A single-side plate type three-position four-way rotary valve with adjustable flow

A three-position, four-way, single-side plate technology, applied in the field of high-frequency hydraulic valves, can solve the problems of unbalanced radial force of the rotary valve, large operating force of the rotary valve core, poor sealing performance, etc., and achieve flow adjustment, reduction The effect of small hydraulic power and increased action frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

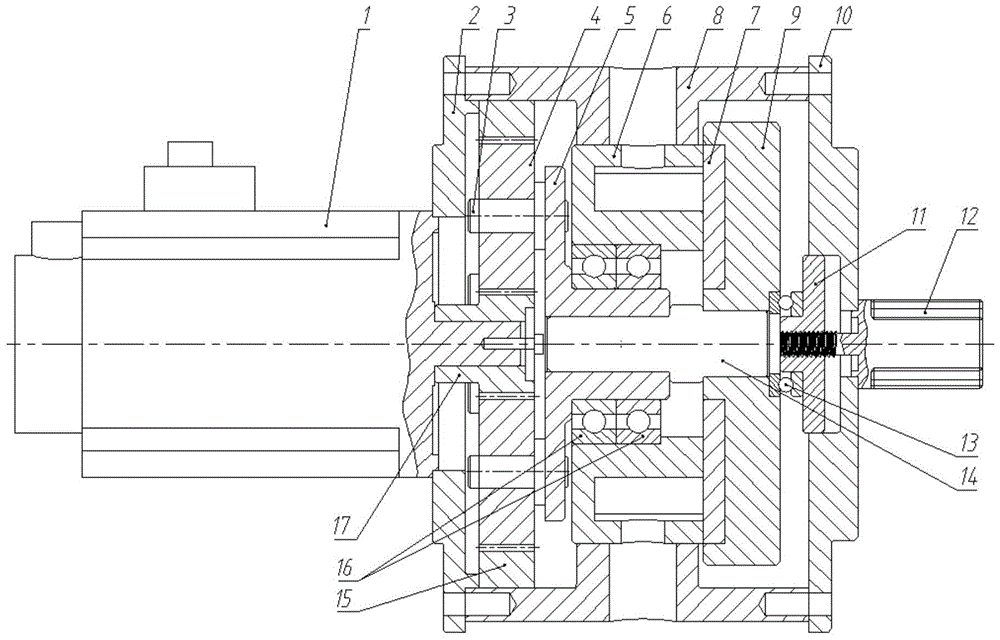

[0015] Such as figure 1 As shown, a flow-adjustable unilateral plate type three-position four-way rotary valve includes a drive motor 1, the output shaft of the drive motor 1 is connected to the center wheel 12 of the planetary gear reducer through a key and the gland, and the planetary gear reducer It is formed by connecting the small center wheel 17, the large center wheel 15 and the planetary gear 4. One end of the drive shaft 14 is connected to the arm sleeve 5 through a spline, and the arm sleeve 5 passes through the pin shaft 3 and the planet of the planetary gear reducer. The planetary gear 4 of the planetary gear reducer drives the rotating arm sleeve 5 and then drives the driving shaft 14 to rotate. The valve core 6 is cylindrical and has a hole in the center. The groove ball bearing 16 cooperates, and the other end is fitted together with the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com