Medium and high strength oil casing for resisting sulfurated hydrogen corrosion and manufacturing method thereof

A technology of anti-hydrogen sulfide and manufacturing method, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems such as the lack of consistent understanding of the cracking of the steel matrix, and achieve the effect of good physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is based on the following technical ideas: for the metal material itself, the factors affecting its corrosion resistance are in the following aspects, (1), the chemical stability of the metal itself, (2) the influence of the alloy composition, (3) The influence of the purity of the metal, (4) the influence of the metallographic structure, and (5) the influence of the metal surface state.

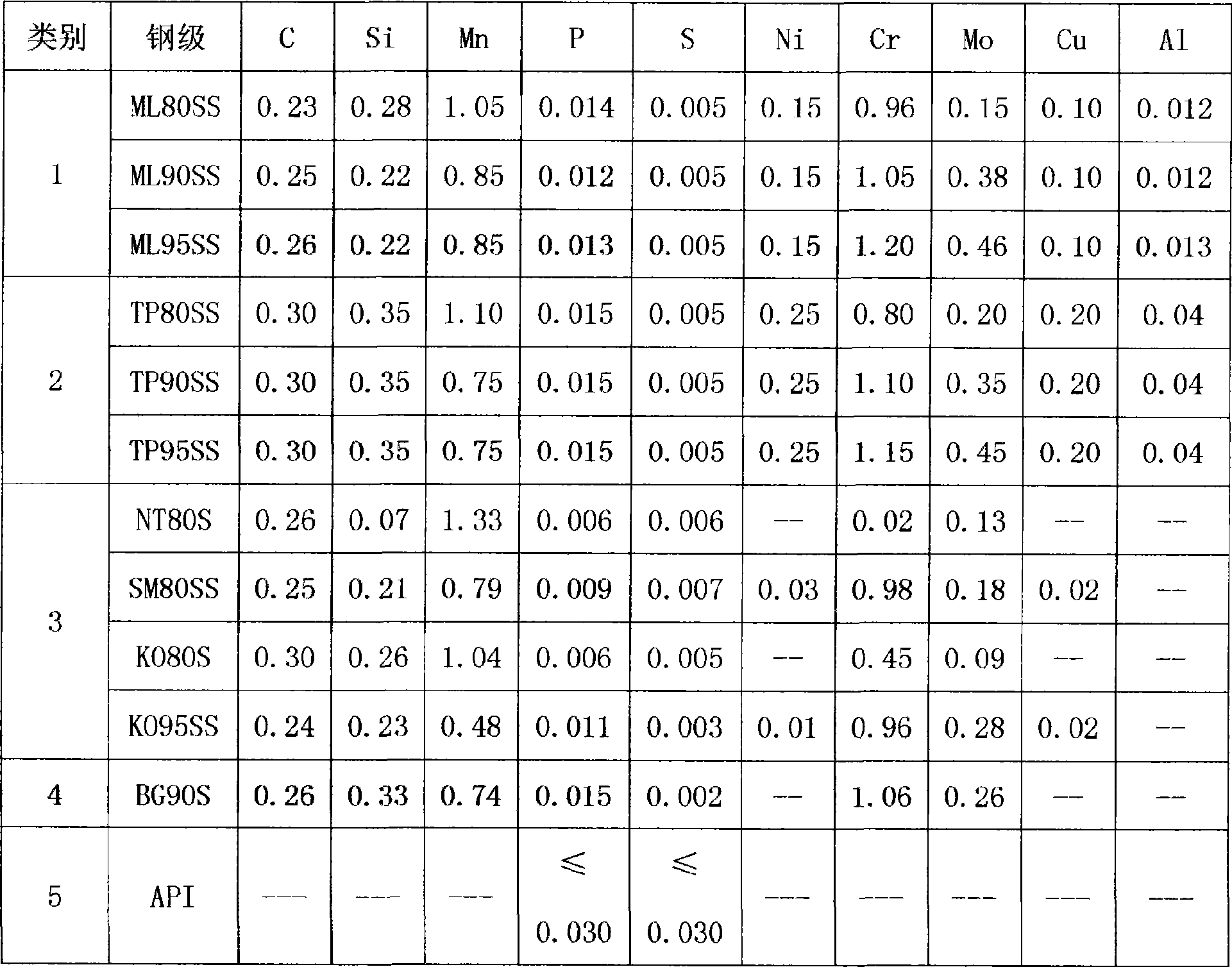

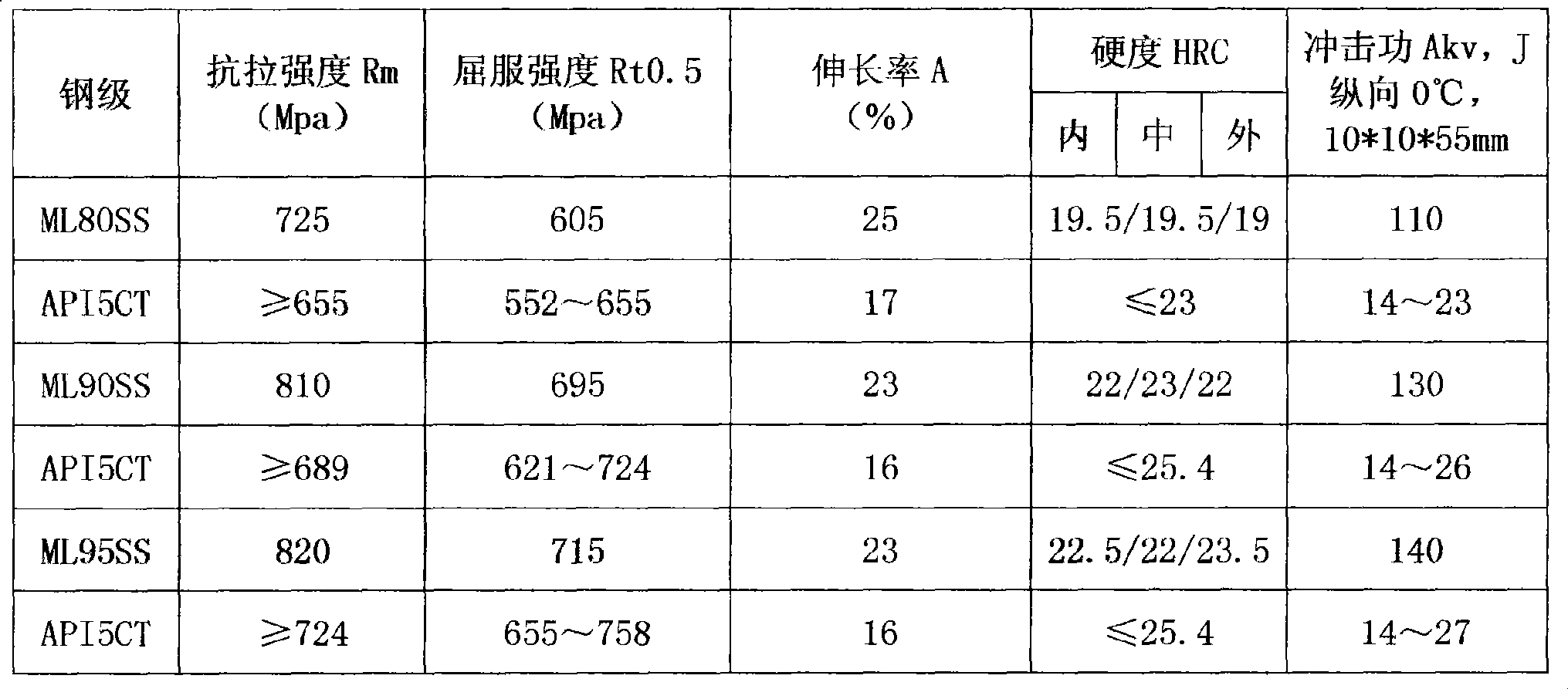

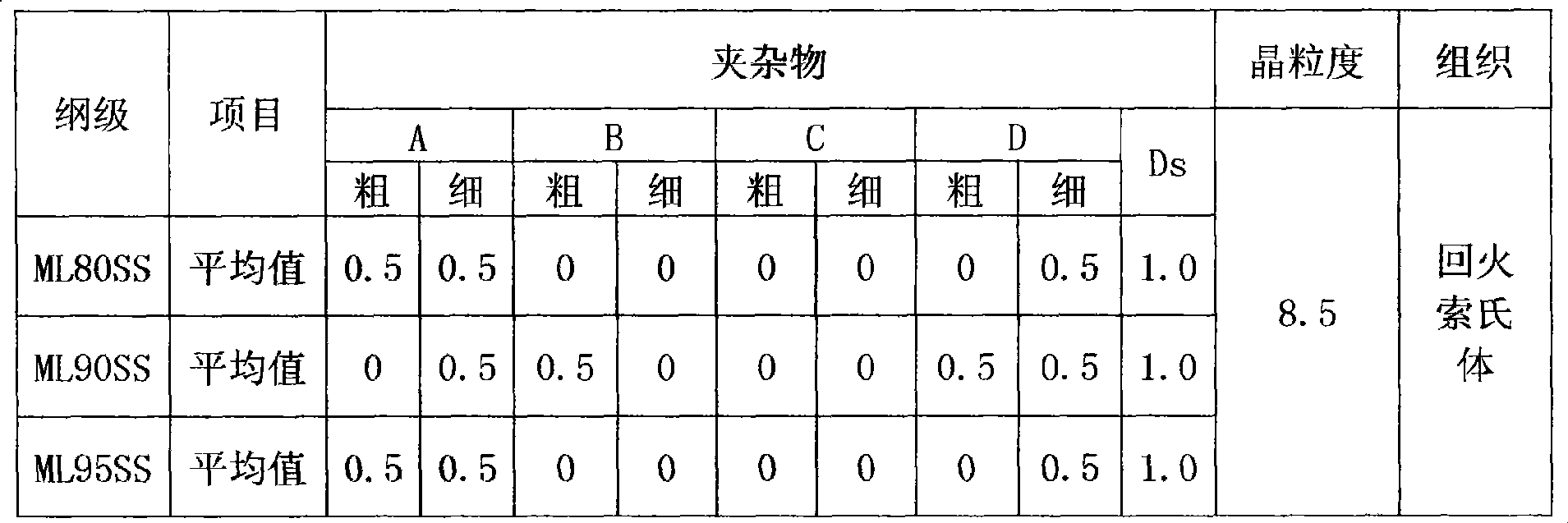

[0016] In order to improve the hydrogen sulfide stress corrosion performance of the oil casing pipe of the present invention, the alloy composition in the steel, the purity of the steel, the metallographic structure and the quality of the inner and outer surfaces of the steel pipe are particularly important.

[0017] A large number of studies have shown that the purity of steel has a great influence on its corrosion resistance. In particular, the content of P and S in steel should be reduced. Controlling the content of P and S can improve the ability to resist sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com