A high-speed switching valve

A high-speed switching valve and valve body technology, applied in multi-port valves, valve devices, engine components, etc., can solve problems such as leakage, affect system efficiency, and small flow capacity, achieve good manufacturability and reduce transient hydraulic power. , the effect of avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and example.

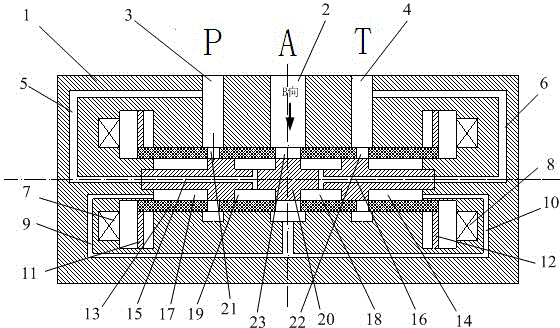

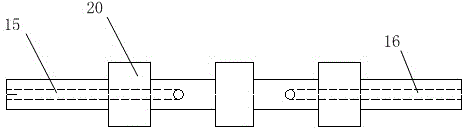

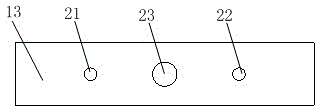

[0017] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes valve body 1, A port 2, P port 3, T port 4, pressure oil drainage channel 5, oil return drainage channel 6, left electromagnet 7, right electromagnet 8, left drainage channel 9, right Drainage channel 10, left armature 11, right armature 12, valve sleeve 13, auxiliary oil return valve cavity 14, spool left drainage channel 15, spool right drainage channel 16, auxiliary pressure valve cavity 17, main oil return valve cavity 18, The main pressure valve cavity 19, and the main valve core 20, the flow hole P21, the flow hole T22, the flow hole A23; the main valve core 20 and the valve sleeve 13 are sequentially installed in the center hole of the valve body 1, and the valve sleeve 13 is connected with the main valve sleeve. The spool 20 is sliding fit, the two ends of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com