Wire arranging compensation device and wire arranging compensation method of wire cutting all-powerful winding machine

A technology for cutting steel wire and compensating device, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve the problems of unsatisfactory wiring effect, slippage, difficulty, etc., and achieves simple structure, Short commutation time, the effect of reducing commutation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

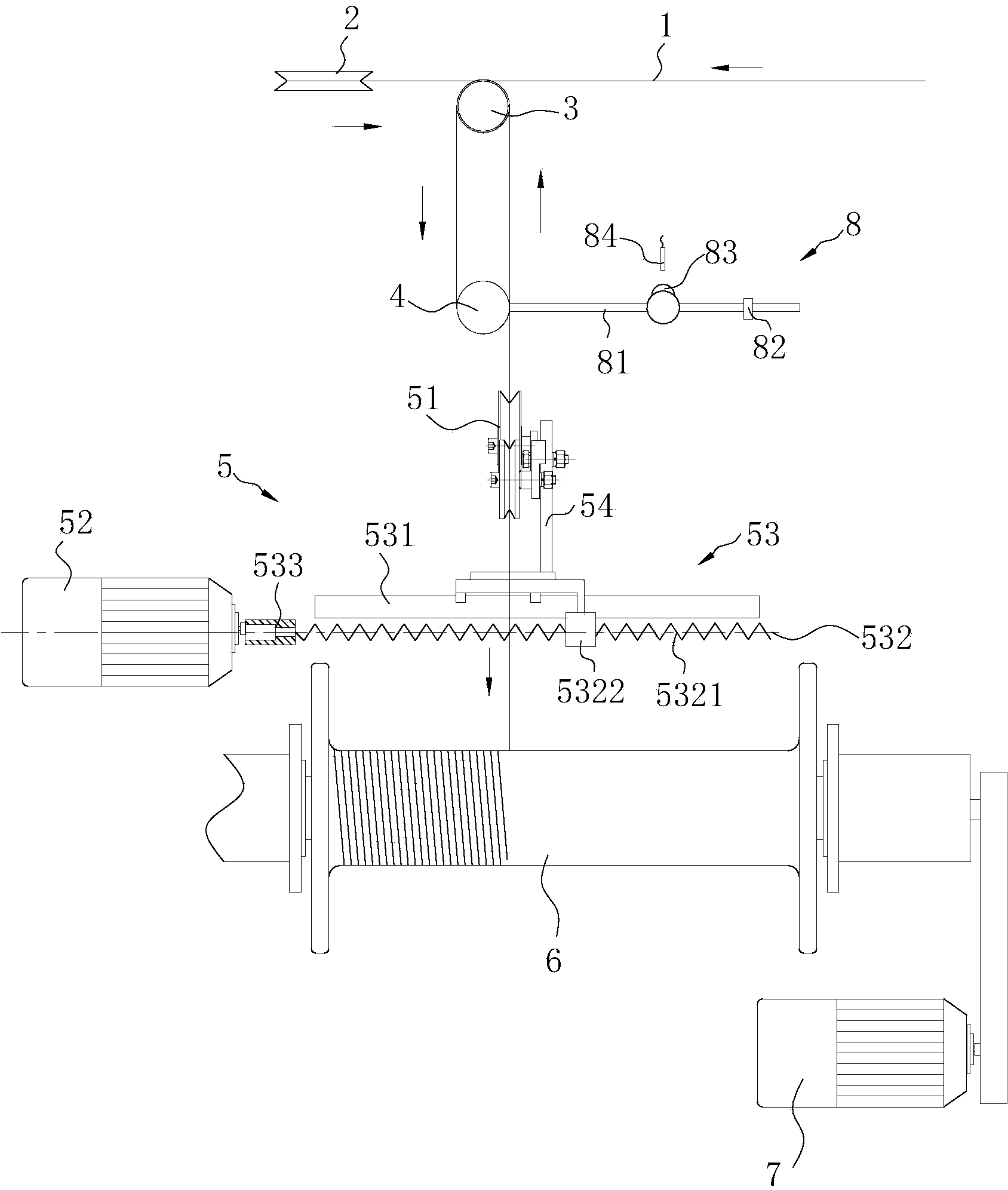

[0026] Such as figure 1 In the illustrated embodiment, the wire-cutting compensation device of the universal take-up machine for cutting steel wire of the present invention includes a wire 1, a first guide wheel 2, a second guide wheel 3, a third guide wheel 4, a wire-arranging device 5, and a wire take-up Wheel 6, the steel wire 1 is fed in from the host direction and in turn passes through the first guide wheel 2, the second guide wheel 3, the third guide wheel 4 and the wire arrangement 5 and finally winds on the take-up reel 6. A wire take-up motor 7 for rotating the wire take-up wheel 6 is provided at one end.

[0027] The cable arrangement 5 includes a cable guide wheel 51 and a cable motor 52. The output shaft end of the cable motor 52 is connected to the cable guide wheel 51 through a horizontal moving assembly 53 so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com