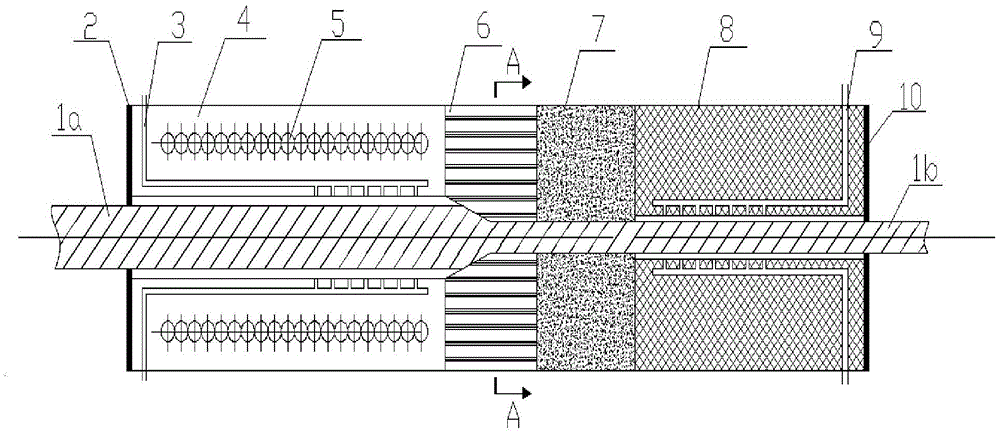

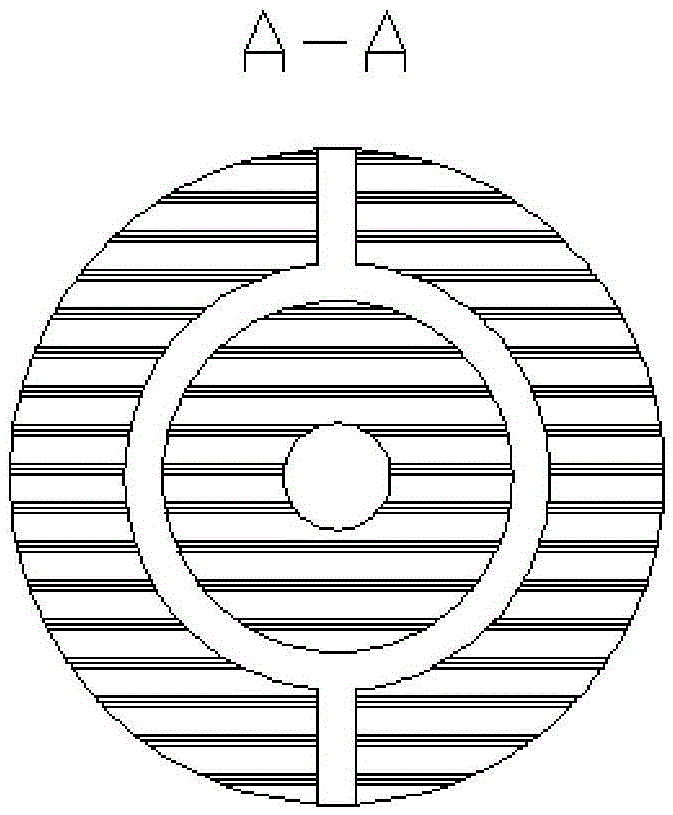

Heating-wiredrawing-finish broaching shaping-cooling wire manufacturing method

A wire and wire drawing technology, which is applied in wire drawing dies, metal wire drawing, metal processing equipment, etc., can solve problems such as no discovery, achieve high production efficiency, increase residence time, and good molding and performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Production of high nitrogen steel wire

[0043] A preparation method based on a heating-drawing-finishing shaping-cooling wire device is used to produce high-nitrogen steel wire, and the specific steps are as follows:

[0044] The first step, according to the diameter Φ of the material to be drawn 0 and the diameter of the target wire Φ 目标 , choose the aperture as Φ 1 , Φ 2 、Φ 3 ,...,Φ n The drawing die and fine drawing shaping mechanism, where Φ 0 >Φ 1 >Φ 2 >Φ 3 >…>Φ n = Φ 目标 , and Φi —Φ i+1 ≤ξ·Ψ·Φ i , (i=0,1,2...n-1), where ξ is a constant, generally 0.2 to 0.6, Ψ is the reduction of area of the material, and n is the number of wire drawing.

[0045] The high nitrogen steel preheating temperature range is 300°C to 500°C, and nitrogen is used as the protective gas.

[0046] Determine the preheating temperature range and the type and ventilation rate of the protective gas according to the type of wire drawing material. For the wire material that is easy ...

Embodiment 2

[0053] Production of copper wire

[0054] The difference from Example 1 is that the copper wire has a relatively high requirement for temperature control during the drawing process. At the same time, the required shielding gas is also different, and argon is used here as the shielding gas.

[0055] Adopt a kind of preparation method based on heating-drawing-finish drawing shaping-cooling wire material device to produce copper wire, comprise concrete steps as follows:

[0056] The first step, according to the diameter Φ of the material to be drawn 0 and the diameter of the target wire Φ 目标 , choose the aperture as Φ 1 , Φ 2 、Φ 3 ,...,Φ n The drawing die and fine drawing shaping mechanism, where Φ 0 >Φ 1 >Φ 2 >Φ 3 >…>Φ n = Φ 目标 , and Φ i —Φ i+1 ≤ξ·Ψ·Φ i , (i=0,1,2...n-1), where ξ is a constant, generally 0.2 to 0.6, Ψ is the reduction of area of the material, and n is the number of wire drawing.

[0057] The copper wire preheating temperature range is 60°C to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com