A double-sided plate-type three-position four-way rotary valve with adjustable flow

A three-position, four-way, flow rate technology, applied in the field of high-frequency hydraulic valves, can solve the problems of unbalanced radial force of the rotary valve, large operating force of the rotary valve core, and poor sealing performance, so as to achieve flow adjustment and reduce hydraulic pressure. Motivation, the effect of increasing the frequency of movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

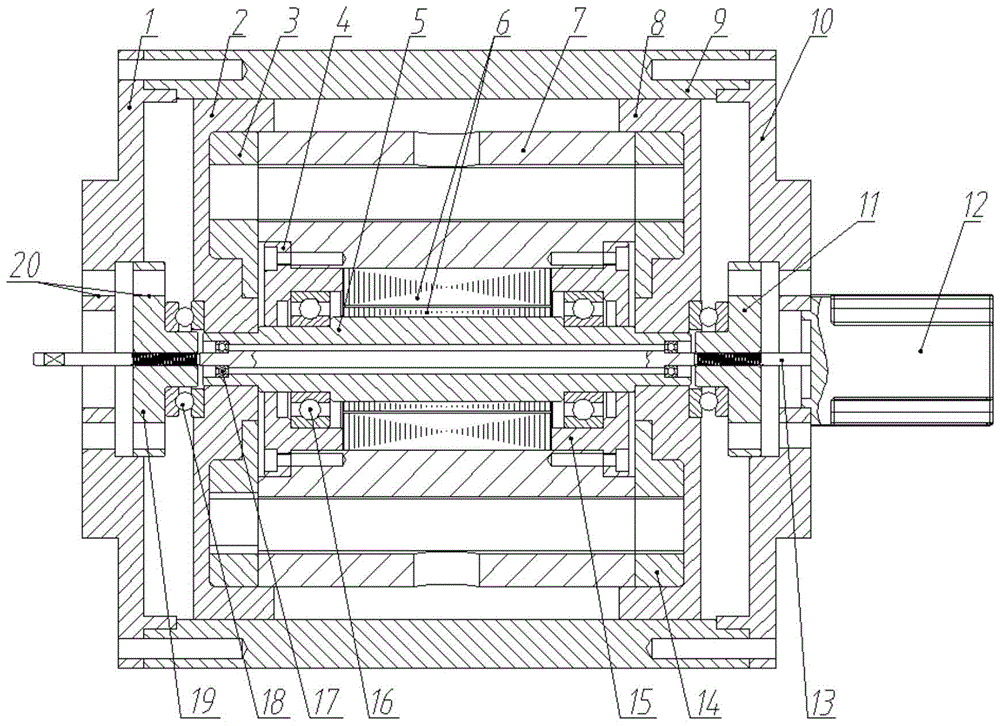

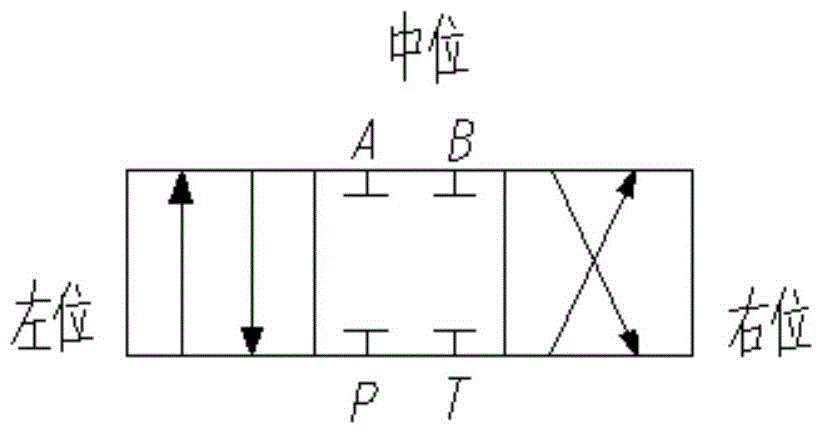

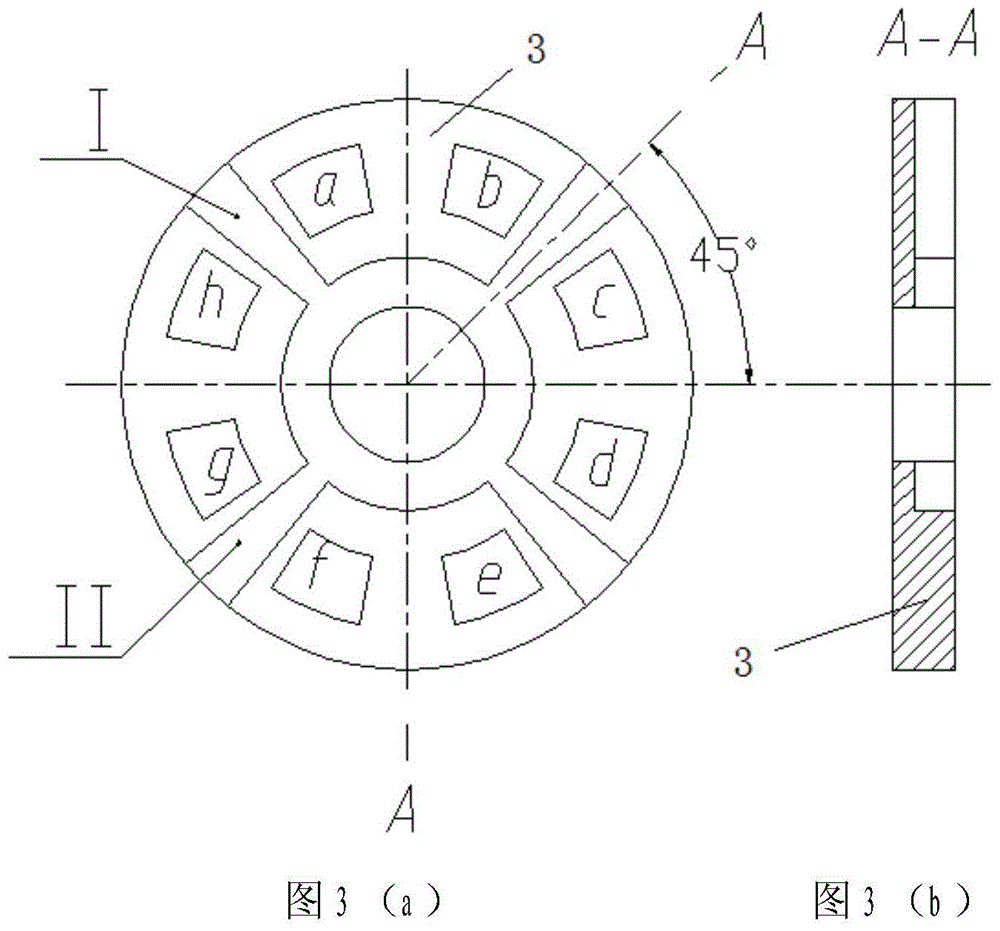

[0016] Such as figure 1 As shown, a two-sided plate type three-position four-way rotary valve with adjustable flow includes a valve core 7, which is cylindrical, with a central opening for placing a built-in motor 6, and there are 8 axially divided according to the end circle. Fan-shaped flow channel through hole, the two ends of the valve core 7 are equipped with two identical circular first valve plates 3 and second valve plates 14, and the first valve plate 3 and the second valve plate 14 are provided with valve cores. 8 fan-shaped flow passage holes a, b, c, d, e, f, g, h corresponding to the fan-shaped flow passage holes on 7, the first adjustable boss 2 and the second adjustable boss 8 respectively Installed on the other end of the first valve plate 3 and the second valve plate 14, the first valve plate 3 and the second valve plate 14 are processed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com