Wire surface treatment machine

A surface treatment machine and wire rod technology, applied in the field of wire rod processing, can solve the problems of reducing the quality of finished wire rods, reducing the service life of steel brushes, and failing to achieve the effect, and achieve the effects of long life of steel brushes, avoiding bumps, and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

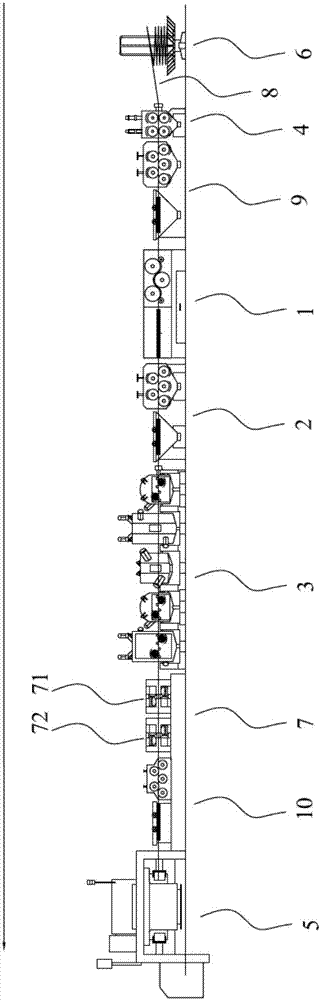

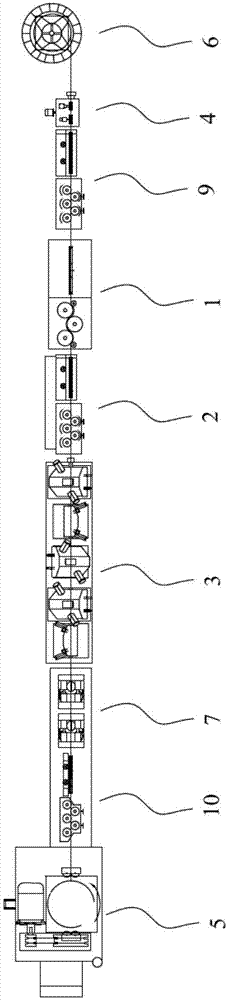

[0047] As shown in Figure 1, a wire surface treatment machine provided in this embodiment includes a wire-feeding assembly 6, a wire-feeding wheel set 4, a second straightening unit 9, a peeling unit 1, a first straightening unit 2, a steel The brush unit 3, the roller unit 7, the third straightening unit 10 and the wire take-up assembly 5, the direction indicated by the arrow in the figure is the direction of movement of the wire 8 during processing.

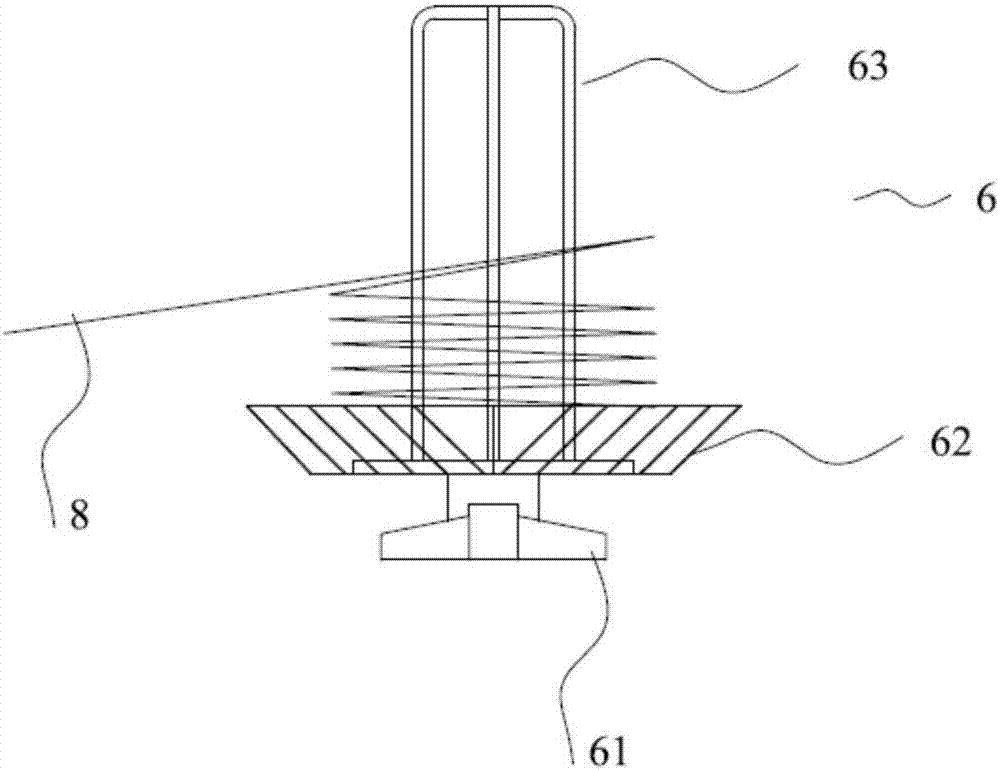

[0048] pay-off assembly 6, such as figure 2 As shown, it is mainly used to place the wire to be processed. The pay-off assembly 6 includes a base 61, a tray 62 that is connected to one side of the base 61 and can rotate relative to the base 61, the side of the tray 62 away from the base 61 is detachably connected with a pay-off frame 63, and the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com