Interaxial permanent magnet coupling mechanism

A permanent magnetic coupling and inter-shaft technology, which is applied in the direction of electromechanical devices, electromechanical transmission devices, electrical components, etc., can solve the problems of shortening the life of equipment, poor stability of electronic devices, and difficulty in accurately ensuring the alignment of two axes, so as to reduce equipment Accuracy requirements, realization of soft start function, and effect of reducing installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

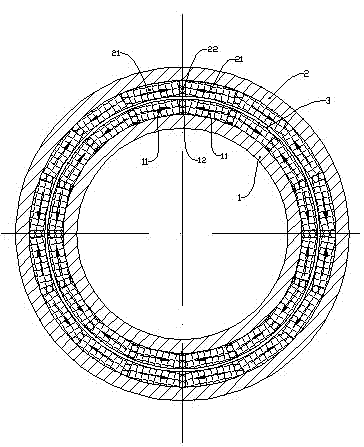

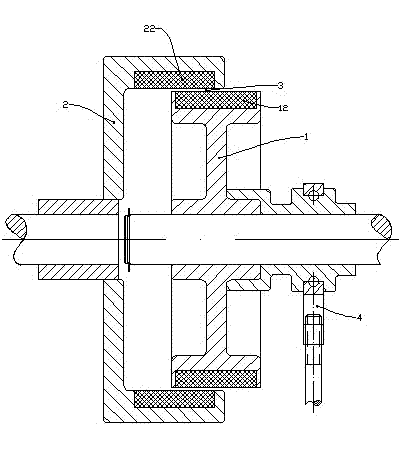

[0013] As shown in the figure, the inter-shaft permanent magnet coupling mechanism includes an inner permanent magnet rotor 1 and an outer permanent magnet rotor 2 arranged coaxially. The outer permanent magnet rotor 2 is in the shape of a cylinder, and the inner permanent magnet rotor 1 is located 2 In the inner cavity, permanent magnets are distributed on the inner permanent magnet rotor 1 and the outer permanent magnet rotor 2, and there is an air gap 3 between the inner permanent magnet rotor 1 and the outer permanent magnet rotor 2. A plurality of inner permanent magnets 11 on the inner permanent magnet rotor 1 are distributed along the circumference, and inner permanent magnets 12 made of magnetically permeable materials are arranged between adjacent inner permanent magnets 11; the magnetic pole directions of the inner permanent magnets 11 ( That is, the connecting direction of the S pole and the N pole) is located in the circumferential direction of the inner permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com