High-speed large-flow clearence slide valve

A large flow and gap technology, applied in the direction of sliding valves, valve devices, fuel injection pumps, etc., can solve the problems that valves are not widely used in engines and poor temperature adaptability, so as to increase the opening and closing speed and reduce the liquid at the valve port. The effect of high power and energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

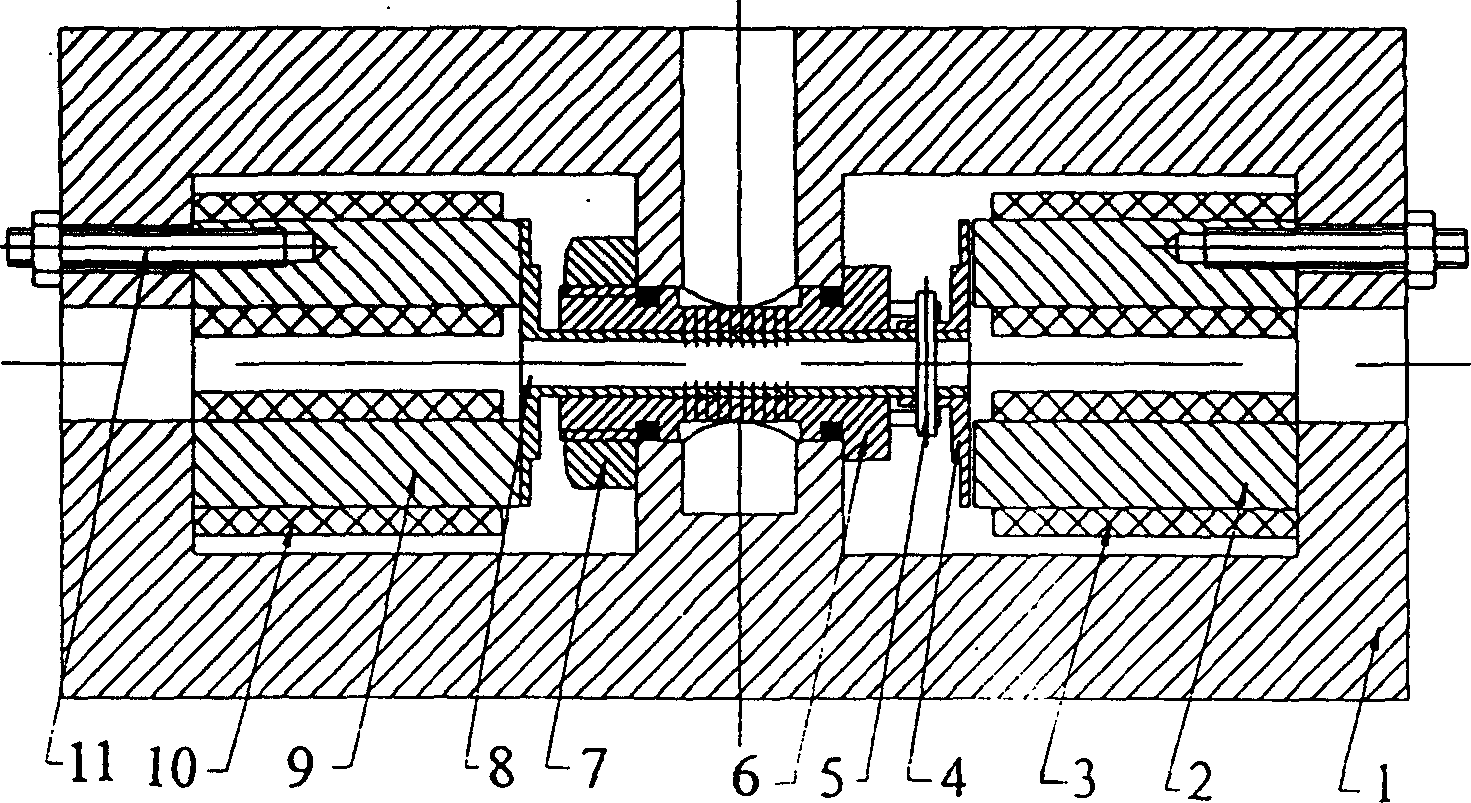

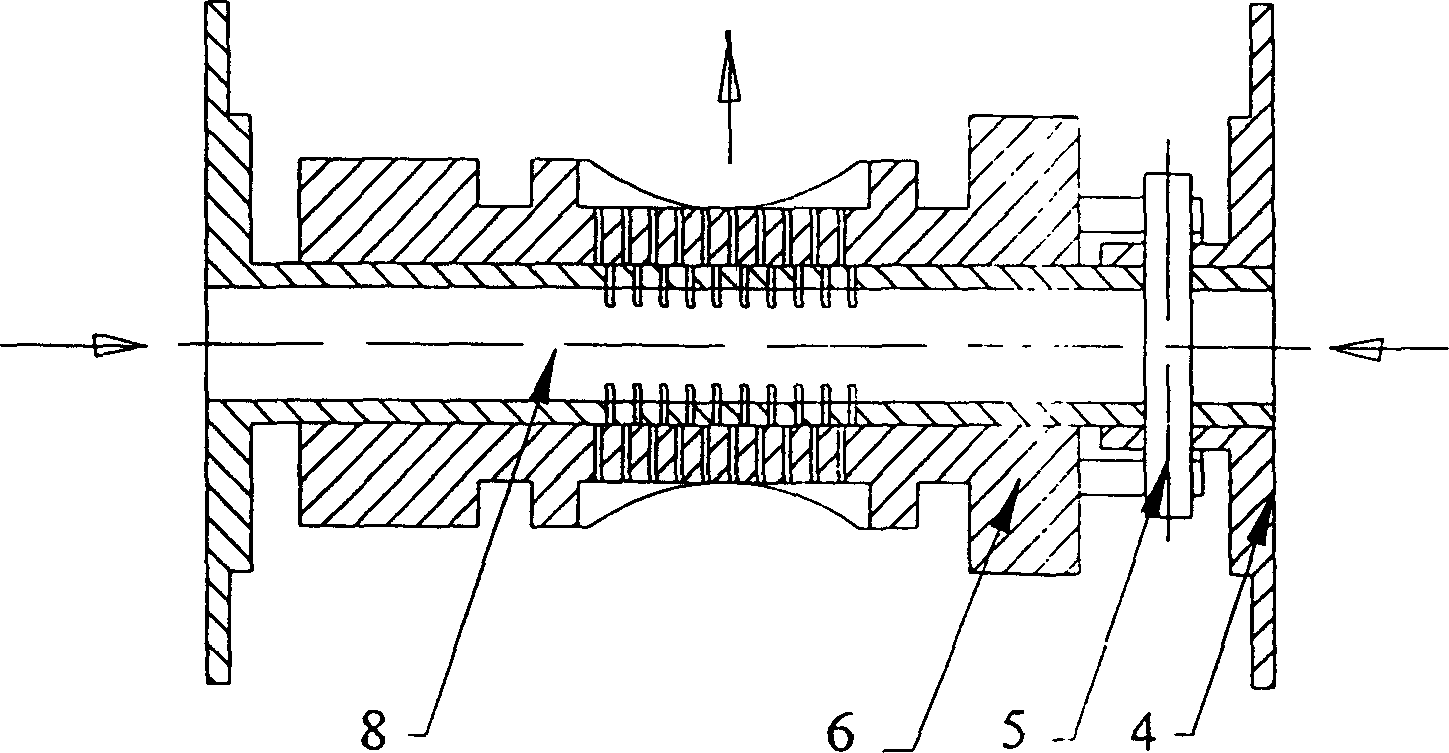

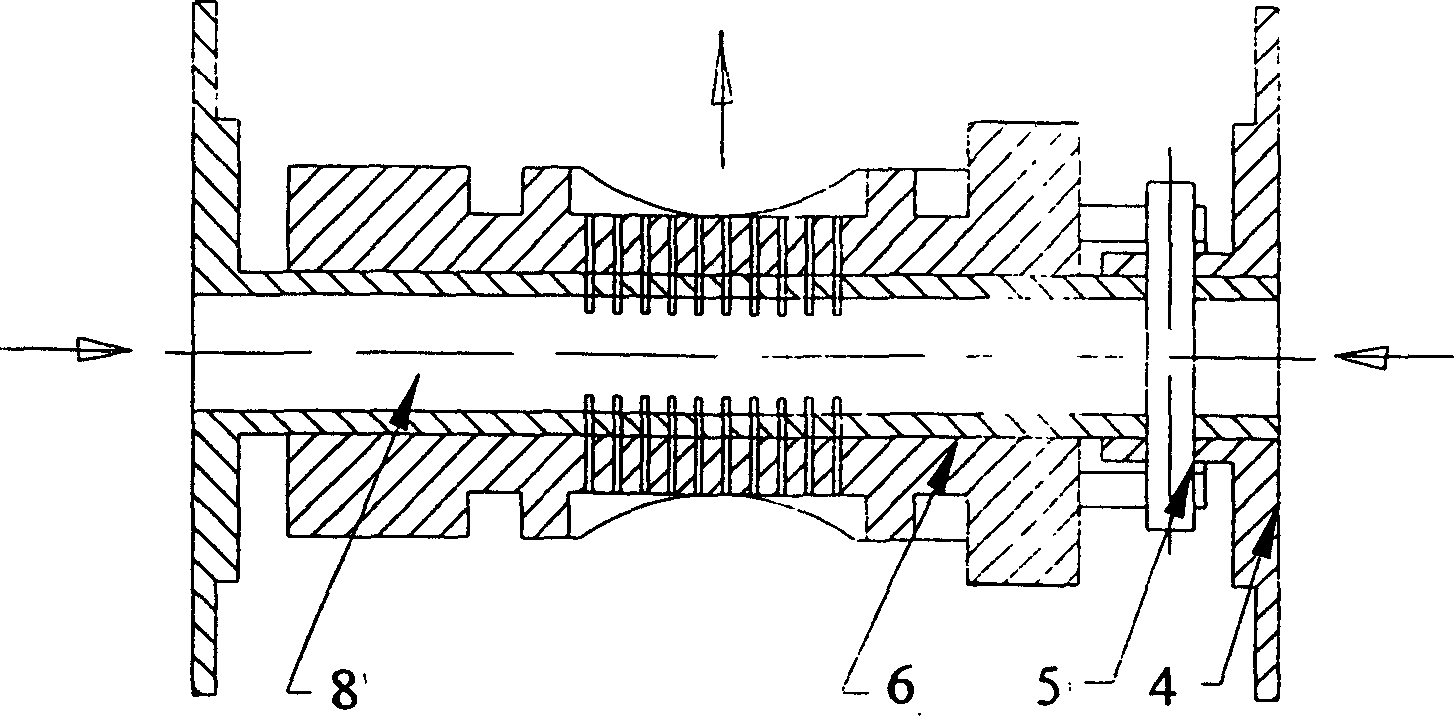

[0010] Such as figure 1 As shown, two snap-fit electromagnets are symmetrically installed in the valve body 1 cavity at both ends of the hollow valve core 8, and the two snap-fit electromagnets are respectively fixed with connecting screws 11 installed on the valve body, and the valve core 8 is covered with a valve Sleeve 6, valve sleeve 6 is fixed between the two cavities of valve body 1 with fastening screw 7, one end of spool 8 can be clutched with the clapping type electromagnet at one end, and the other end of spool 8 is equipped with magnetic pole 4, with a pin 5 is connected with the spool 8 as a whole, and the magnetic pole 4 can be clutched with the snap-on electromagnet at the other end; the mating surfaces of the spool 8 and the valve sleeve 6 are respectively opened with the same number, the same width, and the same distance between non-circumferential gaps. The valve port is connected with the oil outlet of valve body 1.

[0011] The working principle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com