Balanced high-pressure large-current AC (Alternating Current) servo direct-driven cartridge valve

A technology of AC servo and AC servo motor, applied in the field of hydraulic valves, can solve the problems of increasing the cost of electro-hydraulic servo systems, high oil purity requirements, sensitive oil pollution, etc., achieve good repeat positioning accuracy, overcome difficulties in use, Use simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

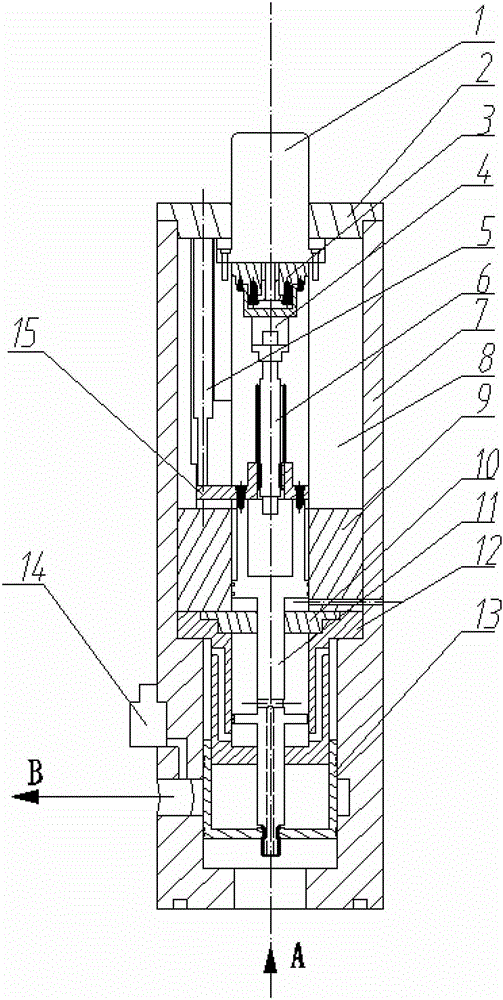

[0026] refer to figure 1 , a balanced high-pressure and large-flow AC servo direct-drive cartridge valve, including an AC servo motor 1, the AC servo motor 1 and a harmonic reducer 3 are connected to the valve sleeve 8 by bolts, and the output shaft of the AC servo motor 1 is in harmony with the harmonic The input shaft of the wave reducer 3 is connected, and the output shaft of the harmonic reducer 3 is connected with the lead screw 6 through the coupling 4. The lead screw 6 is provided with a slider 15, and the rotation of the lead screw 6 drives the slider 15 to perform linear motion. , the slider 15 is connected with a linear displacement sensor 5, which can directly respond to the displacement of the slider 15. The slider 15 is connected to the valve stem 11 through a bolt connection. The end of the valve stem 11 has an external thread, and the valve core 13 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com