Electromagnetic directional valve

An electromagnetic reversing valve and electromagnet technology, which is applied in fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of miniaturization of electromagnetic reversing valves, reversing sensitivity and energy consumption that cannot meet actual requirements, etc. problems, to achieve the effects of miniaturization design, reduced reaction force, and shortened working stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

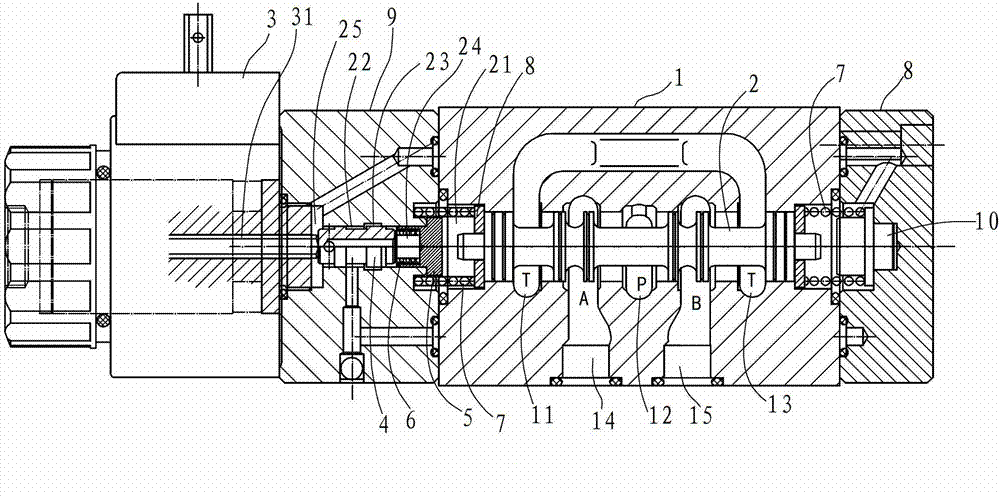

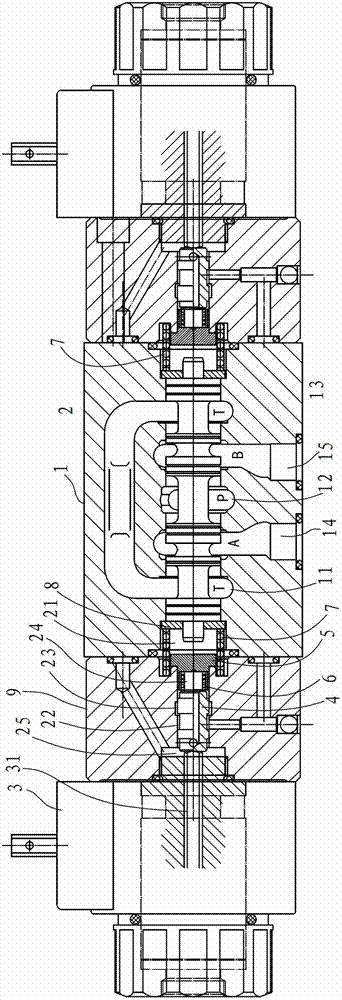

[0021] Such as figure 1 As shown, the electromagnetic reversing valve in this embodiment is a single-control electromagnetic reversing valve, including valve body 1, main valve core 2, electromagnet 3, main return spring 7, side cover 9, pilot spool 4, pilot reset Spring 6 and end cap 8.

[0022] The valve body 1 has an oil inlet chamber 12, an oil return chamber 11, a working chamber 14 and a working chamber 15. The main valve core 2 is located in the valve body 1 and can move back and forth along the axial passage of the valve body to change the reversing direction. The working state of the valve. The middle part of the rear end of the main valve core 2 protrudes axially to form a convex part 21 .

[0023] The main return spring 7 acts on the main spool 2 and moves the main spool 2 to the initial position. There are two main return spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com