Method of machining metallic tubes

a tube and tube body technology, applied in the direction of metal drawing, manufacturing tools, wire straightening devices, etc., can solve the problems of lowering the entire weight of the material used, spd cannot be used to process tubes, and angular pressing (ecap) is only suitable, so as to reduce the thickness of the tube, and improve the mechanical strength of the tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

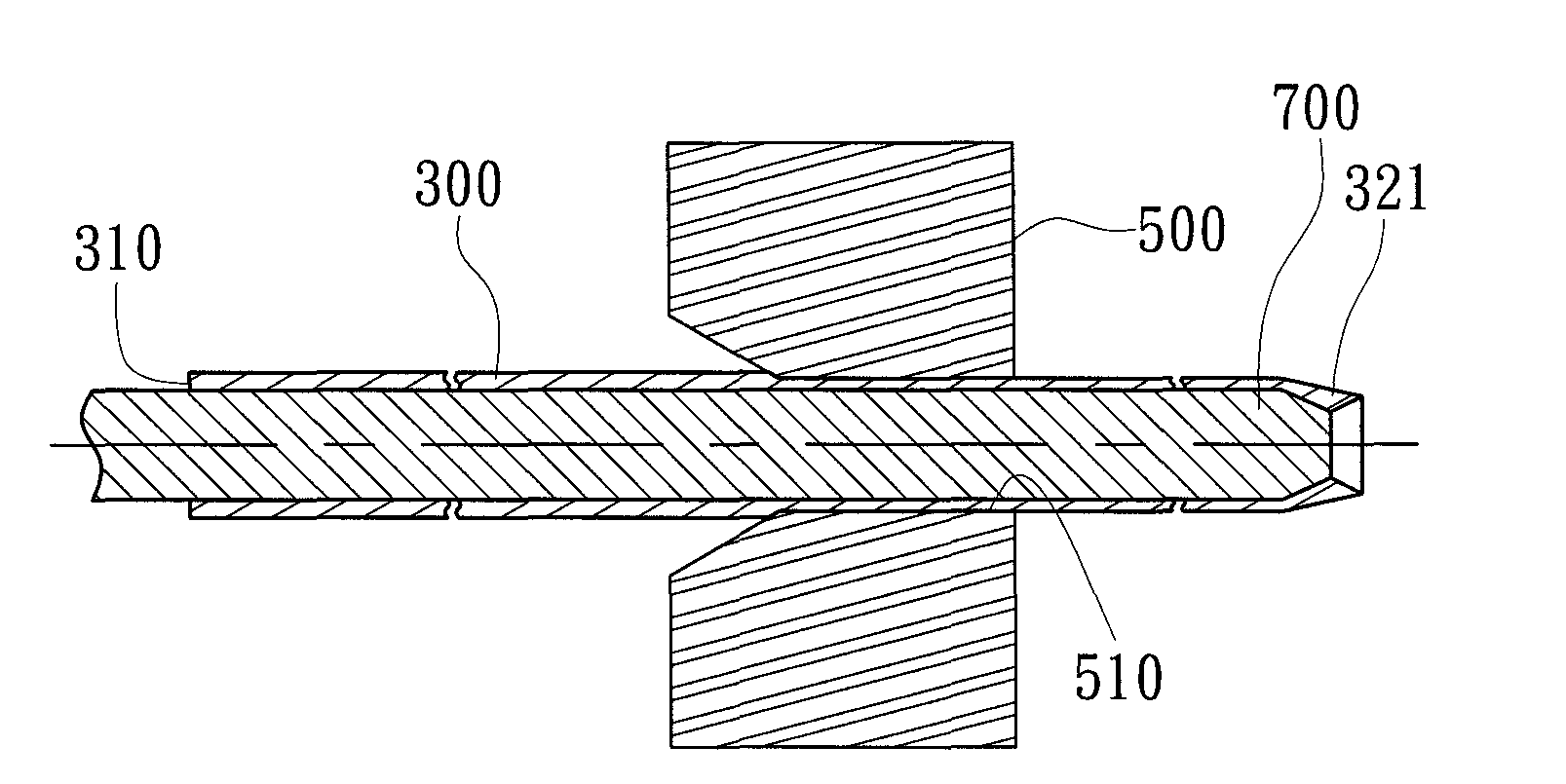

[0038]For machining a 7050 Al—Zn—Mg aluminum tube as an example, before machining the tube, the original external diameter of the tube is 31 millimeters, the original internal diameter of the tube is 25 millimeters, the thickness of the tube is 3 millimeters, and the length of the tube is 250 millimeters. A predetermined thickness of the tube is 1.5 millimeters after machining. This embodiment illustrates reducing the external diameter of the tube from 31 millimeters to 28 millimeters, while the internal diameter of the tube is still kept at 25 millimeters after machining.

[0039]The tube is annealed at 430° C. for one hour, and furnace cooled. The annealing treatment softens the tube. A portion (about 25 millimeters in length) of the tube at the first end is necked to form the first pressing portion. A soap treatment is performed to the surface of the tube, which coats a layer of solid soap material on the surface of the tube. The soap treatment may immerse the tube in sulfurized oil...

embodiment 2

[0044]For machining a 7050 Al—Zn—Mg aluminum tube as an example, before machining the tube, the original external diameter of the tube is 31 millimeters, the original internal diameter of the tube is 25 millimeters, the thickness of the tube is 3 millimeters, and the length of the tube is 250 millimeters. A predetermined thickness of the tube is 1.5 millimeters after machining. This embodiment illustrates increasing the internal diameter of the tube from 25 millimeters to 28 millimeters, while the external diameter of the tube is still kept at 31 millimeters after machining.

[0045]The tube is annealed at 430° C. for one hour, and furnace cooled. The annealing treatment softens the tube. A portion (about 25 millimeters in length) of the tube at the first end is necked to form the first pressing portion.

[0046]A soap treatment is performed to the surfaces including an exterior surface and an interior surface of the tube, which coats a layer of soap material on each surface of the tube. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| internal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com