Patents

Literature

36results about How to "Reduce hydraulic power" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

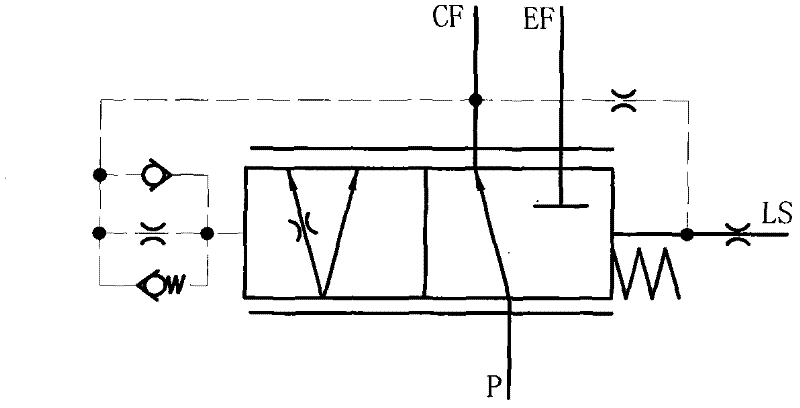

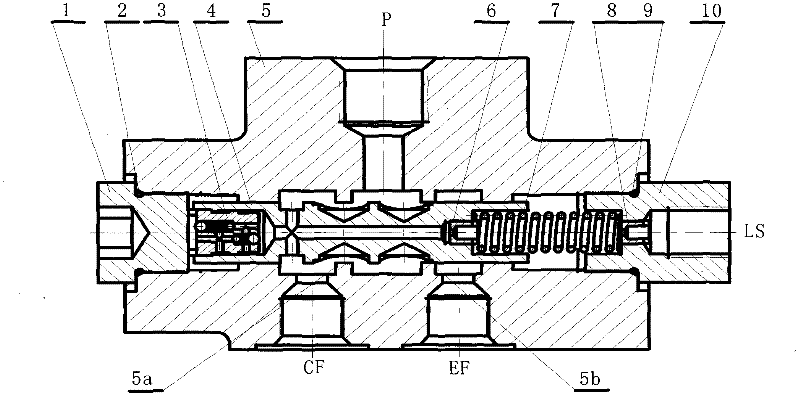

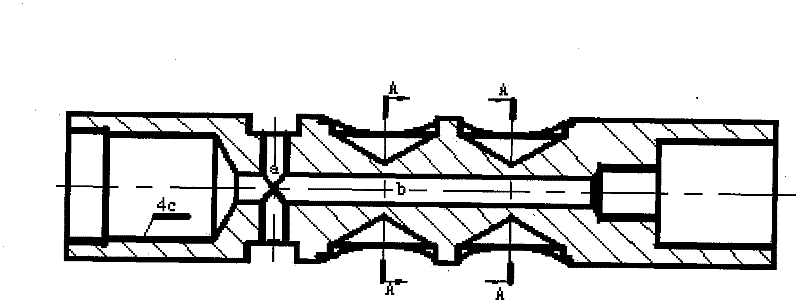

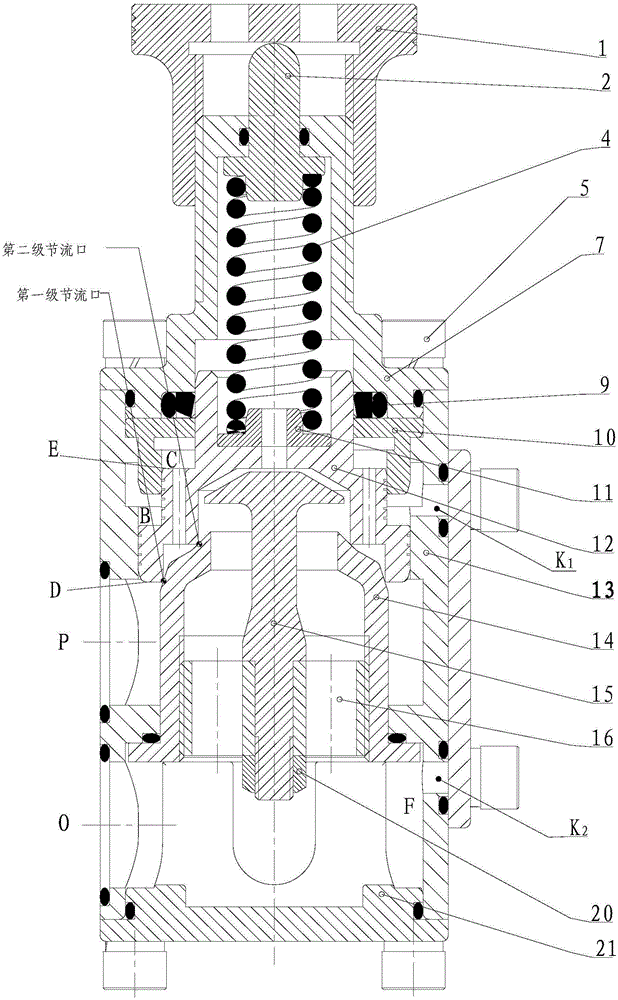

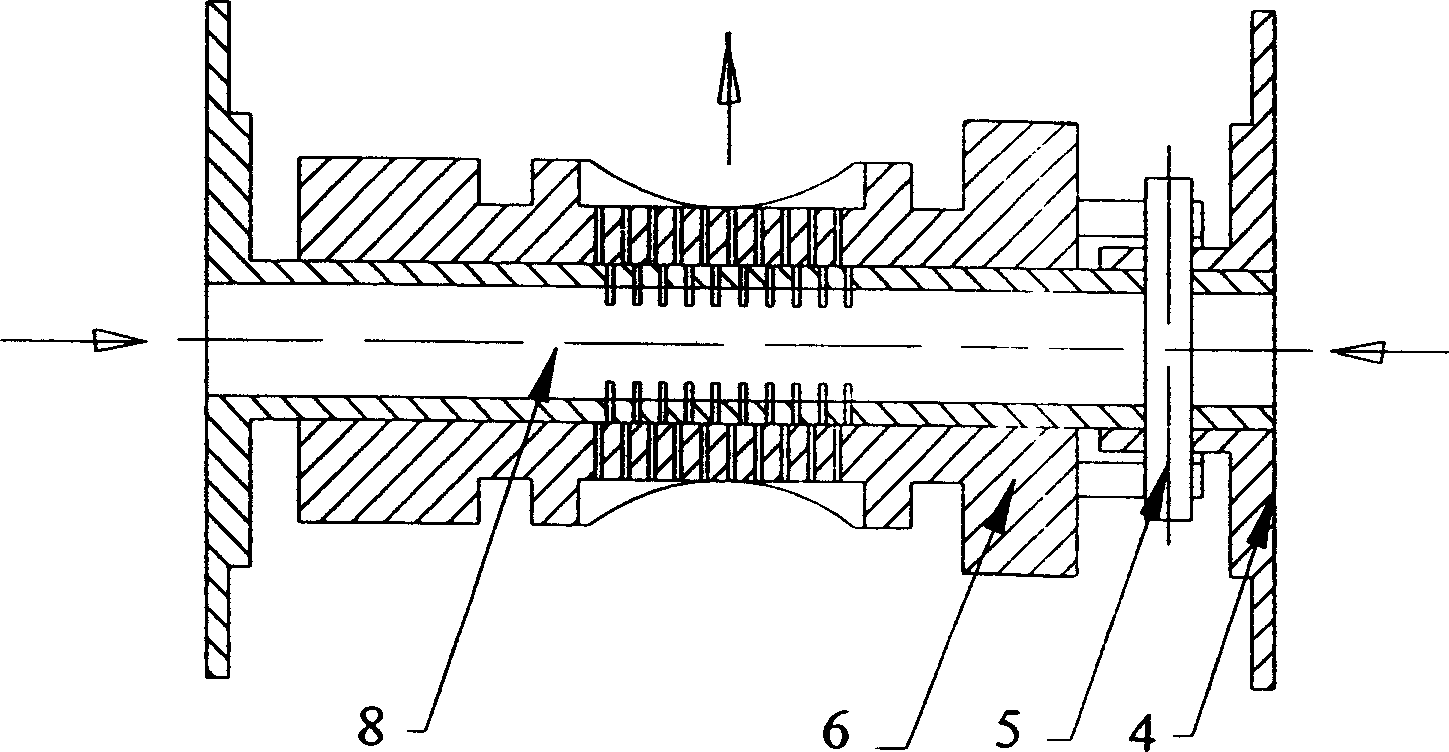

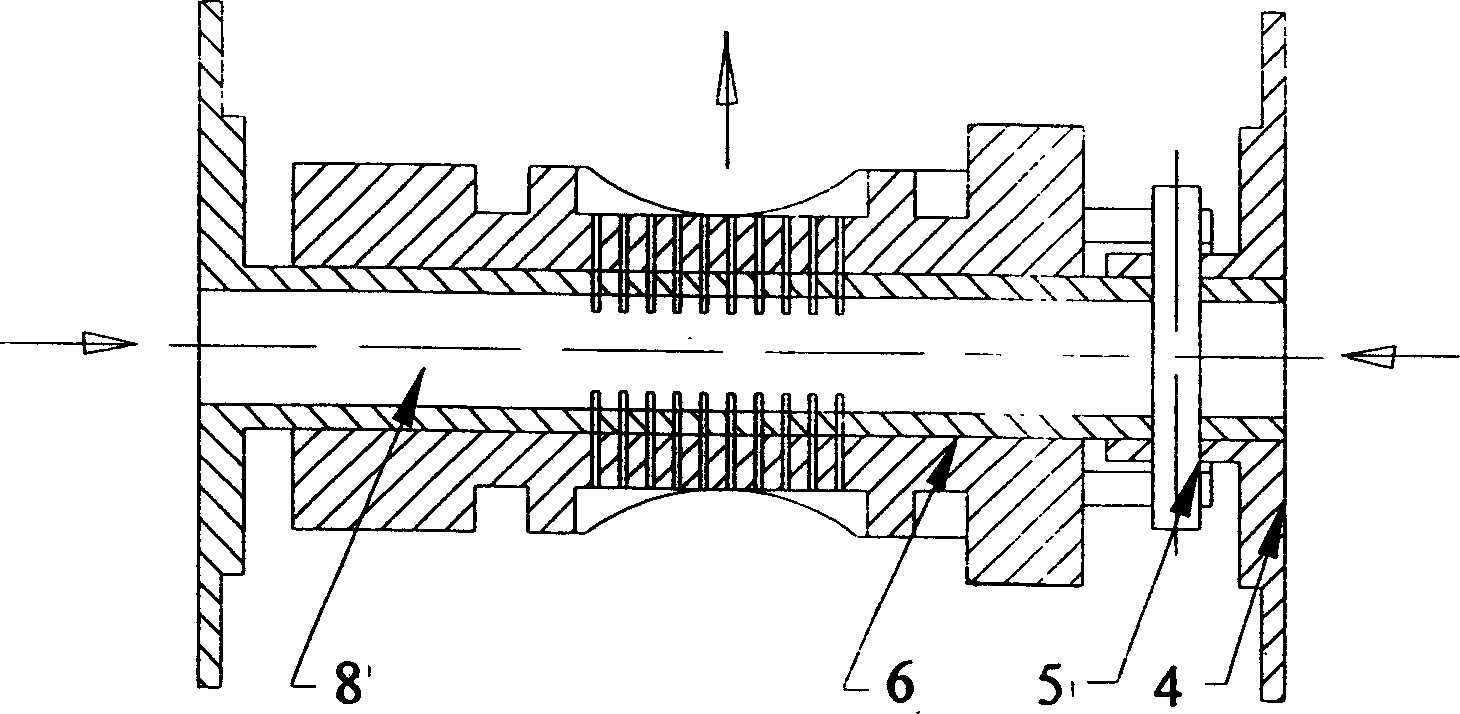

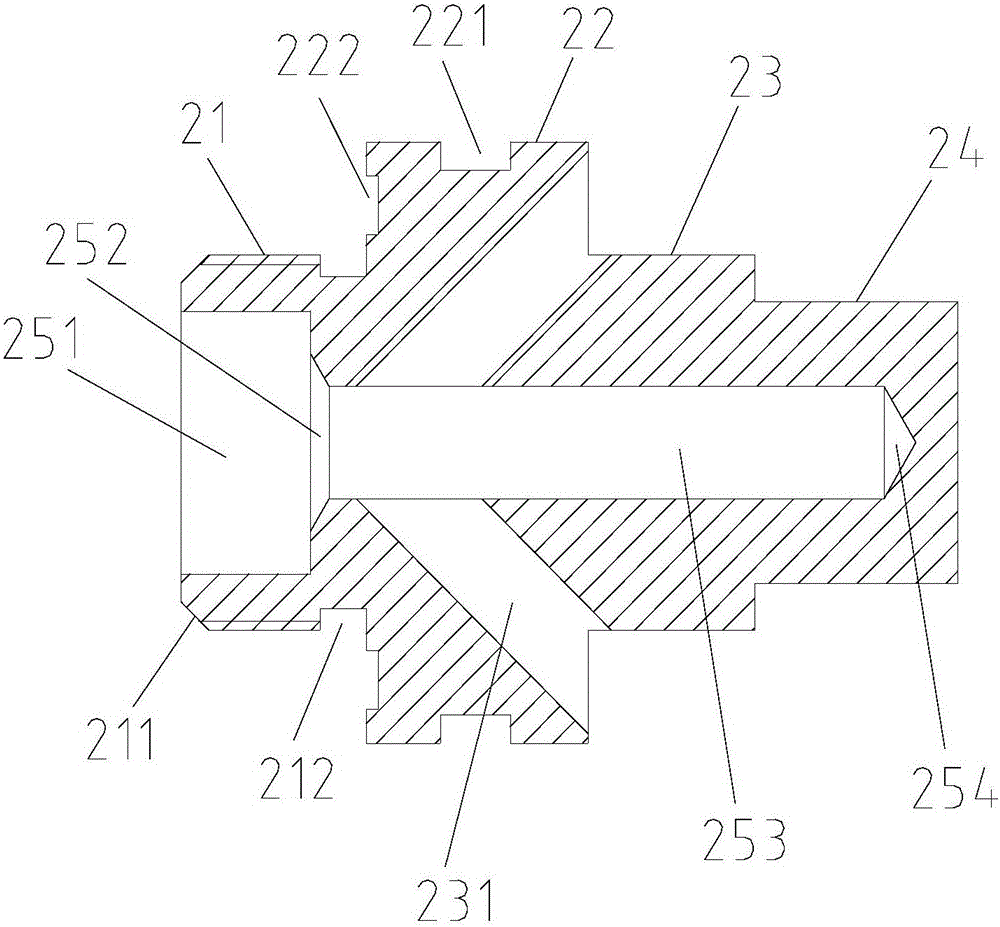

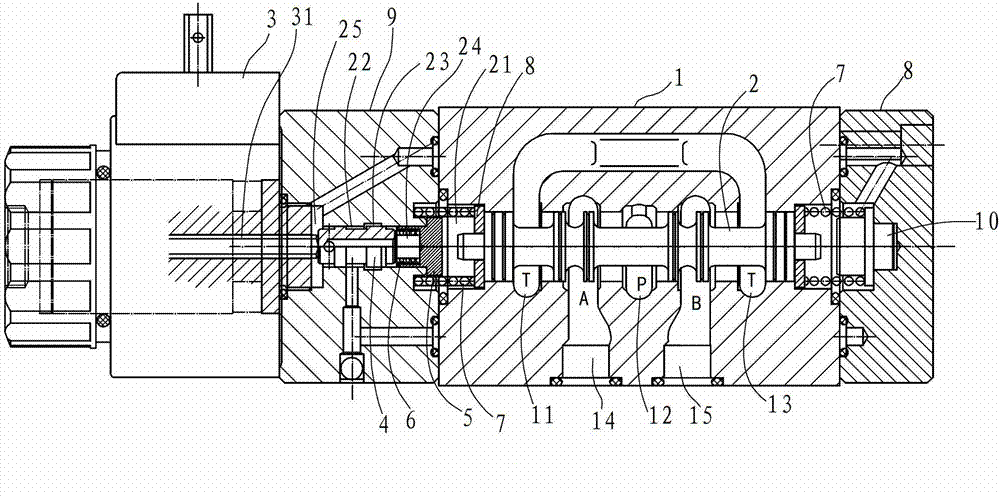

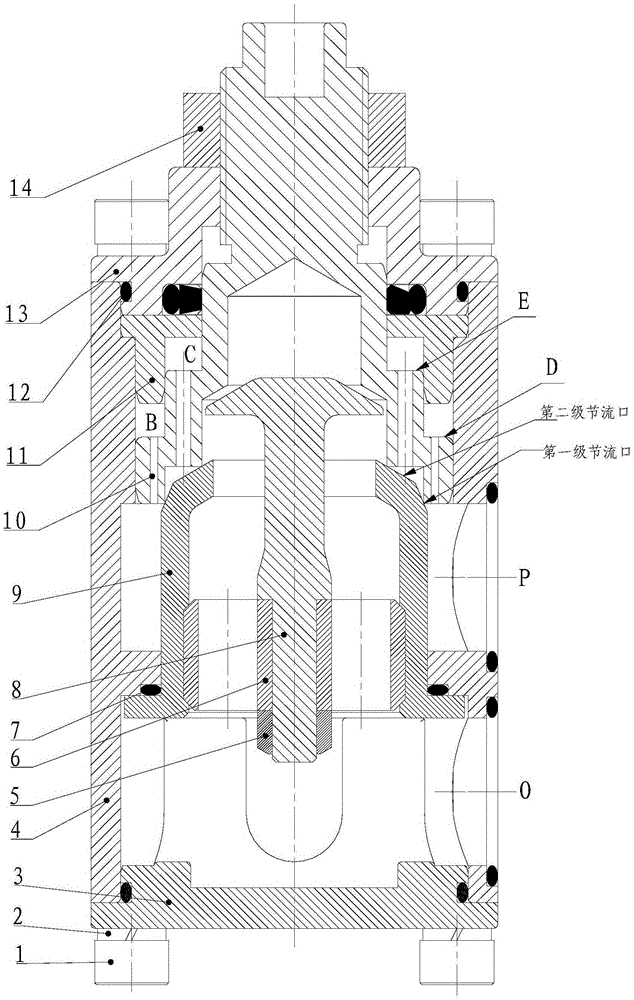

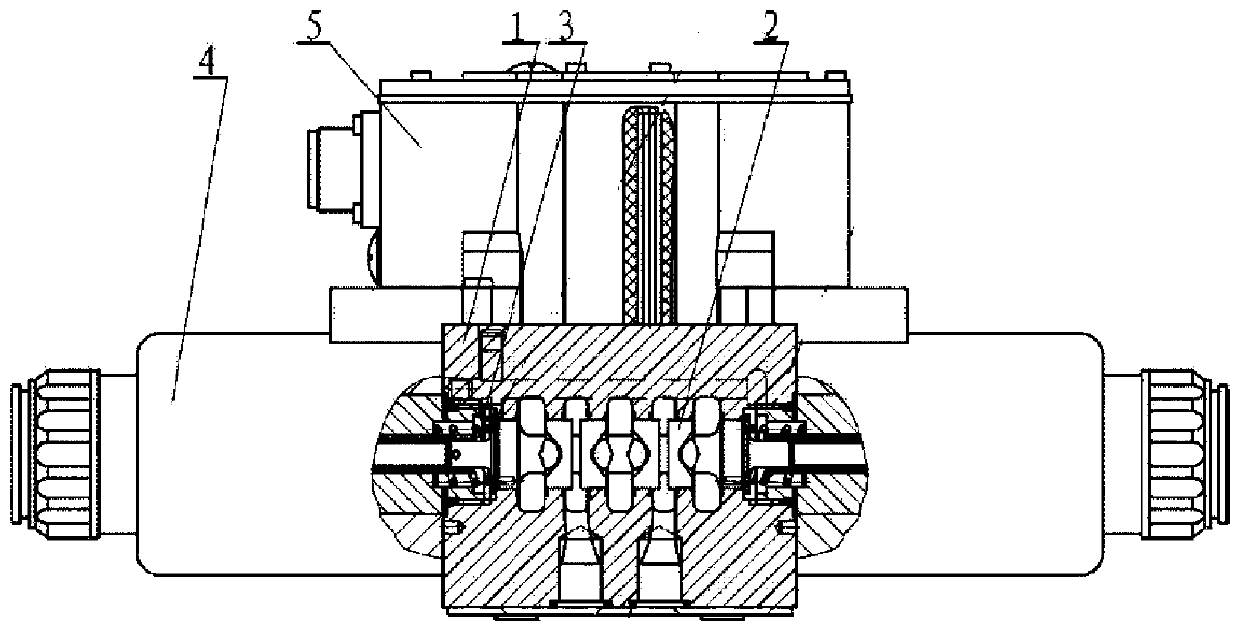

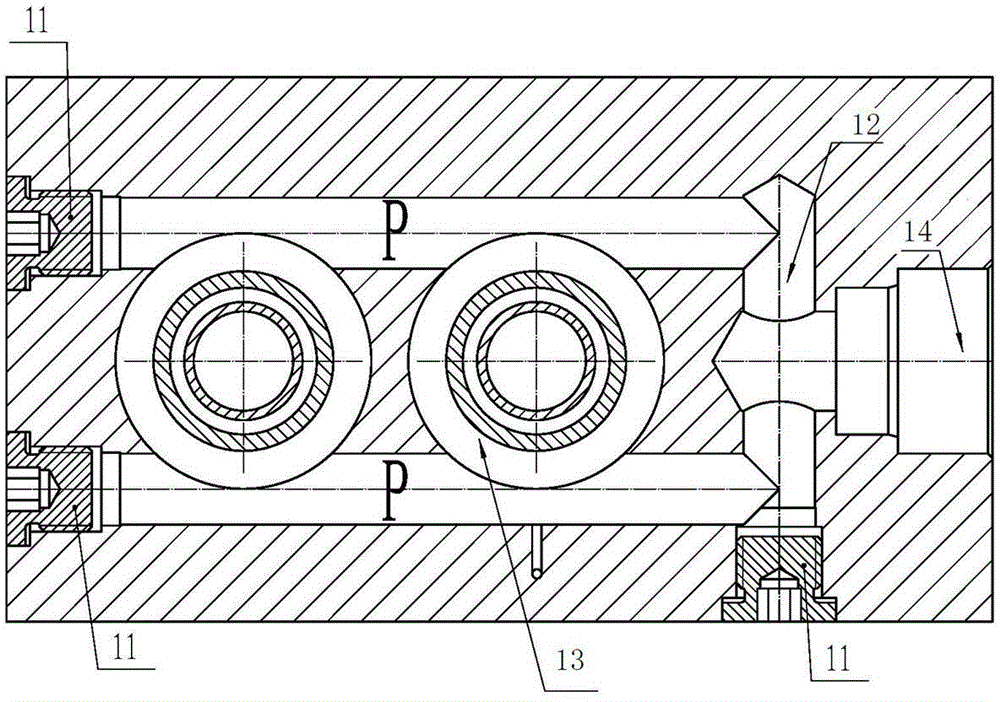

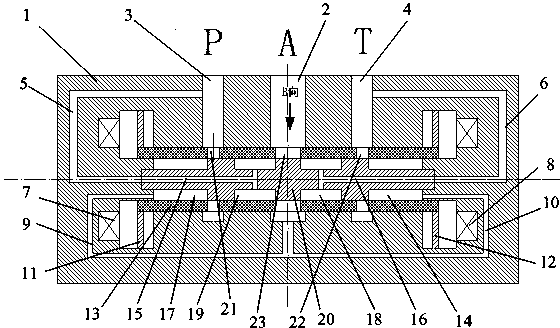

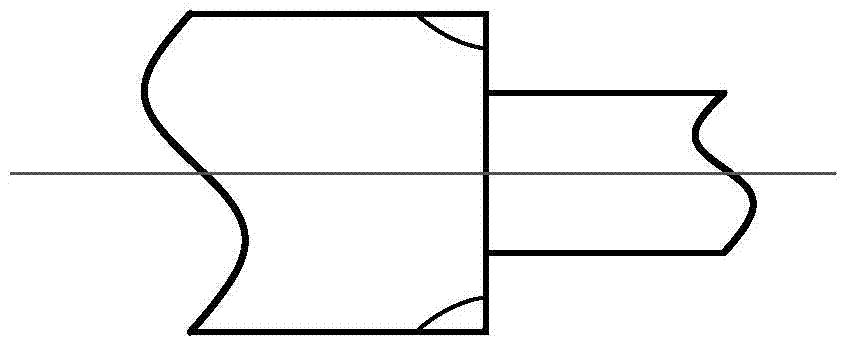

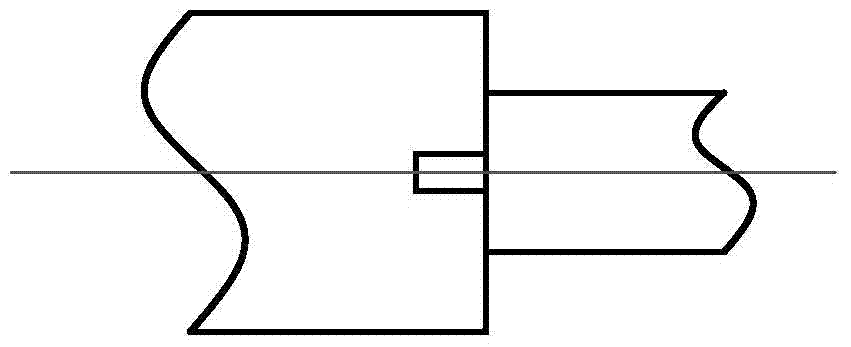

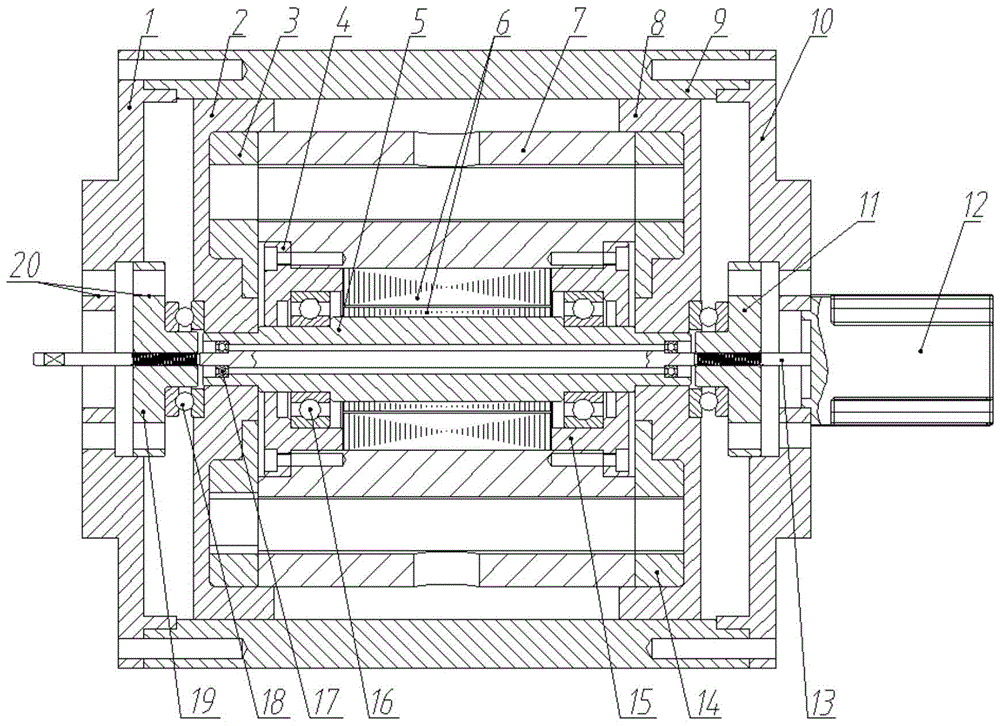

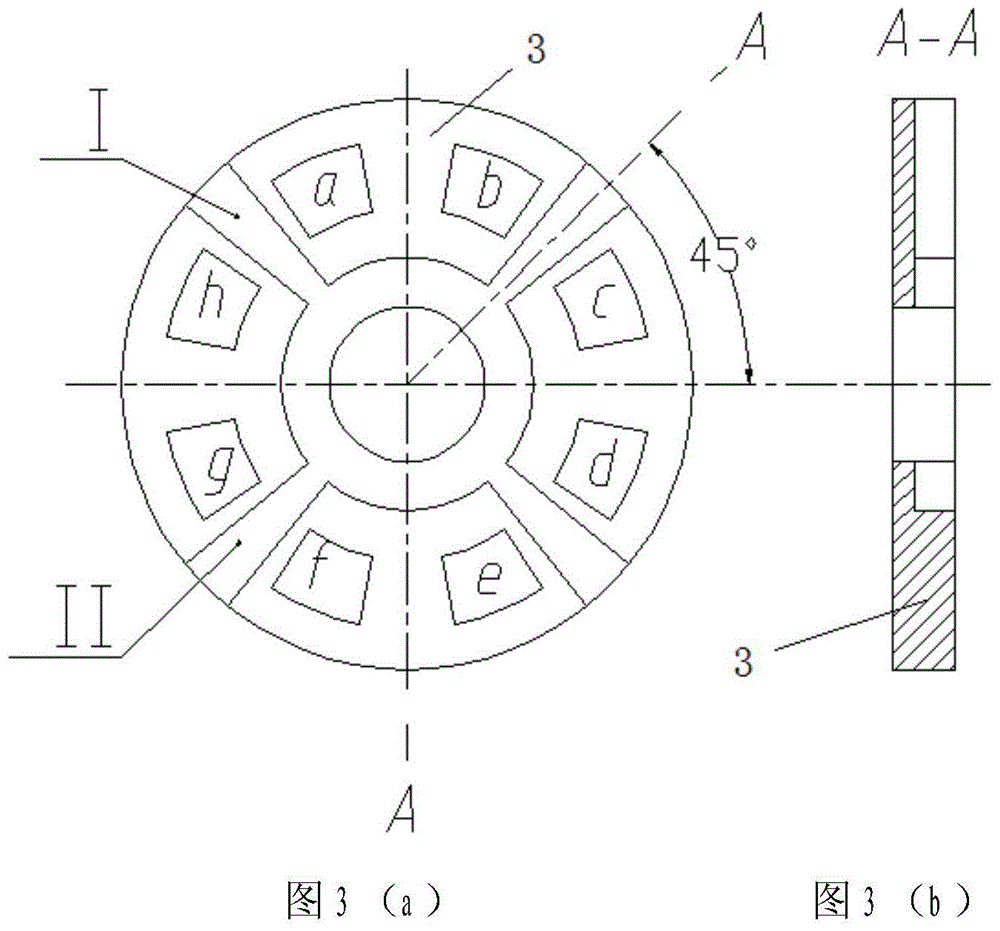

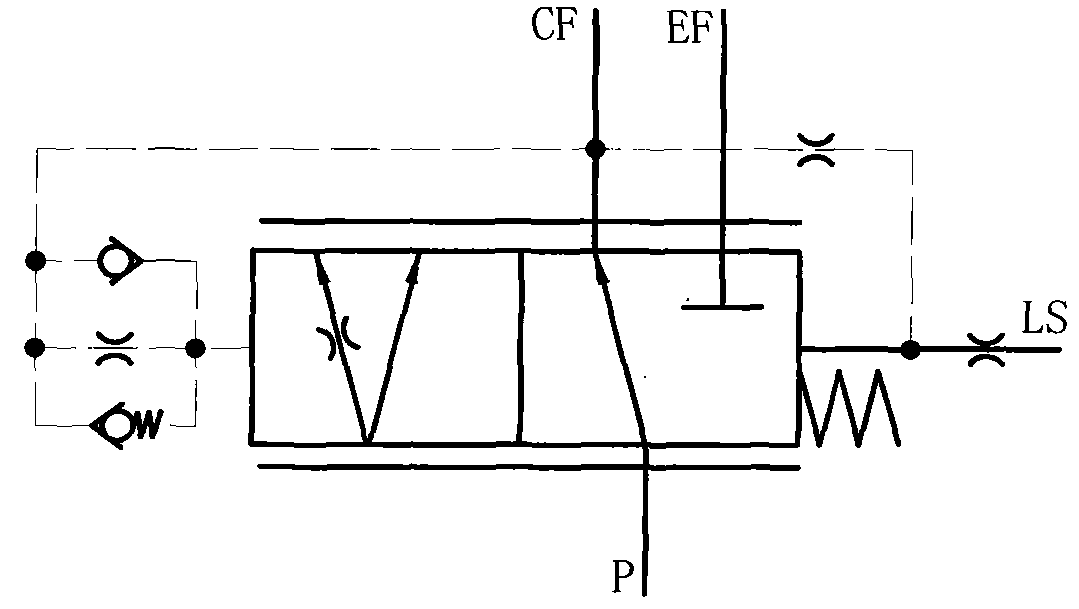

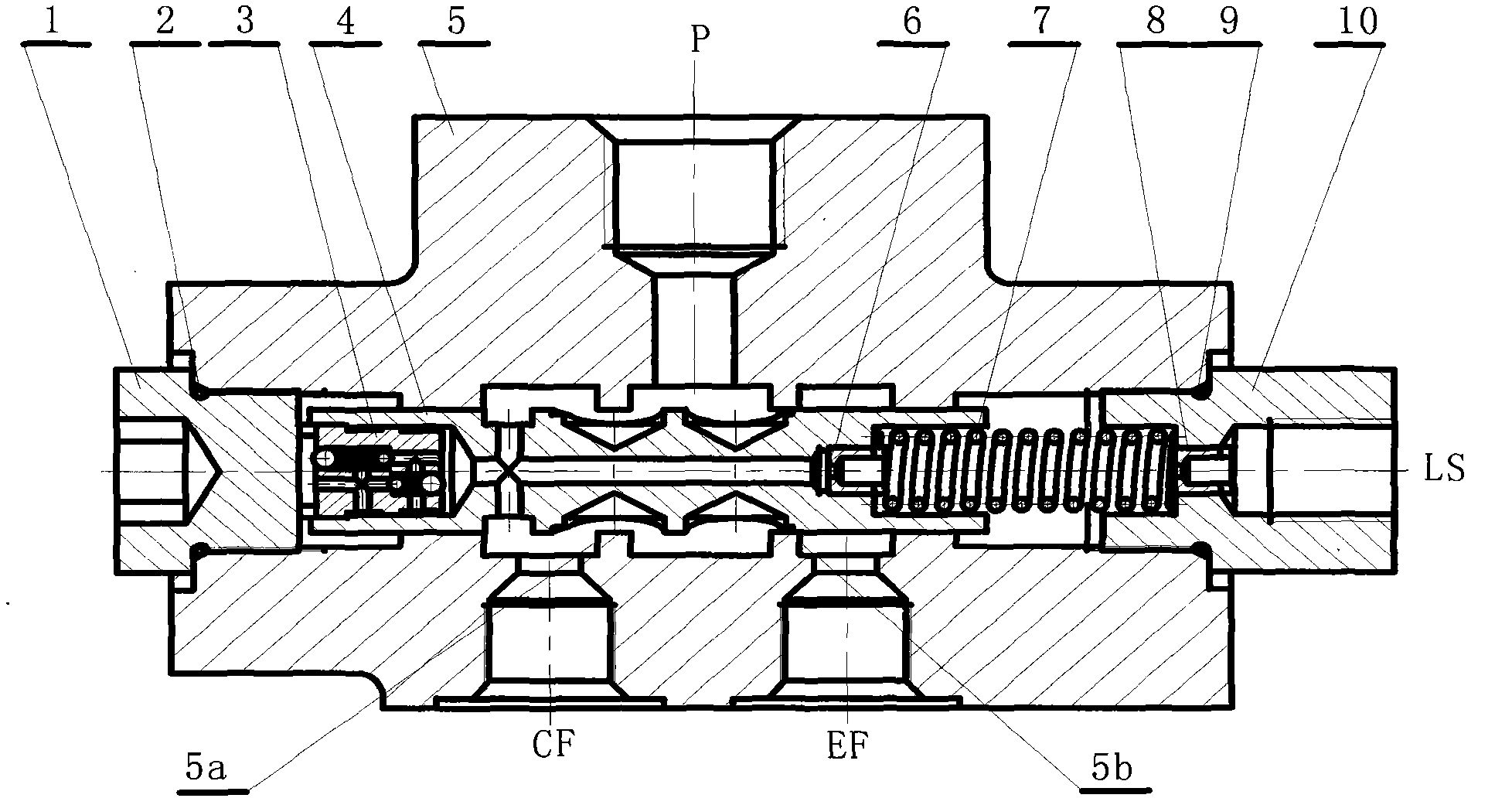

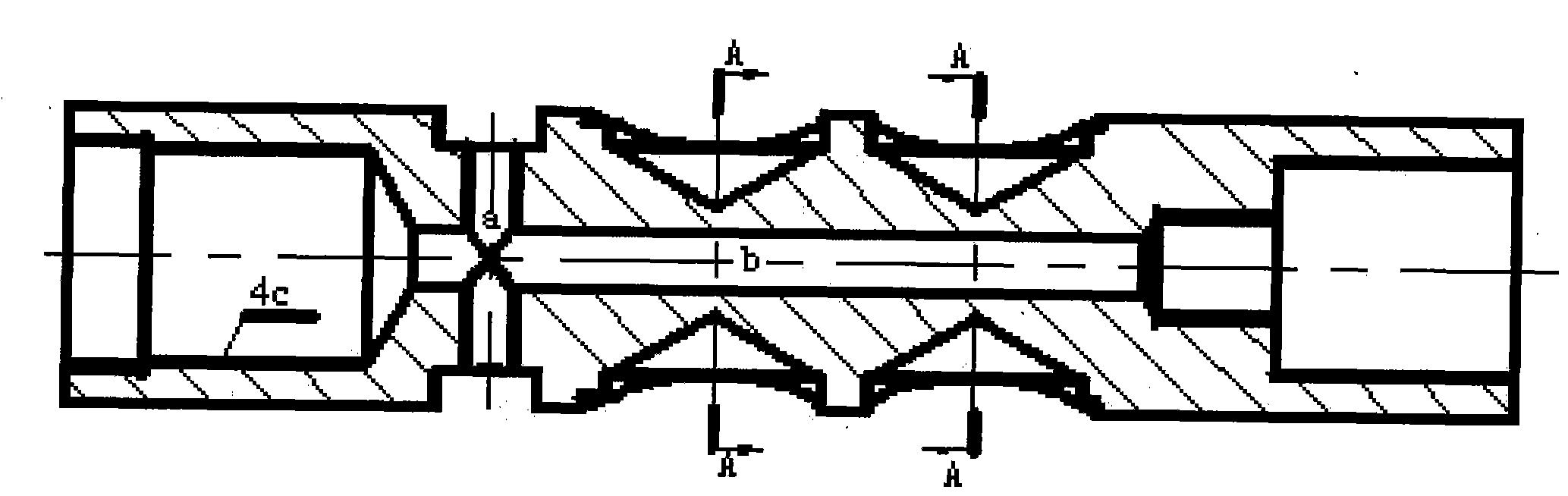

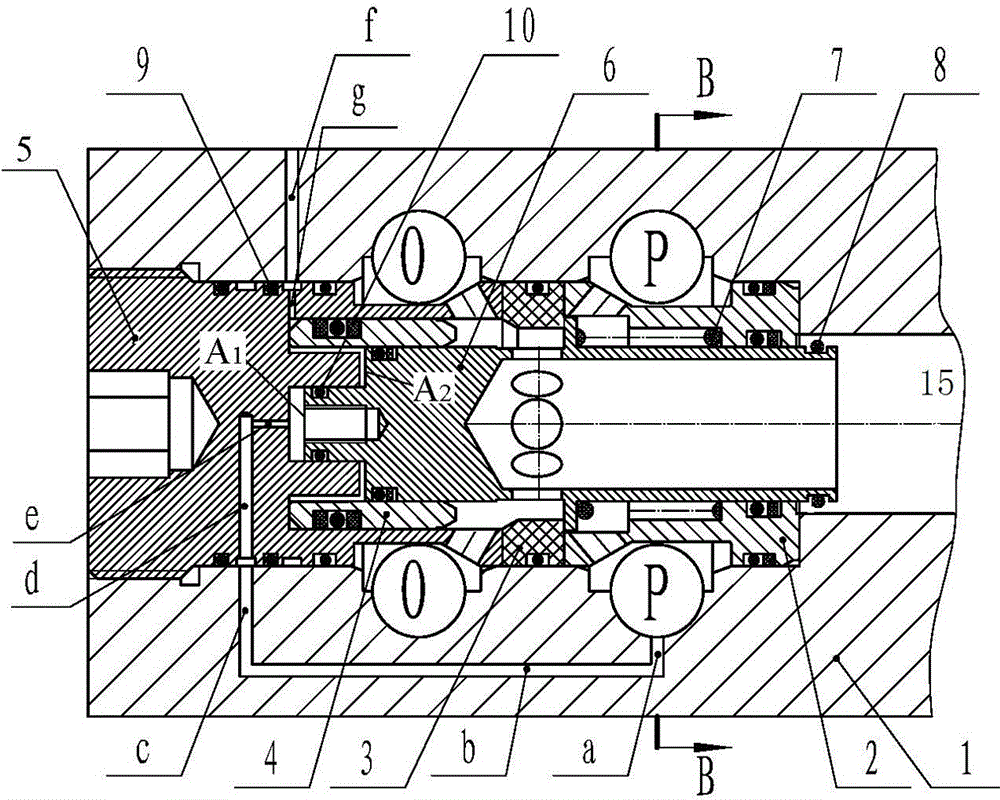

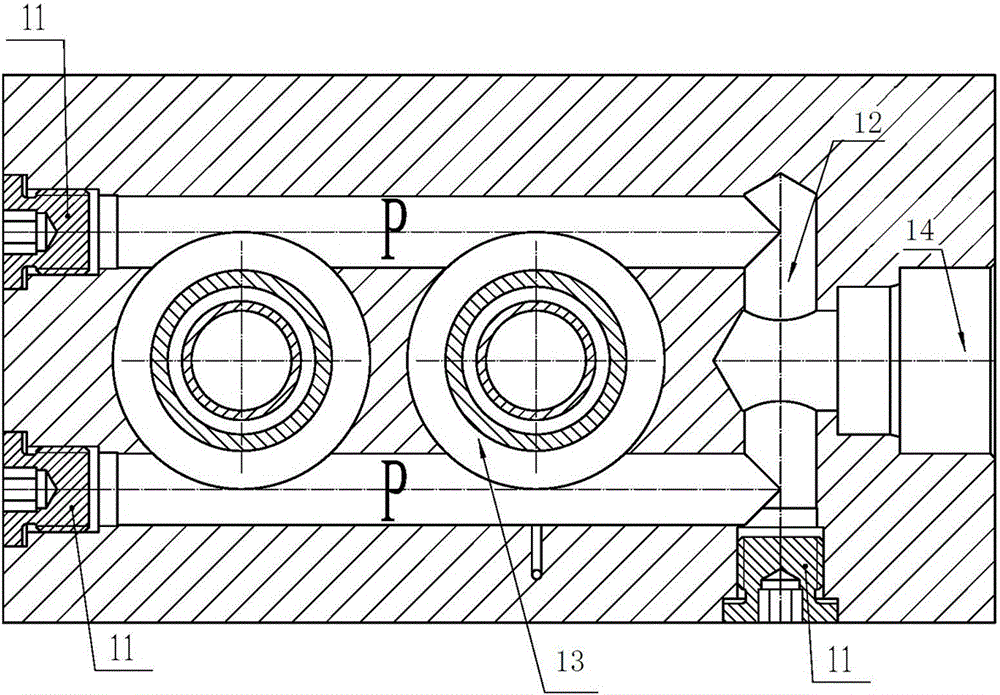

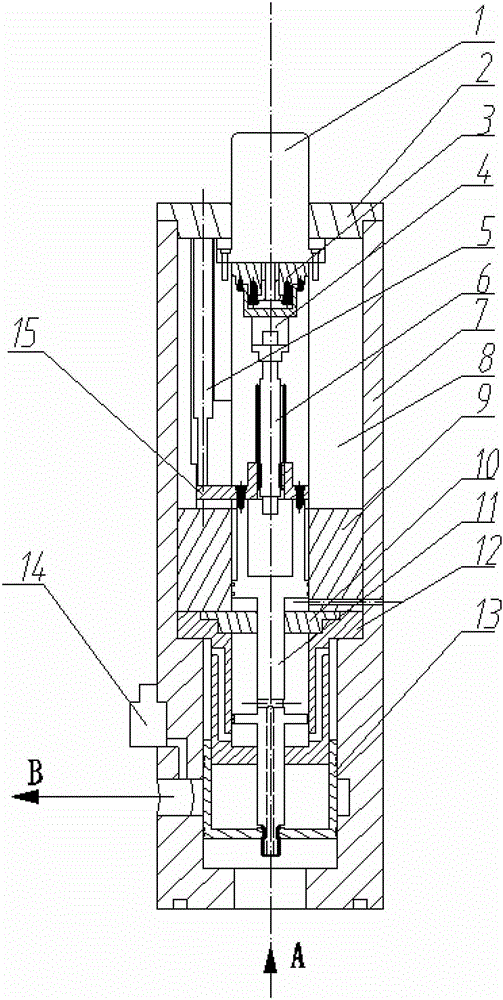

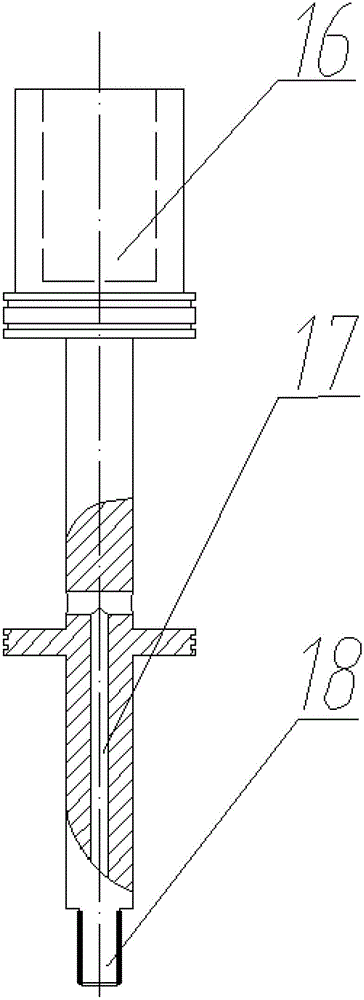

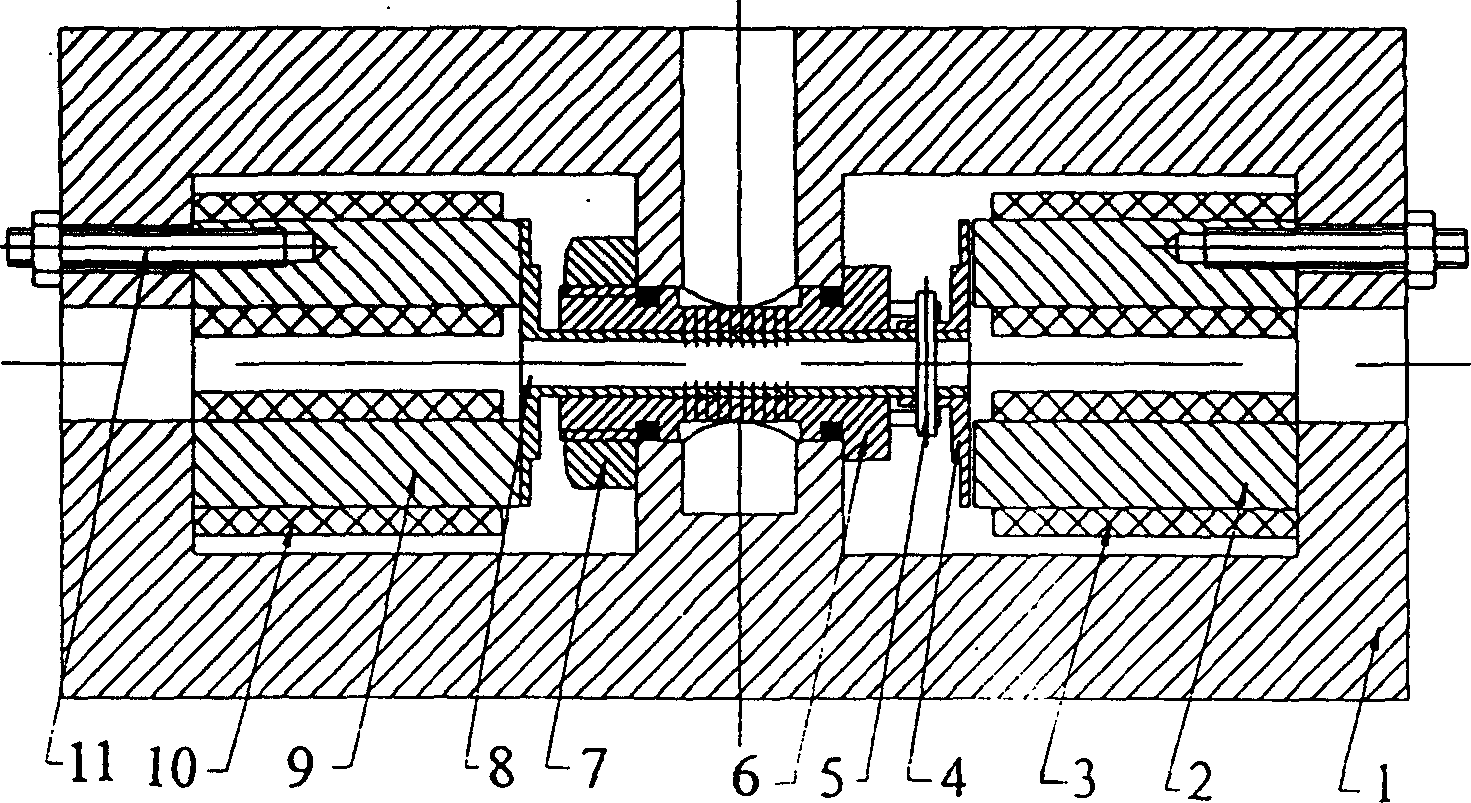

Turning gradient control valve

InactiveCN102410270ASmooth oil flow switchingGuaranteed stabilityServomotor componentsEngineeringThrottle

The invention discloses a turning gradient control valve, which is designed to provide a two-functional turning gradient control valve which can absorb vibration of the system, has low noise and energy saving, and can be applied to a static signal type and a dynamic signal type, wherein a first hole (P) in communication with a first throttle groove (4a1) and a second throttle groove (4a2) of a second hole (CF) is arranged on a beading at the right side along the circumference direction; the first hole (P) is in communication with a third throttle groove (4b1) and a fourth throttle groove (4b2) of a third hole (EF), wherein the first throttle groove (4a1) and the second throttle groove (4a2) are matched with a throttle side (5a) of a first sunken cutting groove of a valve body (5a) to form a valve port through which the first hole (P) is led to the second hole (CF); the third throttle groove (4b1) and the fourth throttle groove (4b2) are matched with a throttle side (5b) of a second sunken cutting groove of the valve body (5) to form a valve port through which the first hole (P) is led to the third hole (EF); the left end of the valve core (4) is provided with an asymmetric composite damper (3) while the right end of the valve core (4) is provided with a first damping hole (6).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

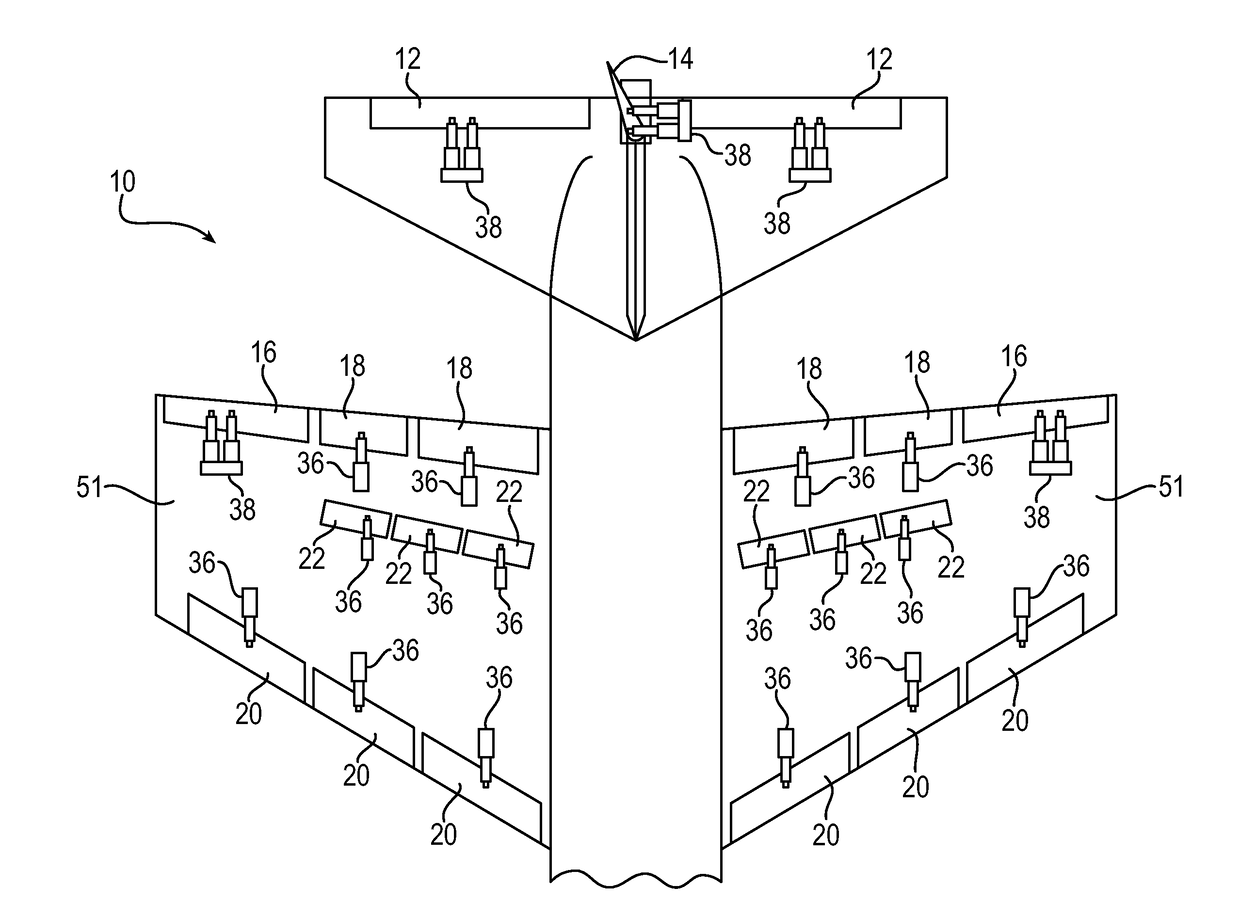

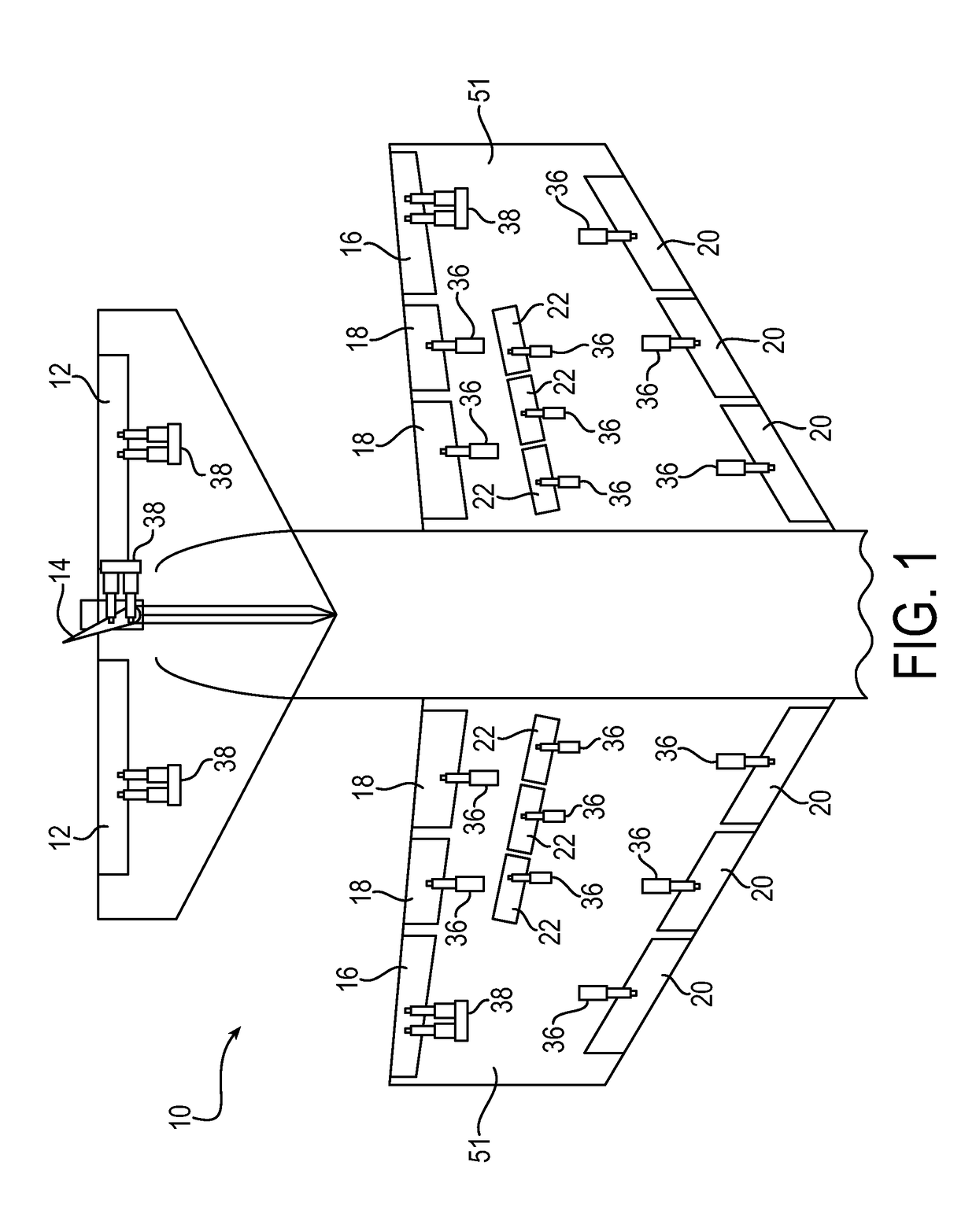

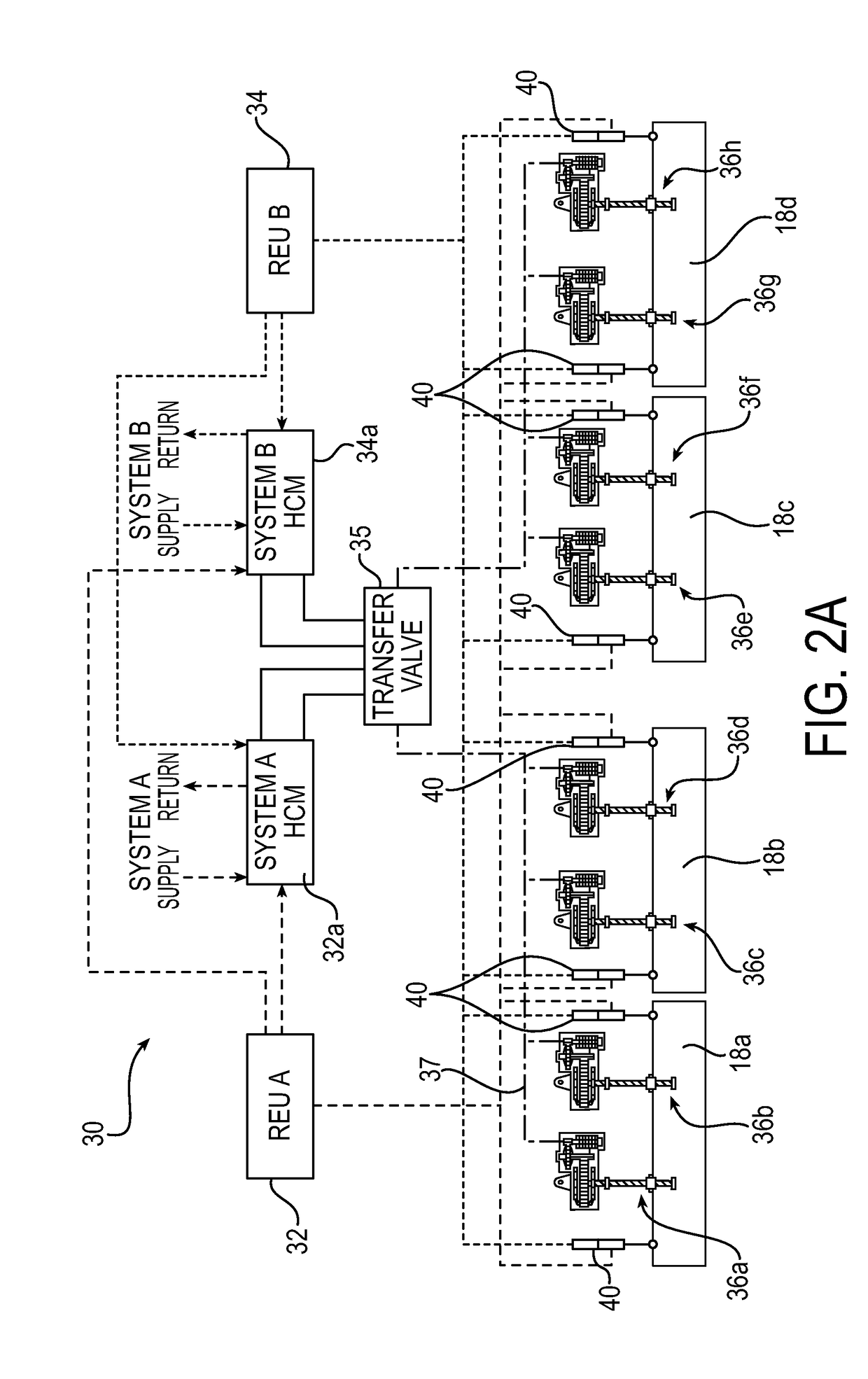

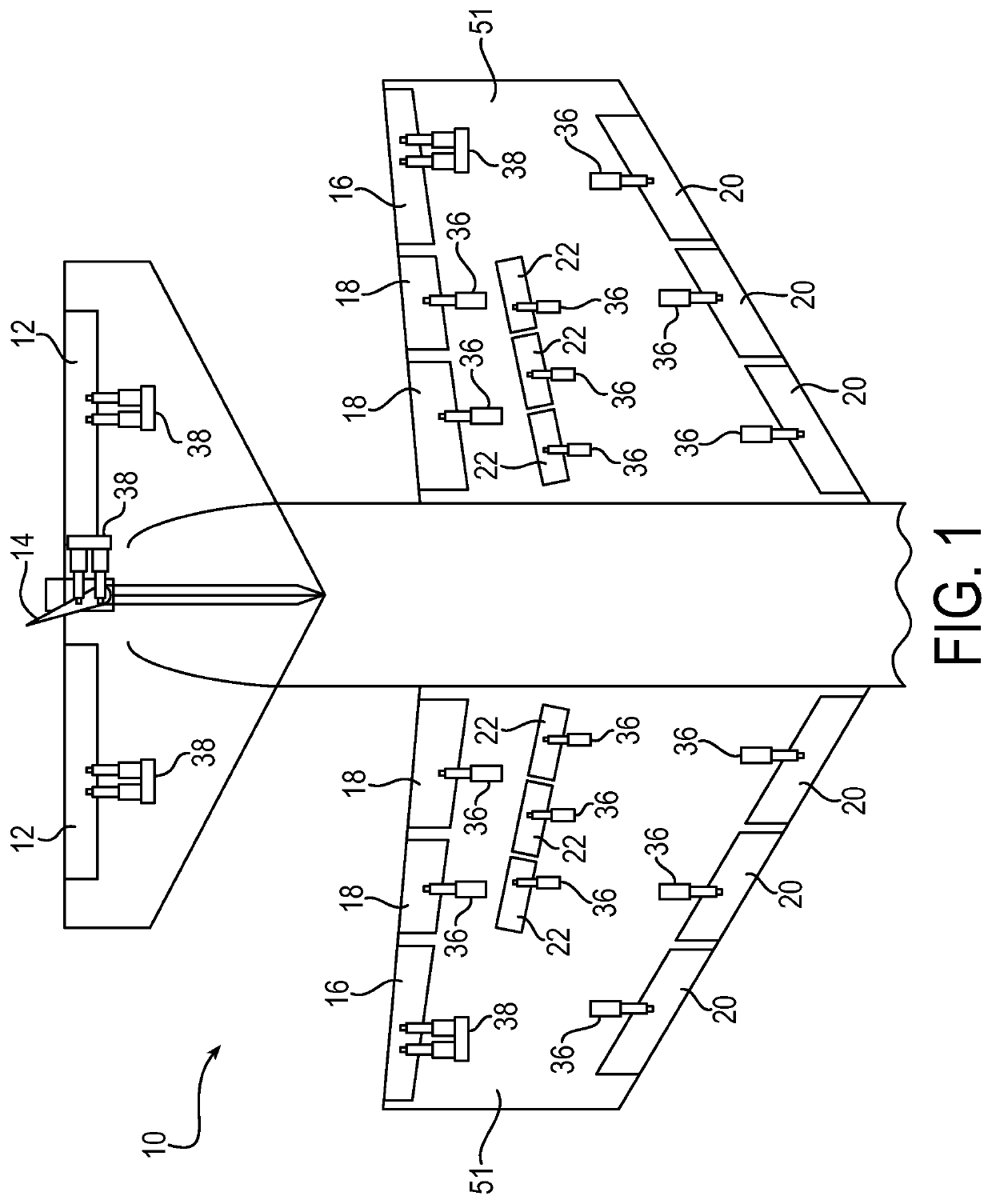

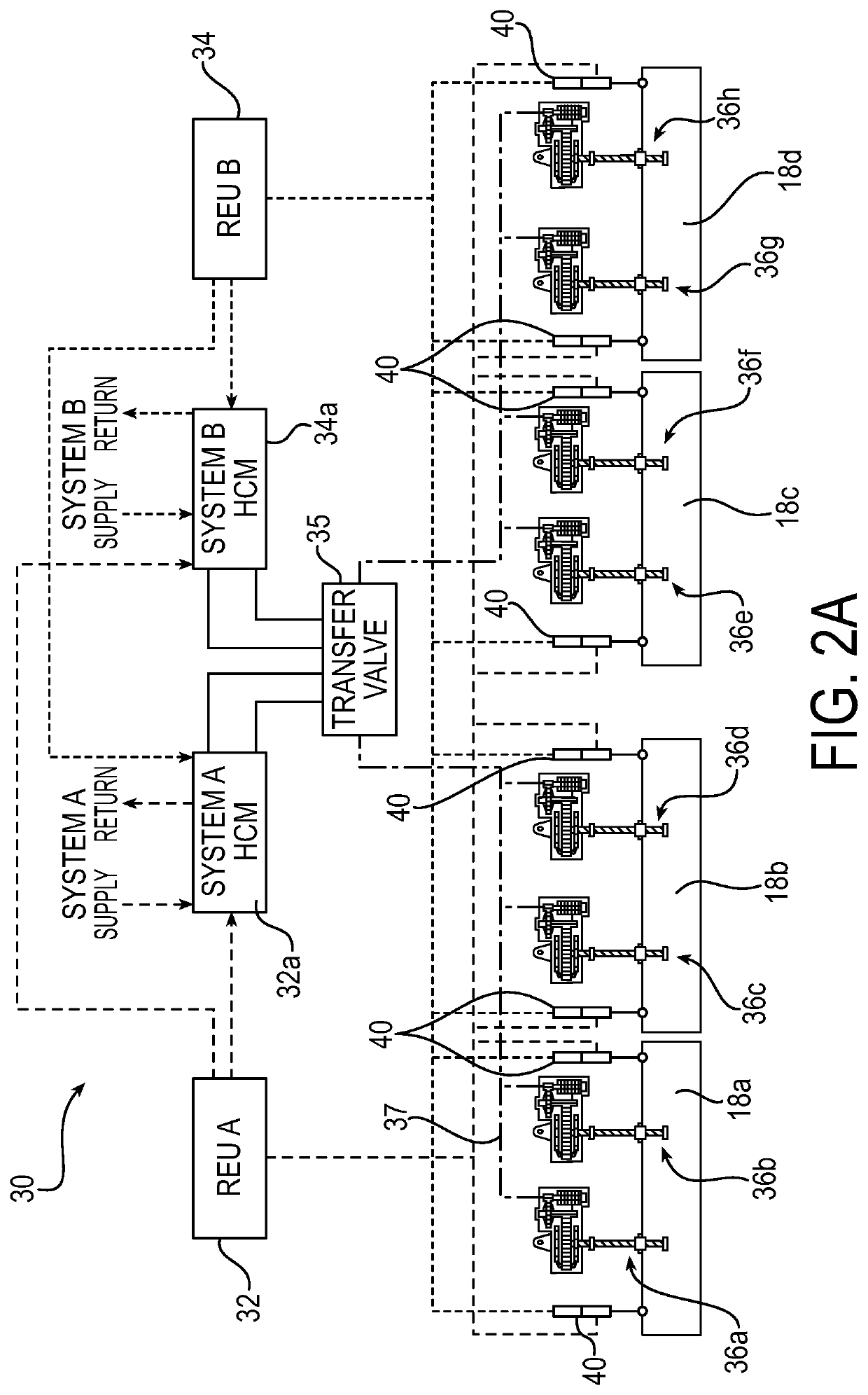

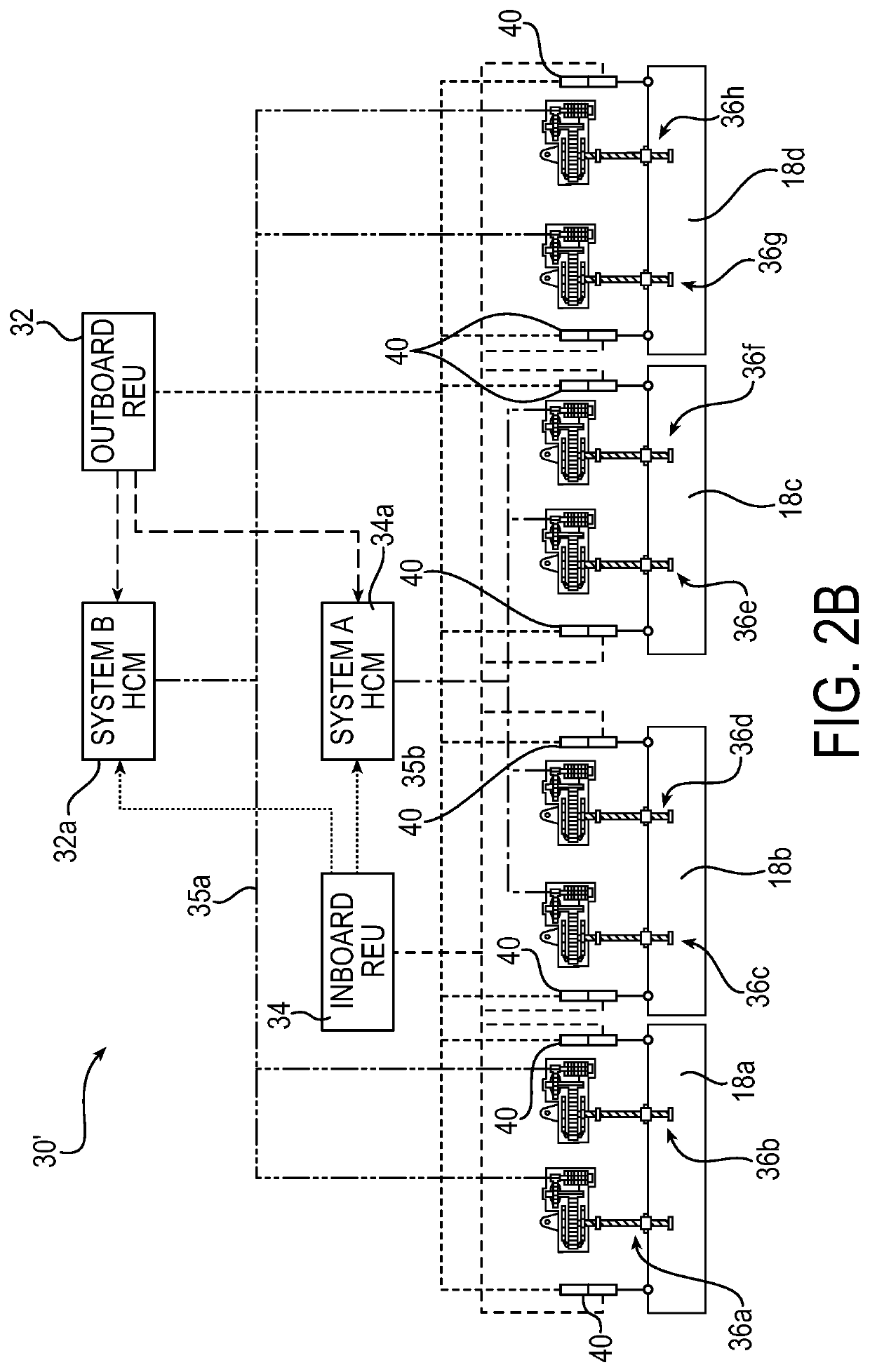

Near synchronous distributed hydraulic motor driven actuation system

ActiveUS20180002028A1Reduce component countCost-efficient to manufactureFluid-pressure actuator safetyFluid-pressure actuator testingMovement controlHydraulic control

A control system may be used to control actuators that actuate movement of flight control surfaces of an aircraft. Each actuator is couplable to a flight control surface and includes a motion control assembly having a hydraulic motor and a drive path from the hydraulic motor to the flight control surface. Each hydraulic motor includes an extend port and a retract port. The system includes a hydraulic control module fluidly connected to the extend port and the retract port of each hydraulic motor and a controller operable to output hydraulic power from the hydraulic control module to the motion control assembly to actuate movement of the flight control surfaces. The controller is configured to identify an actuator that positionally leads the other actuators and reduce hydraulic power to the motion control assembly assigned to such actuator.

Owner:PARKER-HANNIFIN CORP

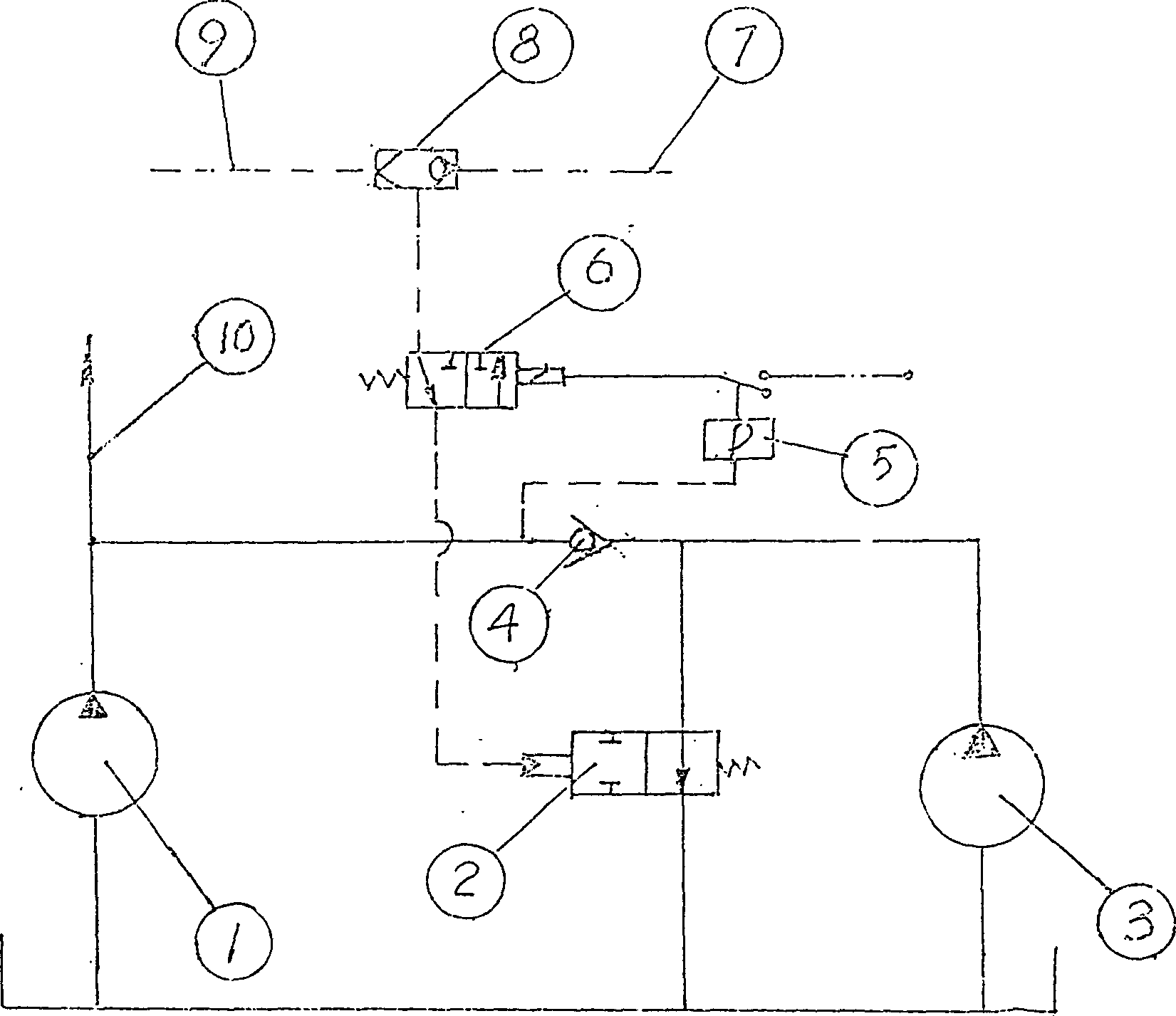

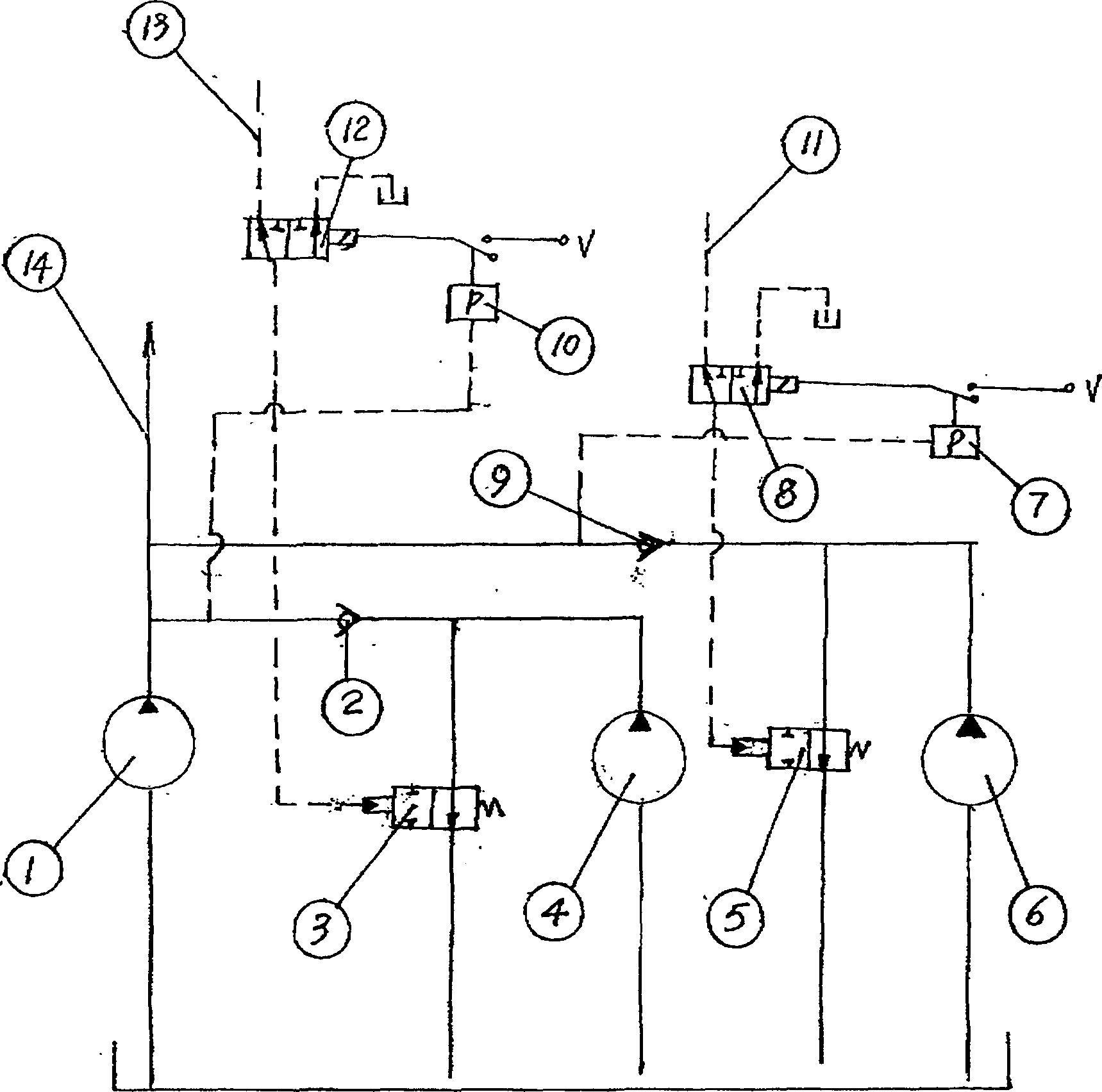

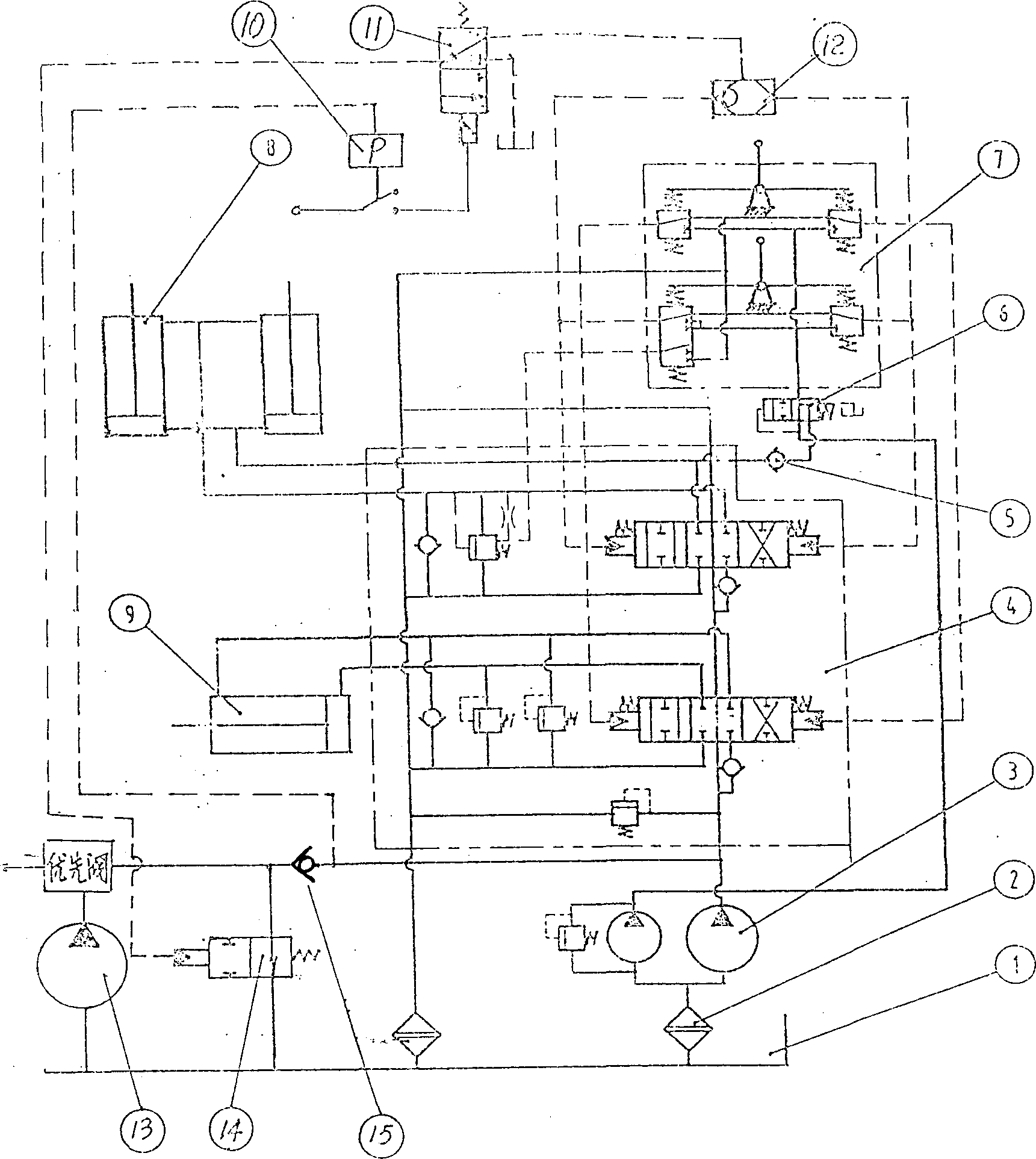

Current associating and unloading control method for multiple-pump hydraulic system

InactiveCN1432739AImplement class variablesReduce hydraulic powerServomotor componentsEngineeringMechanical engineering

The present invention relates to current association and unloading control method for multiple-pump hydraulic system, especially for loading machine and other heavy mechanical apparatus. The present invention uses hydraulically controlled change valve as current associating and unloading control element for multiple-pump hydraulic system, unlike available systems, which has unloading valve. Thus,the current associating and shutting of the pumps may be controlled at will to lower the power consumption and heat producing amount, raise the reliability of element and system and lower cost.

Owner:陈嘉川

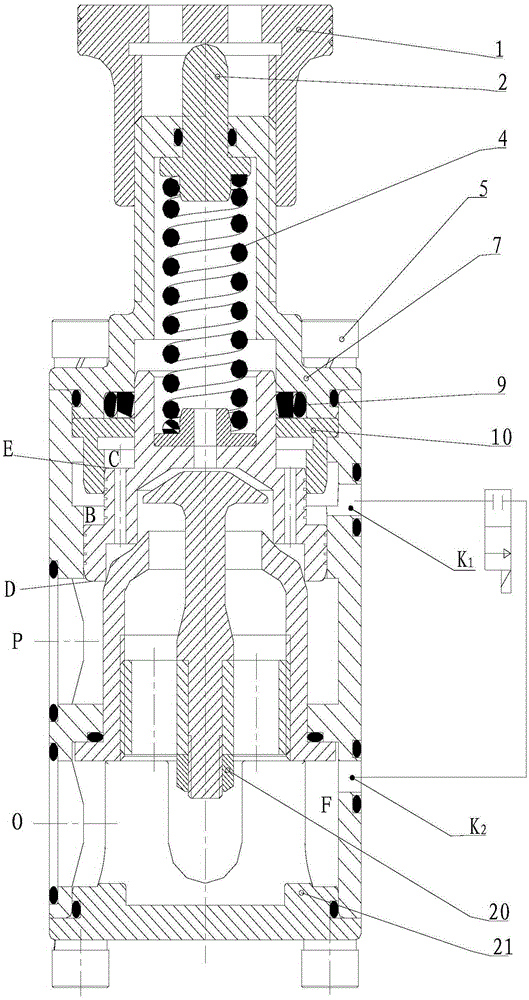

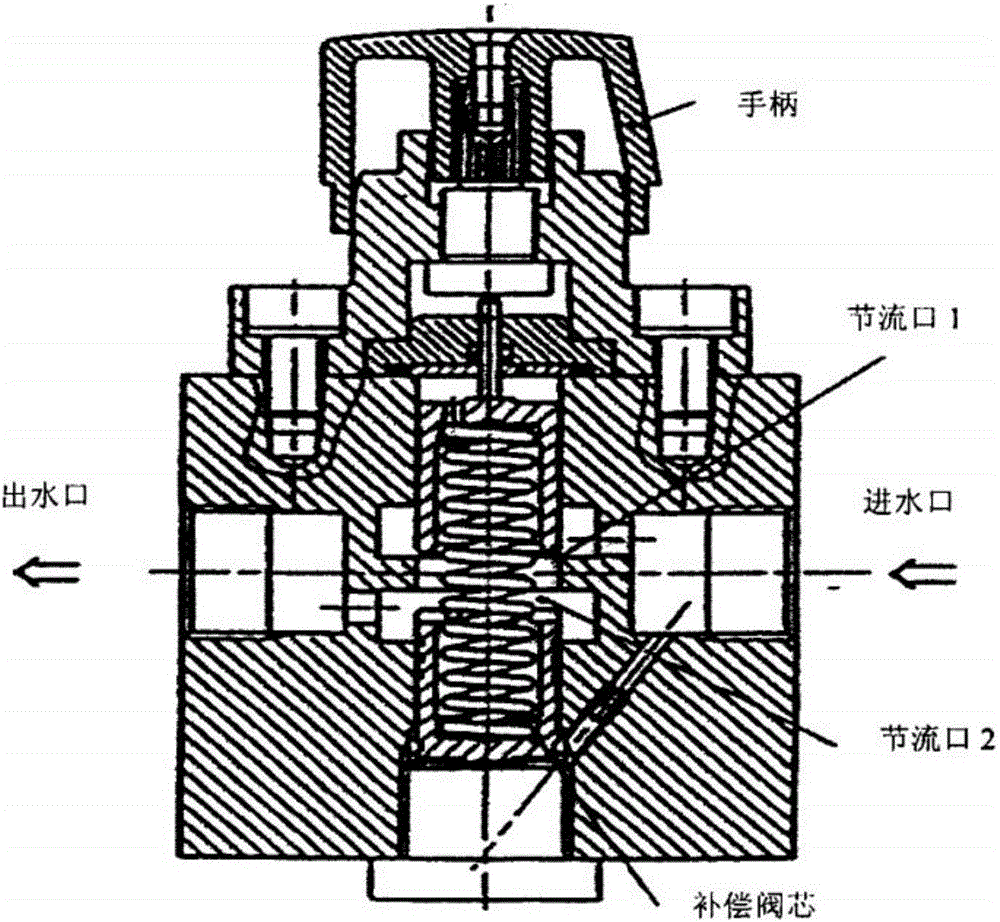

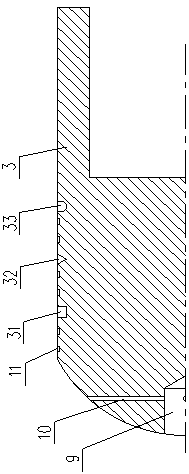

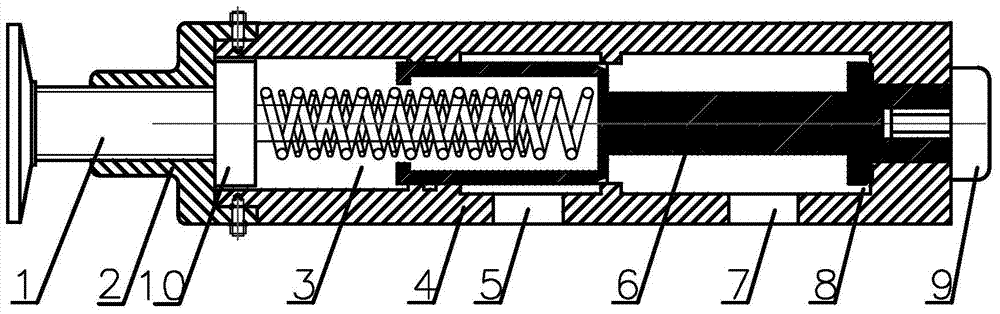

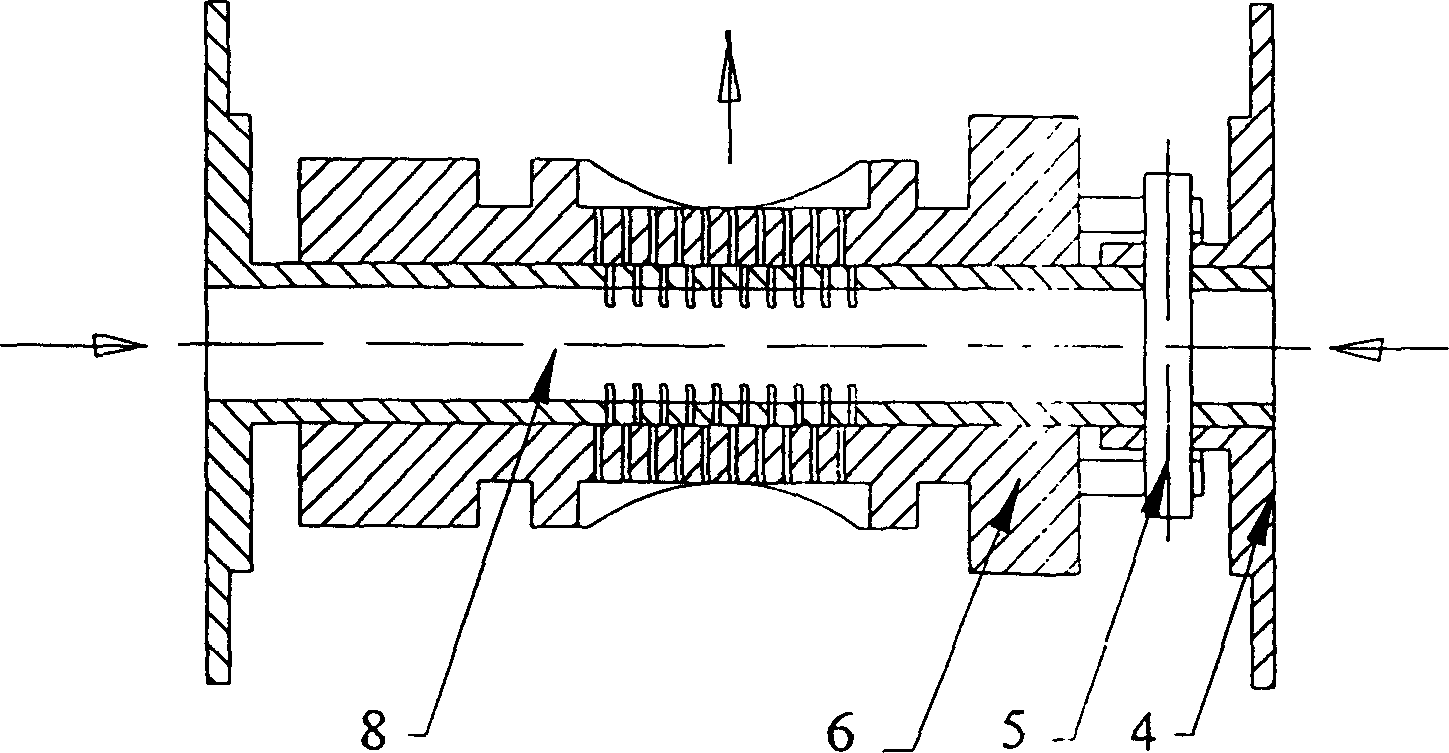

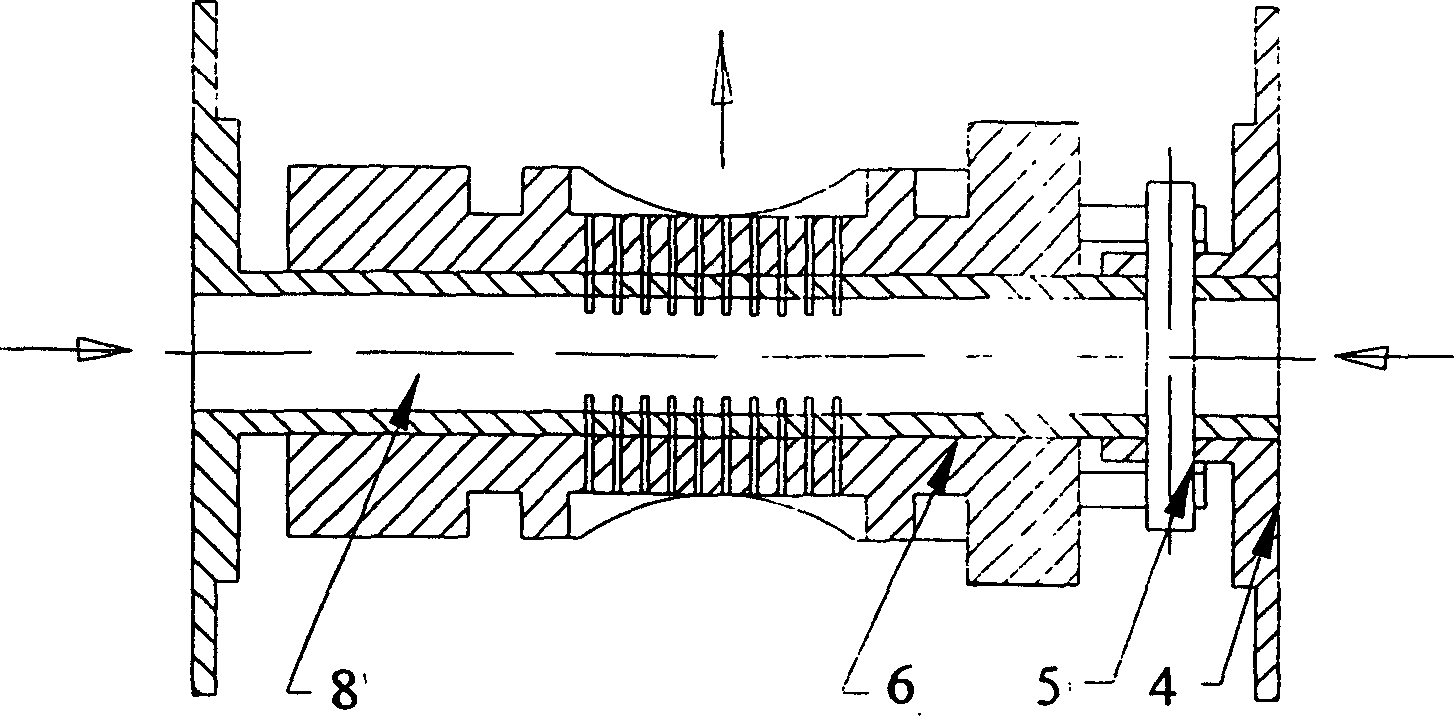

Movable valve seat type spring loaded type relief valve

InactiveCN105351582AReduce frictionExtended service lifeEqualizing valvesSafety valvesEngineeringPartial pressure

The invention discloses a movable valve seat type spring loaded type relief valve. The movable valve seat type spring loaded type relief valve comprises a valve body provided with a cavity body. A water inlet and a water outlet communicated with the cavity body are formed in the valve body. A valve core and a valve seat are arranged inside the cavity body of the valve body. A spring is arranged inside a cavity of the interior of a front end cover. A spring ejection rod is installed at the top of the spring, and a spring base is arranged at the bottom of the spring. One end of the spring abuts against the spring ejection rod, and the other end of the spring abuts against the spring base. The valve seat comprises a two-stage step structure. The ascending end of the step structure is in clearance fit with the valve body and a sleeve. According to the movable valve seat type spring loaded type relief valve, a valve core king-rod structure is designed in the position of an injection inlet where fluid enters the valve core through the valve seat, so that the fluid power of the sprayed fluid is conducted to the valve core through a valve core king-rod, and the impact force and the corrosion to the valve seat by the fluid power are reduced; in addition, the step structure part of the valve seat makes contact with the two-stage conical surfaces of the valve core, so that a two-stage throttling valve port structure is formed between the valve seat and the valve core, and the effective partial pressure can be achieved.

Owner:OCEAN UNIV OF CHINA

High-speed large-flow clearence slide ralve

InactiveCN1438417AShorten exercise distanceIncrease the opening speedMachines/enginesFuel injecting pumpsSpool valveHigh flux

The invention discloses a kind of high-speed high flux gas slide valve. Two electromagnets are set in the valve cavity at the two sides of the valve core symmetrically, the hollow valve core has a valve cover, one end of the valve core can open and close with one end of the electromagnet, there is a magnetic pole at the other end of the valve core, the magnetic pole can open and close with the other electromagnet, there are noncircular gap valve meatuses with the same quantity, breadth and interval on the interface of valve core and valve cover, the valve meatus connects with the oulet. The hollow valve can decrease the weight; the availability of the electromagnet power is high.

Owner:ZHEJIANG UNIV

Novel overflow valve

InactiveCN105697801AImprove cavitation resistanceImprove stroke stabilityServomotor componentsValve members for absorbing fluid energyEtchingEngineering

The invention discloses a novel overflow valve. The novel overflow valve comprises a valve body, a valve core, a valve seat, a valve cover, an adjusting stud, an adjusting nut, an adjusting cap, a flange, a left spring seat, a right spring seat and a spring, wherein the valve core comprises five sections which are a hemispherical section, a circular truncated cone-shaped section A, a cylinder connection section, a circular truncated cone-shaped section B and a guide cylinder section from the left part to the right part in sequence; a hemispherical groove is formed in the outer surface of the circular truncated cone-shaped section A; a radial through-flow hole A and a radial through-flow hole B are formed in the cylinder connection section; the radial through-flow hole A and the radial through-flow hole B are vertically formed in the cylinder connection section; a guide circular groove is formed in the guide cylinder section; an axial through-flow hole is formed in the valve core in the center line direction; one end of the axial through-flow hole is communicated with the outer part of the guide cylinder section, and the other end of the axial through-flow hole is communicated with the radial through-flow hole A; an elastic gasket is mounted in a position where the valve seat is connected with the valve cover. The novel overflow valve can reduce gas etching, lower vibration and noise, and improve the sealing performance.

Owner:黄斌

Near synchronous distributed hydraulic motor driven actuation system

ActiveUS10538310B2Reduce component countCost efficient to manufactureFluid-pressure actuator safetyFluid-pressure actuator testingHydraulic motorFlight control surfaces

A control system may be used to control actuators that actuate movement of flight control surfaces of an aircraft. Each actuator is couplable to a flight control surface and includes a motion control assembly having a hydraulic motor and a drive path from the hydraulic motor to the flight control surface. Each hydraulic motor includes an extend port and a retract port. The system includes a hydraulic control module fluidly connected to the extend port and the retract port of each hydraulic motor and a controller operable to output hydraulic power from the hydraulic control module to the motion control assembly to actuate movement of the flight control surfaces. The controller is configured to identify an actuator that positionally leads the other actuators and reduce hydraulic power to the motion control assembly assigned to such actuator.

Owner:PARKER HANNIFIN CORP

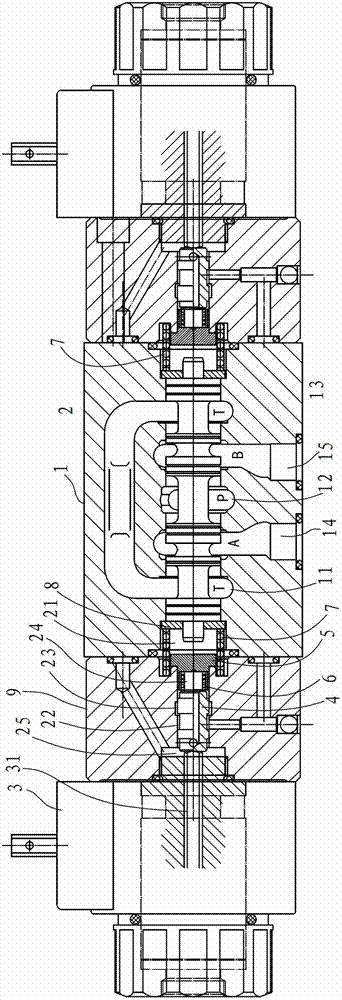

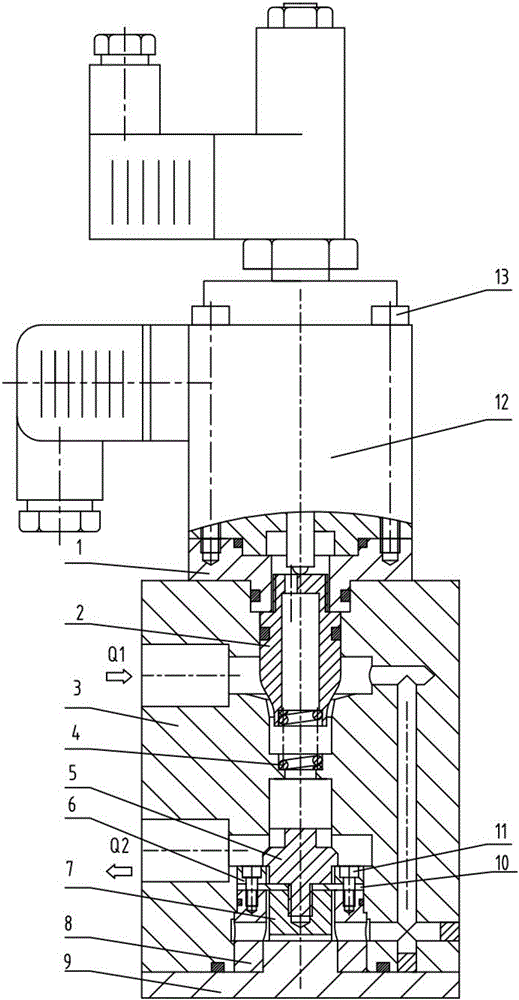

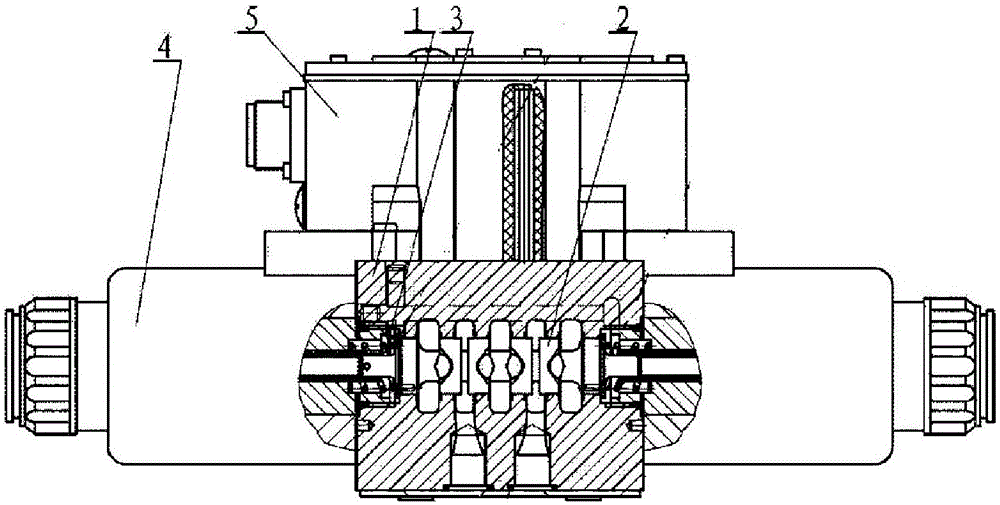

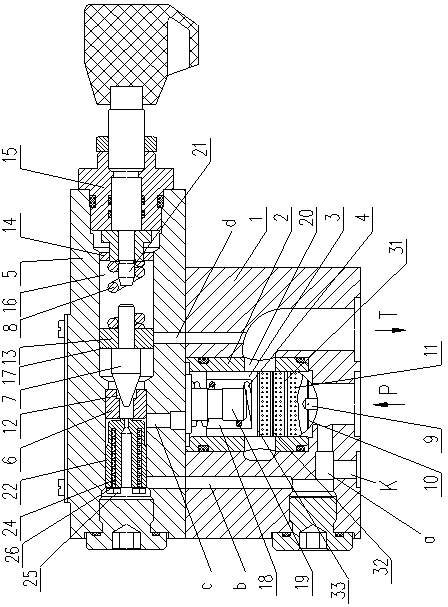

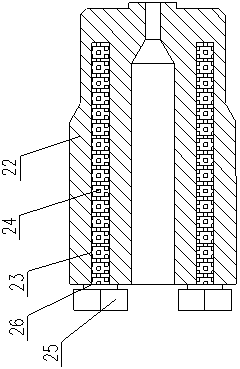

Electromagnetic directional valve

InactiveCN102829013ASmall reaction forcePower reduction requiredServomotor componentsMiniaturizationEngineering

The invention discloses an electromagnetic directional valve which comprises a valve body, a main valve core, an electromagnet and a main restoring spring, wherein the main valve core is positioned in the valve body and can move back and force along an axial channel of the valve body. The electromagnetic directional valve is characterized by also comprising a side cover, a pilot valve core and a pilot restoring spring, wherein the side cover is arranged on one side of the valve body; the pilot valve core can move back and force in an axial duct; the electromagnet is arranged on the other side of the side cover; and a push rod of the electromagnet pushes against the pilot valve core. Compared with the prior art, the electromagnetic directional valve provided by the invention has the advantages that with adoption of a hydraulic amplification principle and combination of a pilot control structure, an original working stroke is greatly shortened, and thus the miniaturization design on the electromagnetic directional valve is favorable; and meanwhile, the working stroke is shortened, and thus power can be greatly reduced.

Owner:NINGBO ZHENHAI HUALI HYDRAULIC ELECTROMECHANICAL CO LTD

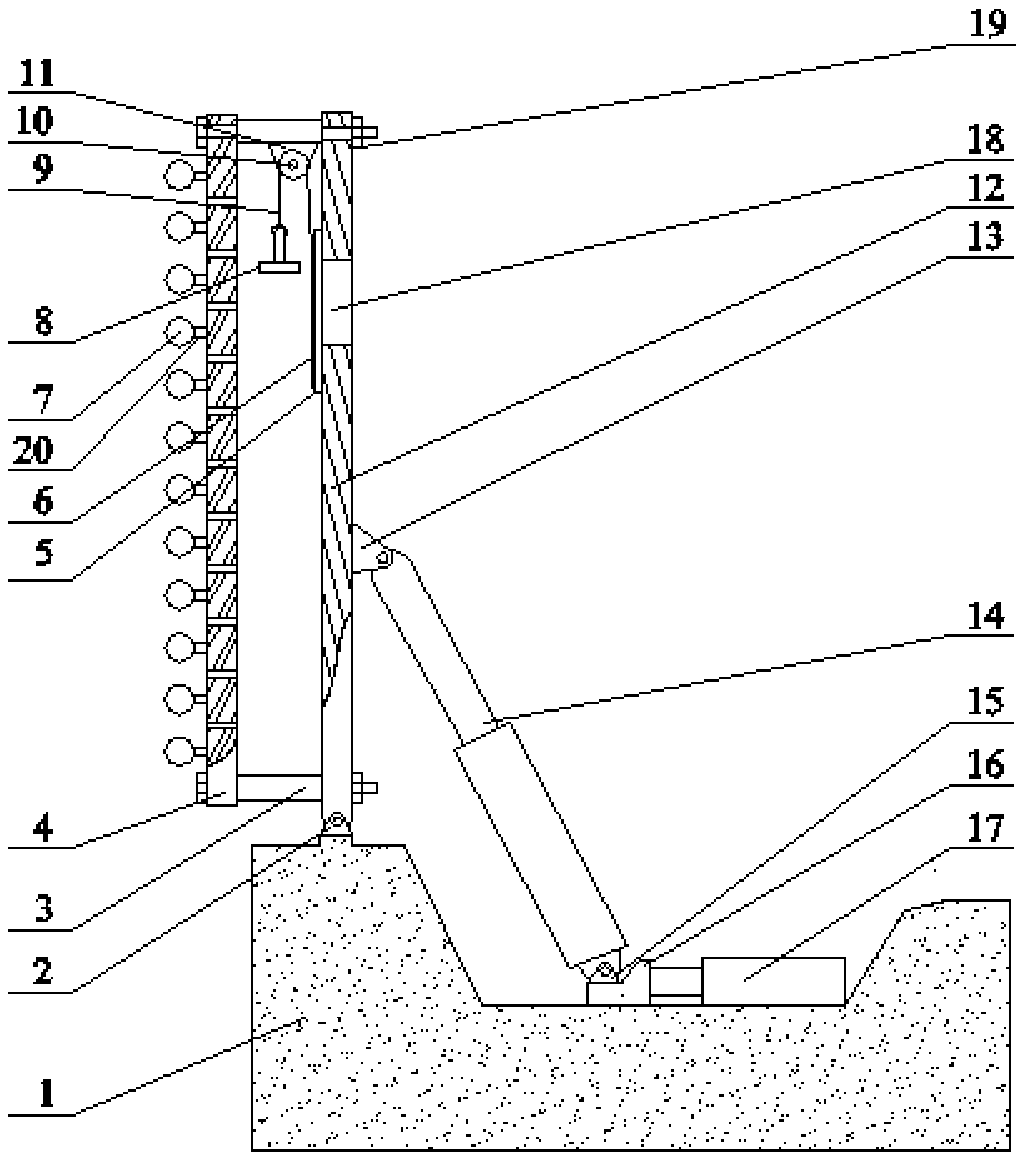

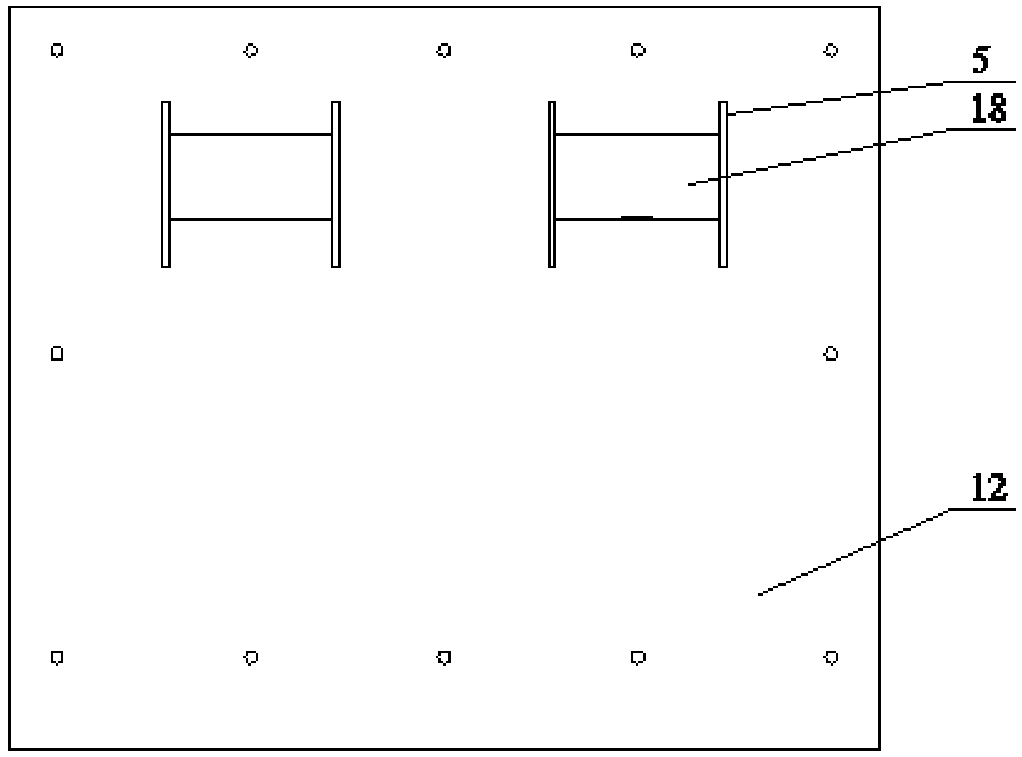

Energy dissipation buffer type hydraulic dam

ActiveCN107604883AExtended service lifeReduce direct impactBarrages/weirsHydraulic cylinderSlide plate

The invention relates to an energy dissipation buffer type hydraulic dam which comprises a dam body. A first mounting base is arranged on the dam body and is connected with a connecting baffle througha first hinge shaft, a second mounting base is arranged on the right side face of the baffle and is connected with a top head of a piston rod of a first multistage hydraulic cylinder through a secondhinge shaft, the tail end of the multistage hydraulic cylinder is connected with a third mounting base through a third hinge shaft, and the third mounting base is fixedly connected to a top head of apiston rod of a second multistage hydraulic cylinder, and the second multistage hydraulic cylinder is horizontally arranged in a foundation pit on the dam; a plurality of drainage holes are formed in the upper portion of the baffle, guide sliding rails are arranged on the two sides of the drainage holes, a sliding plate in sliding connection with the guide sliding rails are arranged between theguide sliding rails, and a displacement adjusting device is arranged above the sliding plate; and a buffer energy dissipation device is connected to the left side of the baffle through a connecting device. According to the energy dissipation buffer type hydraulic dam, the buffer energy dissipation device is additionally arranged in front of the baffle; meanwhile, the anti-rusting treatment on thebaffle is strengthened, the service life of the overall hydraulic dam is prolonged, the practicability is high, and the dam is worthy of popularization.

Owner:查斌 +2

Movable valve seat type throttling valve

The invention discloses a movable valve seat type throttling valve. The throttling valve comprises a valve body with a cavity. A front end cover and a rear end cover are both fixedly connected with the valve body. The valve body is provided with a water inlet and a water outlet which are communicated with the cavity. A valve element and a valve seat are arranged in the cavity of the valve body, and the valve element is fixed into the cavity in the valve body through the rear end cover. The valve seat is embedded in a sleeve and the cavity in the valve body. The upper end of the valve seat stretches out of an axial through hole of the front end cover. The sleeve is in force fit with the front end cover and the valve body. The valve seat comprises a two-step structure, and the two steps have the same superficial area. According to the throttling valve, through the center rod structure of the valve element and the structure that two step surfaces have the same area, the function of compensating hydrodynamic force of fluid can be achieved, impact force and erosion to the valve seat are reduced, and the stability of manual adjustment of the valve seat is improved.

Owner:OCEAN UNIV OF CHINA

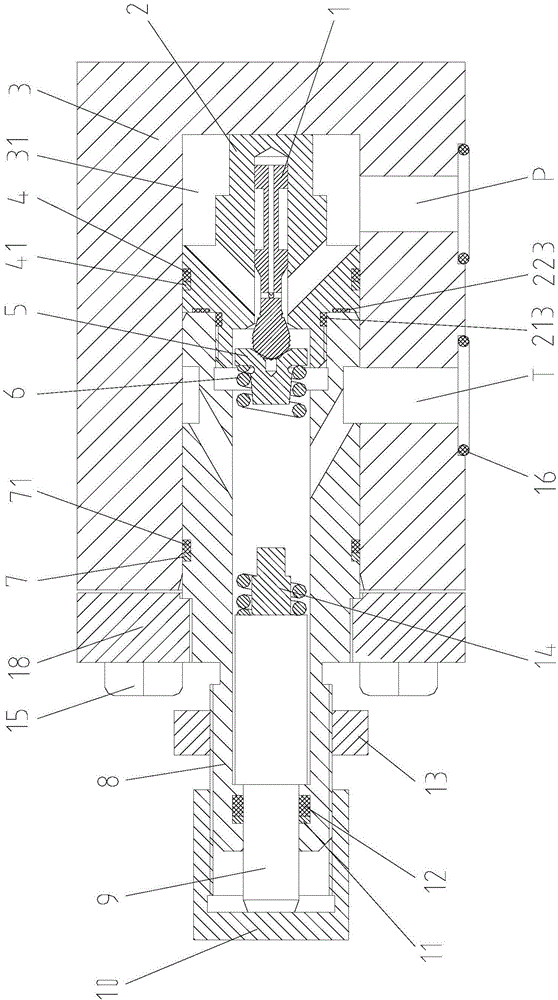

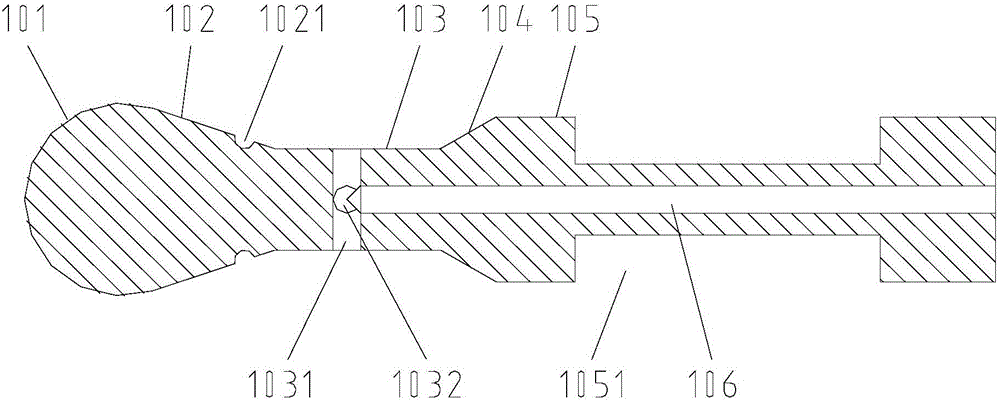

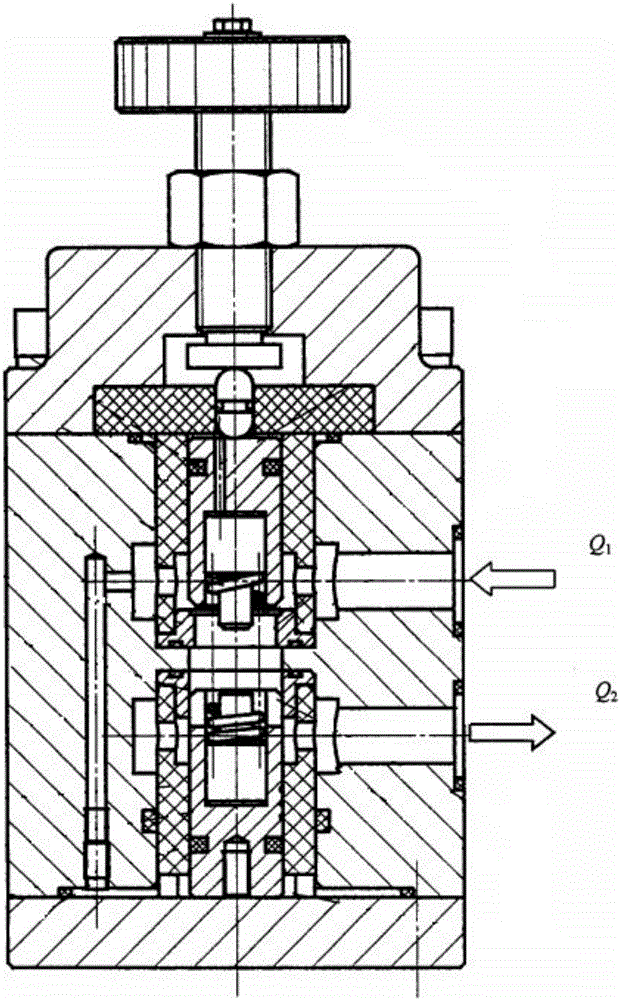

Seawater hydraulic proportional flow control valve

InactiveCN105805405AHigh control precisionEasy to adjustOperating means/releasing devices for valvesSlide valveCavitationControl system

The invention discloses a seawater hydraulic proportional flow control valve with electrical feedback. The valve is controlled by a given flow electrical signal; an upper valve element is directly driven via a proportional electromagnet to perform axial motion; an actual position of a throttle orifice is fed to a control system by a displacement sensor; the control system timely corrects any deviation with a given input value, so that the operation of the flow value is more flexible and convenient, and the control is more accurate and stable. Upper and lower valve elements respectively adopt value body flow guiding and valve element flow guiding structures, so that fluid force received by the valve element is greatly reduced, the cavitation influence is also reduced, and the steady-state performance of the flow valve is improved. A space between the lower valve element and the valve body is sealed by adopting a membrane, on one hand, the problem of sealing between the valve element and a valve sleeve is solved and zero leakage is basically realized; and on the other hand, compared with sealing by a sealing ring, sealing by adopting the membrane has the advantages that the friction of the lower value element is zero in a moving process, the dynamic response of the flow valve is improved greatly and meanwhile, the structure of the flow valve is simplified further.

Owner:BEIJING UNIV OF TECH

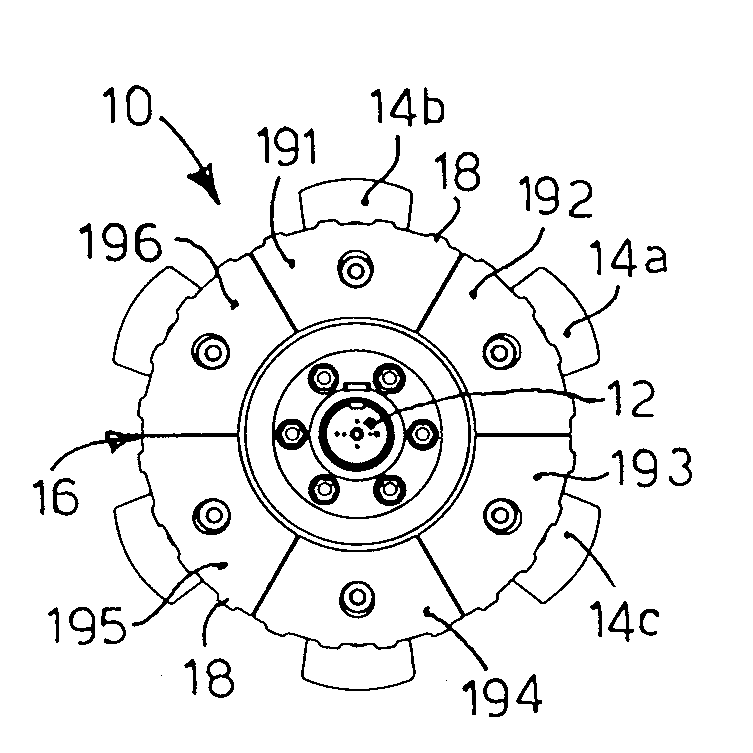

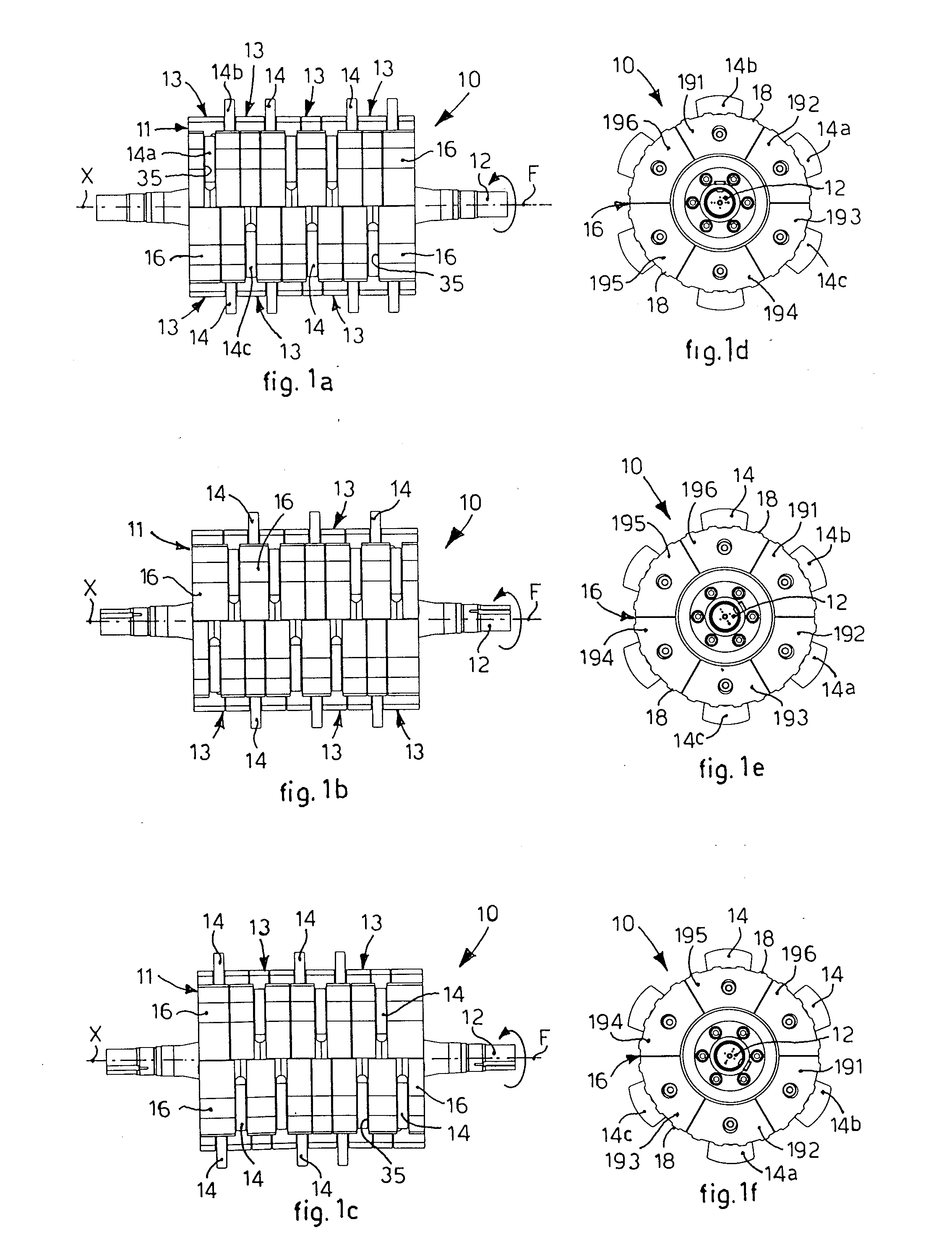

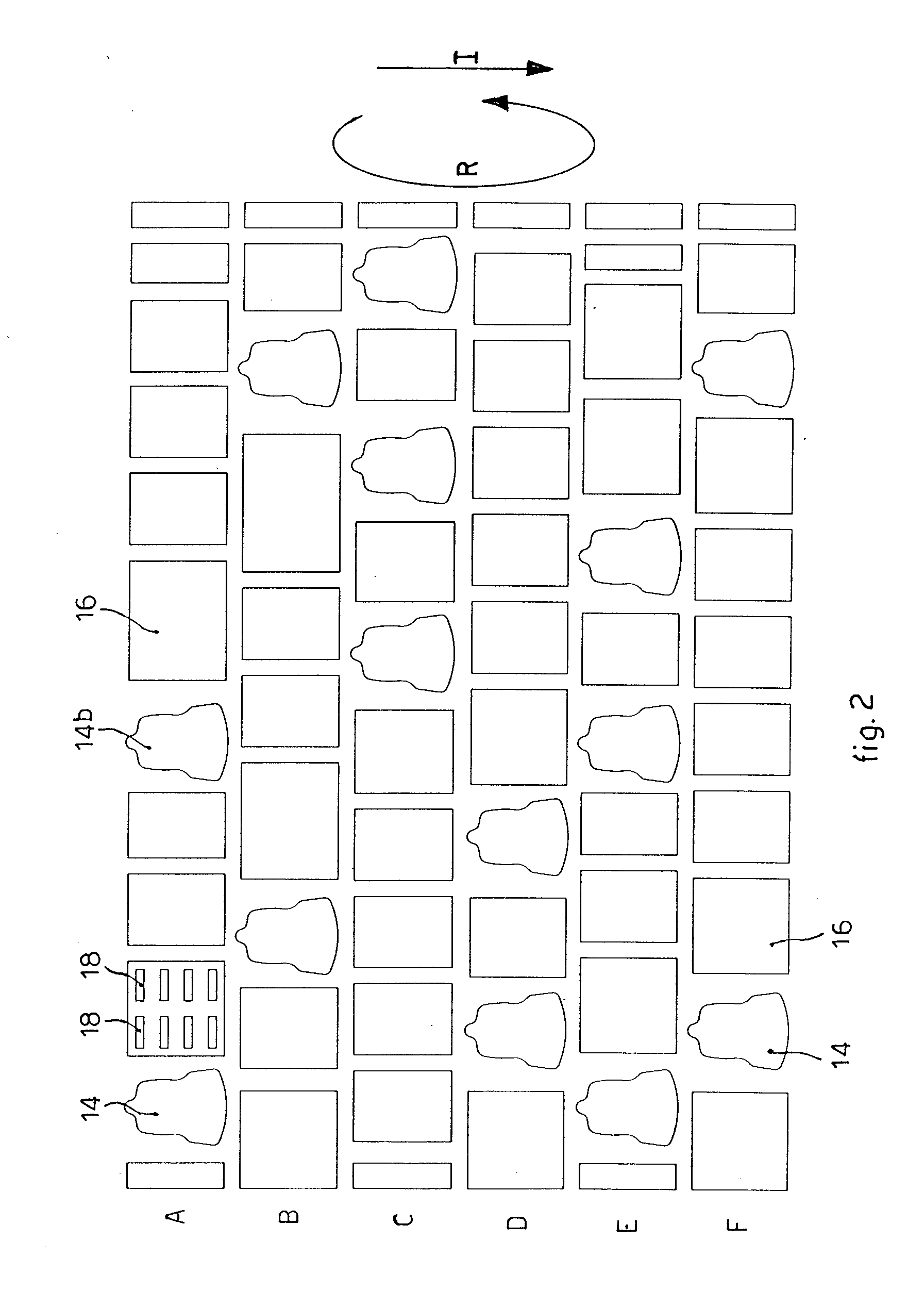

Shredding device for a shredding plant

InactiveUS20110168822A1Effective expansionFor quick ejectionGrain treatmentsEngineeringMechanical engineering

Owner:DANIELI UK HLDG

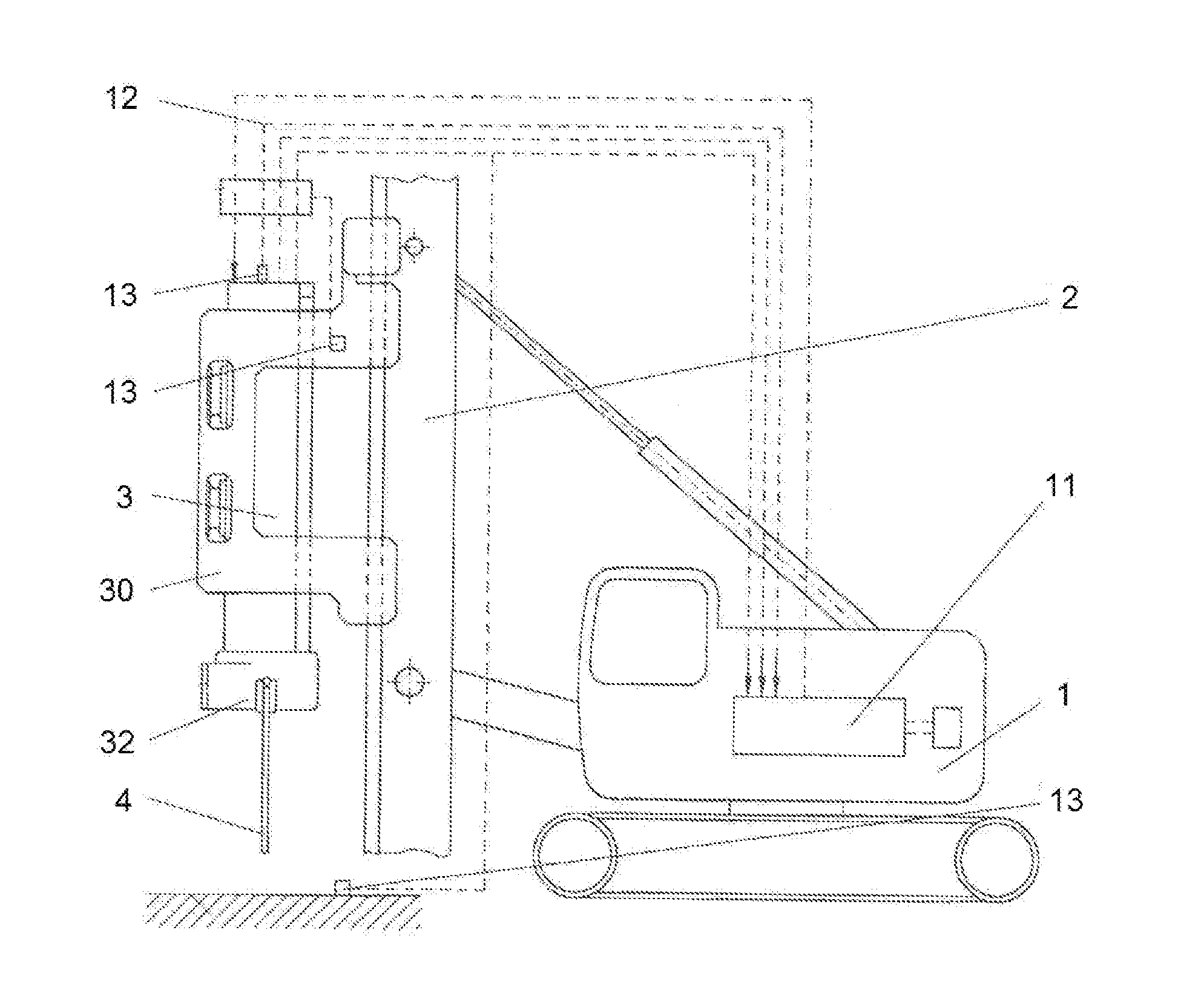

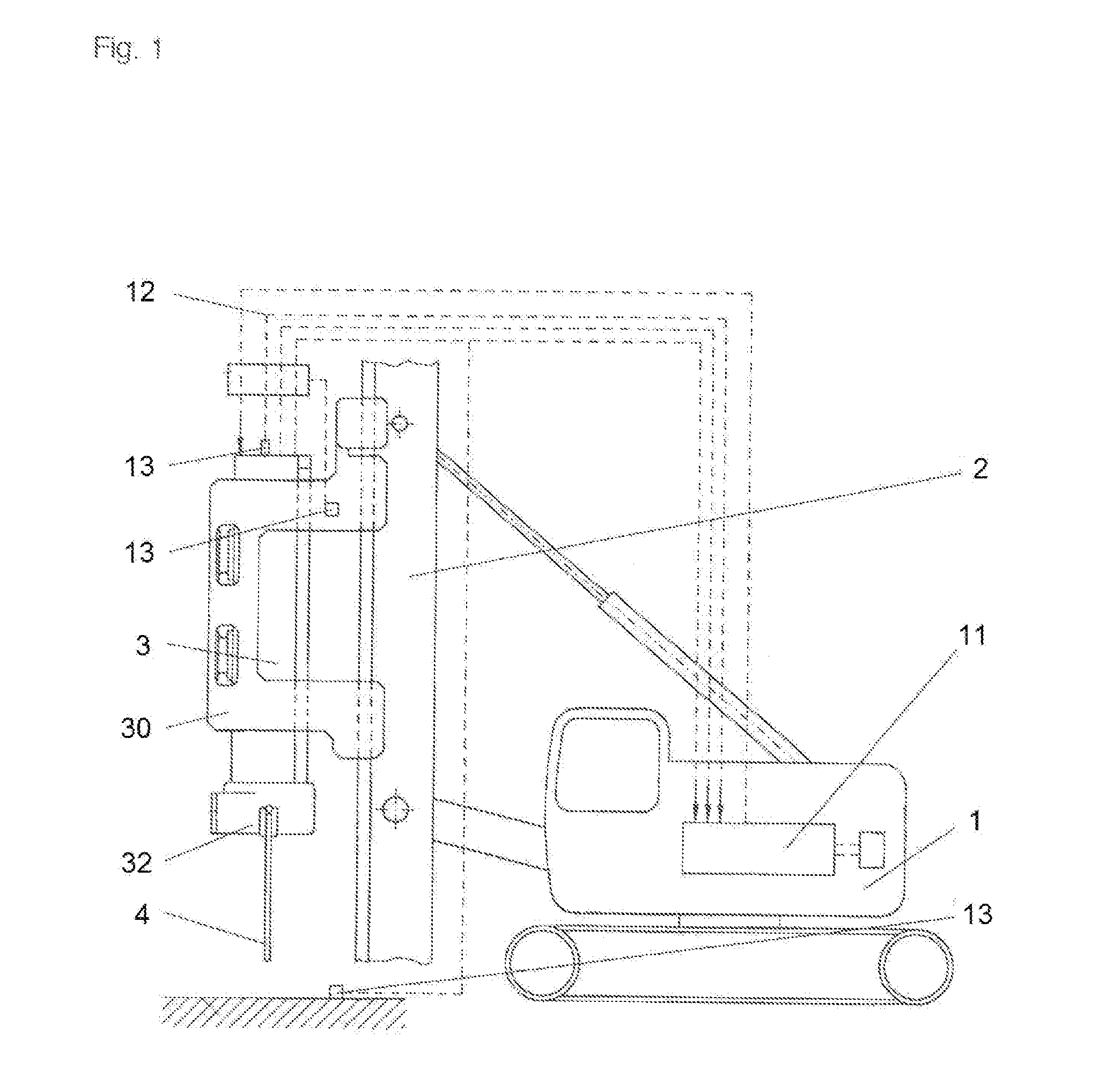

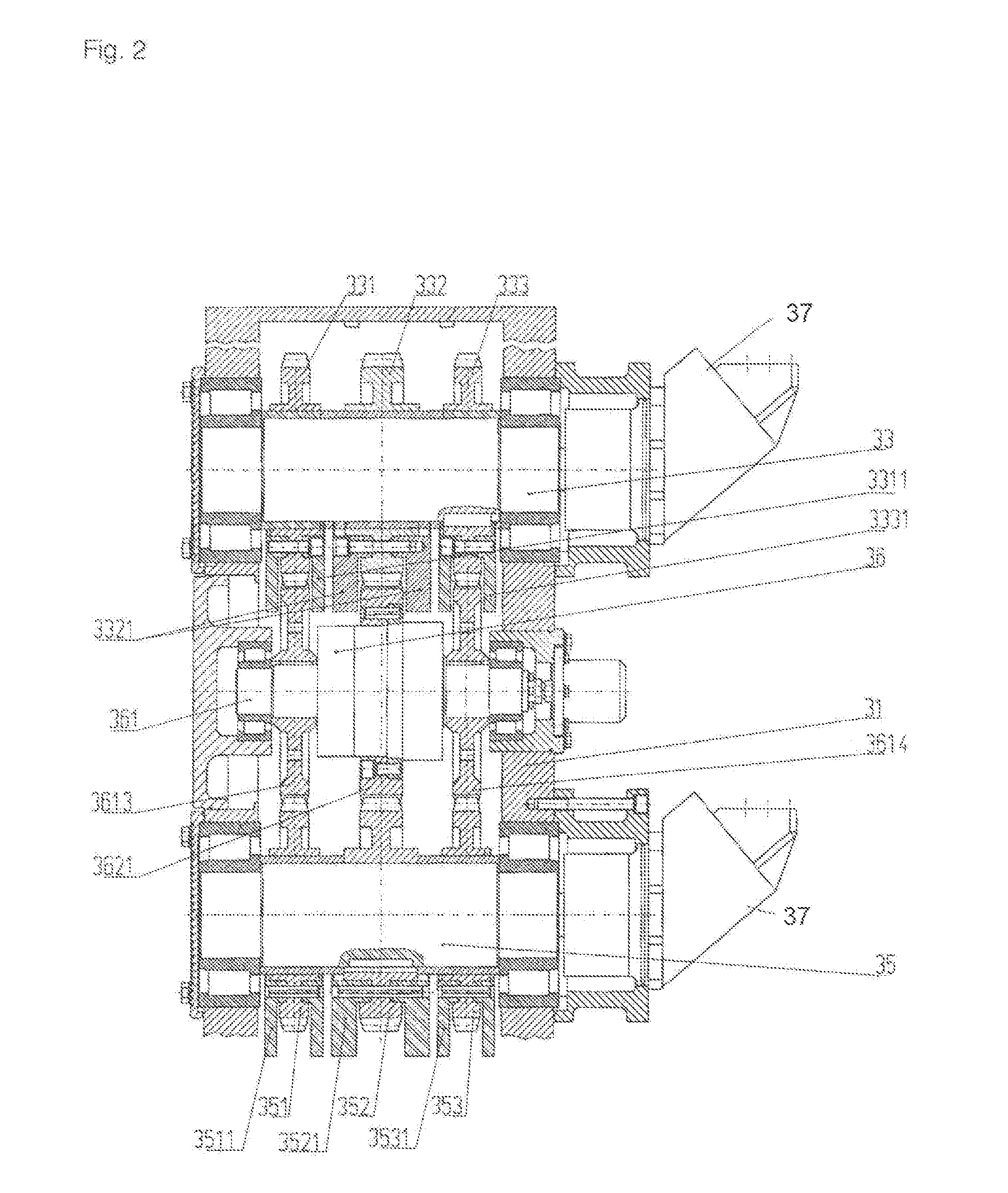

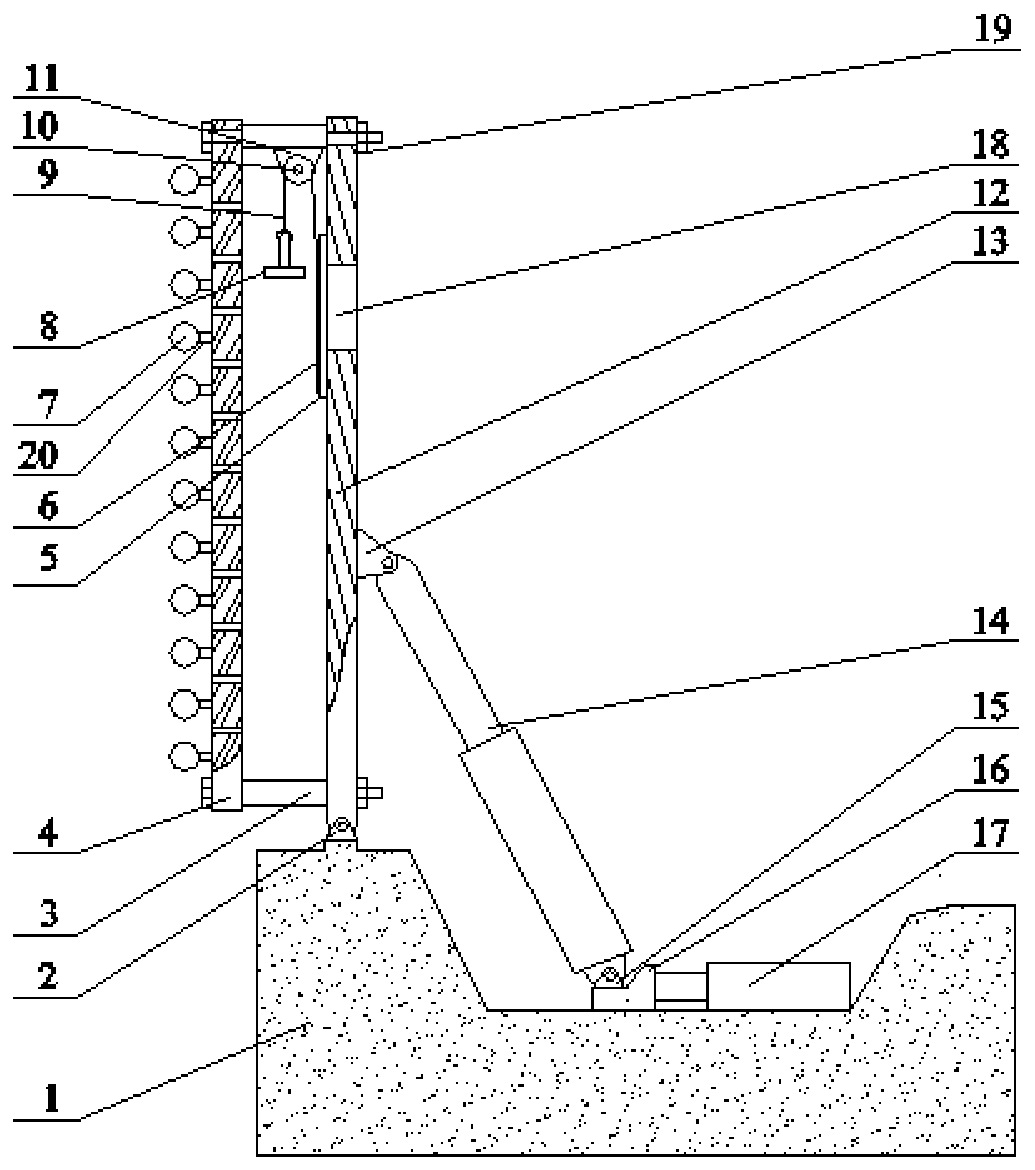

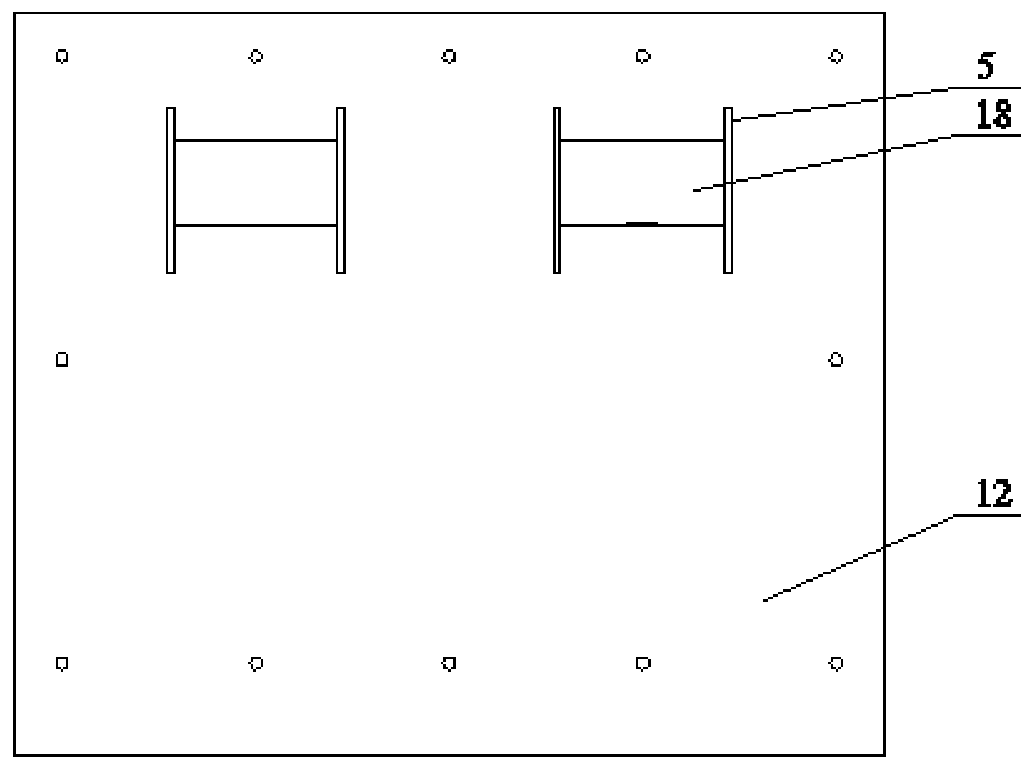

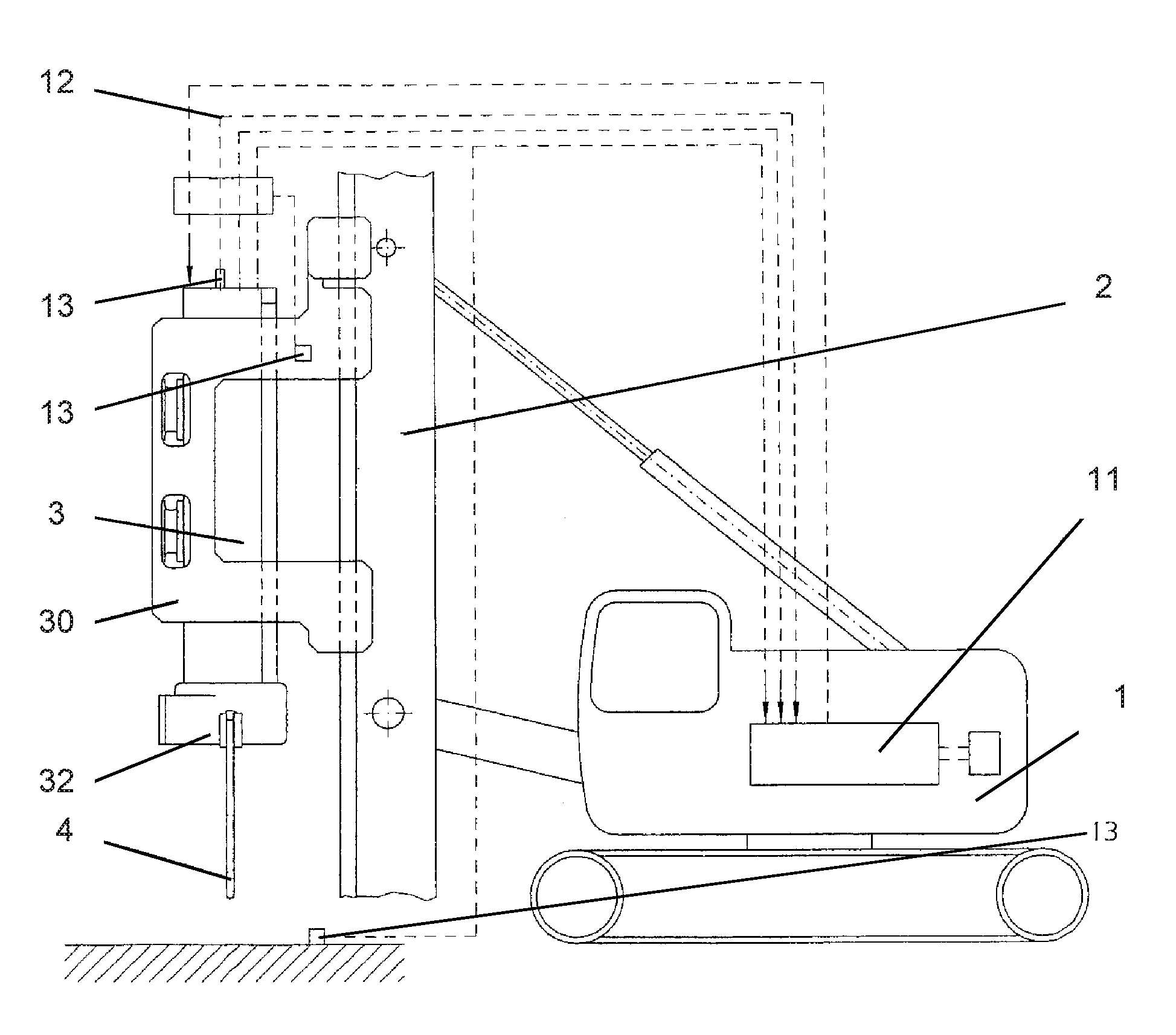

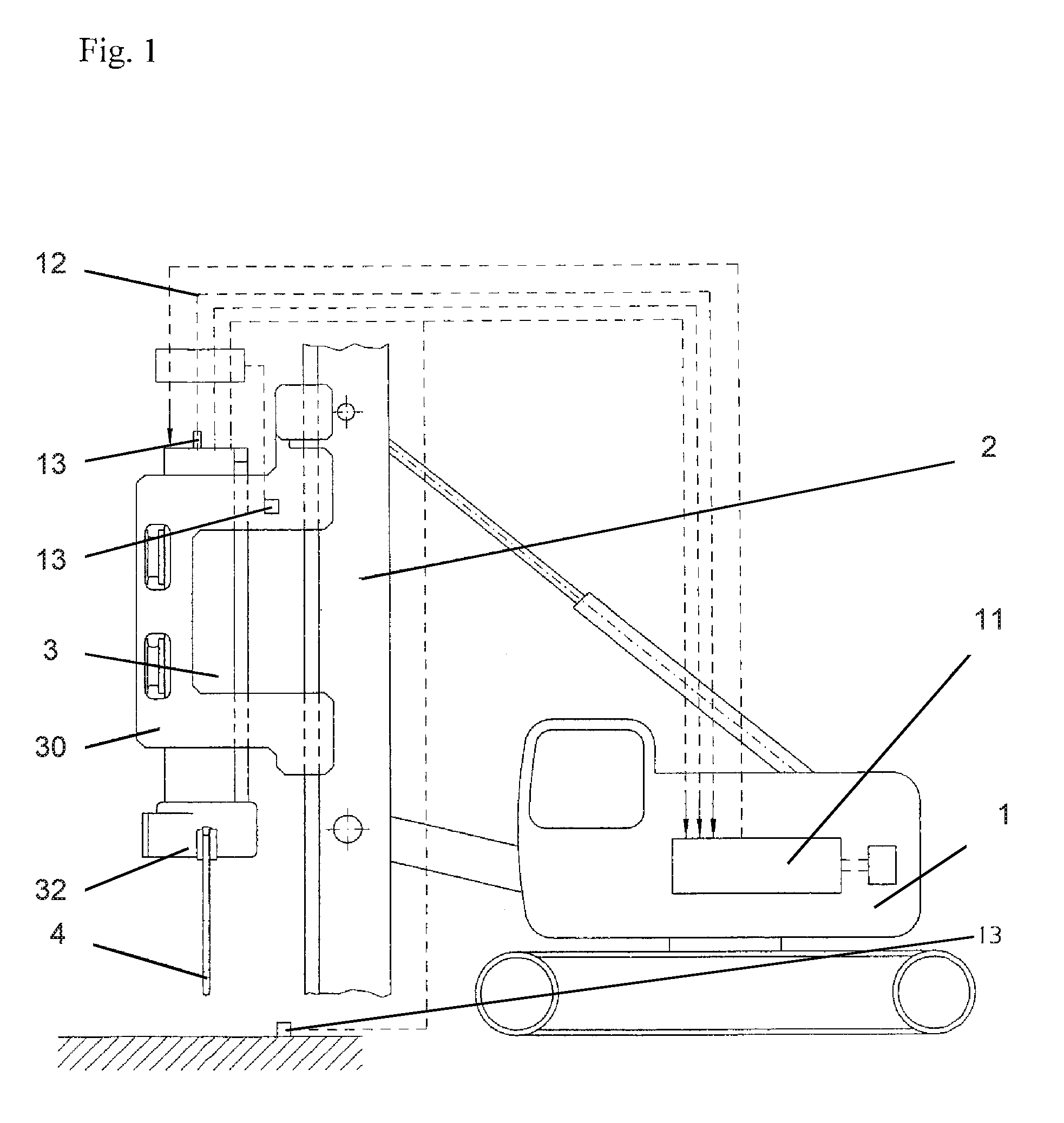

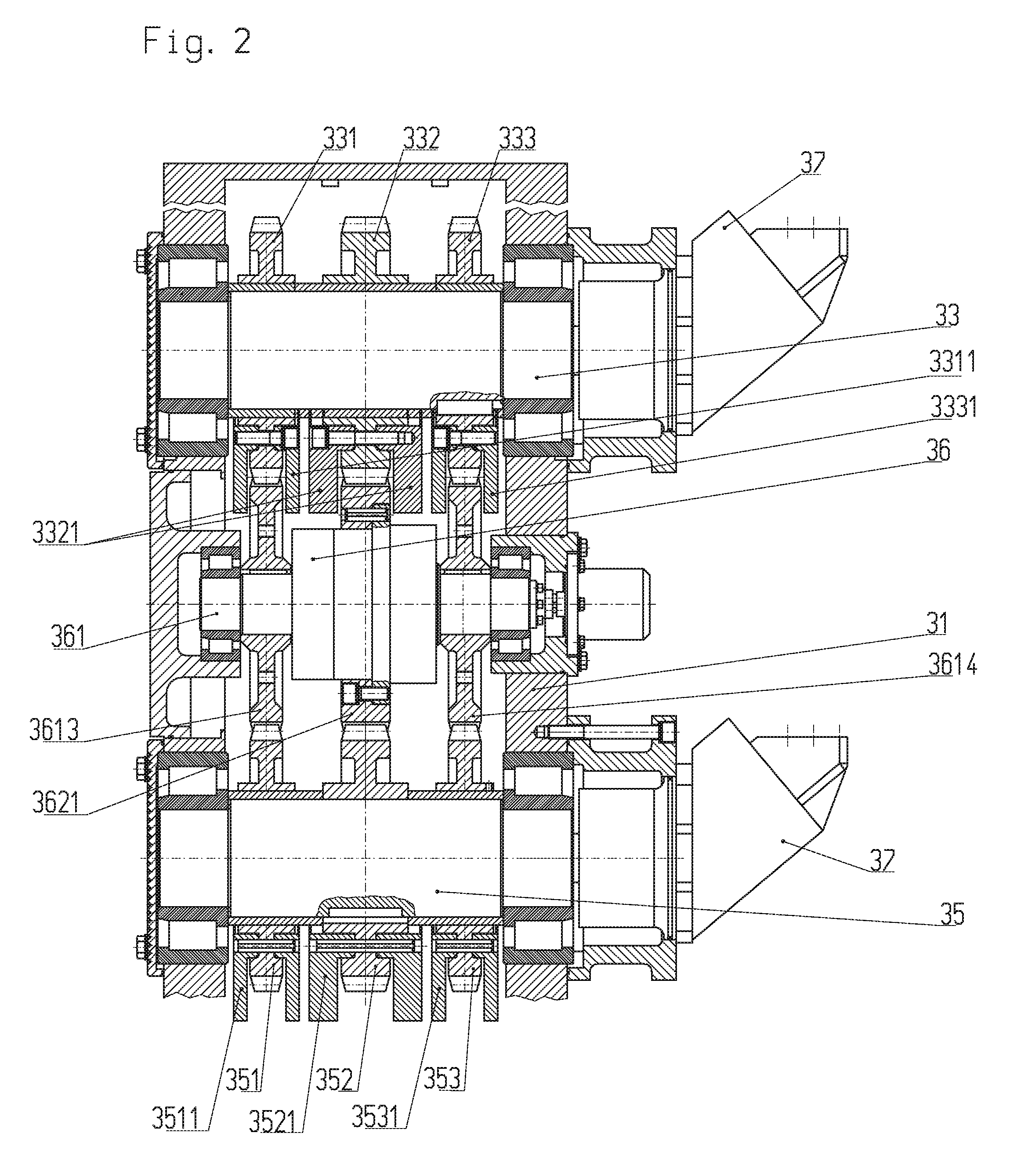

Apparatus for pile-driving or drilling

ActiveUS20150275459A1Avoid flow resistanceReduce hydraulic powerReciprocating drilling machinesRotary drillingHydraulic circuitEngineering

An apparatus for pile-driving or drilling, particularly a foundation machine, including at least one hydraulic drilling or vibration drive, which is connected with a control block in an open hydraulic circuit, by way of which drive at least one further consumer can be operated. The drive is connected with a pump by way of a first feed line and with a tank by way of a first return line. The hydraulic drive is additionally connected directly with the pump by way of a second feed line, and directly with the tank by way of a second return line.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

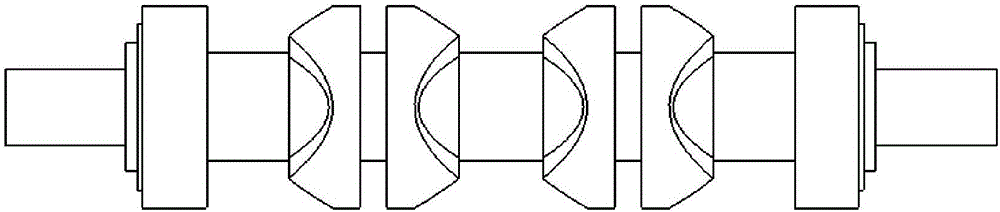

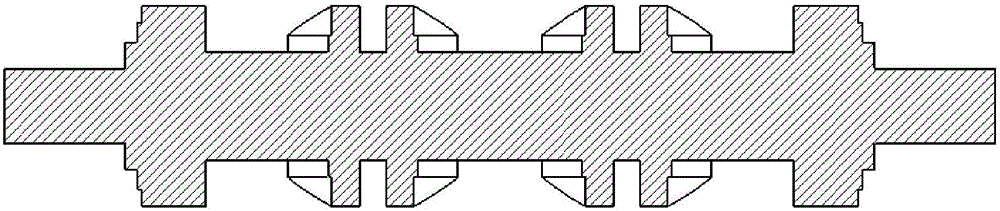

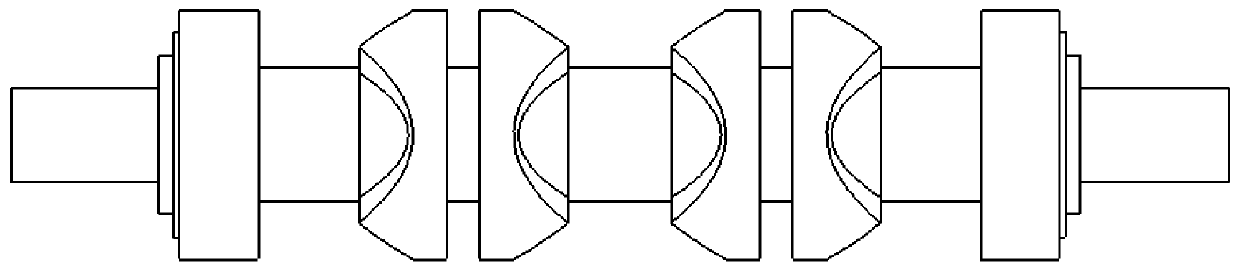

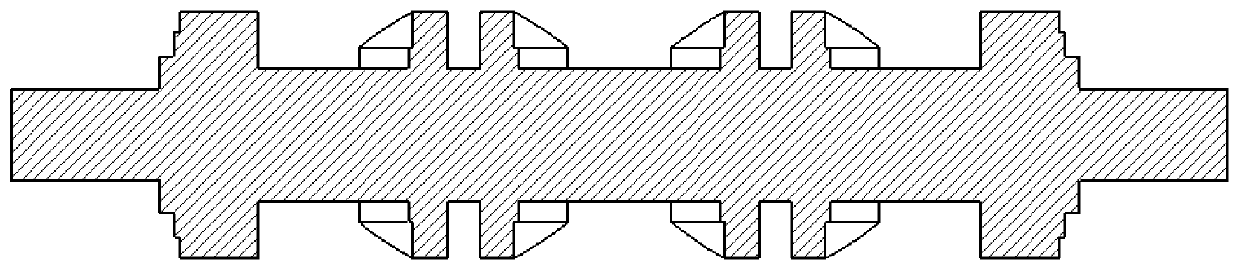

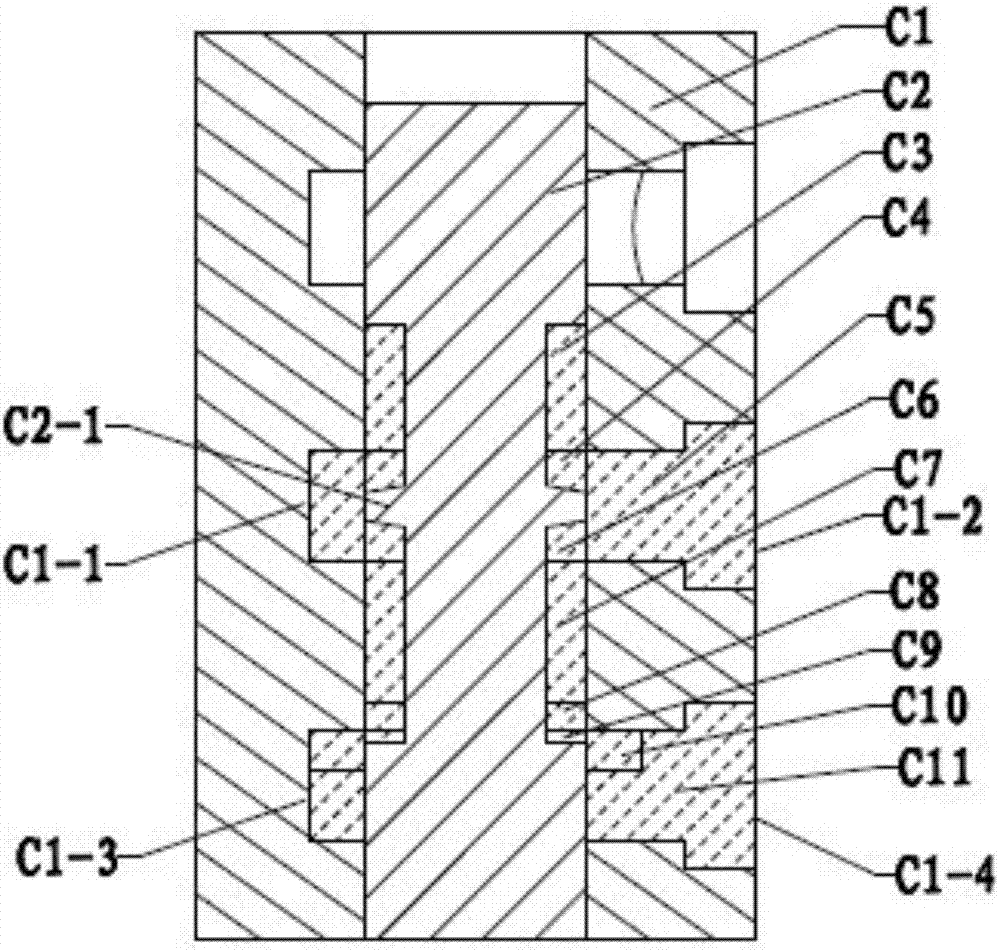

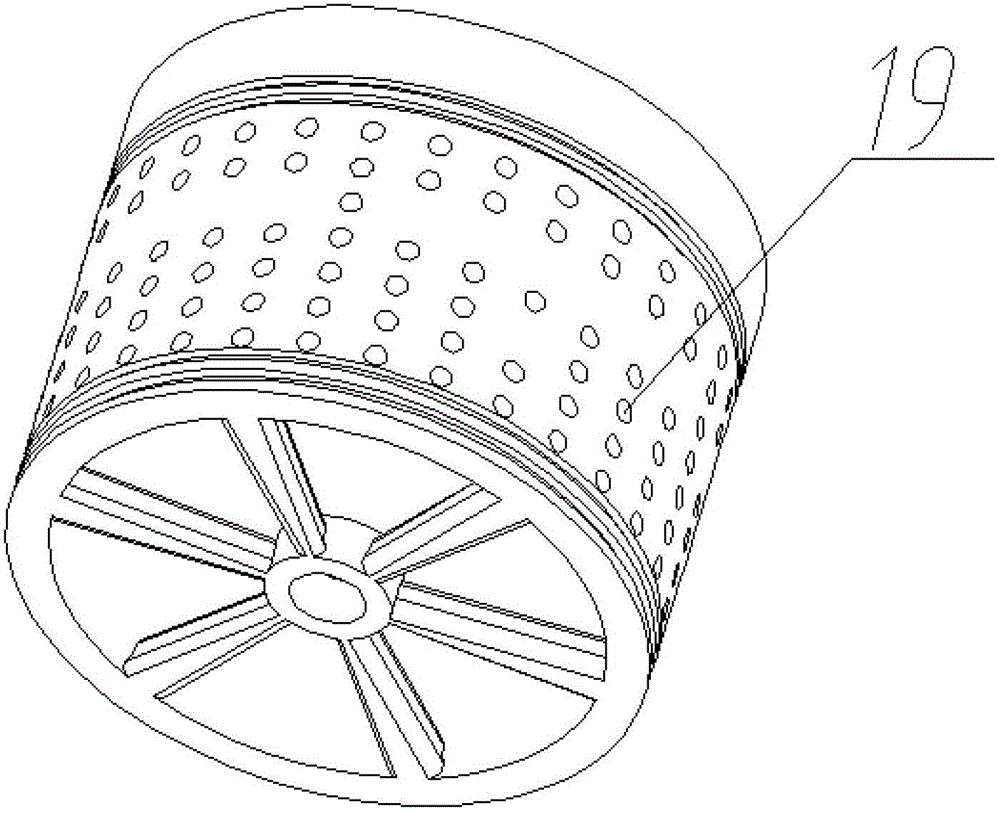

Proportional reversing valve lightweight valve element based on SLM technology and proportional reversing valve

ActiveCN106704622AReduce quality problemsEasy to useOperating means/releasing devices for valvesServomotor componentsEngineeringFriction force

The invention discloses a proportional reversing valve lightweight valve element based on the SLM technology and a proportional reversing valve. The proportional reversing valve lightweight valve element comprises a valve element main body. A plurality of regulator orifice sets are formed outside the valve element main body in the axis direction of the valve element main body. The regulator orifice sets are composed of a plurality of regulator orifices evenly distributed in the circumferential direction of the valve element main body. The two sides of each regulator orifice are both provided with bulges. All the bulges are of a hollowed-out structure. A chamfer with the section being in a quadratic parabola shape is formed between every two adjacent bulges. According to the valve element, provided with the bulges of the hollowed-out structure and the chamfers with the section being in the quadratic parabola shape, of the proportional reversing valve, the fluid motion state can be effectively changed, and fluid power is reduced; and meanwhile, the mass of the valve element can be remarkably lowered, the frequency response can be improved, friction force during motion is reduced, the using performance of the proportional reversing valve is remarkably improved, and the service life of the proportional reversing valve is remarkably prolonged.

Owner:ZHEJIANG UNIV

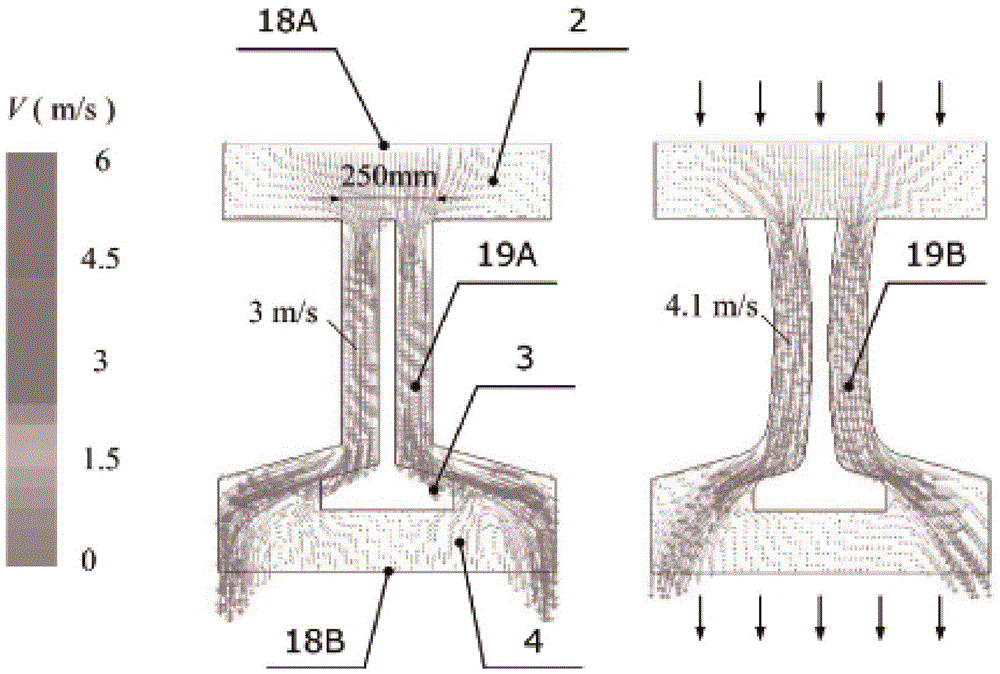

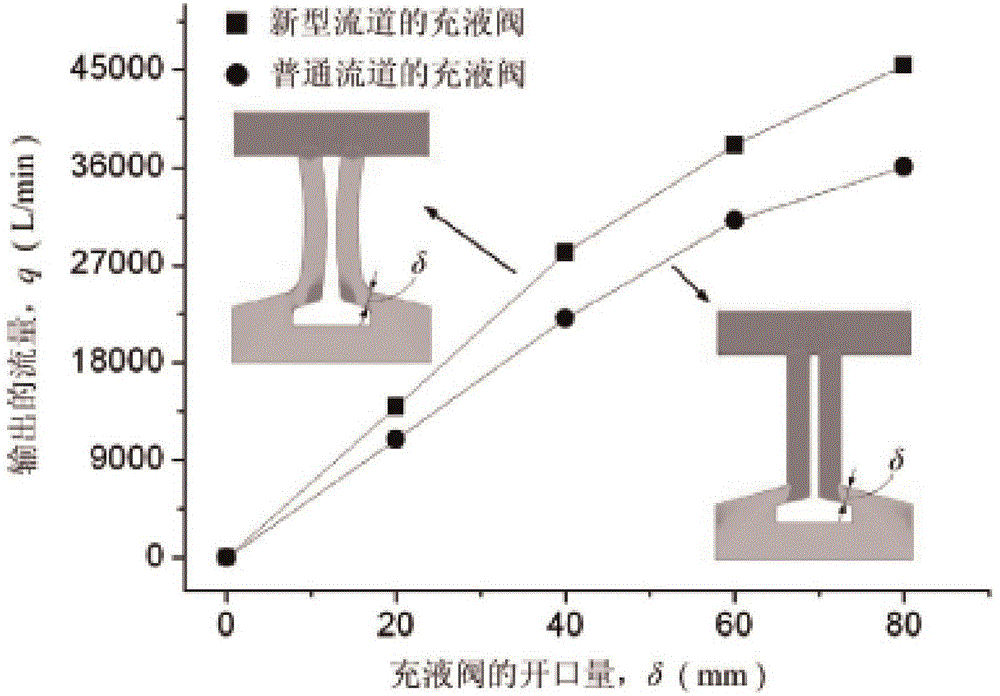

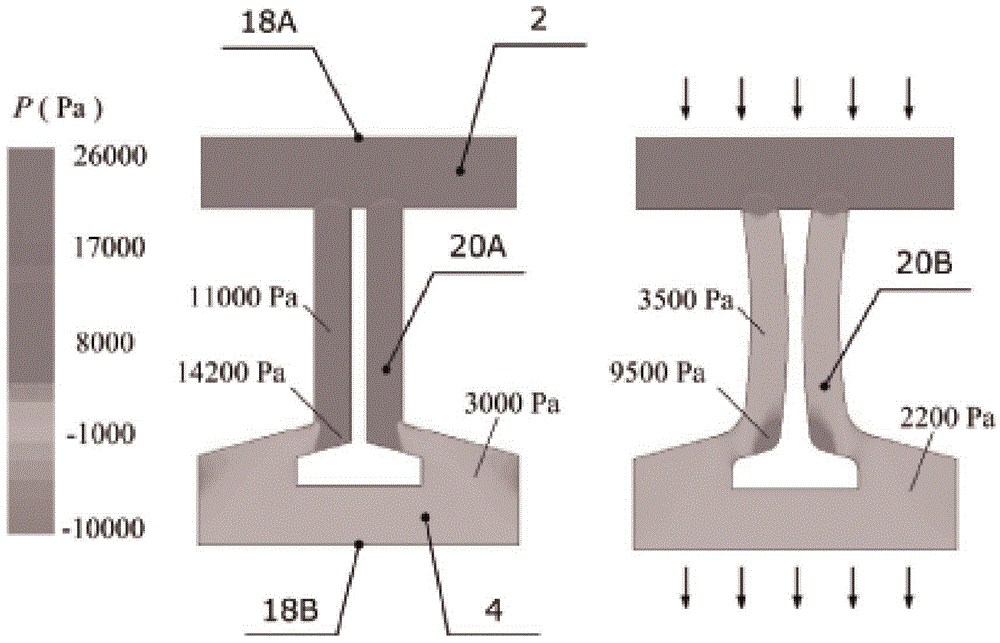

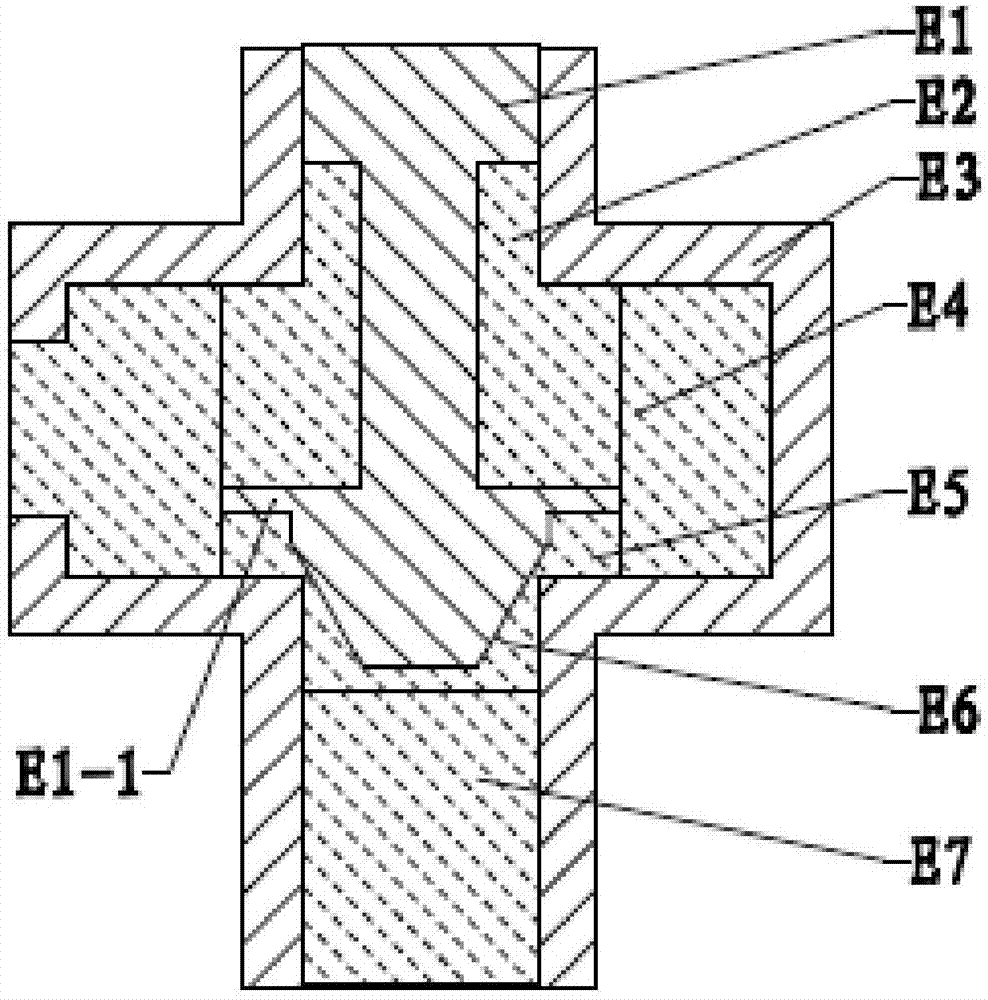

Self-adaptive multistage pressure relief controlled press liquid filling device

ActiveCN103334974AStable and fast unloading processImprove stabilityServomotor componentsHigh pressureSelf adaptive

The invention discloses a liquid supply device of a press. The liquid supply device is a device arranged between a liquid filling tank and a main oil cylinder, and comprises an inner valve core, a middle valve core, an outer valve core and the like, wherein the middle valve core is provided with a damping hole; and the outer valve core is provided with a draining hole. In the return stroke of the main oil cylinder, the inner valve core is opened, and oil in the main oil cylinder enters the liquid filling tank through the damping hole and the draining hole to realize primary pressure relief; and when the pressure of the main oil cylinder falls to a preset pressure respectively, the middle valve core and the outer valve core are opened automatically to realize secondary and tertiary pressure relief, and meanwhile, the oil is returned rapidly. The entire process is characterized by high speed, stability and high adaptability. Moreover, a multi-structure three-dimensional flow guide design is adopted for the profile surface of the valve cores and wall surfaces according to the working characteristics of the press, so that high oil flow speed and good pressure distribution are realized. Due to the adoption of a self-adaptive multistage unloading structure and a full-flow-channel flow guide design, a high-pressure unloading process is stable and efficient, and high oil flow speed and low hydraulic power are realized; and the liquid supply device is particularly suitable for high-pressure and high-flow working conditions.

Owner:FUJIAN HAIYUAN AUTOMATIC EQUIP CO LTD

Proportional directional valve lightweight spool and proportional directional valve based on slm technology

ActiveCN106704622BReduce quality problemsEasy to useOperating means/releasing devices for valvesServomotor componentsEngineeringFriction force

The invention discloses a proportional reversing valve lightweight valve element based on the SLM technology and a proportional reversing valve. The proportional reversing valve lightweight valve element comprises a valve element main body. A plurality of regulator orifice sets are formed outside the valve element main body in the axis direction of the valve element main body. The regulator orifice sets are composed of a plurality of regulator orifices evenly distributed in the circumferential direction of the valve element main body. The two sides of each regulator orifice are both provided with bulges. All the bulges are of a hollowed-out structure. A chamfer with the section being in a quadratic parabola shape is formed between every two adjacent bulges. According to the valve element, provided with the bulges of the hollowed-out structure and the chamfers with the section being in the quadratic parabola shape, of the proportional reversing valve, the fluid motion state can be effectively changed, and fluid power is reduced; and meanwhile, the mass of the valve element can be remarkably lowered, the frequency response can be improved, friction force during motion is reduced, the using performance of the proportional reversing valve is remarkably improved, and the service life of the proportional reversing valve is remarkably prolonged.

Owner:ZHEJIANG UNIV

Two-channel kiloliter-level large-flow reversing valve

ActiveCN104675423AIncreased pressure lossReduce radial unbalance forceMine roof supportsProps/chocksInstabilityEngineering

The invention belongs to a reversing valve used for controlling a hydraulic system of a hydraulic support, and particularly relates to a two-channel kiloliter-level large-flow reversing valve which solves the problem that a traditional reversing valve structure is not suitable for a high-pressure kiloliter-level large-flow working condition. Two-side symmetrical main liquid supply channels used for supplying liquid to a valve core are arranged in a valve body; one end of one two-side symmetrical main liquid supply channel is communicated with one end of the other two-side symmetrical main liquid supply channel via an auxiliary passageway and is connected with a liquid supply high-pressure pipe; two-side symmetrical liquid return channels are also arranged in the valve body; the left end of a liquid feeding valve core is provided with a hydraulic balance end surface and a hydraulic control end surface; a hydraulic balance oil circuit and a hydraulic control oil circuit are also correspondingly arranged in the valve body and a liquid return valve bush. According to the reversing valve, a phenomenon that a traditional reversing valve causes deflecting force by flow field asymmetry is overcome, a clamping lag phenomenon, an abrasion phenomenon and a failure problem appearing during the returning of the kiloliter-level large-flow reversing valve are avoided, the contact stress of a sealing surface of the valve core and a valve seat is lowered, and the instability of a traditional cone valve is overcome, and pressure loss is lowered.

Owner:TAIYUAN UNIV OF TECH

Pilot operated compound relief valve

InactiveCN110056689AReduce spray angleAvoid movement failureValve members for absorbing fluid energyEqualizing valvesEngineeringVALVE PORT

The invention discloses a pilot operated compound relief valve. The pilot operated compound relief valve comprises a main valve and a pilot valve. The main valve comprises a main valve body, a main valve sleeve, a main valve element, a spring cavity and a main valve return spring. The pilot valve comprises a pilot valve body, a pilot valve seat, a pilot valve element, a pilot valve pressure regulating spring, an annular stepped hole, a pilot piston, a guide cylinder, a pressure regulating threaded handle and a pressure regulating cavity. Three sets of double-row micro holes are formed in the outer cylindrical surface of the main valve element. A rectangular uniform-section annular compensation groove, a V-shaped divergent circumferential compensation groove and a U-shaped uniform-section circumferential compensation groove are formed in the main valve element. The outer end surface of a damping sleeve is uniformly provided with six damping cavities in the axis direction of the dampingsleeve. Each damping cavity is filled with sound absorbing material particles. Each damping cavity is sealed through a silencing screw and a vibration absorbing pad. Vibration and noise of the pilot valve can be eliminated to the greatest extent, hydraulic power of the main valve element can be compensated, and thus the performance of the whole pilot operated compound relief valve is improved.

Owner:合肥壹点通信息科技有限公司

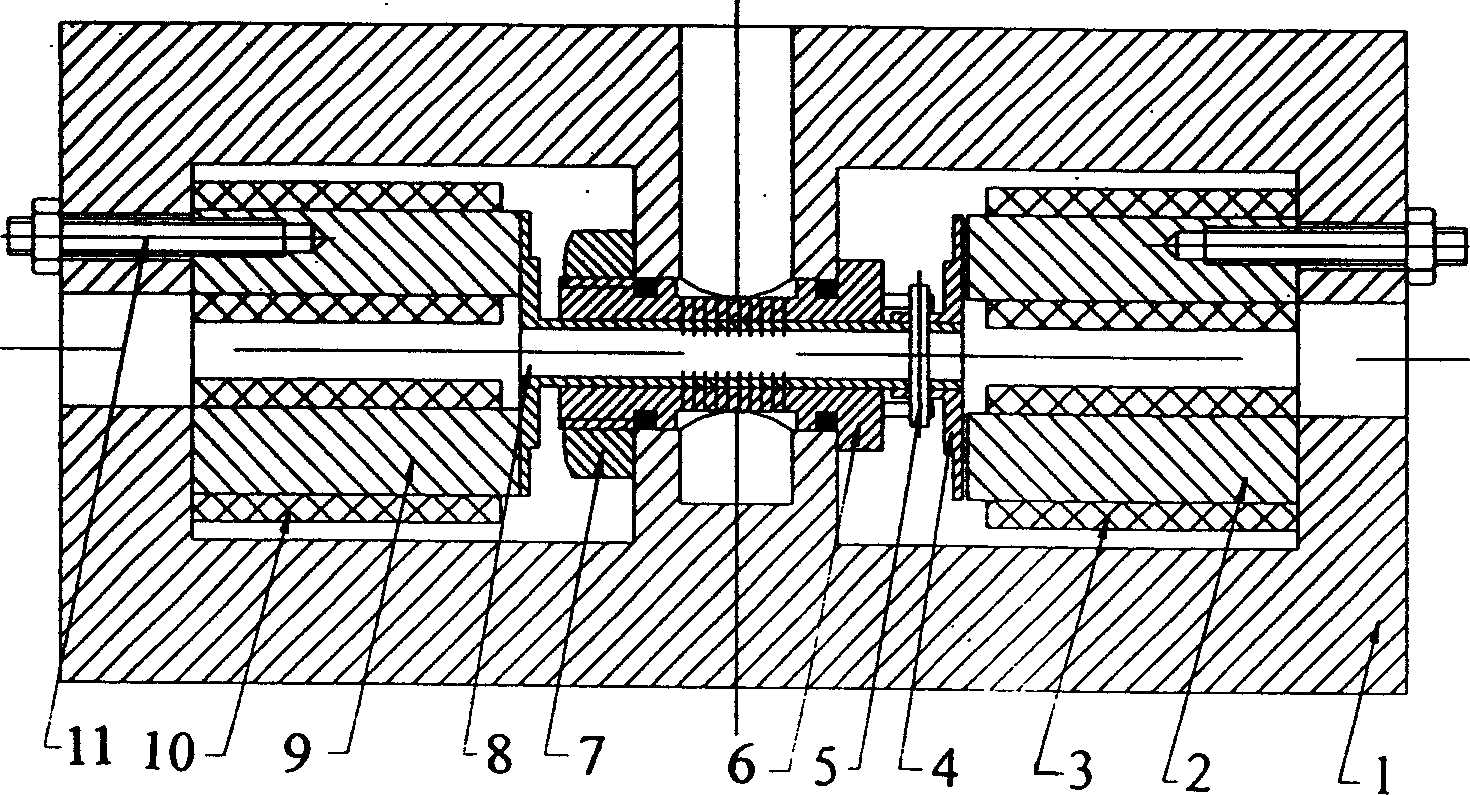

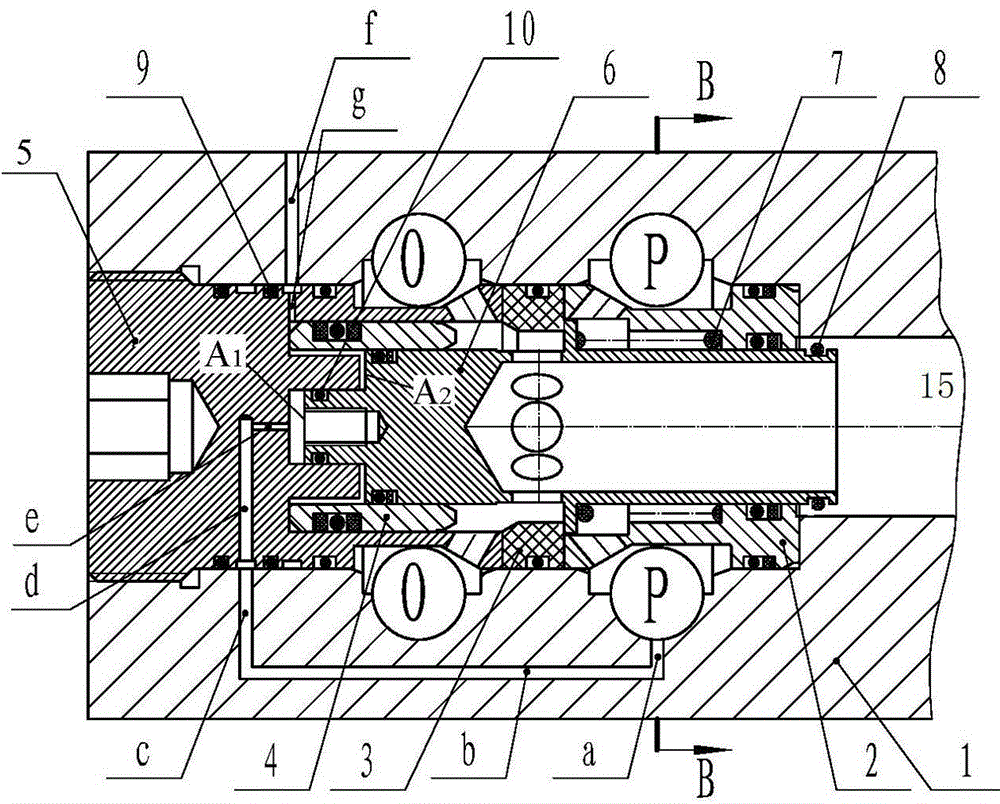

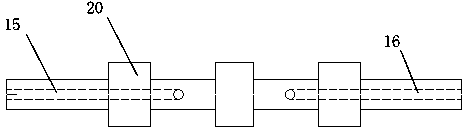

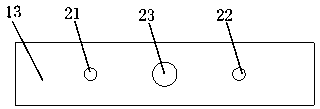

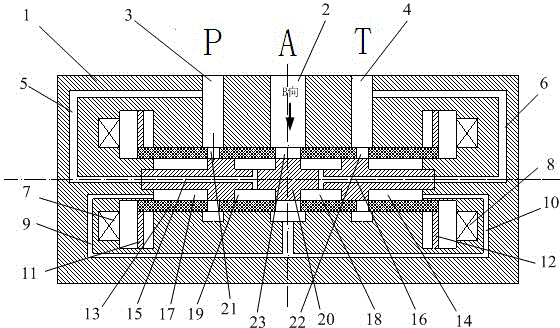

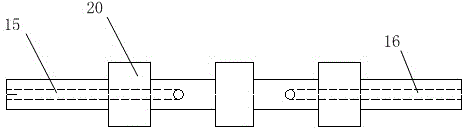

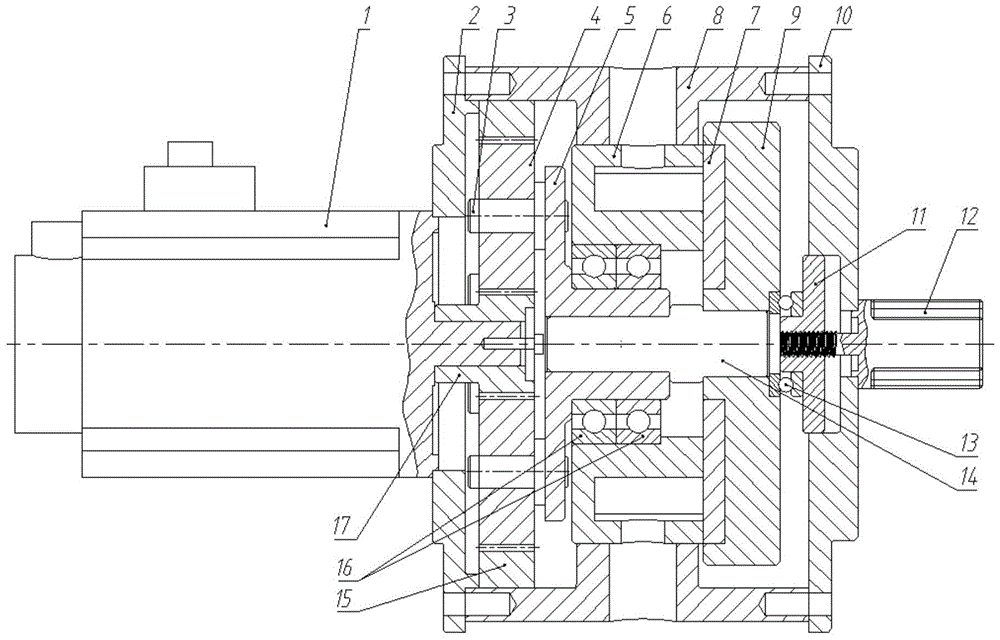

High-speed switch valve

ActiveCN103470807AReduce transient hydraulic forcesReduce hydraulic powerMultiple way valvesMechanical engineering

The invention discloses a high-speed switch valve. A valve sleeve and a main spool are arranged coaxially. Two ends of the main spool are connected with a valve body. A left armature and a right armature are connected with two ends of the valve sleeve. The left end of the main spool is provided with a spool left drainage channel whereby a main pressure cavity is communicated with a port P. The right end of the main spool is provided with a spool right drainage channel whereby a main return oil cavity is communicated with a port T. A port A is communicated with an auxiliary pressure cavity and an auxiliary return oil cavity through the left and right drainage channels respectively. Opening and closing of the valve is switched through the valve sleeve; hydraulic force of the valve is reduced; the valve sleeve and the main spool are in sliding fit, so that leakage during switching is avoided; flow from the port P and the port A is doubly increased through the spool left drainage channel and the auxiliary pressure cavity, and transient hydraulic force borne by the valve sleeve is reduced. The high-speed switch valve has the advantages such as simple structure, high machinability and simplicity of operation; the valve can be opened and closed fast.

Owner:ZHEJIANG UNIV

A direct-acting overflow valve of the oil supply system of transmission device

ActiveCN105299254BChange the area of actionChange opening speedPlug valvesEqualizing valvesEngineeringHigh pressure

The invention discloses a direct acting type overflow valve of an oil supply system of a transmission device. The overflow valve comprises a valve body, a valve core, a pressure adjusting spring set, a pressure adjusting rod, a T-shaped guide rod and a hand wheel. The pressure adjusting spring set coats the T-shaped guide rod, and consists of two springs with different rigidities and lengths; the rigidity ratio range of the two springs is from 2: 1 to 4: 1; the length ratio range is from 1.2: 1 to 2: 1; and the two ends of the pressure adjusting spring set are respectively butted against the valve core and the T-shaped guide rod. The hand wheel can drive the valve core to rotate; through the rotation of the valve core, the opposite positions of a wedged groove in the right end of the valve core and a plane groove in the valve body are changed, the oil acting area is changed, the damping hole change effect is achieved, and the opening speed of the overflow valve is changed; and the overflow valve needs no other complex damping hole adjusting mechanisms, realizes the purposes of higher pressure fixing precision and smaller size. The pressure adjusting spring set adopts the double-spring setting to realize the purposes of stronger adaptability and higher reliability of the overflow valve.

Owner:DALIAN MARITIME UNIVERSITY

An energy-dissipating buffer hydraulic dam

ActiveCN107604883BExtended service lifeReduce direct impactBarrages/weirsHydraulic cylinderEngineering

Owner:查斌 +2

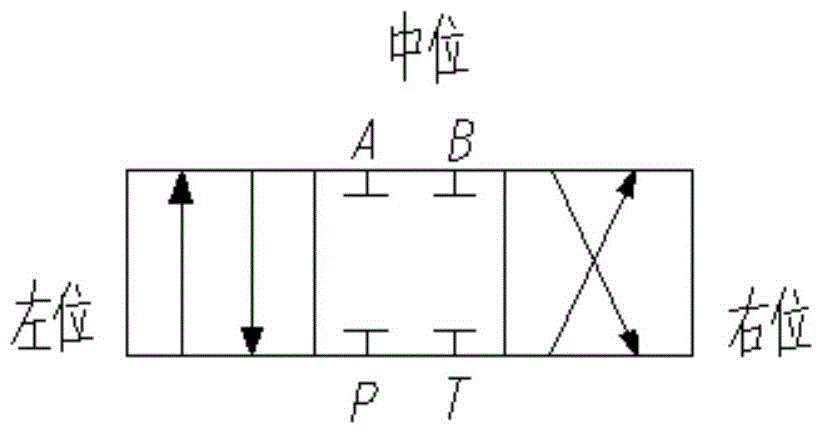

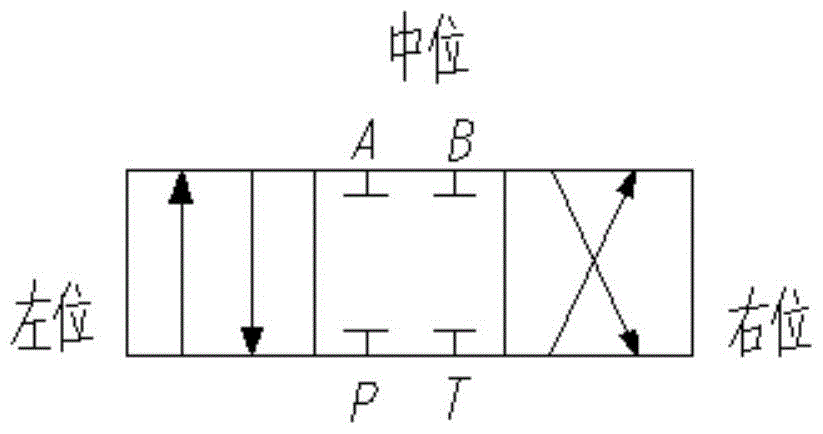

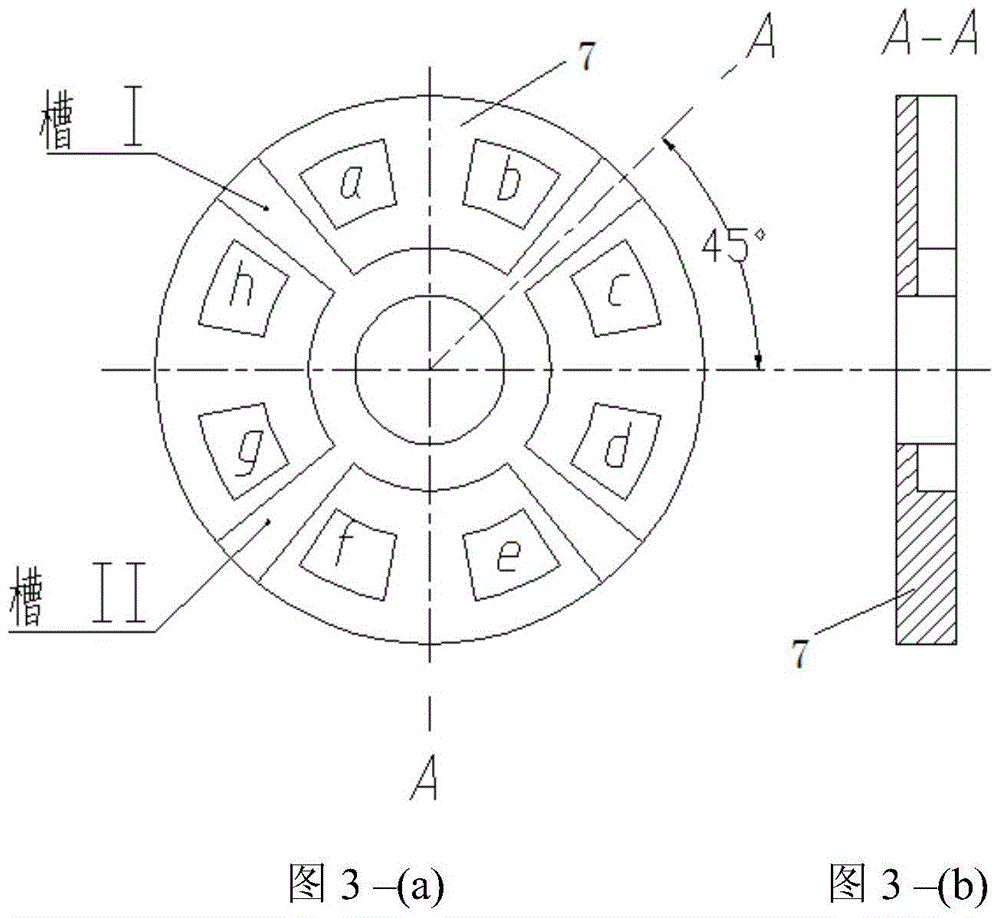

A double-sided plate-type three-position four-way rotary valve with adjustable flow

InactiveCN104806592BEasy to adjustEasy to closeOperating means/releasing devices for valvesServomotor componentsLinear motionBall bearing

A flow-adjustable double side plate type three-position four-way rotary valve comprises a valve element, wherein valve plates are installed at two ends of the valve element in a matched mode, an adjustable boss is installed at the other end of each valve plate, the centers of the adjustable bosses are holed and are installed on an output end of a motor shaft of a built-in motor, a lead screw adjusting nut mechanism consists of an output lead screw shaft slippage nut of the built-in motor, wherein a lead screw shaft is arranged in a central hole of the motor shaft, the slippage nut can slide in an inner hole formed in an outer end cover, thrust ball bearings are connected between the slippage nut and the adjustable bosses, the outer end cover is connected with a valve sleeve, threads at two ends of the lead screw shaft are oppositely symmetric so that the adjustable bosses at two ends of the valve element can perform same-direction or reverse-direction linear motions, four small holes for springs to be arranged are formed in the adjustable bosses to ensure that the adjustable bosses always abut against the end face of the valve element in the axial moving process. The flow-adjustable double side plate type three-position four-way rotary valve controls on and off of hydraulic oil through matched rotations of the valve plates at two ends of the valve element, adjusts oil flow through the adjustable bosses and enables a hydraulic system to be simplified.

Owner:XI AN JIAOTONG UNIV

Turning gradient control valve

InactiveCN102410270BReduce hydraulic powerGuaranteed stabilityServomotor componentsLow noiseControl valves

The invention discloses a turning gradient control valve, which is designed to provide a two-functional turning gradient control valve which can absorb vibration of the system, has low noise and energy saving, and can be applied to a static signal type and a dynamic signal type, wherein a first hole (P) in communication with a first throttle groove (4a1) and a second throttle groove (4a2) of a second hole (CF) is arranged on a beading at the right side along the circumference direction; the first hole (P) is in communication with a third throttle groove (4b1) and a fourth throttle groove (4b2) of a third hole (EF), wherein the first throttle groove (4a1) and the second throttle groove (4a2) are matched with a throttle side (5a) of a first sunken cutting groove of a valve body (5a) to form a valve port through which the first hole (P) is led to the second hole (CF); the third throttle groove (4b1) and the fourth throttle groove (4b2) are matched with a throttle side (5b) of a second sunken cutting groove of the valve body (5) to form a valve port through which the first hole (P) is led to the third hole (EF); the left end of the valve core (4) is provided with an asymmetric composite damper (3) while the right end of the valve core (4) is provided with a first damping hole (6).

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

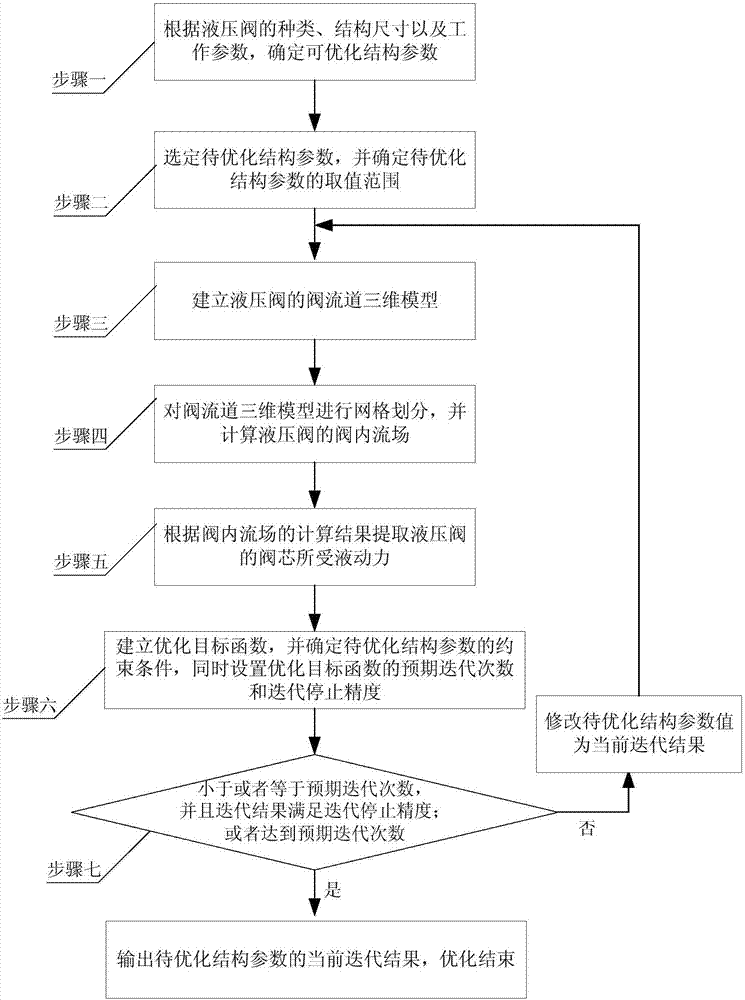

Hydrodynamic Optimization Method of Hydraulic Valve

ActiveCN106089855BReduce hydraulic powerFluid-pressure actuator testingProcess engineeringObject function

The invention provides a fluid power optimizing method for a hydraulic valve and belongs to the technical field of structure optimization of hydraulic valves. By the adoption of the fluid power optimizing method for the hydraulic valve, the problem that in the prior art, since a large quantity of manual calculation and screening is needed for structure optimization design of a hydraulic valve to compensate for the influence of fluid power, the designing efficiency is low is solved. The fluid power optimizing method for the hydraulic valve comprises the steps that structure parameters which can be optimized are determined; structure parameters to be optimized are selected, and the value range of the structure parameters to be optimized is determined; a three-dimensional valve flow channel model of the hydraulic valve is established; an intra-valve flow field in the hydraulic valve is calculated; fluid power borne by a valve element of the hydraulic valve is extracted; an optimized objective function is established according to fluid power of the hydraulic valve, constraint conditions of the structure parameters to be optimized are determined, and meanwhile the expected iteration number and iteration stopping precision of the optimized objective function are set; and optimized iteration is conducted on the optimized objective function according to the constraint conditions of the structure parameters to be optimized till the iteration stopping precision or the expected iteration number is achieved, and the optimization process is ended. The fluid power optimizing method is used for structure optimization of the hydraulic valve.

Owner:HARBIN INST OF TECH

A high-speed switching valve

ActiveCN103470807BReduce transient hydraulic forcesReduce hydraulic powerMultiple way valvesMechanical engineeringMachinability

The invention discloses a high-speed switch valve. A valve sleeve and a main spool are arranged coaxially. Two ends of the main spool are connected with a valve body. A left armature and a right armature are connected with two ends of the valve sleeve. The left end of the main spool is provided with a spool left drainage channel whereby a main pressure cavity is communicated with a port P. The right end of the main spool is provided with a spool right drainage channel whereby a main return oil cavity is communicated with a port T. A port A is communicated with an auxiliary pressure cavity and an auxiliary return oil cavity through the left and right drainage channels respectively. Opening and closing of the valve is switched through the valve sleeve; hydraulic force of the valve is reduced; the valve sleeve and the main spool are in sliding fit, so that leakage during switching is avoided; flow from the port P and the port A is doubly increased through the spool left drainage channel and the auxiliary pressure cavity, and transient hydraulic force borne by the valve sleeve is reduced. The high-speed switch valve has the advantages such as simple structure, high machinability and simplicity of operation; the valve can be opened and closed fast.

Owner:ZHEJIANG UNIV

A dual-channel thousand-liter high-flow reversing valve

ActiveCN104675423BIncreased pressure lossReduce radial unbalance forceMine roof supportsProps/chocksEngineeringMechanics

The invention belongs to a reversing valve for controlling a hydraulic system of a hydraulic support, in particular to a double-channel, thousand-up, high-flow, reversing valve, which solves the problem that the existing reversing valve structure is not suitable for high-pressure, thousand-up, and large-flow working conditions. Inside the valve body, there are double-sided symmetrical main liquid supply channels that supply liquid to the valve core. Symmetrical return channel. The left end of the liquid inlet spool is provided with a hydraulic balance end face and a hydraulic control end face, and a hydraulic balance oil circuit and a hydraulic control oil circuit are correspondingly provided inside the valve body and the liquid return valve sleeve. The invention overcomes the deflection force caused by the asymmetry of the flow field of the traditional reversing valve, avoids the phenomenon of hysteresis, wear and failure of the reversing valve that occurs when the thousand-level high-flow reversing valve returns to its position, and reduces the sealing between the valve core and the valve seat. Surface contact stress; overcome the instability of the traditional cone valve; reduce the pressure loss.

Owner:TAIYUAN UNIV OF TECH

Balanced high-pressure large-current AC (Alternating Current) servo direct-driven cartridge valve

The invention discloses a balanced high-pressure large-current AC (Alternating Current) servo direct-driven cartridge valve, comprising an AC servo motor, wherein the AC servo motor and a harmonic reducer are connected to a valve sleeve, the output shaft of the AC servo motor is connected with the input shaft of the harmonic reducer, the output shaft of the harmonic reducer is connected with a leading screw by a coupler, the leading screw is provided with a sliding block, the sliding block is connected with a linear displacement sensor, the sliding block is connected with a valve rod, the end of the valve rod is provided with an external thread, a valve core is provided with an internal thread, the valve rod drives the opening and closing of the valve core by internal thread connection, a small end cover is connectedly fixed on a valve seat, and is fixedly connected with a valve core sleeve, a valve sleeve is inserted in the valve seat and fixed in the valve seat by a top end cover, the top end cover is fixed with the valve seat, and the valve seat is installed in a hydraulic system by a plug-in manner, so that the influence of the oil-liquid pressure on the valve is reduced, and the instant hydraulic power of the valve is small. According to the invention, as a closed-loop control servo direct-driven manner is adopted, the valve has the advantages of simple structure, rapid response, accurate control and high linearity.

Owner:XI AN JIAOTONG UNIV

A single-side plate type three-position four-way rotary valve with adjustable flow

InactiveCN104747773BEasy to closeRealize integrationOperating means/releasing devices for valvesMultiple way valvesDrive shaftReduction ratio

A unilateral plate type three-position four-way rotary valve with adjustable flow, including a driving motor, the output shaft of the driving motor is connected to the drive shaft through a star gear reducer, a rotating arm sleeve, and one end of the valve core is connected to the rotating arm sleeve , the other end fits with the valve plate, the drive shaft is connected with the adjustable boss, the adjustable boss is connected with the valve plate through a groove, the driving motor is fixed on the left end cover, the adjusting motor is fixed on the right end cover, and the adjusting motor The output shaft of the screw is a lead screw, and the sliding nut of the lead screw can move back and forth in the inner cylindrical groove of the right end cover. The adjustable boss always presses the valve plate against the end face of the valve core during the axial movement, and the driving part Using servo motor plus planetary gear reducer, the present invention improves the control precision and can adjust the reduction ratio, the adjustable boss and the adjustable screw nut mechanism can easily adjust the flow and close the valve, realize the integration of flow adjustment, and simplify the hydraulic system .

Owner:XI AN JIAOTONG UNIV

High-speed large-flow clearence slide valve

InactiveCN1203252CShorten exercise distanceIncrease the opening speedMachines/enginesFuel injecting pumpsBodies oilHigh energy

The invention discloses a high-speed and large-flow slot slide valve. Install two snap-fit electromagnets symmetrically in the valve body cavity at both ends of the valve core. The hollow valve core is covered with a valve sleeve. One end of the valve core can be clutched with the snap-fit electromagnet at one end, and the other end of the valve core is equipped with a magnetic pole. , the magnetic pole can be clutched with the snap-on electromagnet at the other end, the valve core and the valve sleeve have the same number, the same width, and the same distance between the non-circumferential gap-shaped valve ports on the mating surface, the valve port and the oil outlet of the valve body connected. The hollow valve core structure is adopted to reduce the mass of the moving parts; the driving force of the valve core movement is generated by the opposite clapping electromagnet, and the energy utilization rate of the electromagnet is high; , which reduces the movement distance of the valve core when it is opened and closed; at the same time, this gap valve port can reduce the hydraulic power of the valve port. Therefore, the sliding valve structure adopted in the present invention can increase the opening and closing speed of the valve core under the premise of ensuring a certain flow rate.

Owner:ZHEJIANG UNIV

Apparatus for pile-driving or drilling

ActiveUS9469961B2Avoid flow resistanceReduce hydraulic powerReciprocating drilling machinesRotary drillingHydraulic circuitEngineering

An apparatus for pile-driving or drilling, particularly a foundation machine, including at least one hydraulic drilling or vibration drive, which is connected with a control block in an open hydraulic circuit, by way of which drive at least one further consumer can be operated. The drive is connected with a pump by way of a first feed line and with a tank by way of a first return line. The hydraulic drive is additionally connected directly with the pump by way of a second feed line, and directly with the tank by way of a second return line.

Owner:ABI ANLAGENTECHN BAUMASCHEN INDBEBEDARF

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com