Low-dust iron and steel metallurgy method

A technology of iron and steel metallurgy and steel slag, which is applied in the direction of reducing gas emissions, and can solve problems such as palliatives but not root causes, environmental pollution, etc., and achieve the effects of high degree of automation, excellent internal quality of products, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

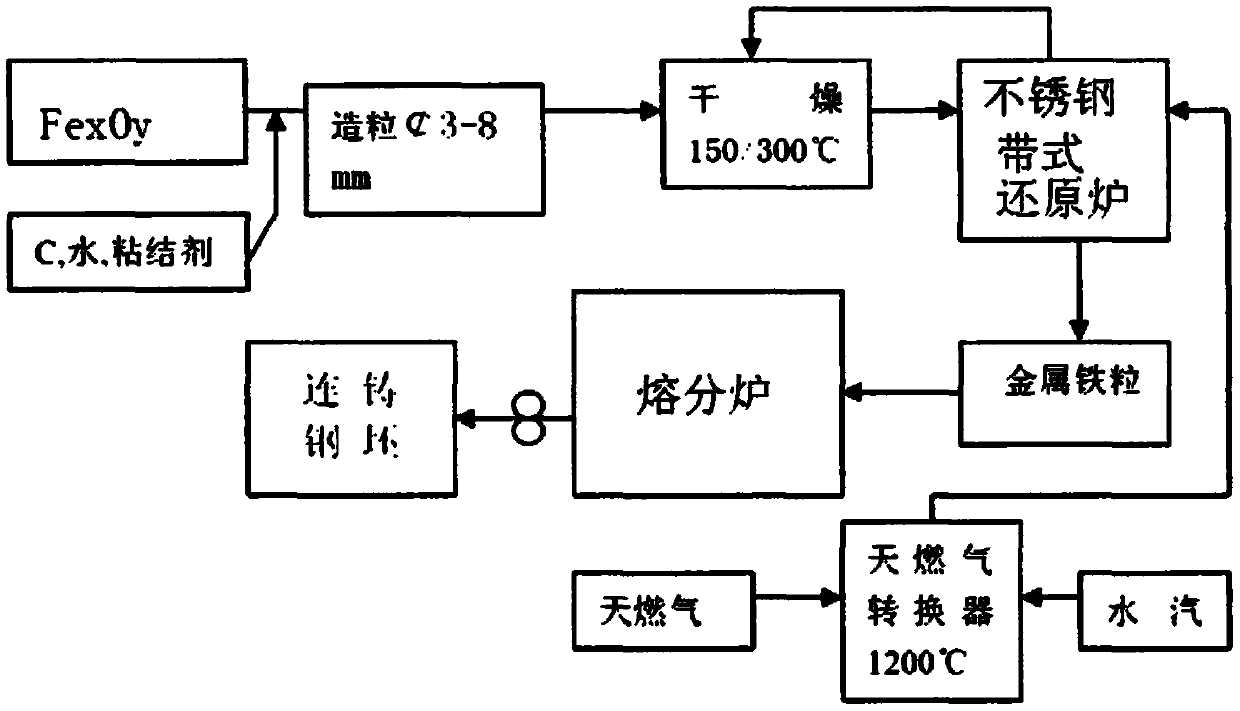

Method used

Image

Examples

Embodiment 1

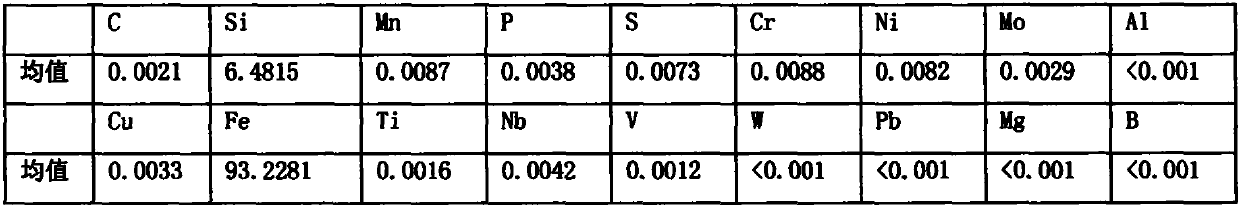

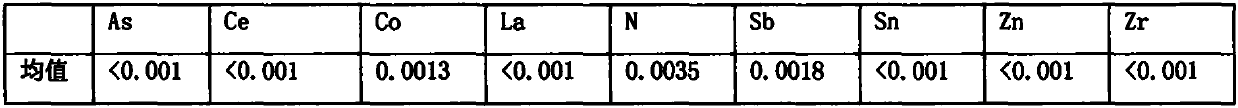

[0040] S1. Select raw materials: choose iron concentrate powder as raw material, and the content of each element in iron concentrate powder is

[0041] Fe: 71.3%; S: 0.018; P: 0.015.

[0042] Granulation (3¢-8mm): Add water, carbon powder and binder to the above-mentioned iron concentrate powder to granulate to obtain iron oxide particles:

[0043] The ratio of each component of the iron oxide particles is: mineral powder: water: binder: graphite powder = 1: 0.08: 0.02: 0.04;

[0044] S2. Reduction: Send the raw materials into the belt reduction furnace, add the catalyst, and use the catalyst to reduce the CH 4 Convert to H 2 and CO to reduce iron oxide, set the temperature to 1000 degrees Celsius, heat for 1-3h, and the thickness of the material layer is 20-30mm to obtain metal iron particles. Other metal elements in iron oxide exist in the form of MxOy in the In the metal iron particles, M is other metal elements.

[0045]The parameters of the belt reduction furnace are:...

Embodiment 2

[0053] S1. Select raw materials: choose iron concentrate powder as raw material, and the content of each element in iron concentrate powder is

[0054] Fe: 71.3%; S: 0.018; P: 0.015.

[0055] Granulation (3¢-8mm): Add water, carbon powder and binder to the above-mentioned iron concentrate powder for granulation to obtain 2# iron oxide particles:

[0056] The ratio of each component of iron oxide particles is: mineral powder: water: binder = 1: 0.08: 0.02;

[0057] S2. Reduction: send the raw materials into the belt reduction furnace, add the catalyst, and use the catalyst to reduce the CH 4 Convert to H 2 and CO to reduce iron oxide, set the temperature to 950 degrees Celsius, heat for 1-3h, and the thickness of the material layer is 20-30mm to obtain metal iron particles. Other metal elements in iron oxide exist in the form of MxOy in the In the metal iron particles, M is other metal elements.

[0058] The parameters of the belt reduction furnace are: stainless steel widt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com