A direct-acting overflow valve of the oil supply system of transmission device

A technology of direct-acting relief valve and oil supply system, which is applied to cocks, valve devices, safety valves and other directions including cut-off devices, which can solve the problems of constant pressure instability, constant pressure instability and poor adjustment performance of the relief valve. problems, to achieve the effect of high constant pressure accuracy, more stable constant pressure and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

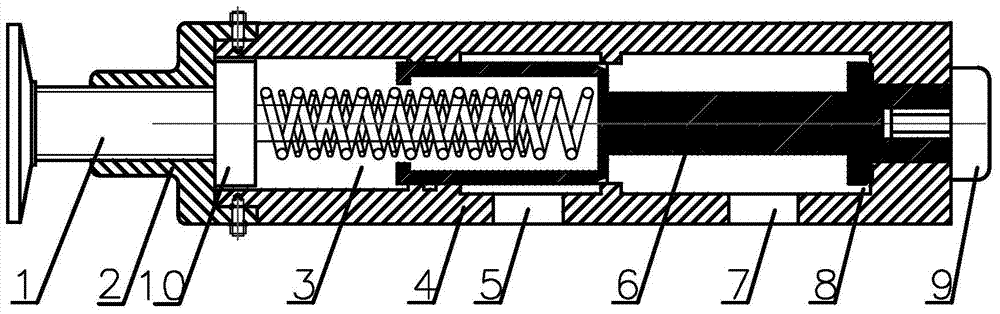

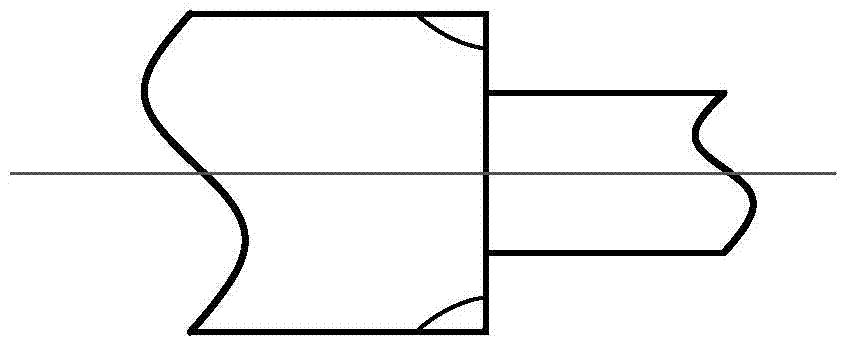

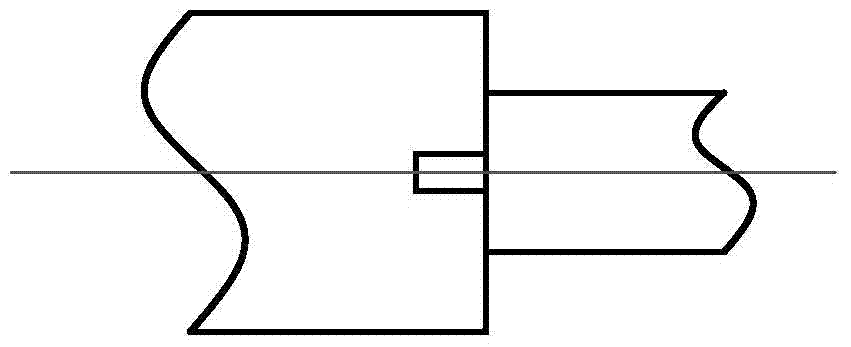

[0028] The present invention will be further described below in conjunction with the accompanying drawings. Such as Figure 1-5 As shown, a direct-acting relief valve includes a pressure regulating rod 1, a sealing cover 2, a pressure regulating spring group 3, a valve body 4, an oil outlet 5, a valve core 6, an oil inlet 7, a damping hole 8, Handwheel 9 and T-shaped guide bar 10.

[0029] The valve body 4 is a cuboid, and its bottom surface is provided with an oil inlet 7 and an oil outlet 5; the pressure regulating rod 1 passes through the sealing cover 2 and leans against the T-shaped guide rod 10, and the T-shaped guide can be adjusted by rotating the pressure regulating rod 1. The position of the rod 10 is used to adjust the preload of the pressure regulating spring group 3. The spool 6 is the core of the relief valve. There is a throttling groove on the shoulder of the spool 6, and the throttling groove is symmetrically arranged on the spool 6. On the shoulder of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com