Wire drawing production system and production technology for steel wire of steel strand

A production system and steel strand technology, applied in the direction of metal wire drawing, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the toughness and strength of steel wire, destroying the molecular structure of wire rod, affecting the quality of steel wire drawing, etc., and achieving improvement Adhesion, abundant resources, effects of avoiding hydrogen embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

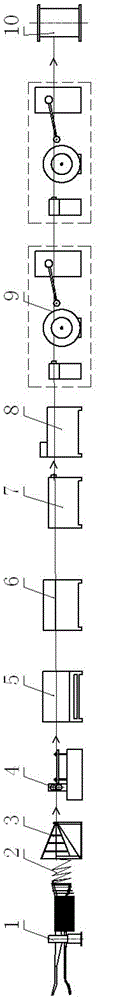

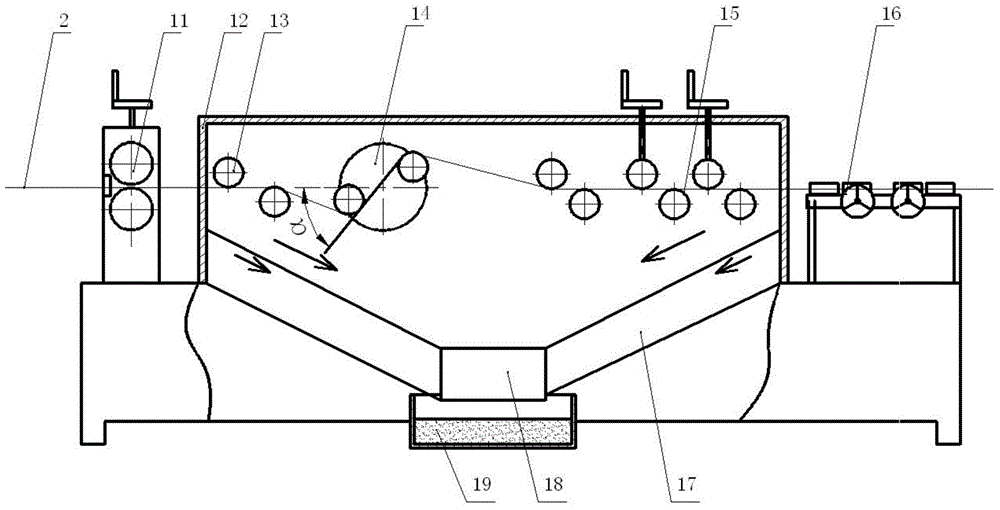

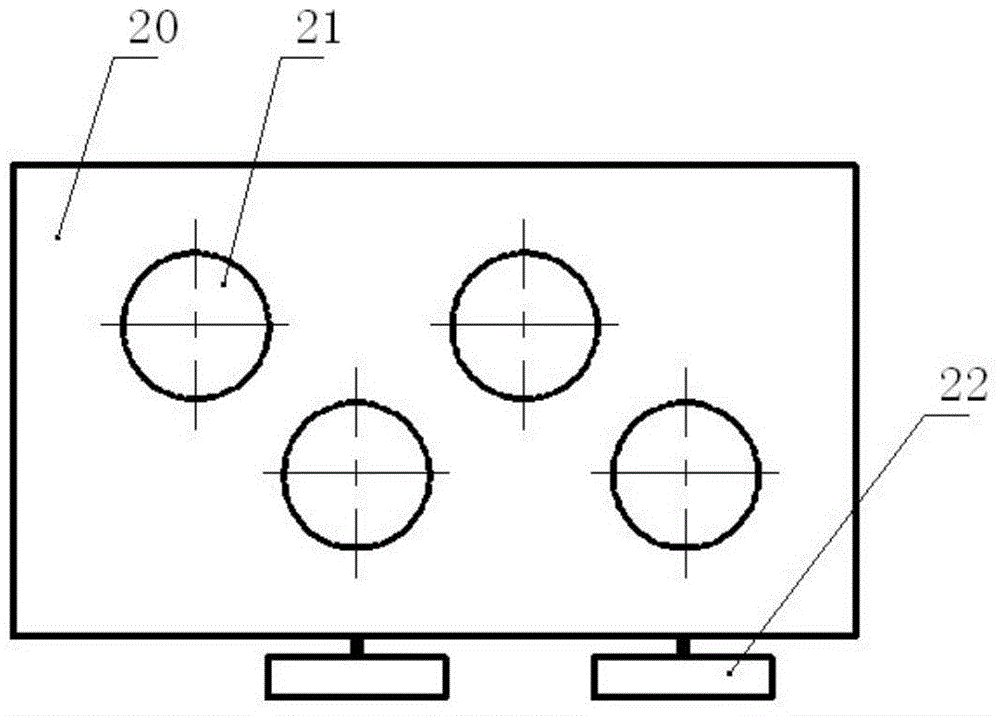

[0071] A steel strand steel wire drawing production system, such as figure 1 The shown includes a pay-off frame 1, a wire management frame 3, a straightening guide device 4, a physical shelling device 5, a rust removal and polishing device 6, a film coating device 7, a drying device 8, and a multi-channel drawing device 9, which are arranged in sequence. And take-up frame 10. Install the wire rod 2 on the pay-off frame, and transfer the wire rod to the straightening guide device stably and reliably through the wire management frame for clamping and straightening processing, and then enter the physical shelling device through coiling and bending. Remove the oxide layer on the surface of the wire rod, and then enter the derusting and polishing device to remove the oxide layer on the surface of the wire rod through multiple wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com