Manufacturing process of aluminum-steel composite pipe with high thermal conductivity for petrochemical

A manufacturing process, high thermal conductivity technology, applied in manufacturing tools, metal processing equipment, metal wire drawing, etc., can solve the problem of insufficient rigidity and strength, and achieve the effect of prolonging life, saving aluminum, and improving heat dissipation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

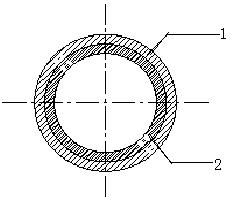

[0013] Such as figure 2 As shown, a manufacturing process of high thermal conductivity aluminum-steel composite pipe for petrochemical industry, the main materials include aluminum pipe 1 and steel pipe 2.

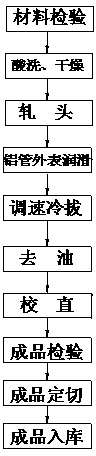

[0014] Such as figure 1 As shown, the aluminum pipe 1 and the steel pipe 2 are first pickled and dried. The specific expression is: when pickling the inner and outer surfaces of the aluminum pipe 1, dilute hydrochloric acid solution is used, the concentration range is 10% to 15%, and the temperature is 30- 40°C, acid wash for 8-10 minutes, put in 2% NaNO after flushing 3 Passivate the solution, then blow it off with compressed air, and dry it with steam; when pickling the steel pipe 2, use a dilute sulfuric acid solution with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com