Graphene oxide/nano cellulose aerogel and preparation method and application thereof

A technology of nanocellulose and graphene, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as difficulty in popularization and application, high cost, and complicated preparation process, and achieve a suitable large-scale The effects of popularization and utilization, low requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

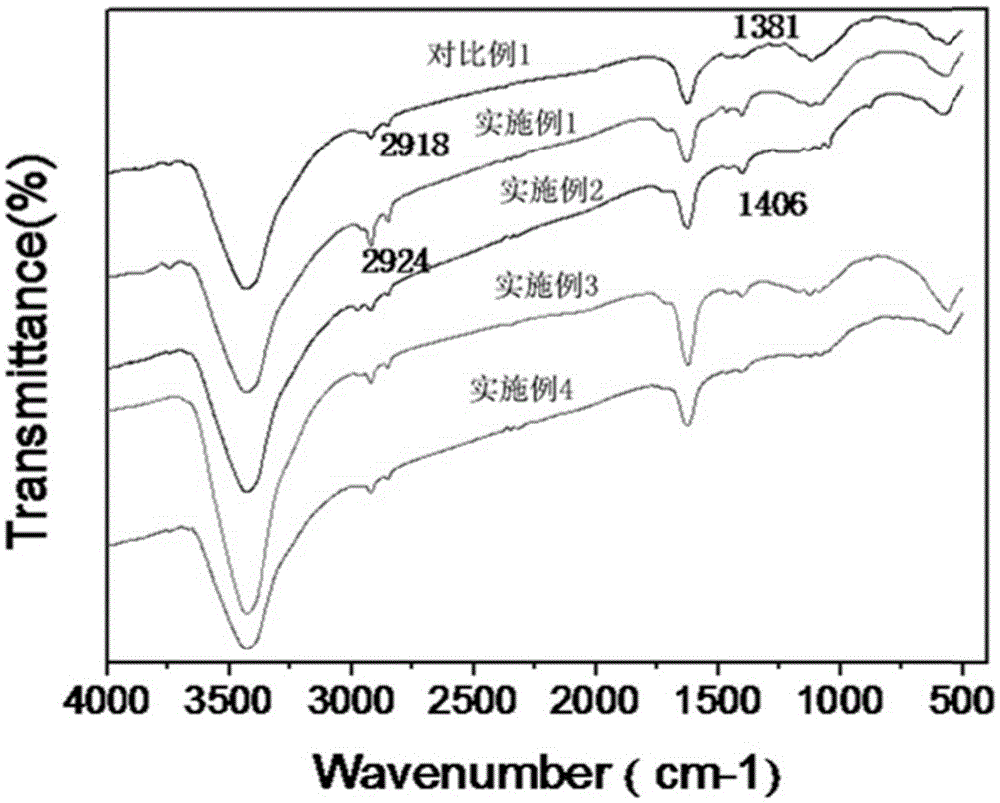

Embodiment 1

[0046] A kind of graphene oxide / nanocellulose airgel is prepared by the method comprising the following steps:

[0047] 1) Dispersing the nanocellulose in hydrochloric acid to make a nanocellulose dispersion; the concentration of the nanocellulose dispersion is 1mg / ml;

[0048] 2) Mix the graphene oxide dispersion with the nanocellulose dispersion obtained in step 1), and perform a hydrothermal reaction at 180° C. for 20 hours to obtain a hydrogel; the concentration of the graphene oxide dispersion is 3 mg / ml, and the graphite oxide The mass ratio of alkene to nanocellulose is 45:1;

[0049] 3) The hydrogel obtained in step 2) is freeze-dried at -50°C and 10Pa to obtain the hydrogel.

[0050] The application of the graphene oxide / nanocellulose airgel of this example in the adsorption and removal of phenol in aqueous phenol solution.

Embodiment 2

[0052] A kind of graphene oxide / nanocellulose airgel is prepared by the method comprising the following steps:

[0053] 1) Dispersing the nanocellulose in hydrochloric acid to make a nanocellulose dispersion; the concentration of the nanocellulose dispersion is 2mg / ml;

[0054] 2) Mix the graphene oxide dispersion with the nanocellulose dispersion obtained in step 1), and perform a hydrothermal reaction at 180° C. for 20 hours to obtain a hydrogel; the concentration of the graphene oxide dispersion is 3 mg / ml, and the graphite oxide The mass ratio of alkene to nanocellulose is 45:2;

[0055] 3) The hydrogel obtained in step 2) is freeze-dried at -50°C and 10Pa to obtain the hydrogel.

[0056] The application of the graphene oxide / nanocellulose airgel of this example in the adsorption and removal of phenol in aqueous phenol solution.

Embodiment 3

[0058] A kind of graphene oxide / nanocellulose airgel is prepared by the method comprising the following steps:

[0059] 1) Dispersing the nanocellulose in hydrochloric acid to make a nanocellulose dispersion; the concentration of the nanocellulose dispersion is 3mg / ml;

[0060] 2) Mix the graphene oxide dispersion with the nanocellulose dispersion obtained in step 1), and perform a hydrothermal reaction at 180° C. for 20 hours to obtain a hydrogel; the concentration of the graphene oxide dispersion is 3 mg / ml, and the graphite oxide The mass ratio of alkene to nanocellulose is 45:3;

[0061] 3) The hydrogel obtained in step 2) is freeze-dried at -50°C and 10Pa to obtain the hydrogel.

[0062] The application of the graphene oxide / nanocellulose airgel of this example in the adsorption and removal of phenol in aqueous phenol solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com