first slide bar 14, Drive shaft 15, first spring 16, guide wheel 17, pay-off roller 18 and second support plate 19 are formed, and one end of described workbench 4 is fixedly connected with support plate 5, and the top of described ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com