Patents

Literature

48results about How to "Suitable for large-scale promotion and utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene oxide/nano cellulose aerogel and preparation method and application thereof

ActiveCN105566659AGood removal effectEfficient purificationWater/sewage treatment by sorptionOrganic dyePhenol

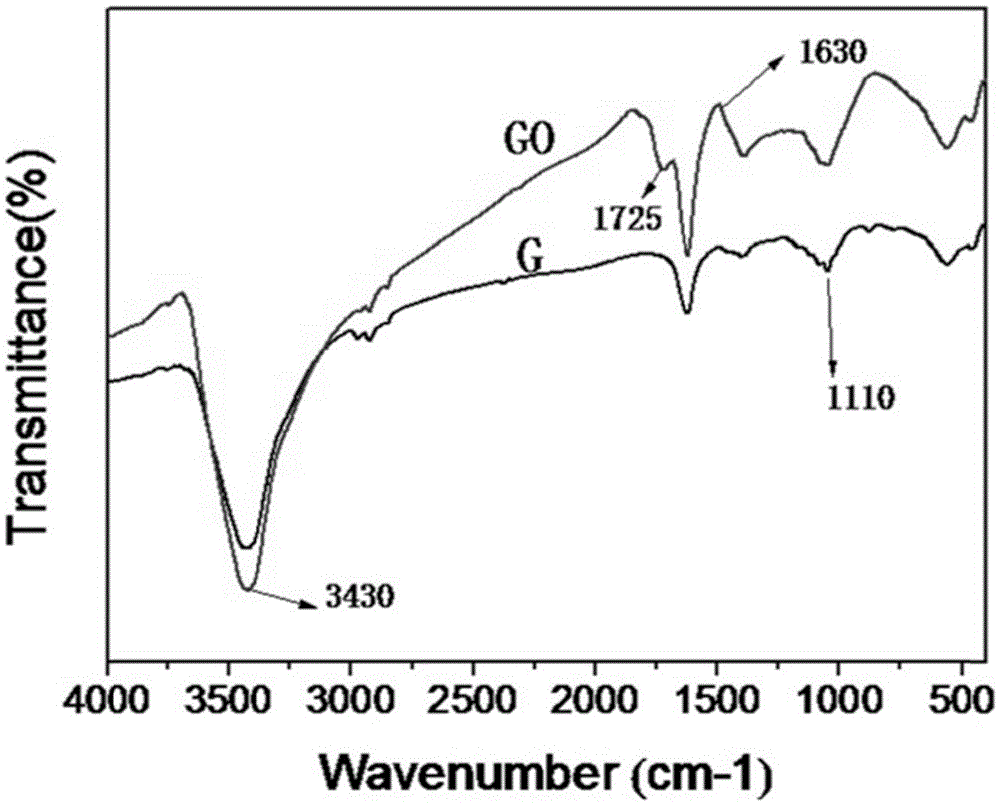

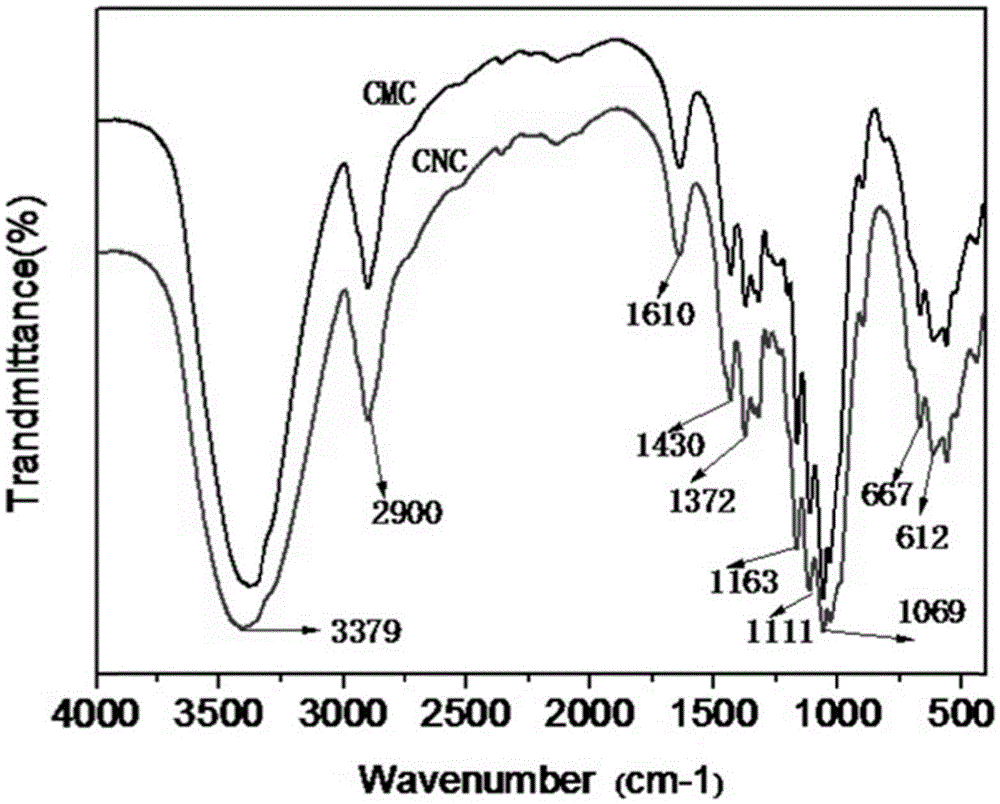

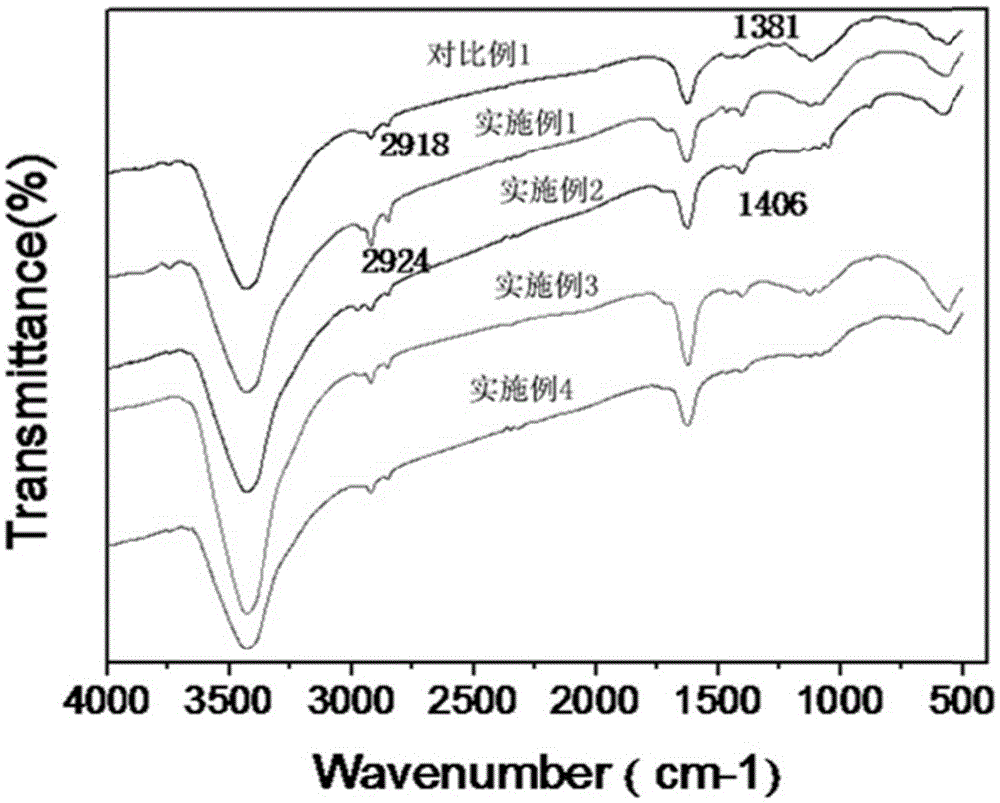

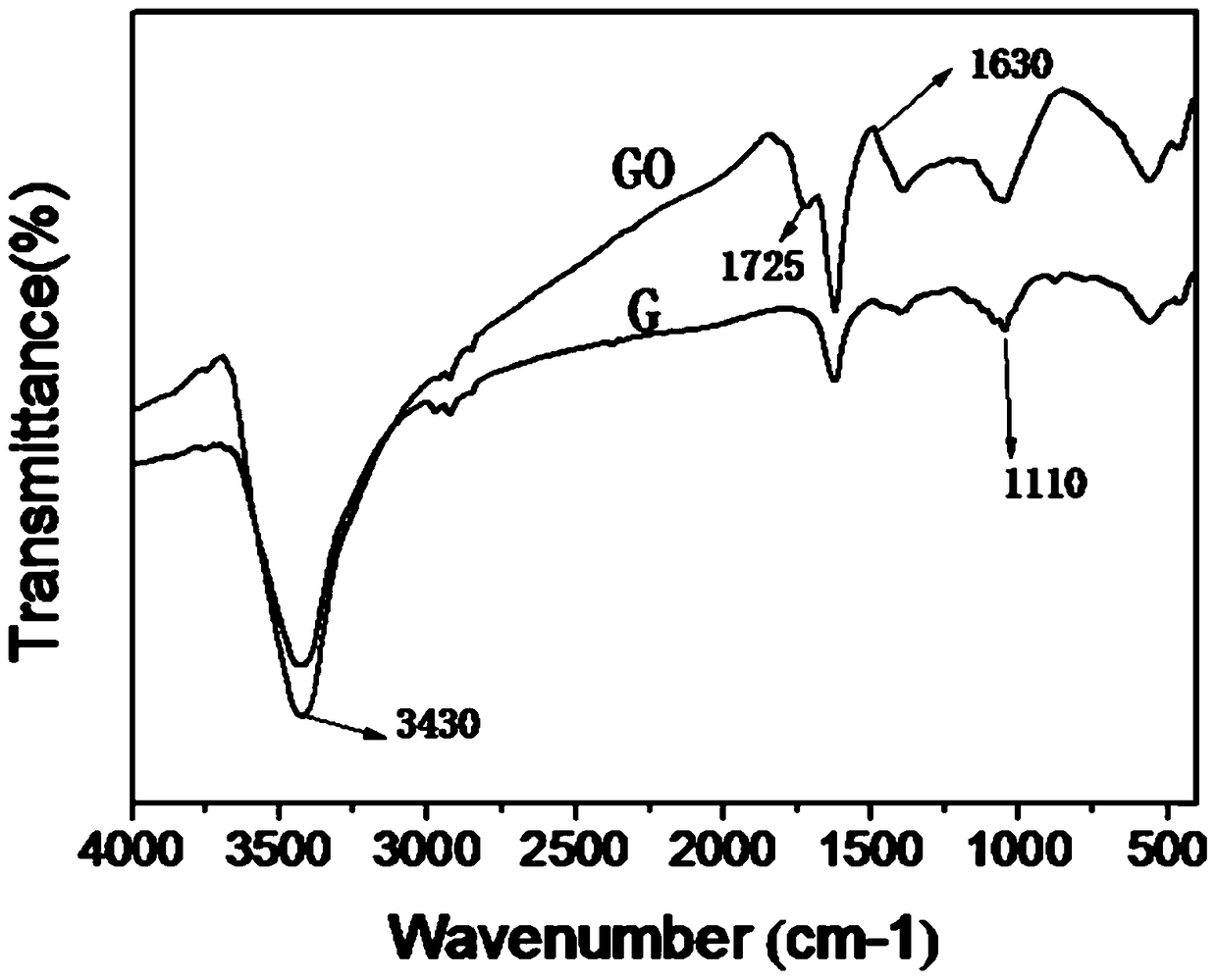

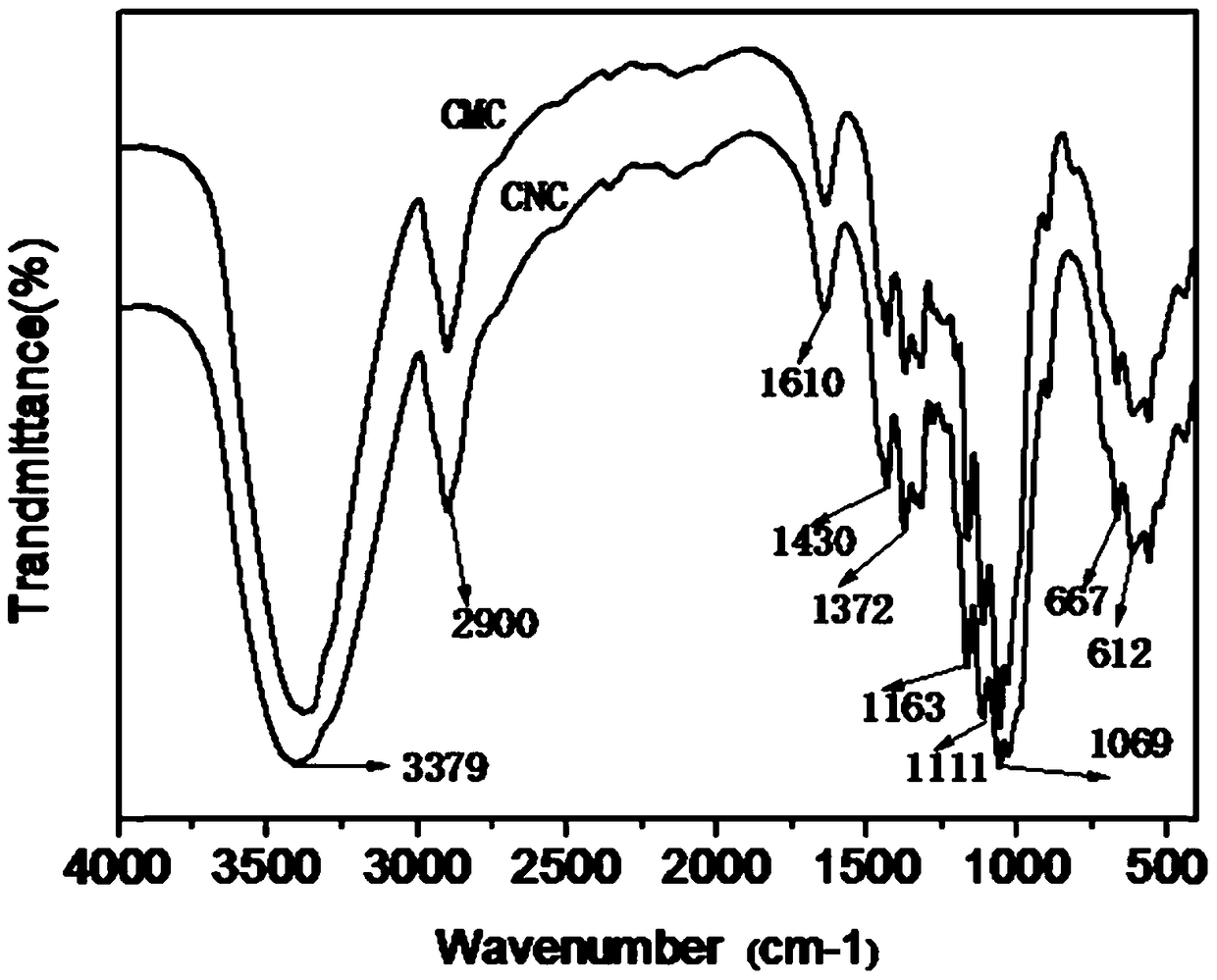

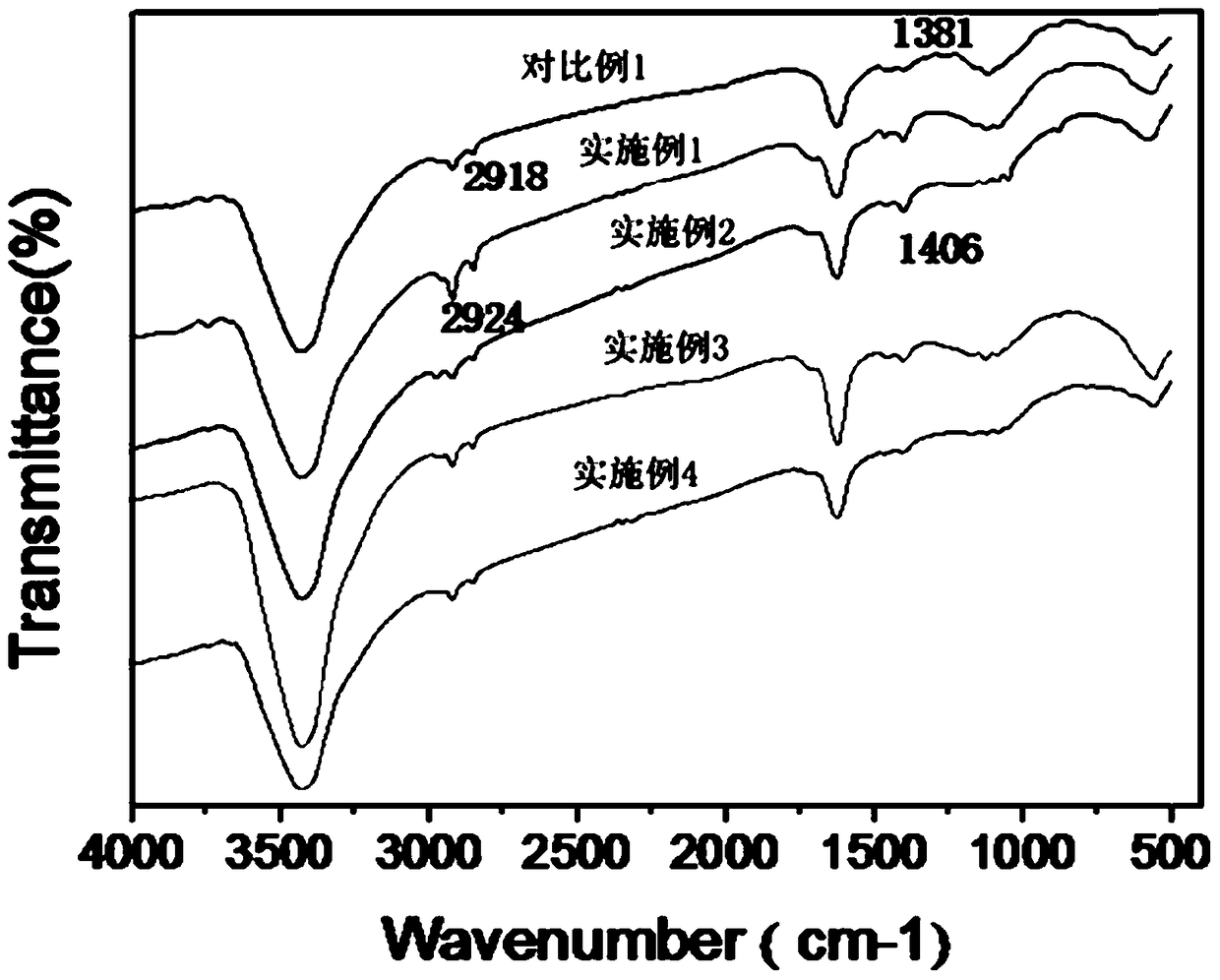

The invention discloses a graphene oxide / nano cellulose aerogel and a preparation method and an application thereof, and belongs to the technical field of aerogel material. The aerogel is prepared by the method including the following steps: 1) dispersing nano cellulose in hydrochloric acid to prepare a nano cellulose dispersion liquid; 2) mixing a graphene oxide dispersion liquid with the nano cellulose dispersion liquid obtained in the step 1) evenly, and carrying out a hydrothermal reaction at the temperature of 170-190 DEG C to obtain a hydrogel; and 3) carrying out freeze drying of the hydrogel obtained in the step 2) to obtain the aerogel. According to the graphene oxide / nano cellulose aerogel provided by the invention, nano cellulose and graphene oxide as raw materials are subjected to hydrothermal reaction to prepare the hydrogel, the hydrogel is further subjected to freeze drying to obtain the final product. Compared with a graphene oxide aerogel, the aerogel has better removal effect on phenol in a phenol aqueous solution, can be used for removal of organic dye molecules or other impurities in sewage, and efficiently purifies the sewage.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

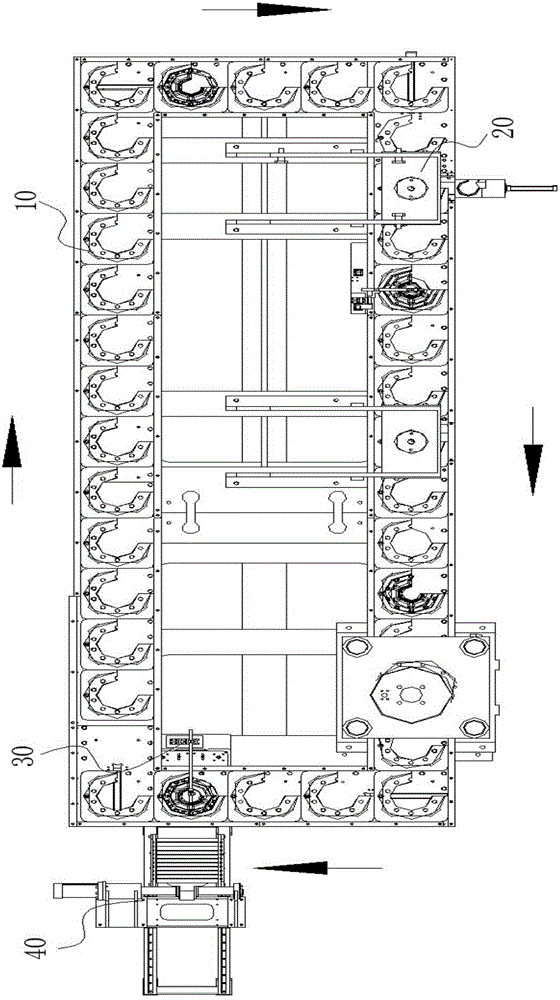

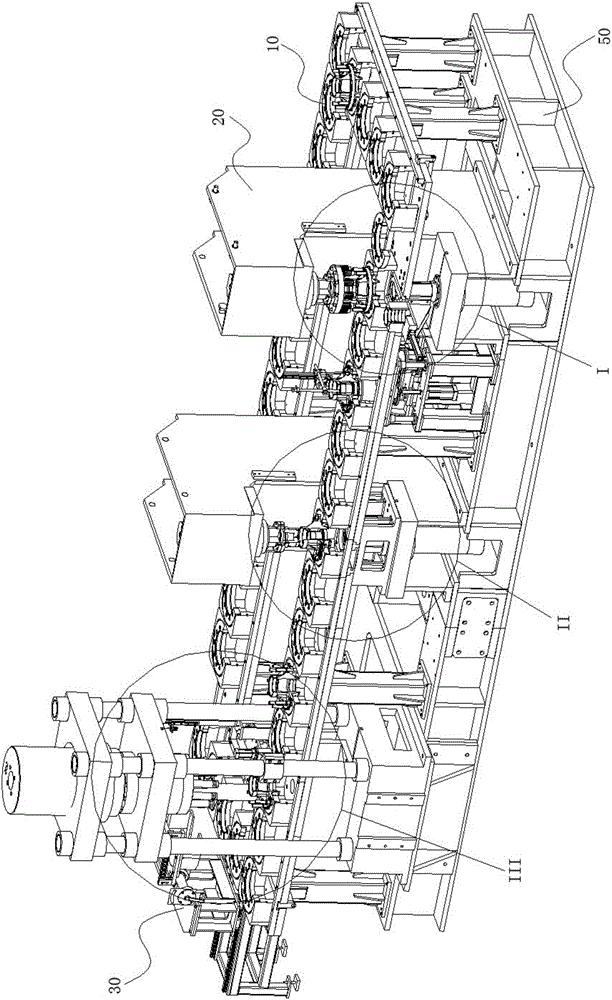

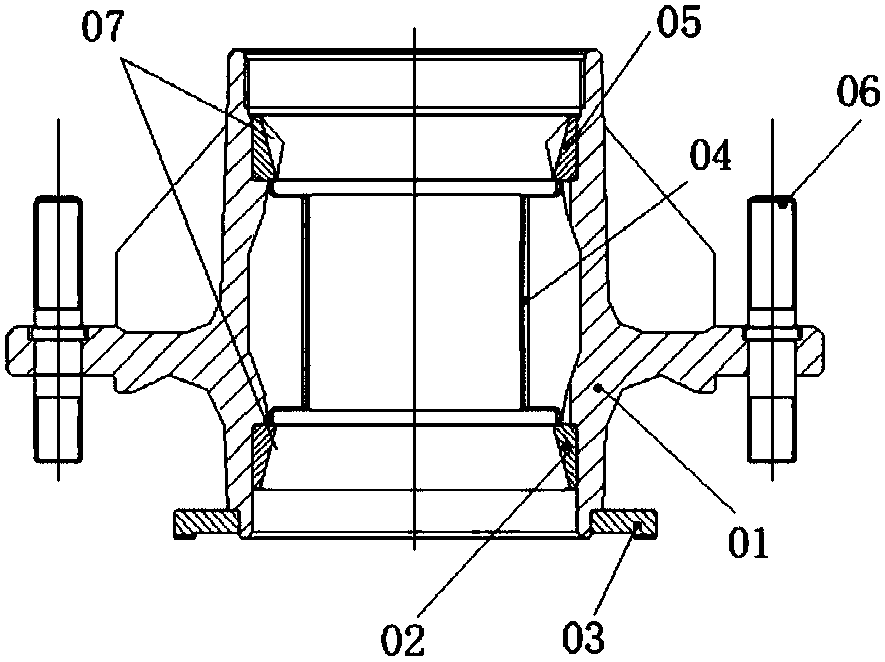

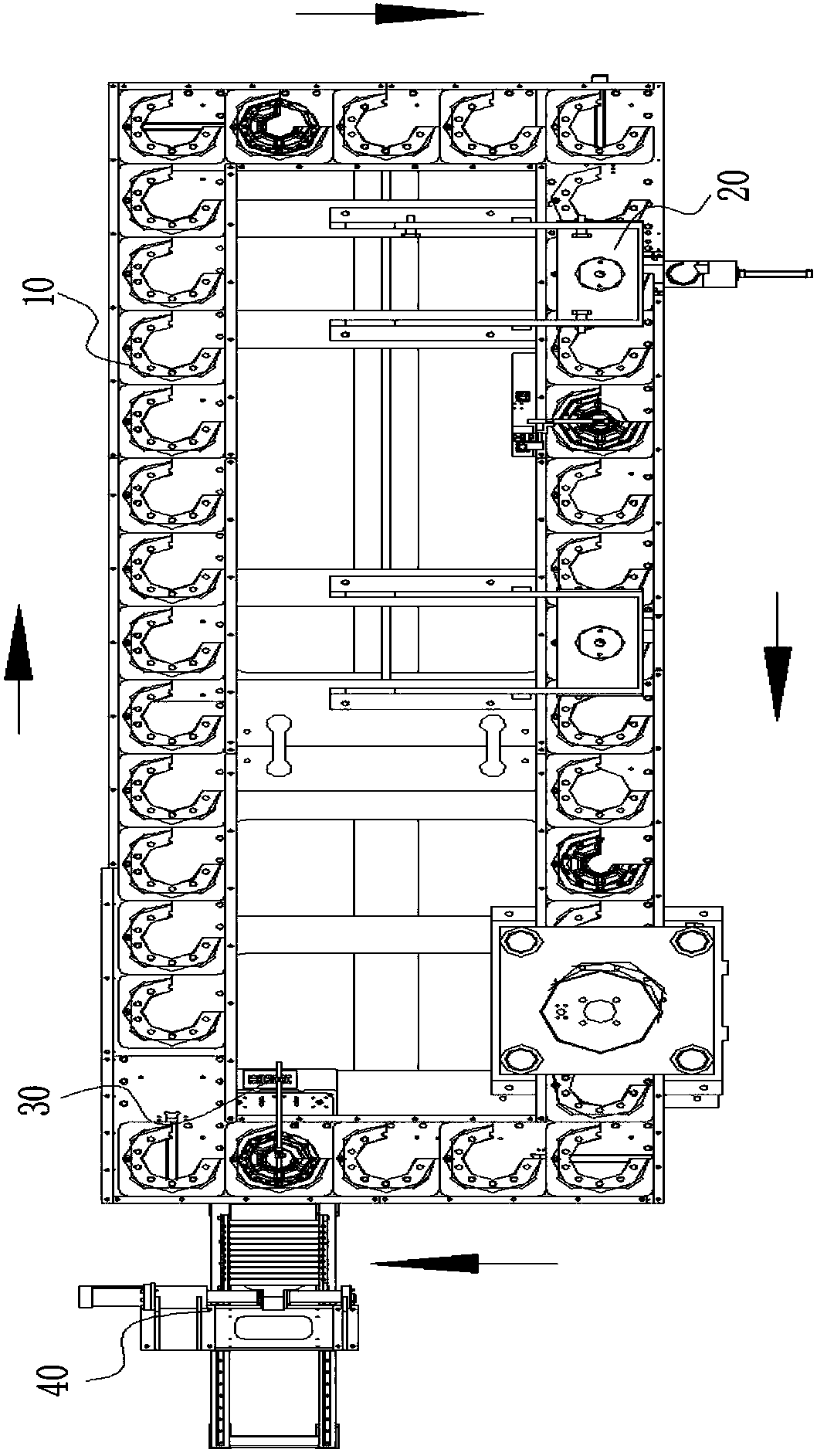

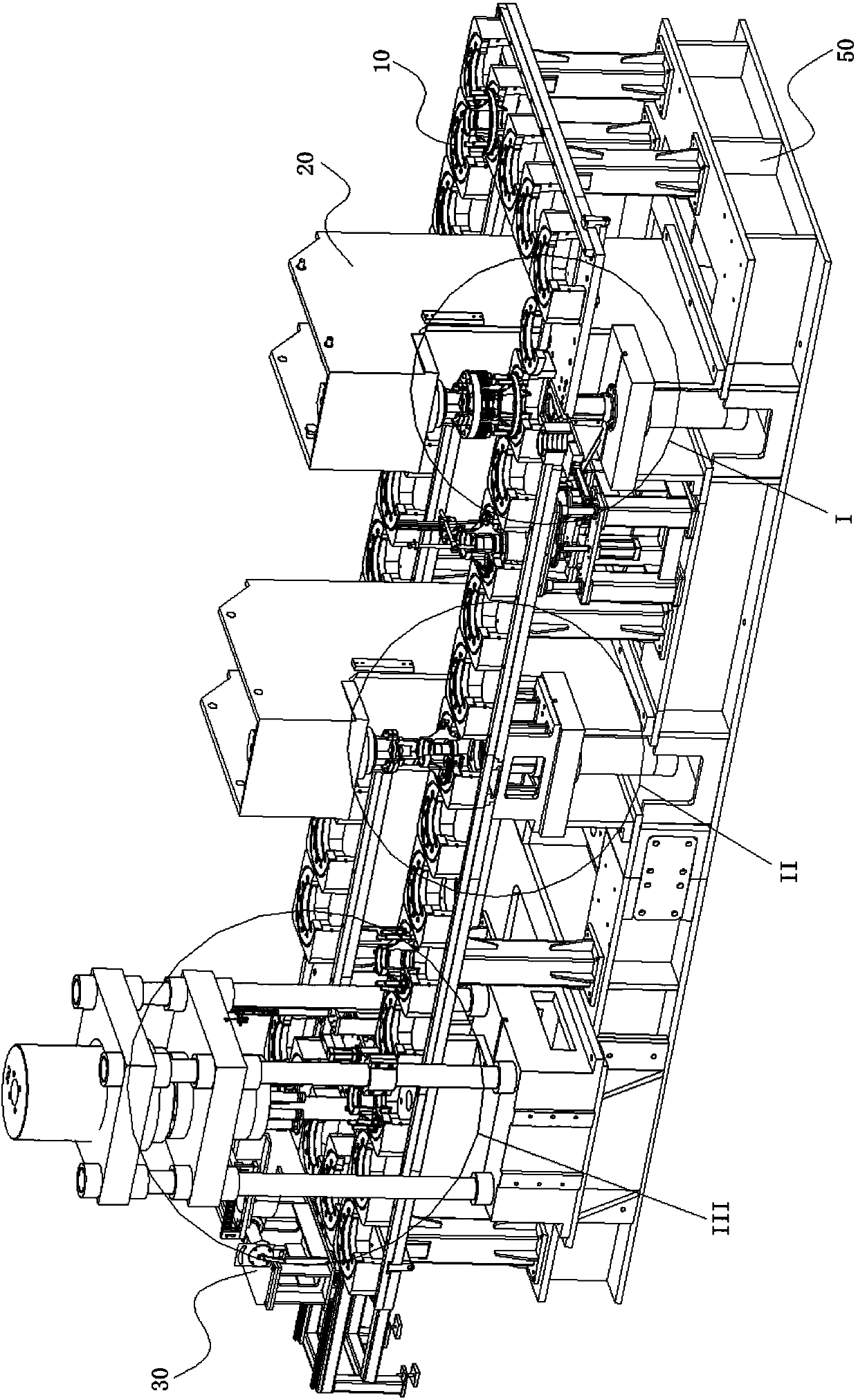

Press-fitting production line for hub assemblies

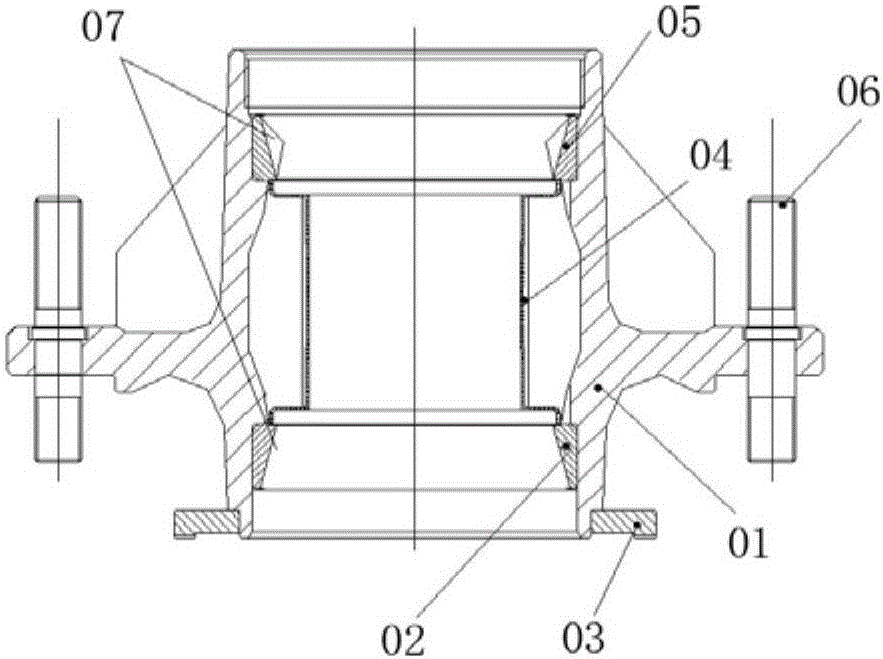

ActiveCN106112511AHigh degree of automationIncrease productivityAssembly machinesVehicle componentsAutomationProduction line

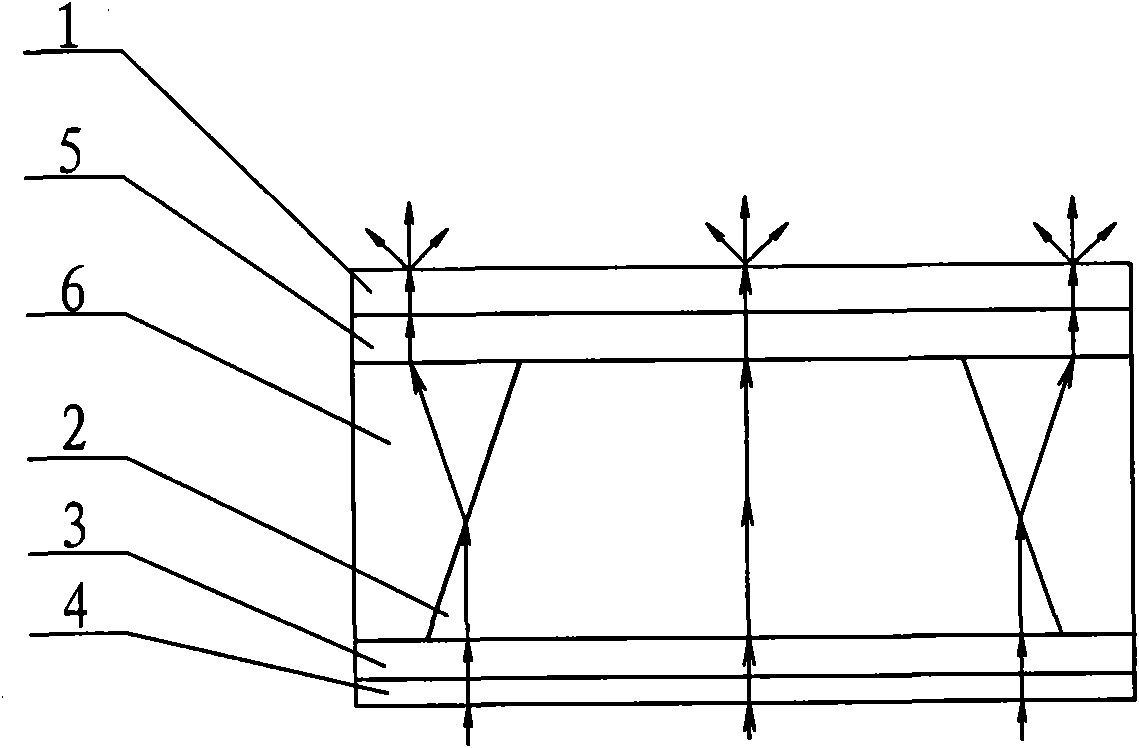

The invention discloses a press-fitting production line for hub assemblies. The press-fitting production line comprises a circulatory conveying assembly and a part press-fitting mechanism; the circulatory conveying assembly comprises a support and a plurality of supporting brackets arranged on the support, and the multiple supporting brackets are used for conveying hubs on the support in a circulation mode so that the hubs can undergo the press-fitting work of each process; and the part press-fitting mechanism comprises a lower bearing outer ring pressing machine, an upper bearing outer ring pressing machine, an ABS gear ring pressing machine and a bolt pressing machine, wherein the lower bearing outer ring pressing machine, the upper bearing outer ring pressing machine, the ABS gear ring pressing machine and the bolt pressing machine are arranged along the support, the lower bearing outer ring pressing machine is used for carrying out press-fitting on lower bearing outer rings of the hubs, the upper bearing outer ring pressing machine is used for carrying out press-fitting on upper bearing outer rings of the hubs, the ABS gear ring pressing machine is used for pressing ABS gear rings on the hubs, and the bolt pressing machine is used for pressing bolts on the hubs. The press-fitting production line for the hub assemblies has the advantages of being high in automation level and safe and saving energy and is suitable for being widely popularized and used.

Owner:GUANGDONG FUWA HEAVY IND

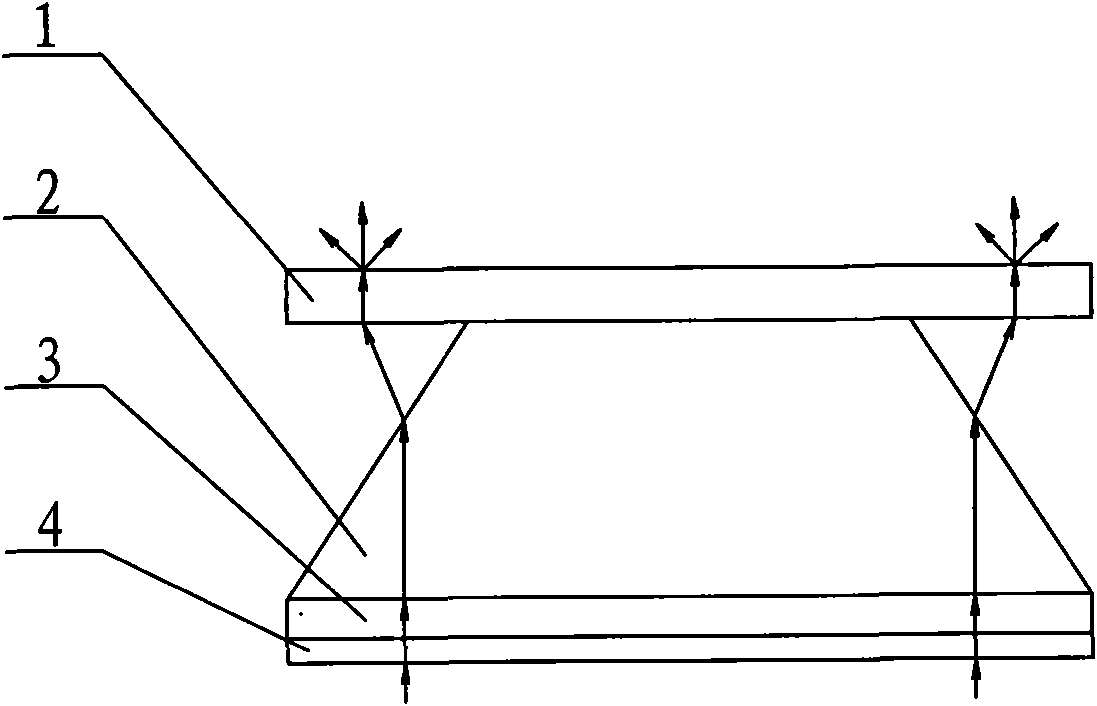

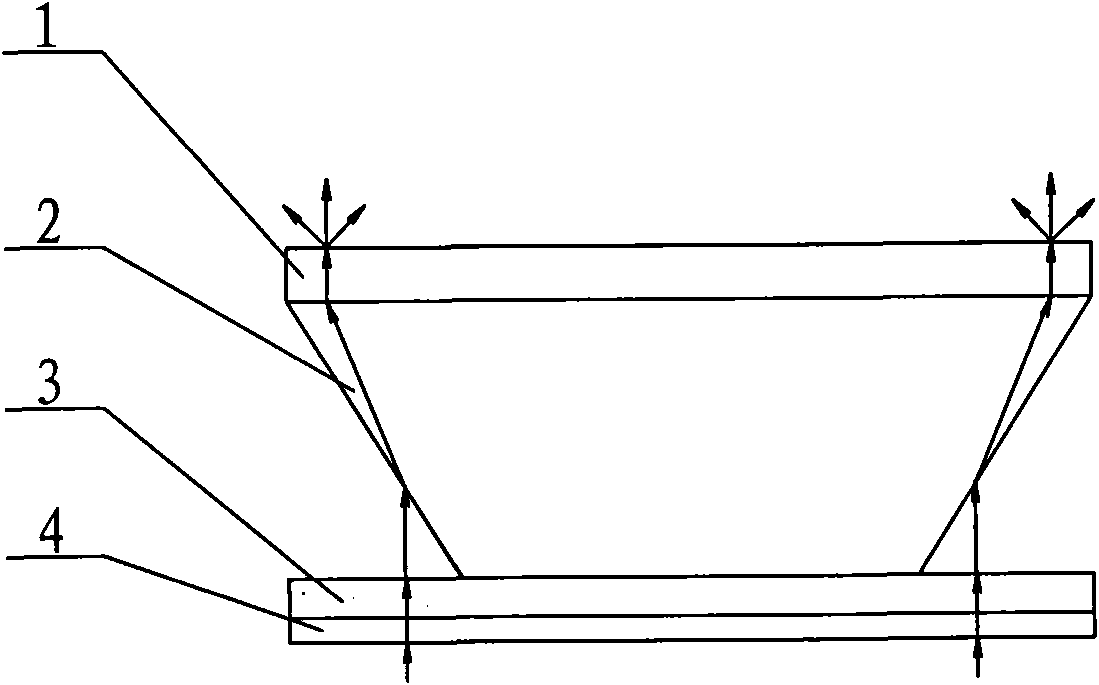

Display panel and image correction method thereof

The invention relates to a display panel and an image correction method thereof, belonging to the technical field of image shift-forward display and amplification. The display panel comprises a light guiding layer, a scattering layer made of a one-side light permeating material is arranged on the upper surface of the light guiding layer in a matching way, and a light converging layer is arranged on the lower surface of the light guiding layer in a matching way. The light guiding layer comprises a hollow or solid light permeating plate with a quadrangular frustum pyramid or inverted quadrangular frustum pyramid structure, and the lower surface of the light permeating plate is provided with a bottom light permeating plate in a matching way. For the display panel and the image correction method thereof, the light guiding layer made of a transparent material is used for changing the light path, the lower surface of the light guiding layer is provided with the light converging layer, and thus, light rays are converged to be approximately parallel and then guided into the light guiding layer. The upper surface is provided with the scattering layer, and meanwhile, an image corrector is arranged to optimize and improve a displayed image. The display unit can be used for visually eliminating the gap between every two display units, and the integral effect of a screen picture is realized. The device has the characteristics of low production cost, convenient installation and stable quality and is applicable to large-scale popularization and utilization.

Owner:应骏

Matrix special for soilless culture of celery

InactiveCN106220385ARaw materials are cheap and easy to getImprove fertilizer efficiencyAlkali orthophosphate fertiliserExcrement fertilisersBiotechnologyNutrient

The invention discloses a matrix special for soilless culture of celery. The matrix is prepared from, by weight, 60-80 parts of carbonized sawdust, 30-40 parts of camellia seed shells, 10-20 parts of plant ash, 5-6 parts of ammonium dihydrogen phosphate, 3-6 parts of borax, 10-18 parts of xylitol residues, 1-3 parts of straw decayed bacteria, 10-20 parts of wormcast, 10-20 parts of dry cow dung, 1-2 parts of cotton cakes, 10-18 parts of pine bark powder, 10-18 parts of perlite, 10-18 parts of carbonized rice hulls, 5-12 parts of alfalfa hay, 5-12 parts of kieselguhr and 5-12 parts of rotten wood. Compared with the prior art, the raw materials of the matrix special for soilless culture are cheap and easy to obtain, the matrix has a lasting fertilizer effect and provides sufficient nutrients, growth of celery is promoted, the yield is increased, and the quality is improved; besides, the matrix has good moisture retention and breathability, is not prone to hardening in the use process and is suitable for large-area utilization and popularization in production.

Owner:柳州市欧亚农业发展有限公司

A kind of graphene oxide/nanocellulose airgel and its preparation method and application

ActiveCN105566659BSimple processRaw materials are easy to getWater/sewage treatment by sorptionFreeze-dryingOrganic dye

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

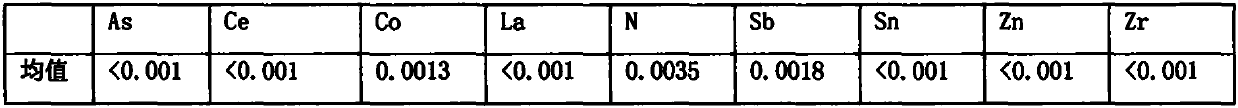

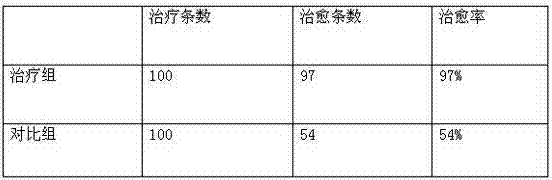

Traditional Chinese medicine composition for treating anglerfish liver and gall syndromes

InactiveCN104873597ACompatibility is reasonableNon-toxicDigestive systemPlant ingredientsLiver function testsInjury prevention

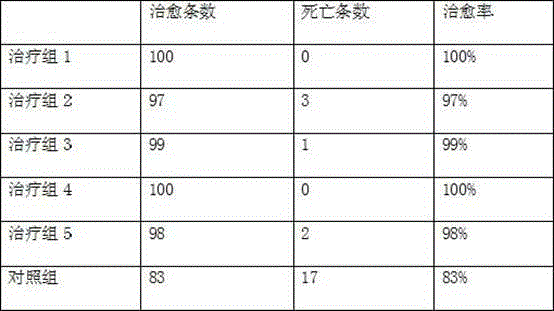

The invention provides a traditional Chinese medicine composition for treating anglerfish liver and gall syndromes, and belongs to the technical field of traditional Chinese medicine. The traditional Chinese medicine composition comprises, by weight, 5-15 parts of radix isatidis, 6-16 parts of felwort, 6-15 parts of uncaria rhynchophylla, 5-15 parts of astragalus membranaceus, 4-15 parts of angelica sinensis, 6-16 parts of capillary artemisia, 8-16 parts of liquorice and 4-15 parts of atractylodes macrocephala koidz. The traditional Chinese medicine composition for treating the anglerfish liver and gall syndromes is reasonable in compatibility, through the complementary effect of traditional Chinese medicine, the functions of detoxication, liver injury prevention, bleeding stop, blood stasis removal, regeneration of the liver cells and restoration of the liver function can be achieved, stress reactions are effectively reduced, the anglerfish liver and gall syndromes can be well prevented and treated, and the treatment effective rate reaches up to 98%. The traditional Chinese medicine composition is environmentally friendly, free of pollution and any toxic action, and suitable for being widely used and popularized.

Owner:诸葛渭航

Substrate special for soilless culture of sugar beans

InactiveCN106316615ARaw materials are cheap and easy to getImprove fertilizer efficiencyAlkali orthophosphate fertiliserExcrement fertilisersAmmonium sulfateNutrient

The invention discloses a substrate special for soilless culture of sugar beans. The substrate comprises the following components in parts by weight: 60-80 parts of bagasse, 30-40 parts of bamboo charcoal powder, 10-20 parts of straw powder, 5-6 parts of ammonium dihydrogen phosphate, 3-6 parts of ammonium sulfate-nitrate, 10-18 parts of hickory husks, 1-3 parts of straw decomposing bacteria, 10-20 parts of grass stalks, 10-20 parts of dried cow dung, 1-2 parts of vermiculite, 10-18 parts of turfy soil, 10-18 parts of perlite, and 10-18 parts of coconut shell powder. Compared with the prior art, the soilless culture substrate disclosed by the invention has low-price and easily-available raw materials, has a relatively long fertilizer effect, contains sufficient nutrients, can promote the growth of the sugar beans, increase the yield and improve the quality, has good moisture retention and air permeability, can not harden easily in use, and is suitable large-area promotion and application in production.

Owner:柳州市欧亚农业发展有限公司

Fine processing method for artemia cyst

InactiveCN107711640AImprove hatchabilityQuality improvementClimate change adaptationPisciculture and aquariaCystTime cost

The invention relates to the technical field of production of aquacultural seedings, and particularly relates to a fine processing method for an artemia cyst. The fine processing method comprises thesteps of soaking, extracting, temporarily storing, pickling, storing by refrigerating, detecting the hatching rate, slowly unfreezing, soaking, dehydrating, drying and packaging. The two big problemsproduced in the artificial processing of the artemia cyst are that the hatching rate is not high and the quality of the artemia cyst is relatively low, the quality of the artemia cyst and the hatchingrate of the artemia cyst are greatly improved by soaking and extracting twice, strictly controlling the temperature of freezing, unfreezing and refrigerating and strictly controlling the salinitythetime and the operation steps in soaking and dehydrating, so that the hatching rate of the artemia cyst meets the requirement of a commercial artemia cyst at a time as much as possible, the times for repeatedly processing the artemia cyst, whose hatching rate does not meet the requirement, are greatly reduced, so that the labor cost, the time cost and the processing cost are lowered, and the benefit of a production unit is increased.

Owner:GUANGXI SHATIAN XIANRENTAN AGRI INVESTMENT CO LTD

Special medium for large-leaf caraway soilless culture

InactiveCN106212238ARaw materials are cheap and easy to getImprove fertilizer efficiencyAgriculture gas emission reductionCultivating equipmentsAdditive ingredientBiology

The invention discloses a special medium for large-leaf caraway soilless culture. The special medium comprises the following ingredients in parts by weight: 60 to 80 parts of turfy soil, 30 to 40 parts of pig manure, 10 to 20 parts of wood flour, 5 to 6 parts of vinegar residue, 3 to 6 parts of vermiculite, 10 to 18 parts of peanut hull powder, 10 to 20 parts of bagasse, 10 to 20 parts of coconut shell flour, 1 to 2 parts of sheep manure, 10 to 18 parts of plant ash, 10 to 18 parts of borax, 10 to 18 parts of carbonized rice husk, 5 to 12 parts of kieselguhr and 5 to12 parts of cassava residual. Compared with the prior art, the special medium for large-leaf caraway soilless culture has the advantages that raw materials are low in price and easily available, and the special medium has relatively long fertilizer efficiency period and sufficient in nutrients, is capable of promoting growth of large-leaf caraway, increasing the yield and improving the quality, has favorable moisture retention property and air permeability, is low in hardening possibility during a use process, and is suitable for large-area popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Specific medium for okra soilless culture

InactiveCN106316528ARaw materials are cheap and easy to getImprove fertilizer efficiencyAlkali orthophosphate fertiliserExcrement fertilisersBiotechnologyFermentation

The invention discloses a specific medium for okra soilless culture. The medium is prepared from the following components in parts by weight: 60-80 parts of alcohol biogas residue fermentation material, 30-40 parts of fermented cassava residues, 10-20 parts of edible fungi residues, 5-6 parts of ammonium dihydrogen phosphate, 3-6 parts of artemisia argyi powder, 10-18 parts of borax, 1-3 parts of straw decayed bacteria, 10-20 parts of wormcast, 10-20 parts of cow chip, 1-2 parts of ceramsite, 10-18 parts of turfy soil, 10-18 parts of perlite, 10-18 parts of carbonised rice husk, 5-12 parts of green alga, 5-12 parts of spirogyra and 5-12 parts of rottenwood. Compared with the prior art, the specific medium has the advantages of low-price easily-available raw materials, long fertilizer efficiency, sufficient nutrition, okra growth promotion, high yield, high quality, excellent moistening and air-permeable performance and caking prevention during use, and is suitable for large-scale popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Pepper soilless culture substrate

InactiveCN106106107ATurn waste into treasureImprove fertilizer efficiencyAgriculture gas emission reductionCultivating equipmentsBiologyToxic industrial waste

The invention discloses a pepper soilless culture substrate which is prepared from, by weight, 30-40 parts of vermiculite, 30-40 parts of sawnwood flour, 10-20 parts of plant ash and 5-8 parts of humic acid. Compared with the prior art, the raw materials of the soilless culture substrate are basically agricultural or industrial waste and are low in price and easy to obtain, waste is made profitable really, the fertilizer acting time is long, nutrient is sufficient, pepper is prompted to grow robustly, the yield is increased, the quality is improved, humidity preservation and breathability are good, hardening is not likely to be caused in the using process, and the soilless culture substrate is suitable for being used and popularized in a large area in production.

Owner:柳州市欧亚农业发展有限公司

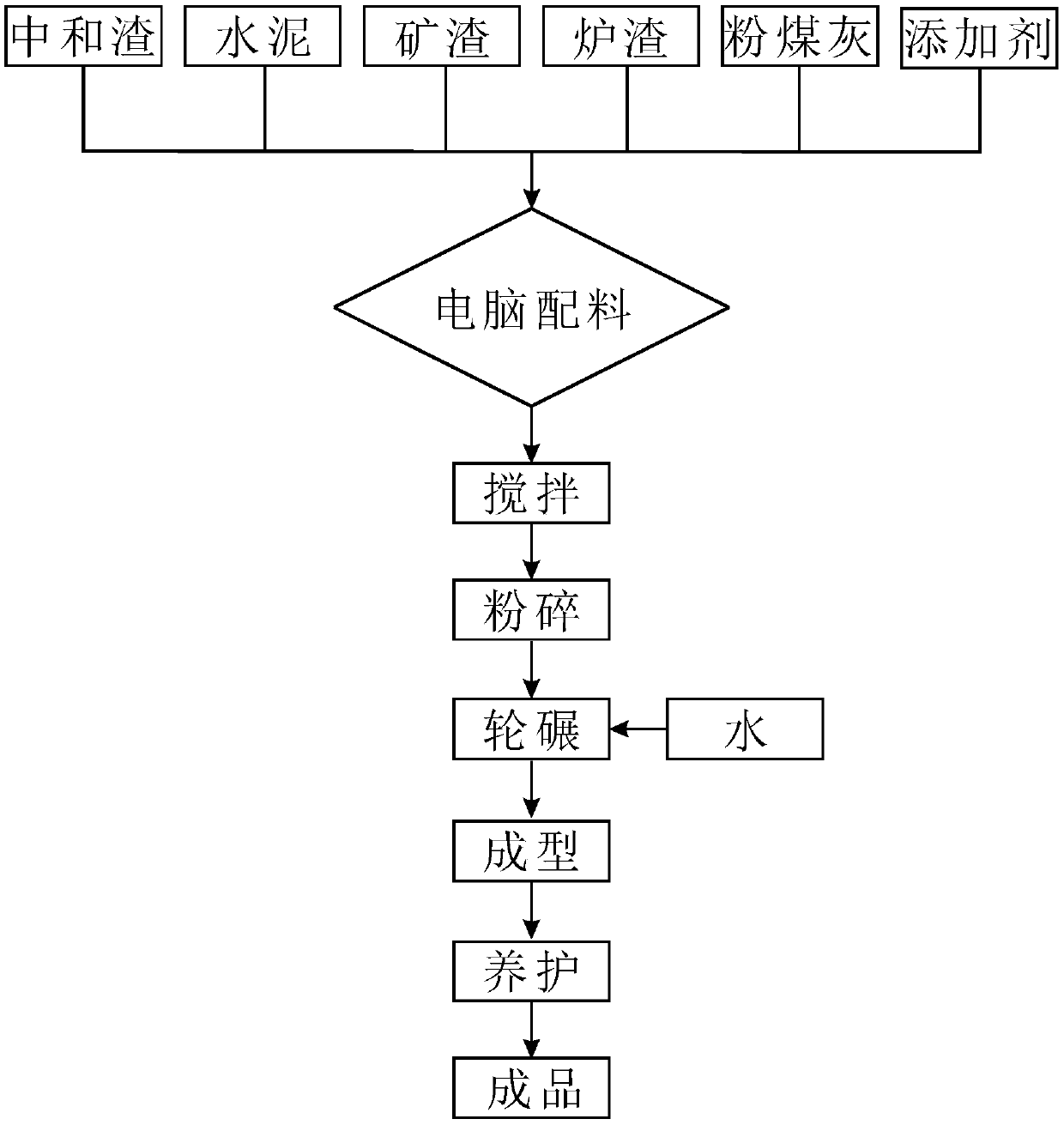

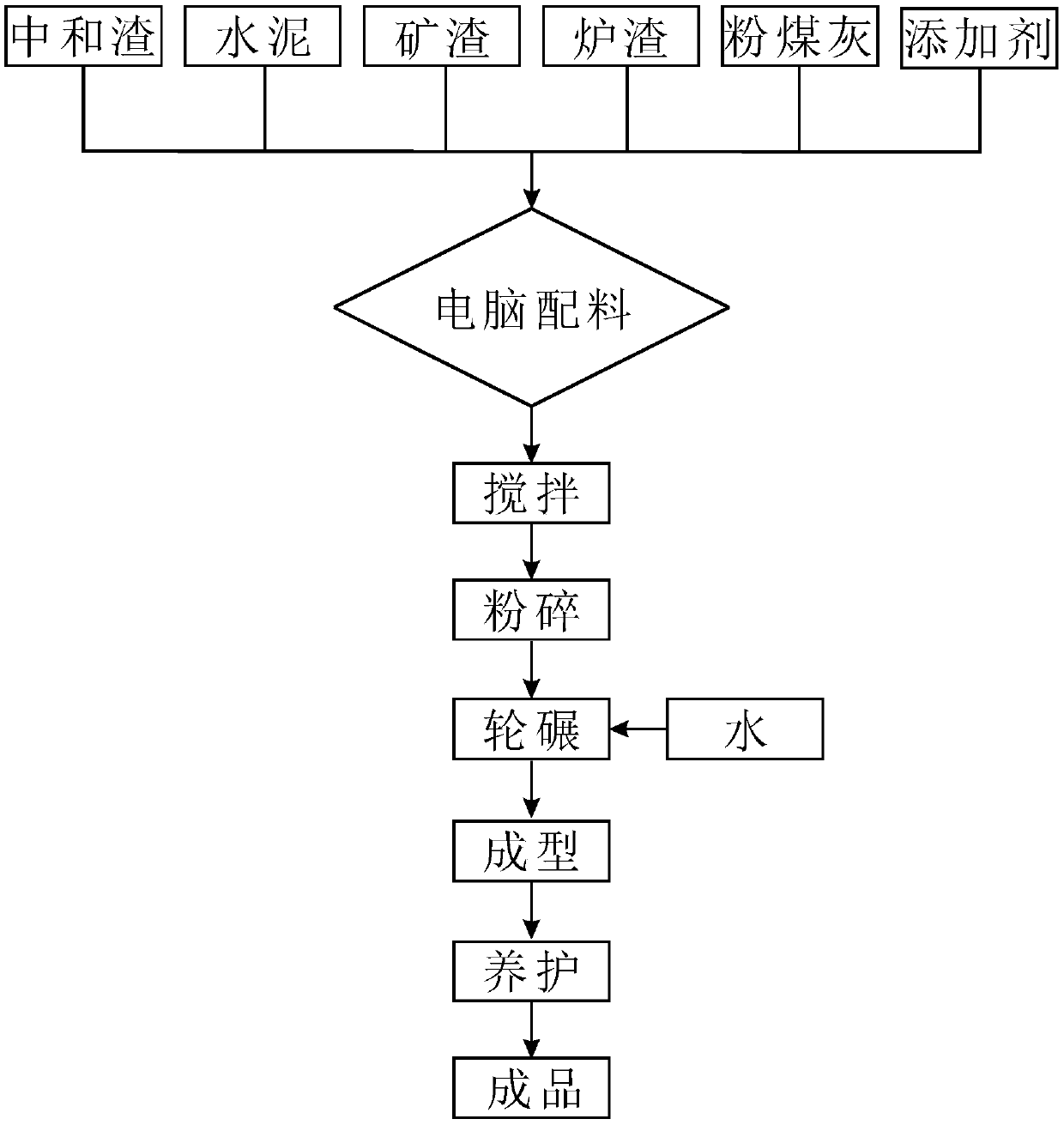

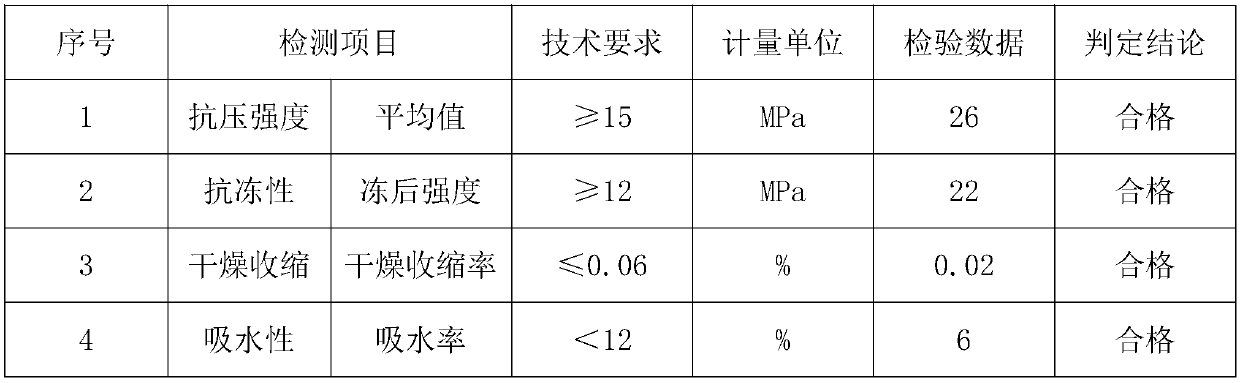

Non-ferrous smelting sewage treatment neutralization slag concrete brick and preparation method thereof

The invention discloses a non-ferrous smelting sewage treatment neutralization slag concrete brick and a preparation method thereof. The concrete brick comprises the following raw materials in percentage by mass: 25 to 35% of neutralization slag, 3 to 6% of cement, 8 to 12% of mineral slag, 35 to 45% of furnace slag, 0 to 15% of fly ash, and 1 to 2% of admixture. The invention also discloses a preparation method of the non-ferrous smelting sewage treatment neutralization slag concrete brick. The prepared neutralization slag concrete brick has excellent performance, the leaching toxicity meetsthe environmental protection requirement, and many problems such as environmental pollution, waste of land resources and high disposal cost caused by the non-ferrous smelting sewage treatment neutralization slag are solved, and the non-ferrous smelting sewage treatment neutralization slag is used as a resource and is harmless, and other raw materials are conventional industrial solid waste which are cheap and easy to obtain, therefore, waste is used to treat waste, the cost of non-ferrous smelting wastewater treatment neutralization slag is greatly reduced, and a broad market prospect is provided.

Owner:CHANGSHA HAIHONG BUILDING MATERIALS

Traditional Chinese medicine composition for treating white head-mouth disease of fishes

InactiveCN103933184AEasy to solveGood treatment effectAntibacterial agentsAnthropod material medical ingredientsDiseaseMyxobacteria

The invention relates to a traditional Chinese medicine composition for treating white head-mouth disease of fishes and belongs to the technical field of traditional Chinese medicines. The composition is prepared from the following raw materials in parts by weight: 4-15 parts of gallnuts, 6-18 parts of cyrtomium fortunei, 1-8 parts of pomegranate barks, 4-15 parts of radix sophorae flavescentis, 6-18 parts of golden cypress, 2-10 parts of encalyptus robusta, 2-10 parts of hairyvein agrimony, 1-8 parts of quispualis indica and 1-8 parts of cortex acanthopanacis. The traditional Chinese medicine composition for treating white head-mouth disease of fishes provided by the invention is reasonable in compatibility and can inhibit and eliminate myxobacteria in fishes by the effect of traditional Chinese medicines which supplement each other so as to better prevent and treat the white head-mouth disease. The effective rate for treatment reaches up to over 99%. The traditional Chinese medicine composition provided by the invention is green and pollution-free, free from any toxic effect and suitable for being popularized and used on a large scale.

Owner:湖州天健兽药有限公司

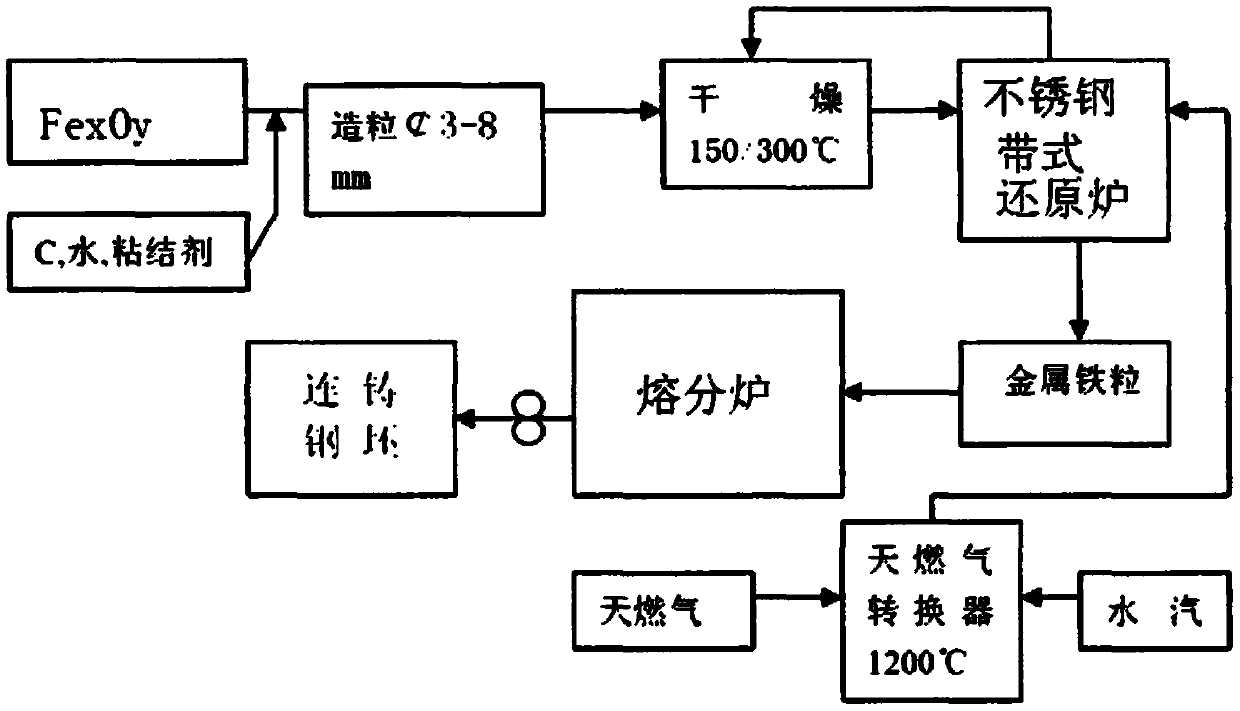

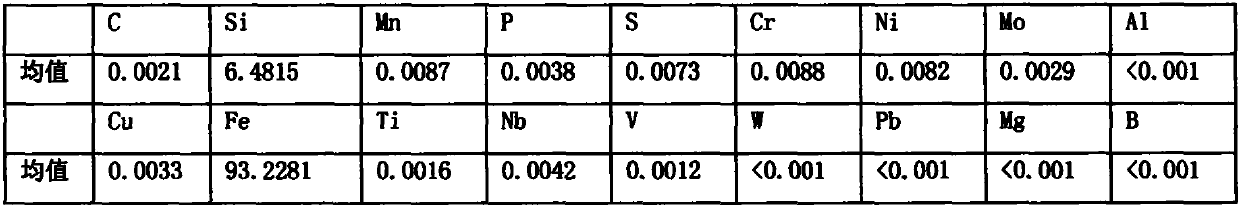

Low-dust iron and steel metallurgy method

PendingCN110016550AHigh degree of automationThe steelmaking process is environmentally friendly and energy-savingGas emission reductionSlagMassicot

The invention provides a low-dust iron and steel metallurgy method. The low-dust iron and steel metallurgy method comprises the following steps that S1, raw materials are selected, specifically, concentrate powder with the Fe content being greater than or equal to 65% or crushed rolled steel oxidized scale, water and a binder are selected for pelletizing; S2, reduction is conducted, specifically,the raw materials are fed into a belt-type reduction furnace, a catalyst is added, CH4 is converted into H2 and CO through the catalyst at the high temperature, ferric oxide is subjected to reductionsmelting, the temperature is set to be 900-1050 DEG C, the heating time is 1-3 h, the thickness of a material layer is 20-30 mm, thus metal iron particles are obtained, other metal elements in the ferric oxide exist in the metal iron particles in the form of MxOy, and M is the other metal elements; S3, cold pressing or hot pressing is conducted, specifically, the metal iron particles at the temperature of 50-800 DEG C are directly subjected to cold pressing and hot pressing to be 3-5 g / cm<3> of blocky iron; and S4, smelting separation is conducted, specifically, 3-10% of CaO or CaF2 is added into the furnace, and smelting separation is conducted to obtain clean molten steel with the Fe content being greater than or equal to 99.0% and a small amount of solid steel slag containing impurities. According to the low-dust iron and steel metallurgy method, almost no dust is generated in the whole production process, and thus low-dust environment-friendly metallurgy is carried out.

Owner:武汉桂坤科技有限公司

Method for preventing and treating cracking of citrus

InactiveCN107711022AImprove fertilityHigh densityExcrement fertilisersGrowth substratesFruit treeSoil fertility

The invention relates to the technical field of citrus fruit crack prevention, in particular to a method for preventing citrus fruit cracking, which comprises the steps of preparing fertilizer, covering with plastic film, fertilizing, watering, pruning and the like. Scientific research shows that there are three main reasons for citrus fruit cracking: uneven nutrient absorption, insufficient water, and low peel thickness. According to the main causes of citrus fruit cracking, targeted measures are taken, and scientific and reasonable fertilization is used to improve soil fertility. The compound fertilizer promotes the balanced development of the pulp and the peel, enhances the flexibility of the peel, regulates the nutrients and moisture of the fruit through scientific water, and finally ensures the reasonable light and sufficient nutrients of the fruit forest by pruning and removing bad fruits in time, so that Effectively reduce citrus fruit cracking, improve the quality of citrus, and increase the income of citrus growers.

Owner:容县科学实验研究所

Special substrate for soilless culture of bell pepper

InactiveCN106278646ARaw materials are cheap and easy to getImprove fertilizer efficiencyAlkali orthophosphate fertiliserExcrement fertilisersAdditive ingredientPhosphate

The invention discloses a special substrate for soilless culture of bell pepper. The special substrate is prepared from the following ingredients in parts by weight: 60 to 80 parts of carbonized wood dust, 30 to 40 parts of biogas residue, 10 to 20 parts of plant ash, 5 to 6 parts of monoammonium phosphate, 3 to 6 parts of expanded porcelain granules, 10 to 18 parts of peanut hull meal, 1 to 3 parts of lignite powder, 10 to 20 parts of wormcast, 10 to 20 parts of dry cow dropping, 1 to 2 parts of iron powder, 10 to 18 parts of pine bark powder, 10 to 18 parts of pearlite, 10 to 18 parts of carbonized rice husk, 5 to 12 parts of alfalfa hay, 5 to 12 parts of kieselguhr and 5 to 12 parts of rottenwood. Compared with the prior art, the special substrate for soilless culture has the advantages that the raw materials are cheap and can be easily obtained; the long fertilizer effect can be achieved; the nutrition is sufficient; the bell pepper is promoted to grow; the yield is increased; the quality is improved; good moisture retention performance and ventilation performance are realized; the hardening cannot easily occur in the use process; the special substrate is suitable for being popularized and used in large area in the production process.

Owner:柳州市欧亚农业发展有限公司

Special substrate for soilless culture of tomatoes

InactiveCN106305393ARaw materials are cheap and easy to getImprove fertilizer efficiencyAgriculture gas emission reductionCultivating equipmentsPotassiumHumic acid

The invention discloses a special substrate for soilless culture of tomatoes. The special substrate for soilless culture of the tomatoes is prepared from the following components in parts by weight: 100 to 150 parts of bagasse, 30 to 50 parts of peanut shells, 30 to 40 parts of rice bran, 30 to 40 parts of sawing wood powder, 10 to 20 parts of turf, 5 to 6 parts of ammonium dihydrogen phosphate, 3 to 6 parts of humic acid, 10 to 18 parts of potassium sulphate, 1 to 3 parts of straw decayed bacterium, 1 to 3 parts of potassium sulphate, 10 to 20 parts of straw stems, 10 to 20 parts of dried cow dung, and 1 to 2 parts of vermiculite. Compared with the prior art, the soilless culturing substrate provided by the invention has the advantages of cheap and easy-to-get raw materials, longer fertilizer efficiency, adequate nutrient, capability of promoting the tomato growth, increasing the yield and improving the quality, favorable moisture retention and gas permeability, non-easiness in hardening during a use process, and suitability in large-area popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Substrate special for soilless culture of green peppers

InactiveCN106278481ARaw materials are cheap and easy to getImprove fertilizer efficiencyAlkali orthophosphate fertiliserExcrement fertilisersMushroomGreen pepper

The invention discloses a substrate special for soilless culture of green peppers. The substrate is prepared from, by weight, 100-150 parts of bagasse, 30-50 parts of hawthorn bark, 30-40 parts of mushroom residues, 30-40 parts of bamboo charcoal powder, 10-20 parts of straw powder, 5-6 parts of ammonium dihydrogen phosphate, 3-6 parts of ammonium sulfate-nitrate, 10-18 parts of pecan husks, 1-3 parts of straw decomposing bacteria, 10-20 parts of straw, 10-20 parts of dried cow dung and 1-2 parts of vermiculite. Compared with the prior art, according to the substrate special for soilless culture of the green peppers, the raw materials are low in price and easy to obtain, the fertilizer efficiency is long, the nutrients are sufficient, green pepper growth is promoted, the yield is increased, the quality is improved, good moisture retention and air permeability are achieved, hardening is not prone to occur in the use process, and the substrate is suitable for being applied and popularized in a large area in production.

Owner:柳州市欧亚农业发展有限公司

Light-weight soilless culture substrate for fresh gingers

InactiveCN106305379ALight weightGood moisturizing effectBioloigcal waste fertilisersAgriculture gas emission reductionGingerolBiology

The invention discloses a light-weight soilless culture substrate for fresh gingers. The light-weight soilless culture substrate for the fresh gingers is prepared from the following components in parts by weight: 30 to 40 parts of rice bran, 30 to 40 parts of sawing wood flour, 10 to 20 parts of plant ash, 5 to 6 parts of perlite and 3 to 6 parts of humic acid. Compared with the prior art, the soilless culture substrate provided by the invention has the raw materials which are easily obtained at a low price, has longer fertilizer efficiency and adequate nutrient for promoting the fresh gingers to grow, is beneficial to increasing the yield and improving the quality, has favorable moisture retention and breathability, is not easy to harden during a use process, and is suitable to be large-scale popularized and utilized during production.

Owner:柳州市欧亚农业发展有限公司

Special soilless cultivation medium for amaranthus tricolor

InactiveCN106359034AImprove fertilizer efficiencySufficient nutritionAlkali orthophosphate fertiliserExcrement fertilisersMoisture retentionNutrient

The invention discloses a special soilless cultivation medium for amaranthus tricolor. The special soilless cultivation medium comprises the following components in parts by weight: 60-80 parts of turfy soil, 30-40 parts of tea leaf dregs, 10-20 parts of bits of wood, 5-6 parts of wheat straw, 3-6 parts of expanded ceramsite, 10-18 parts of peanut shell powder, 1-3 parts of potassium sulfate, 10-20 parts of soybean shell powder, 10-20 parts of dried cow dung, 1-2 parts of ammonium dihydrogen phosphate, 10-18 parts of plant ash, 10-18 parts of perlite, 10-18 parts of carbonized rice husk, 5-12 parts of kieselguhr and 5-12 parts of medical stone; and the water content of the special soilless cultivation medium is 15-30%. Compared with the prior art, the special soilless cultivation medium disclosed by the invention is cheap and easy in raw material obtaining, relatively long in fertilizer efficiency, sufficient in nutrient, capable of promoting growth of the amaranthus tricolor, capable of increasing the yield and improving the quality, good in moisture retention and breathability, not liable to cake in the use process, and applicable to large-scale popularization and application in production.

Owner:柳州市欧亚农业发展有限公司

Traditional Chinese medicine composition for treating turtle liver and gall syndrome

InactiveCN105878937APrevention and treatment of hepatobiliary syndromeNo side effectsFood processingClimate change adaptationSalvia miltiorrhizaSide effect

The invention discloses a traditional Chinese medicine composition for treating a turtle liver and gall syndrome. The traditional Chinese medicine composition is prepared from 30-70 g of radix bupleuri, 50-150 g of herba artemisiae scopariae, 30-70 g of radix scutellariae, 30-50 g of radix angelica sinensis, 50-100 g of fructus gardenia, 100-150 g of herba plantaginis, 100-200 g of herba lysimachiae, 35-50 g of radix curcumae, 20-30 g of fructus gardenia, 10-20 g of radix salvia miltiorrhiza, 5-20 g of licorice roots, 5-12 g of silybum marianum, 15-20 g of Chinese wax gourd peel and 15 kg of turtle bait. According to the traditional Chinese medicine composition, all the Chinese herbs achieve the effect of supplementing one another, reasonable compatibility is achieved, the medicinal raw materials are easy to purchase, the using method is simple, therefore, the turtle liver and gall syndrome can be well prevented and treated, and the treatment efficiency is high; in addition, the whole process is green and free of pollution, and no toxic or side effect is generated after turtles eat the composition; the turtle growth water body environment is not influenced, and the composition is suitable for being massively applied and popularized.

Owner:ANHUI PROVINCE JINGDE COUNTY GUOYOU IMPROVED VARIETY OF TERRAPIN BREEDING FARM

Drug for treating soft-shelled turtle rotten mouth disease

InactiveCN104825731AEasy to solveGood treatment effectAntibacterial agentsInorganic active ingredientsAndrographis paniculataDrug

The invention discloses a drug for treating soft-shelled turtle rotten mouth disease, and belongs to the technical field of veterinary drugs. The drug is composed of the following raw materials in parts by weight: 4 to 15 parts of mulberry leaf, 1 to 8 parts of pomegranate rind, 4 to 15 parts of Chinese yam, 6 to 18 parts of andrographis paniculata, 2 to 10 parts of medical stone, 1 to 8 parts of haw, 1 to 8 parts of Chinese magnoliavine, and 2 to 10 pars of polygonum cuspidatum. The provided drug has a reasonable formula, the traditional Chinese herbals can cooperate with each other to generate a synergetic effect so as to inhibit and eliminate harmful bacteria in soft-shelled turtles, thus the soft-shelled turtle rotten mouth disease can be well prevented and treated, the effective rate can reach 90% or more, and moreover, the provided drug is green and pollution-free, does not have any side or toxic effect, and is suitable for promotion and application in a large scale.

Owner:XINCHANG DACHENG BIOLOGICAL SCI & TECH

Special matrix for fennel soilless culture

InactiveCN106316616ARaw materials are cheap and easy to getImprove fertilizer efficiencyExcrement fertilisersBioloigcal waste fertilisersSodium BentoniteBiology

The invention discloses a special matrix for fennel soilless culture. The special matrix comprises the following components in parts by weight: 60 to 80 parts of chicken manure, 30 to 40 parts of bagasse, 10 to 20 parts of cottonseed hull powder, 5 to 6 parts of bran, 3 to 6 parts of expanded ceramsite, 10 to 18 parts of peanut hull powder, 1 to 3 parts of charcoal, 10 to 20 parts of bentonite, 10 to 20 parts of dry cow dung, 1 to 2 parts of iron powder, 10 to 18 parts of plant ash, 10 to 18 parts of perlite, 10 to 18 parts of carbonized rice hulls, 5 to 12 parts of wheat bran powder, 5 to 12 parts of diatomite and 5 to 12 parts of medical stone. Compared with the prior art, the raw materials of the matrix for soilless culture are low in price and easy to obtain, the matrix has relatively high fertilizer efficiency and sufficient nutrients, the fennel growth is promoted, the yield is increased, the quality is improved, the matrix has good moisture retention and gas permeability, the matrix is unlikely to be hardened in the using process, and the matrix is applicable for large-area popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Special substrate for green pinto bean soilless culture

InactiveCN106332751ARaw materials are cheap and easy to getImprove fertilizer efficiencyExcrement fertilisersBioloigcal waste fertilisersPinto beanBiology

The invention discloses a special substrate for green pinto bean soilless culture. The special substrate for green pinto bean soilless culture comprises the following components in parts by weight: 60 to 80 parts of human manure, 30 to 40 parts of rotten plants, 10 to 20 parts of cottonseed hull powder, 5 to 6 parts of bean pulp powder, 3 to 6 parts of expanded ceramsite, 10 to 18 parts of peanut hull powder, 1 to 3 parts of charcoal, 10 to 20 parts of earthworm manure, 10 to 20 parts of dry cow dung, 1 to 2 parts of iron powder, 10 to 18 parts of bacterial stick waste residues, 10 to 18 parts of perlite, 10 to 18 parts of carbonized rice hulls, 5 to 12 parts of wheat skin powder, 5 to 12 parts of diatomite and 5 to 12 parts of medical stone. Compared with the prior art, the soilless culture substrate has cheap and easily available raw materials, long fertilizer effect and sufficient nutrients, promotes the growth of green pinto beans, increases the yield, improves the quality, has high moisturizing property and air permeability, is not liable to harden in the use process, and is suitable for large-area popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Medicine for treating turtle mouth rote

InactiveCN104840590AEasy to solveGood treatment effectAntibacterial agentsPlant ingredientsSaposhnikoviaTwig

The invention discloses a medicine for treating turtle mouth rote, and belongs to the technical field of veterinary medicines. The medicine is made of raw materials including, by weight, 2-10 parts of houttuynia cordata, 4-12 parts of semen plantaginis, 10-30 parts of schisandra chinensis, 10-30 parts of Chinese thorowax root, 2-10 parts of divaricate saposhnikovia root, 4-12 parts of elecampane, 6-16 parts of Tuckahoe, 8-25 parts of cassia twig and 1-5 parts of mint. The medicine for treating turtle mouth rote is reasonable in compatibility, harmful bacteria in turtles can be restrained and removed by the aid of the complementary actions of traditional Chinese medicines, so that turtle mouth rote can be effectively prevented and treated, treating effective rate reaches up to more than 90%, the medicine is green, pollution-free, free of any toxic effects and suitable for large-scale popularization and utilization.

Owner:XINCHANG DACHENG BIOLOGICAL SCI & TECH

A wheel hub assembly press assembly production line

ActiveCN106112511BHigh degree of automationIncrease productivityAssembly machinesVehicle componentsProduction lineEngineering

The invention discloses a press-fitting production line for hub assemblies. The press-fitting production line comprises a circulatory conveying assembly and a part press-fitting mechanism; the circulatory conveying assembly comprises a support and a plurality of supporting brackets arranged on the support, and the multiple supporting brackets are used for conveying hubs on the support in a circulation mode so that the hubs can undergo the press-fitting work of each process; and the part press-fitting mechanism comprises a lower bearing outer ring pressing machine, an upper bearing outer ring pressing machine, an ABS gear ring pressing machine and a bolt pressing machine, wherein the lower bearing outer ring pressing machine, the upper bearing outer ring pressing machine, the ABS gear ring pressing machine and the bolt pressing machine are arranged along the support, the lower bearing outer ring pressing machine is used for carrying out press-fitting on lower bearing outer rings of the hubs, the upper bearing outer ring pressing machine is used for carrying out press-fitting on upper bearing outer rings of the hubs, the ABS gear ring pressing machine is used for pressing ABS gear rings on the hubs, and the bolt pressing machine is used for pressing bolts on the hubs. The press-fitting production line for the hub assemblies has the advantages of being high in automation level and safe and saving energy and is suitable for being widely popularized and used.

Owner:GUANGDONG FUWA HEAVY IND

Special medium for soilless culture of radish bud/seedling

InactiveCN106305390ARaw materials are cheap and easy to getImprove fertilizer efficiencyAgriculture gas emission reductionCultivating equipmentsBiotechnologyPeat

The invention discloses a special medium for soilless culture of a radish bud / seedling, prepared from the following components in parts by weight: 60-80 parts of peat, 30-40 parts of fermented cassava dregs, 10-20 parts of edible fungi dregs, 5-6 parts of ammonium dihydrogen phosphate, 3-6 parts of ammonium sulfate nitrate, 10-18 parts of pecan husk, 1-3 parts of straw decayed bacteria, 10-20 parts of furfural residue, 10-20 parts of dried cow dung, 1-2 parts of ceramsite, 10-18 parts of turfy soil, 10-18 parts of perlite and 10-18 parts of carbonized rice husk. Compared with the prior art, the special medium for the soilless culture disclosed by the invention has the advantages of cheap and easily available raw materials, longer manurial effect, abundant nutrition, promoted growth of the radish bud / seedling, increased yield, improved quality, good moisture retention and air permeability, and low possibility of hardening during the using process, and is applicable to large-area popularization and utilization in production.

Owner:柳州市欧亚农业发展有限公司

Composition for treating liver and gallbladder syndrome of anglerfish

InactiveCN105012445ANon-toxicCompatibility is reasonableDigestive systemPlant ingredientsDandelionAnglerfish

The invention discloses a composition for treating a liver and gallbladder syndrome of anglerfish, and belongs to the technical field of fish medicines. The composition comprises the following raw materials in parts by weight: 5-15 parts of indigowoad root, 6-16 parts of gentian, 6-15 parts of uncaria rhynchophylla, 5-15 parts of astragalus membranaceus, 4-15 parts of angelica, 6-16 parts of herba artemisiae scopariae, 8-16 parts of liquorice and 10-20 parts of taraxacum. The traditional Chinese medicine composition provided by the invention is reasonble in compatibility; through complementation of all of the Chinese herbal raw materials, the functions of detoxication, resistance to liver injury, hemostasis and removal of blood stasis, promotion of liver cell regeneration, and liver function recovery can be realized, and the incidence of stress responses can be effectively reduced, so that the traditional Chinese medicine composition is capable of preventing and treating the liver and gallbladder syndrome of the anglerfish well, and the effective treatment rate reaches up to 96% or above; moreover, the traditional Chinese medicine composition is environmentally friendly, free from pollution, toxic effect and harmful effect, and suitable for large-scale popularization and utilization.

Owner:XINCHANG DACHENG BIOLOGICAL SCI & TECH

Traditional Chinese medicine for treating turtle mouth rote

InactiveCN105878688AFacilitated releasePromote absorptionOrganic active ingredientsClimate change adaptationVitaminGypsum

The invention discloses traditional Chinese medicine for treating turtle mouth rote. The traditional Chinese medicine is prepared from 50-100 g of rhizoma anemarrhenae, 30-70 g of radix scutellariae, 30-70 g of cortex moutan, 30-50 g of radix angelica sinensis, 30-70 g of rhizoma cimicifugae, 30-70 g of radix et rhizoma rhei, 20-40 g of semen plantaginis, 20-50 g of caulis spatholobi, 100-200 g of raw gypsum, 1-3 g of livestock multiplex vitamin, 0.5-1 g of licorzine and 10 Kg of turtle bait. According to the traditional Chinese medicine, all the Chinese herbs achieve the effect of supplementing one another, the using method is simple, harmful bacteria in turtles can be inhibited and removed, and therefore the turtle mouth rote can be well prevented and treated; in addition, the whole process is green and free of pollution.

Owner:ANHUI PROVINCE JINGDE COUNTY GUOYOU IMPROVED VARIETY OF TERRAPIN BREEDING FARM

A traditional Chinese medicine composition for treating white-headed white-mouth disease of fish

InactiveCN103933184BEasy to solveGood treatment effectAntibacterial agentsAnthropod material medical ingredientsMyxobacteriaDisease

The invention relates to a traditional Chinese medicine composition for treating white head-mouth disease of fishes and belongs to the technical field of traditional Chinese medicines. The composition is prepared from the following raw materials in parts by weight: 4-15 parts of gallnuts, 6-18 parts of cyrtomium fortunei, 1-8 parts of pomegranate barks, 4-15 parts of radix sophorae flavescentis, 6-18 parts of golden cypress, 2-10 parts of encalyptus robusta, 2-10 parts of hairyvein agrimony, 1-8 parts of quispualis indica and 1-8 parts of cortex acanthopanacis. The traditional Chinese medicine composition for treating white head-mouth disease of fishes provided by the invention is reasonable in compatibility and can inhibit and eliminate myxobacteria in fishes by the effect of traditional Chinese medicines which supplement each other so as to better prevent and treat the white head-mouth disease. The effective rate for treatment reaches up to over 99%. The traditional Chinese medicine composition provided by the invention is green and pollution-free, free from any toxic effect and suitable for being popularized and used on a large scale.

Owner:湖州天健兽药有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com