DC convergent current bus bar insulator bracket

A technology of insulating support and DC confluence, which is applied in busbar installation, open busbar installation, electrical components, etc., can solve the problems of difficult insulator replacement, unsafe replacement of insulators, inconvenient disassembly, etc., and achieves great practical value and facilitates replacement of insulators. , the effect of structural science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

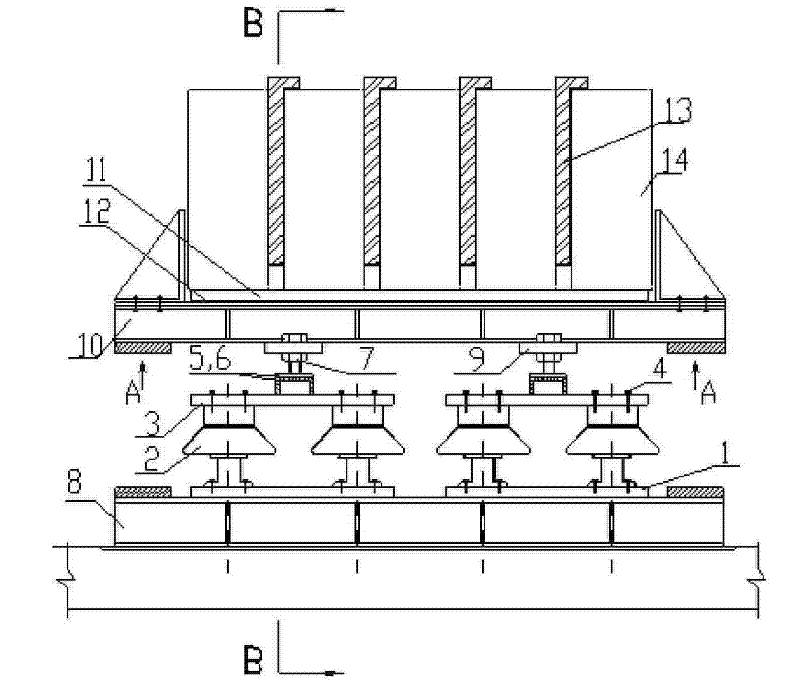

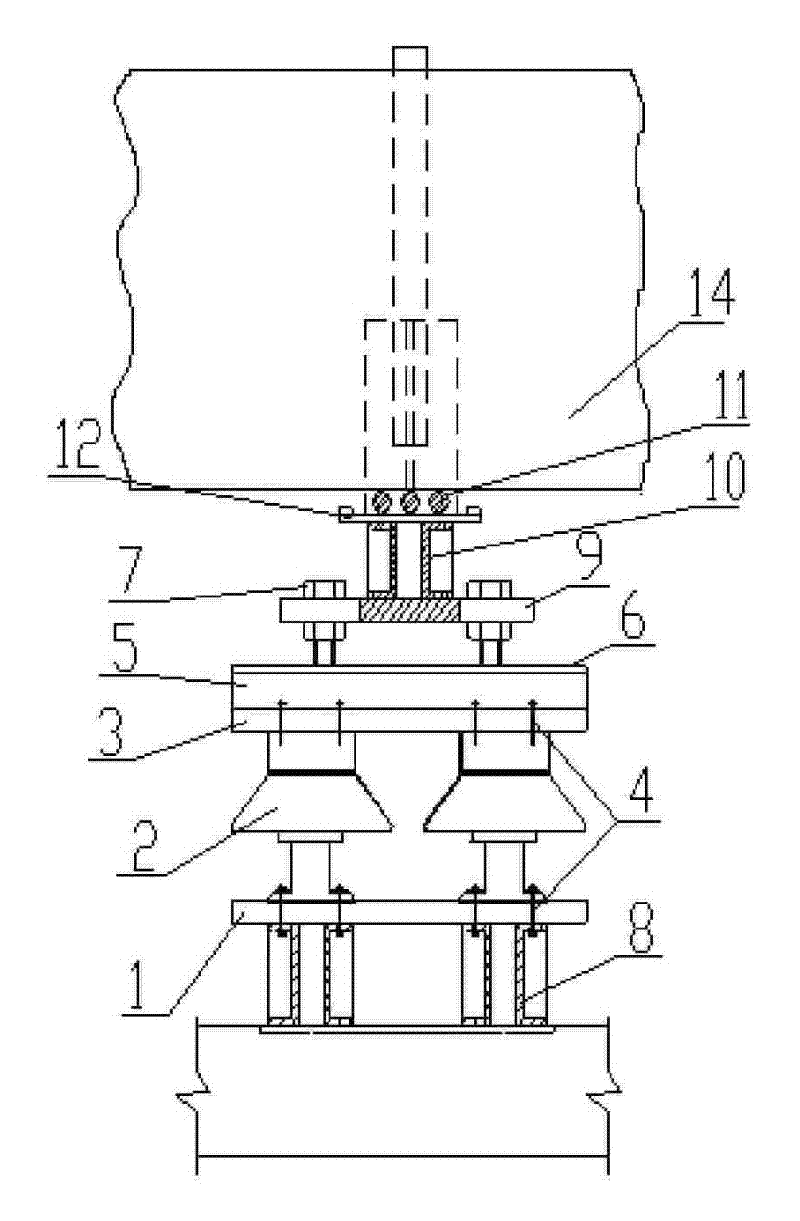

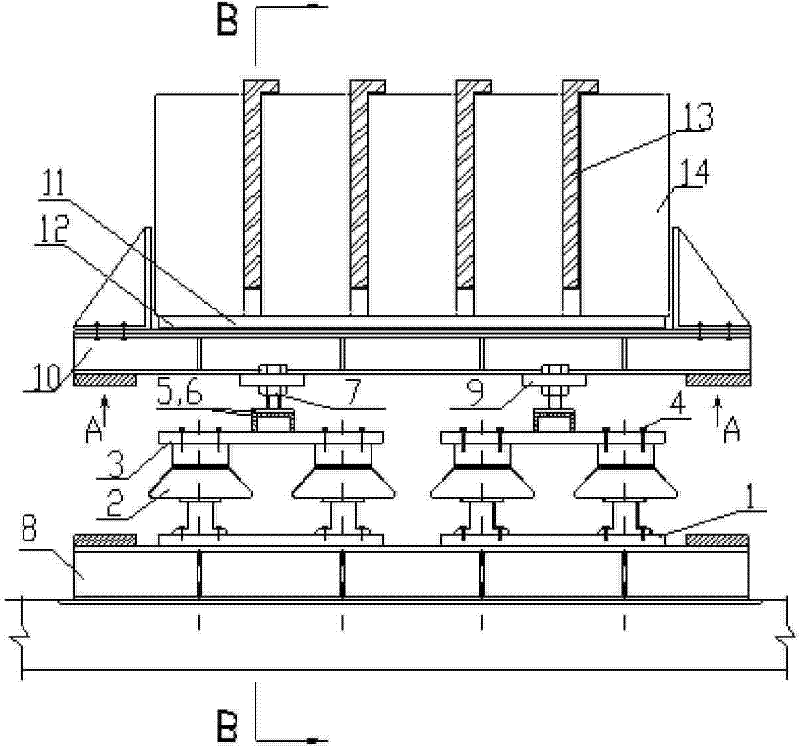

[0018] Embodiments of the present invention: first, calculate the quantity of required insulators 2 according to needs; make bracket 5, lower bracket 8, upper bracket 10 with channel steel, make lower support plate 1, upper support plate 3, the second support plate with steel plate A support plate 6, a second support plate 9, and a third support plate 12; then, group the insulators 2 (4 in a group), and fix them between a lower support plate 1 and an upper support plate 3 by first bolts 4 Weld the bracket 5 on the upper support plate 3, weld the first support plate 6 on the bracket 5; weld the second support plate 9 equal to the number of insulators 2 groups under the upper bracket 10, and in each second Two high-strength second bolts 7 with a diameter of not less than 30 mm and grade 8.8 or above are installed on the support plate 9; the third support plate 12 is welded on the upper bracket 10, and 2 to 3 round steel bars 11 are placed on the on the third support plate 12. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com