Secondary evaporator series production device in tar distillation and its application

A technology of secondary evaporator and production device, which is applied in the direction of tar processing by distillation method, etc., to achieve the effects of convenient operation, safe operation and rapid replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

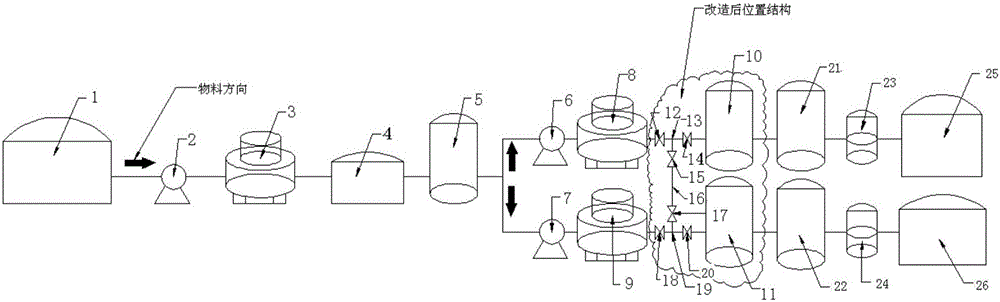

[0038] A series production device for secondary evaporators in tar distillation, comprising a first-stage evaporator connected in sequence, a parallel I system production part and a II system production part, respectively connected to the parallel I system production part and II system production part The second-stage evaporation part of system I and the second-stage evaporation part of system II;

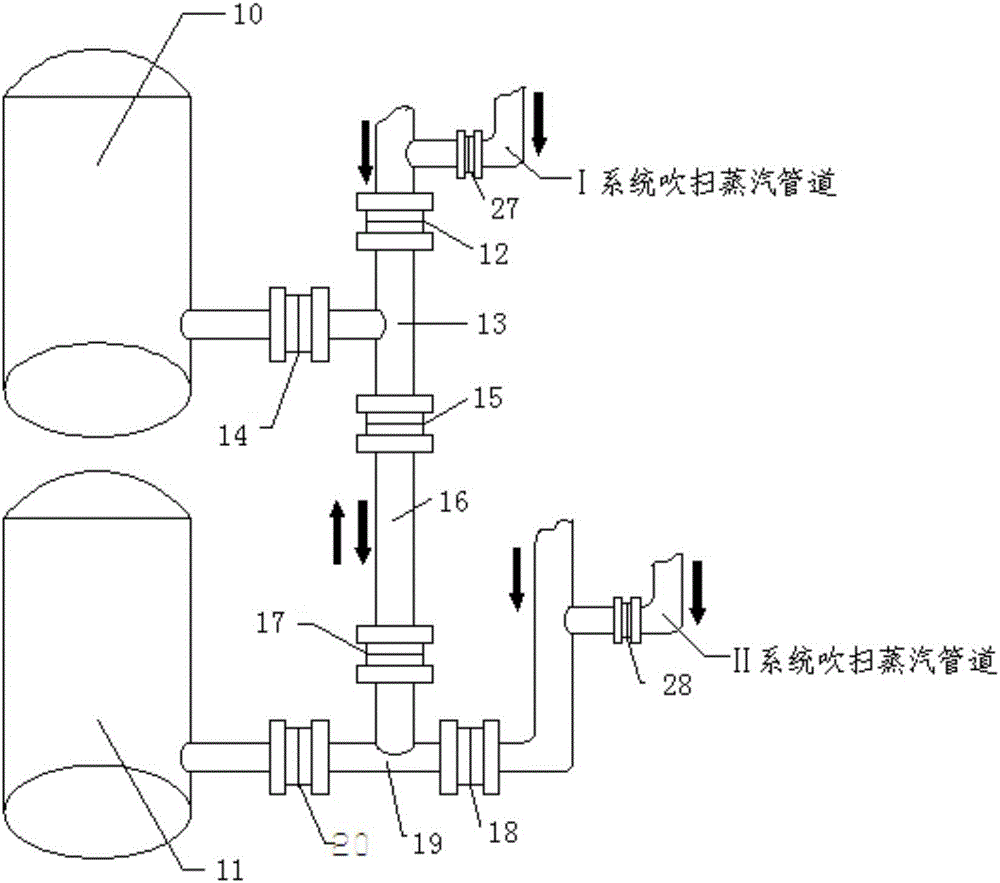

[0039] A first three-way pipe 13 is provided between the production part of the I system and the second-stage evaporation part of the I system, and a second three-way pipe 19 is provided between the production part of the II system and the second-stage evaporation part of the II system, The first three-way pipe 13 and the second three-way pipe 19 are connected.

[0040] The first-stage evaporator includes a raw material tar tank 1, a first-stage plunger pump 2, a tubular heating furnace 3, an anhydrous tar tank 4, and a first-stage evaporator 5 connected in sequence.

[0041] The I syste...

Embodiment 2

[0047] According to the second evaporator tandem production device in the tar distillation described in Example 1, the difference is that the discharge port of the tubular heating furnace 8 of the I system and the input port of the two-stage evaporator 10 of the I system are different A steam purge valve 27 of the I system is provided between the two; a steam purge valve 28 of the II system is provided between the discharge port of the tube heating furnace 9 of the II system and the feed port of the second-stage evaporator 11 of the II system.

Embodiment 3

[0049] A working method in tar distillation using the secondary evaporator series production device as described in Examples 1 and 2, including the following steps:

[0050] The production department of the I system is connected in series with the two-stage evaporation part of the I system to form the I system; the production department of the system II is connected in series with the two-stage evaporation part of the II system to form the II system;

[0051] When I system and II system work in parallel:

[0052] Open the first tar control valve 12 and the first feed valve 14, close the first control valve 15, and make the I system work;

[0053] Open the second tar control valve 18 and the second feed valve 20, close the second control valve 17 to make the II system work;

[0054] When the second stage evaporation part of the I system fails, the first feed valve 14 is closed; the first control valve 15 and the second control valve 17 are opened to realize rapid switching to the II syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com