A kind of rare earth permanent magnet transmission clutch

A rare-earth permanent magnet and clutch technology, applied in the field of clutches, can solve problems such as vibration noise, friction loss, and reduced sealing performance, and achieve the effects of simple structure, no need for lubrication, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

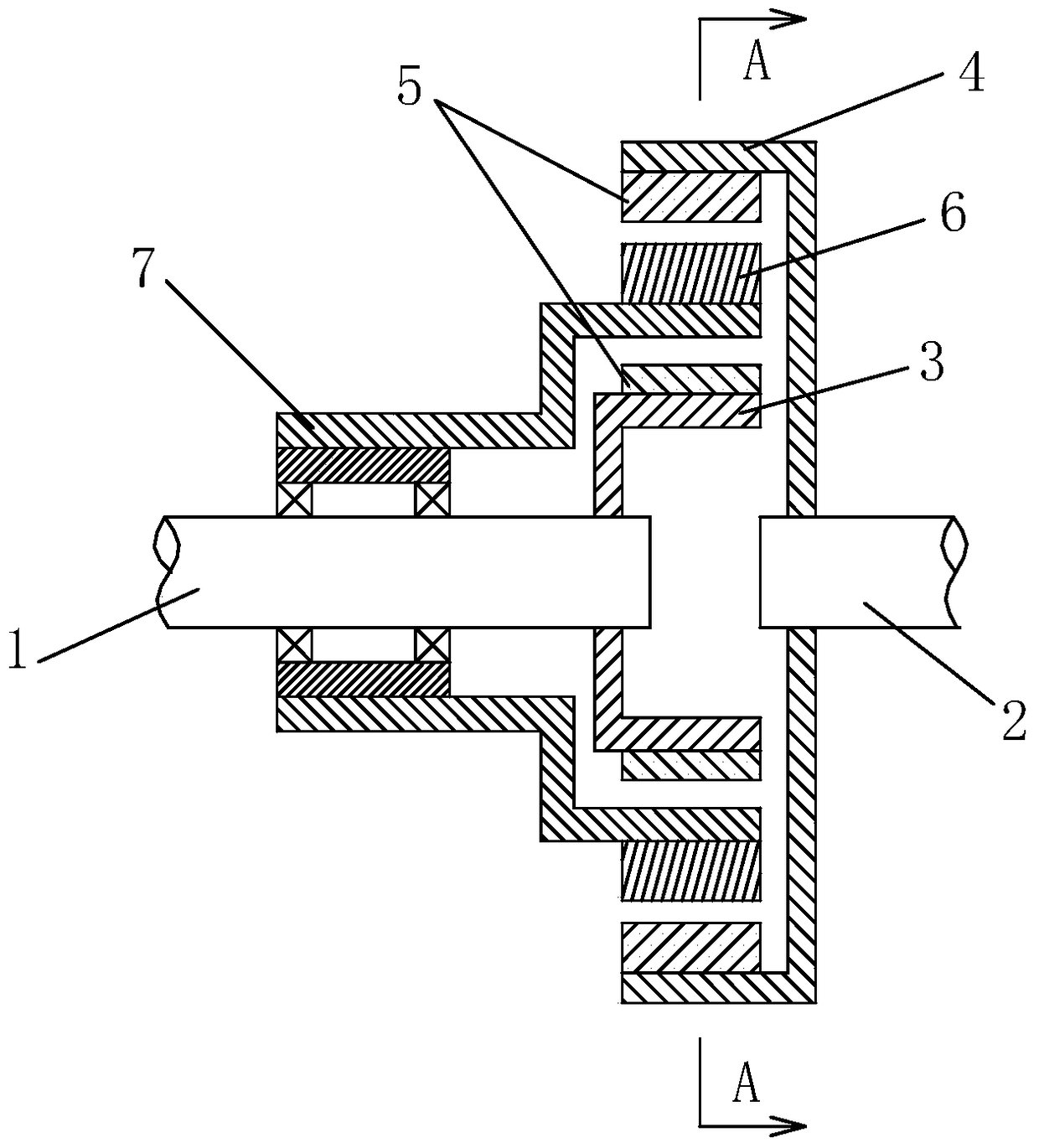

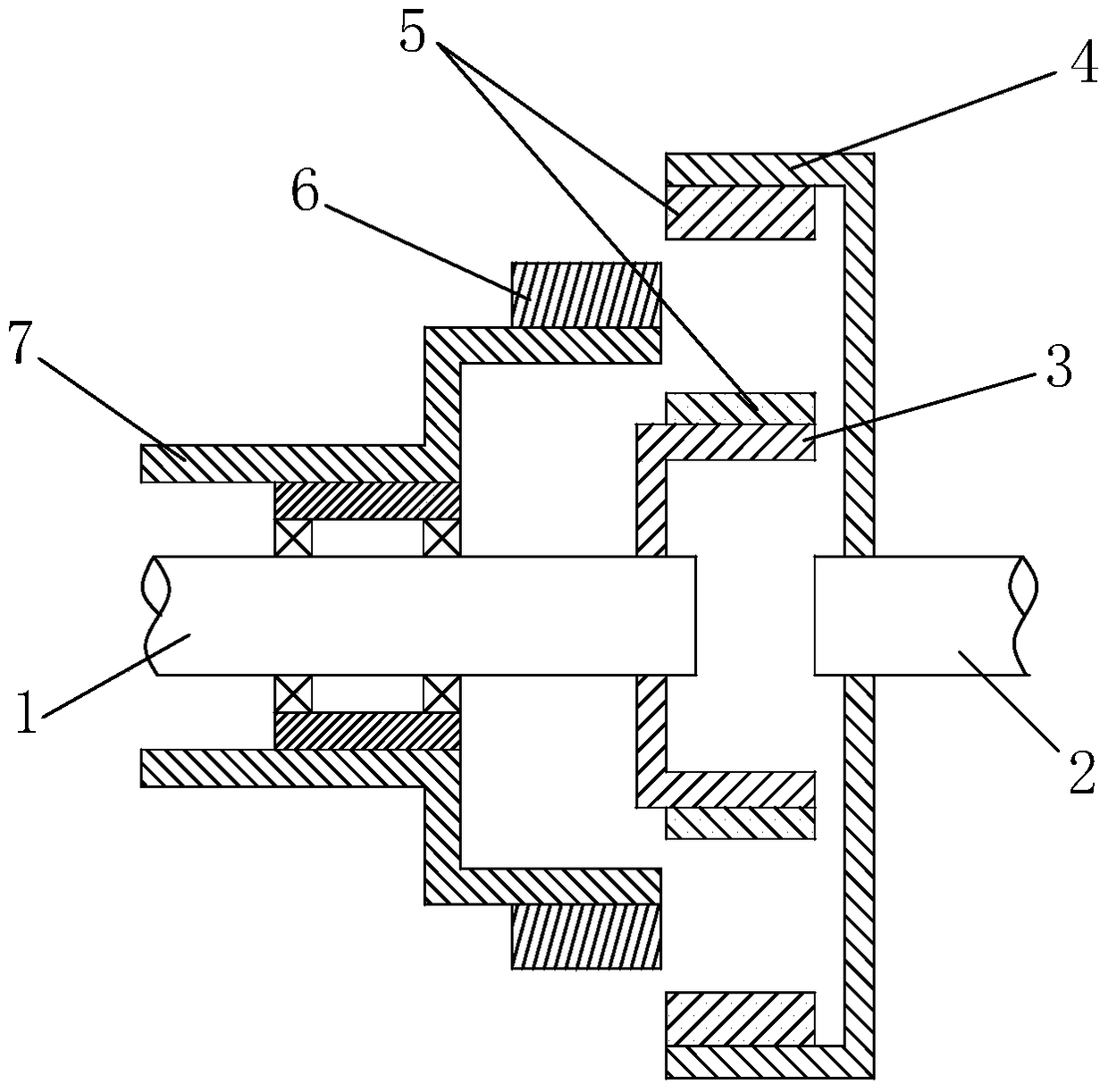

[0019] see figure 1 and Figure 5 As shown, a rare earth permanent magnet transmission clutch includes a first shaft body 1 and a second shaft body 2, the shaft end of the first shaft body 1 is equipped with an inner magnetic rotor 3 that rotates synchronously with the first shaft body 1, The shaft end of the second shaft body 2 and the position corresponding to the inner magnetic rotor 3 are installed with an outer magnetic rotor 4 that rotates synchronously with the second shaft body 2, and permanent magnets 5 are distributed on the outer wall of the inner magnetic rotor 3. The N-level and S-level magnets are arranged alternately, and the permanent magnets 5 are also distributed on the inner wall of the outer magnetic rotor 4, and the N-level and S-level permanent magnets are also arranged alternately. The outer magnetic rotor 4 and the inner magnetic rotor 3 are sleeved with The modulation ring 6, the modulation ring 6 is composed of magnetic modulation materials distribut...

Embodiment 2

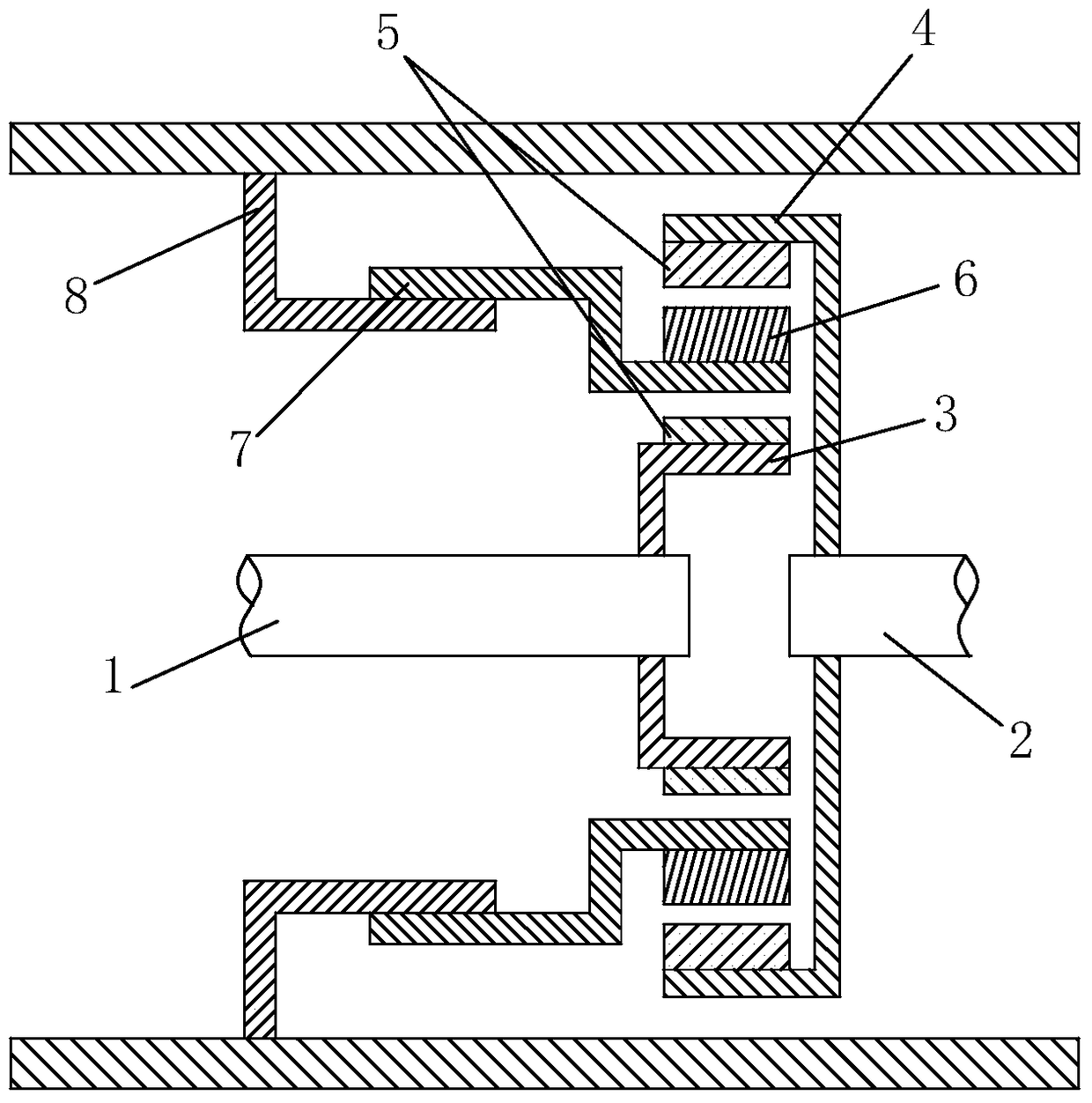

[0022] see image 3 As shown, a rare earth permanent magnet transmission clutch includes a first shaft body 1 and a second shaft body 2, the shaft end of the first shaft body 1 is equipped with an inner magnetic rotor 3 that rotates synchronously with the first shaft body 1, The shaft end of the second shaft body 2 and the position corresponding to the inner magnetic rotor 3 are installed with an outer magnetic rotor 4 that rotates synchronously with the second shaft body 2, and permanent magnets 5 are distributed on the outer wall of the inner magnetic rotor 3. The N-level and S-level magnets are arranged alternately, and the permanent magnets 5 are also distributed on the inner wall of the outer magnetic rotor 4, and the N-level and S-level permanent magnets are also arranged alternately. The outer magnetic rotor 4 and the inner magnetic rotor 3 are sleeved with The modulation ring 6, the modulation ring 6 is composed of magnetic modulation materials distributed at intervals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com