A wheel hub assembly press assembly production line

A technology for press-fitting production lines and hubs, which is applied to assembly machines, transportation and packaging, and metal processing equipment. It can solve problems such as increased labor costs, increased safety hazards, and low production efficiency. It achieves a high degree of automation, improves production efficiency, and Effects of Energy Saving and Safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

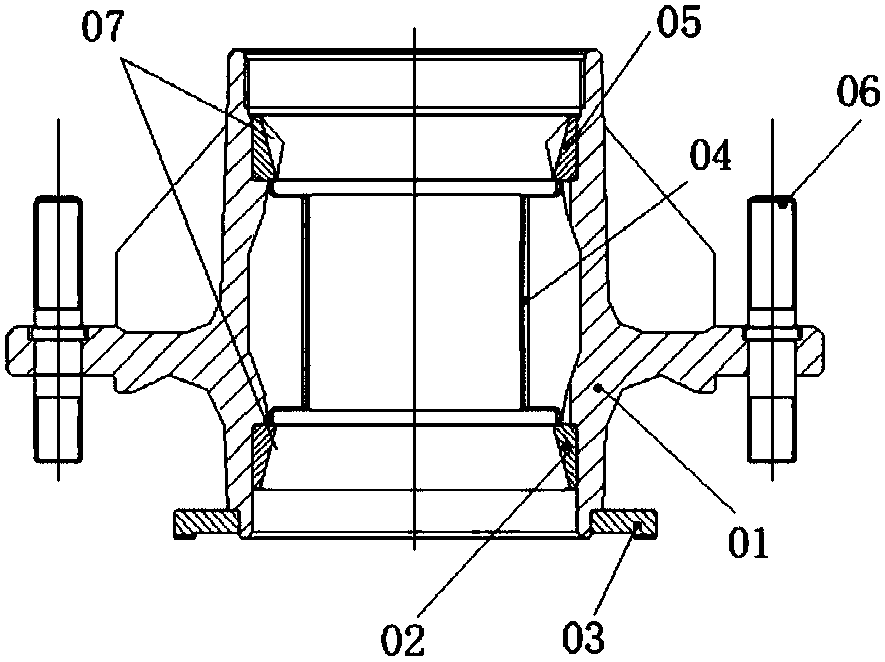

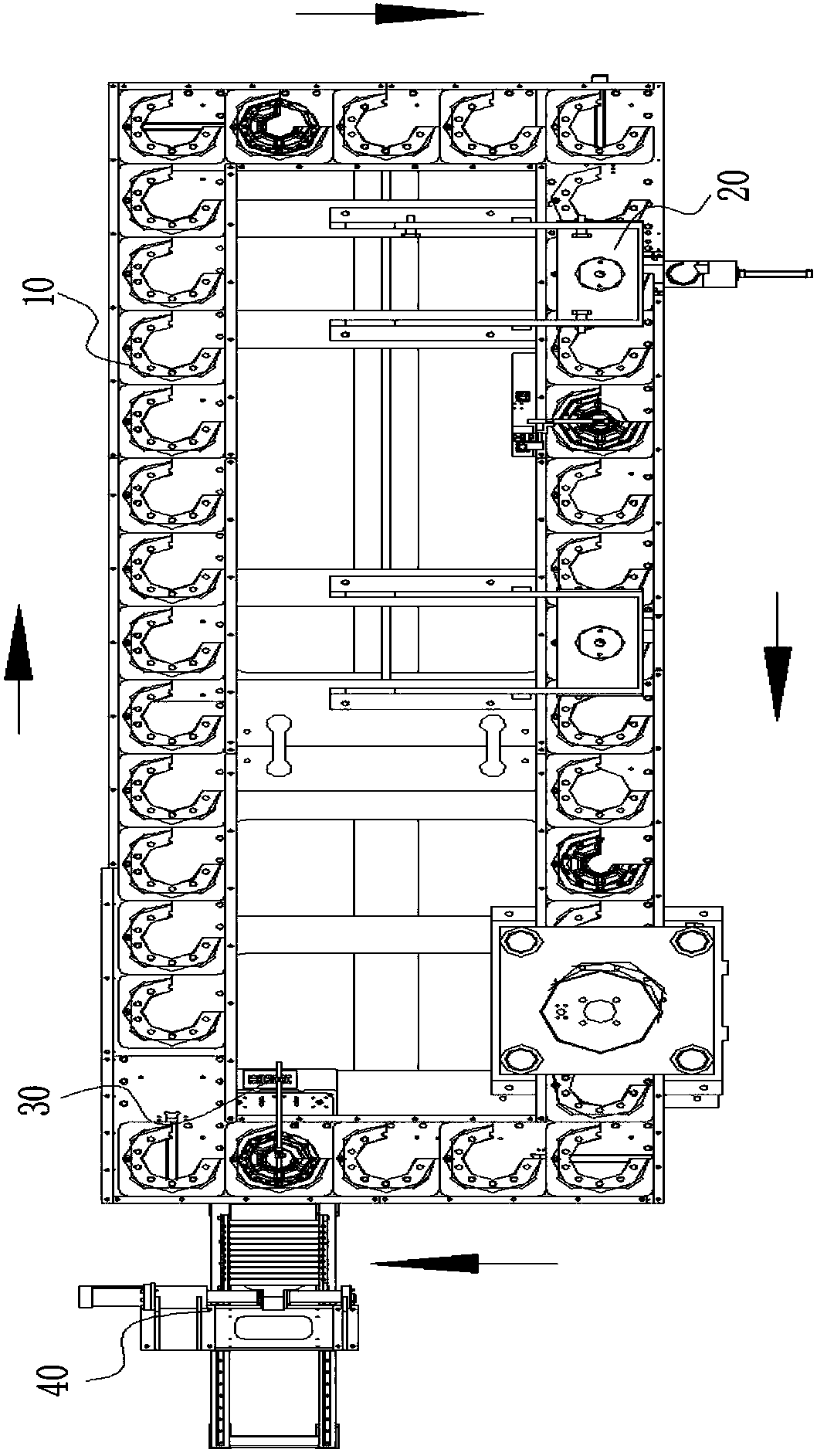

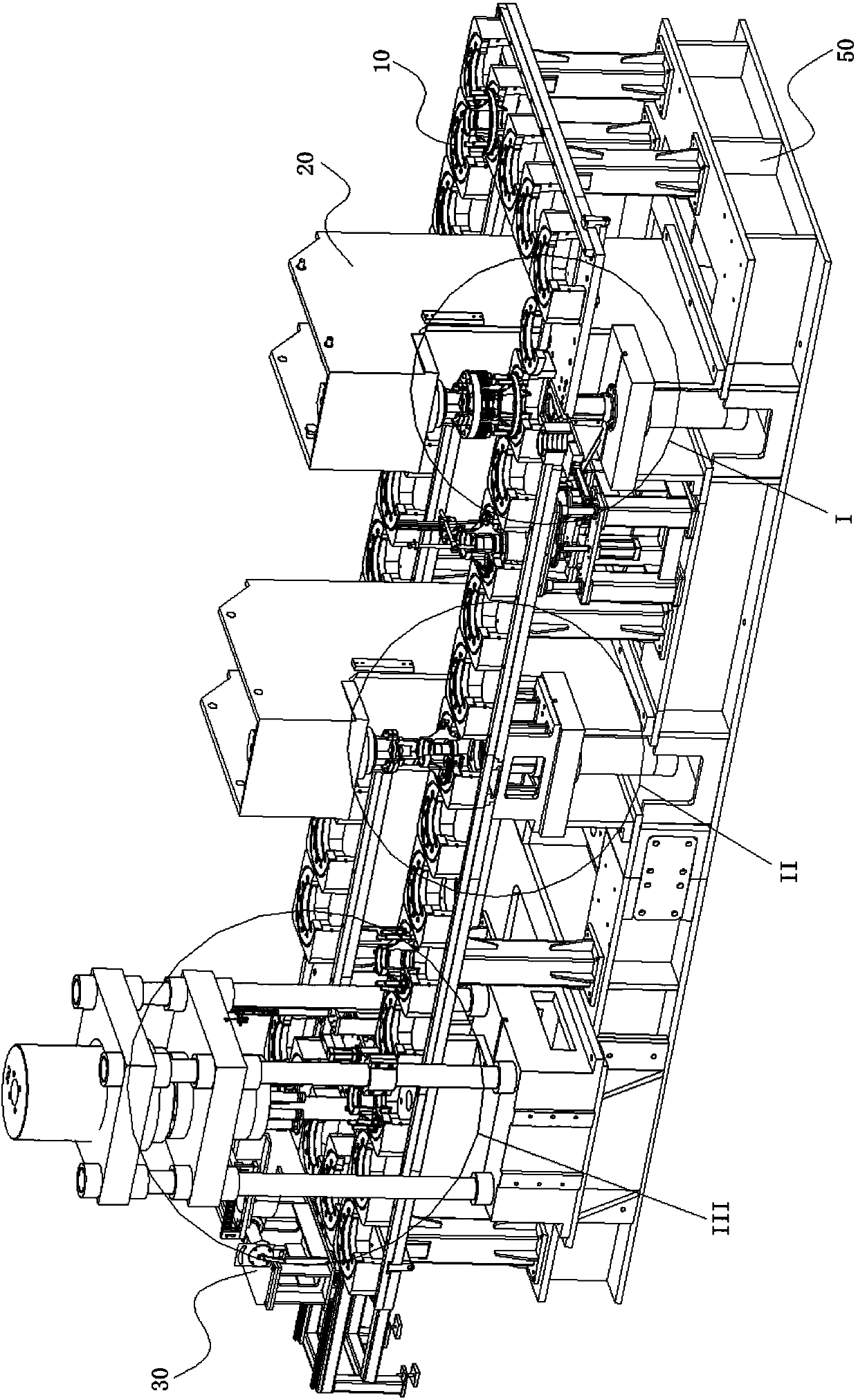

[0040] see Figure 2-Figure 16 . figure 2 It is a top view of the wheel hub assembly press-fitting production line of the present invention. image 3 It is a structural schematic diagram of the wheel hub assembly press-fitting production line of the present invention. Figure 4 It is a structural schematic diagram of another angle of the wheel hub assembly press-fitting production line of the present invention. Figure 5 It is a schematic diagram of the structure of the cycle feeding assembly. Figure 6 It is a schematic diagram of the bottom structure of the circulating feeding assembly. Figure 7 It is a schematic diagram of the structure of the die cylinder. Figure 8 yes image 3 Schematic diagram of the structure at I. Figure 9 It is a schematic diagram of the structure of the feeding plate. Figure 10 is a schematic diagram of the structure of the indenter. Figure 11 yes image 3 Schematic diagram of the structure at II. Figure 12 is a schematic diagram of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com