Improved automatic drawing machine

A drawing machine and automatic technology, applied in metal wire drawing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency, low yield, high labor intensity of workers, etc., to prevent damage, high utilization rate, and convenient process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

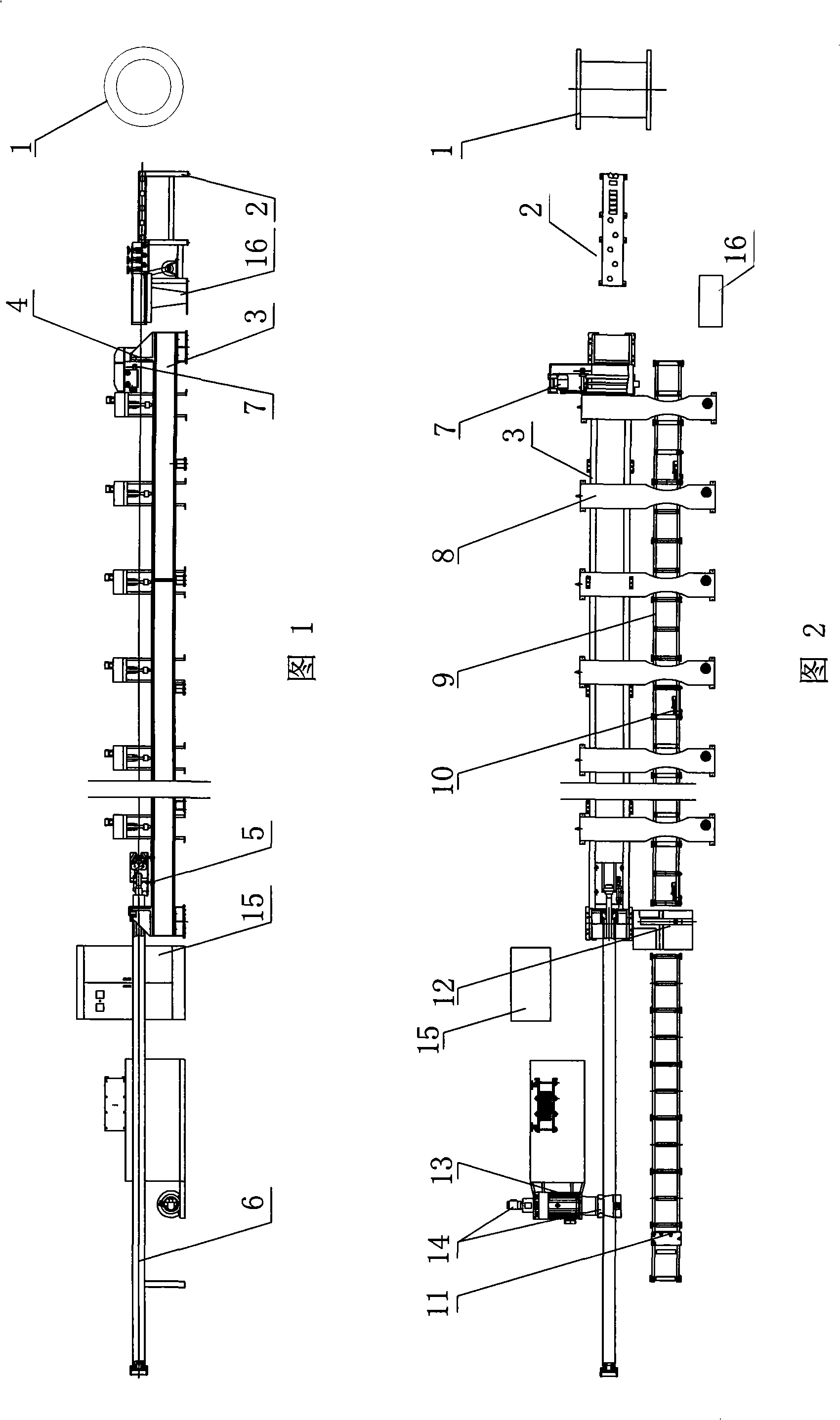

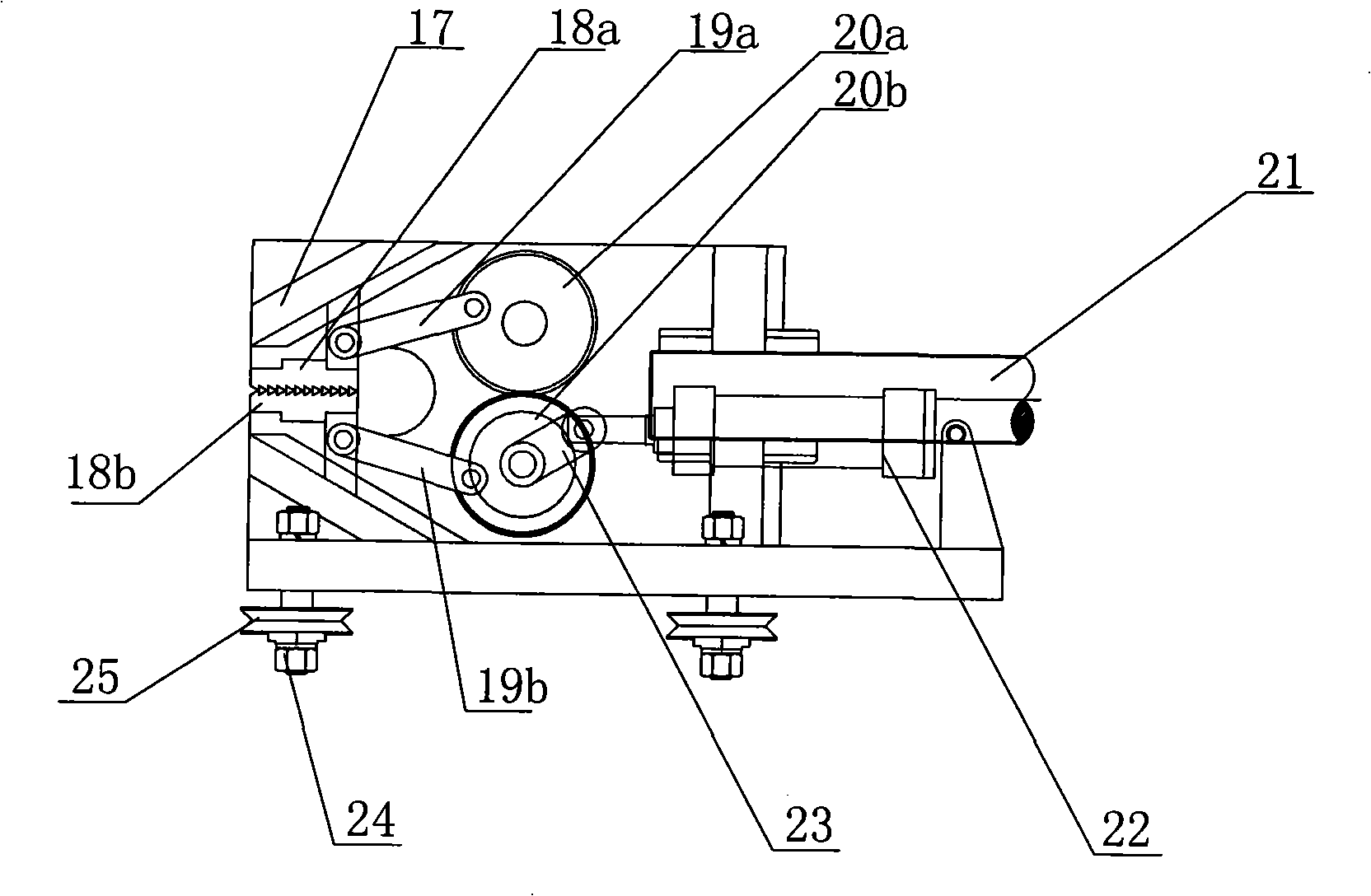

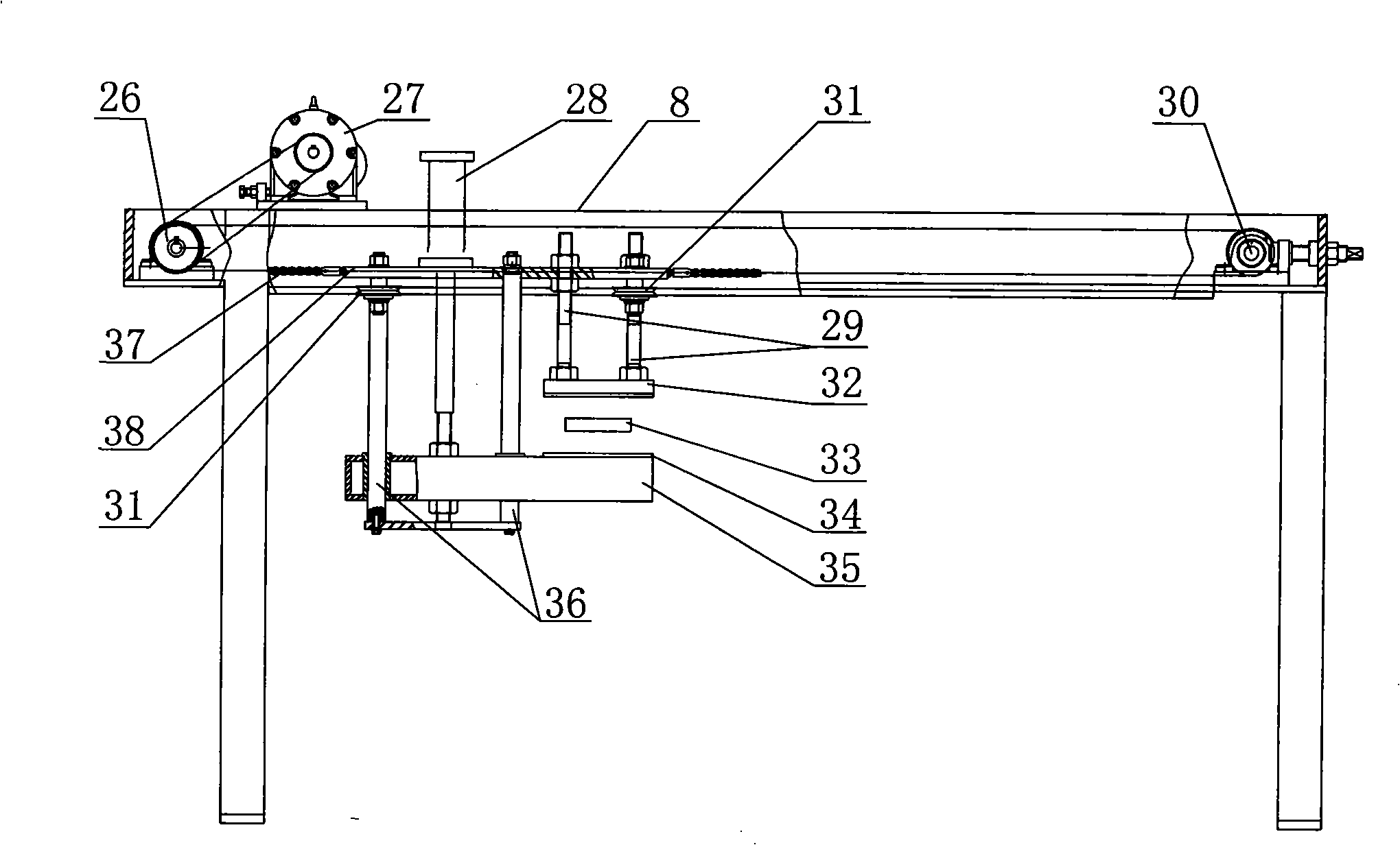

[0014] See Fig. 1, Fig. 2, the present invention comprises frame 3, and frame 3 is equipped with drawing and clamping structure 5, drawing die 4, is provided with sawing machine 7 at the side of drawing die 4, in drawing die 4, the frame 3 is provided with a feeder 1 and a straightener 2. The side of the frame 3 is provided with a material transfer structure, the material transfer structure includes a fixed frame 8, the fixed frame 8 spans both sides of the frame 3, and the fixed frame 8 is equipped with a transmission structure, see Figure 4 , the transmission structure includes a conveyor chain 37, the conveyor chain 37 is connected to a slide plate 38, and a cylinder 28 is installed on the slide plate 38; the piston rod of the cylinder 28 is connected to the lower manipulator 35, and the upper manipulator 32 and the lower manipulator 35 are arranged correspondingly up and down, and the upper manipulator 32 and the lower manipulator 35 are sleeved on support shafts 36, 29 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com