A dual-channel thousand-liter high-flow reversing valve

A large-flow, dual-channel technology, applied in mining equipment, earthwork drilling, pillars/supports, etc., can solve the problem that the reversing valve is not suitable for high-pressure, thousand-up and large-flow conditions, and achieve small hydraulic power and flexible and reliable movements , the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

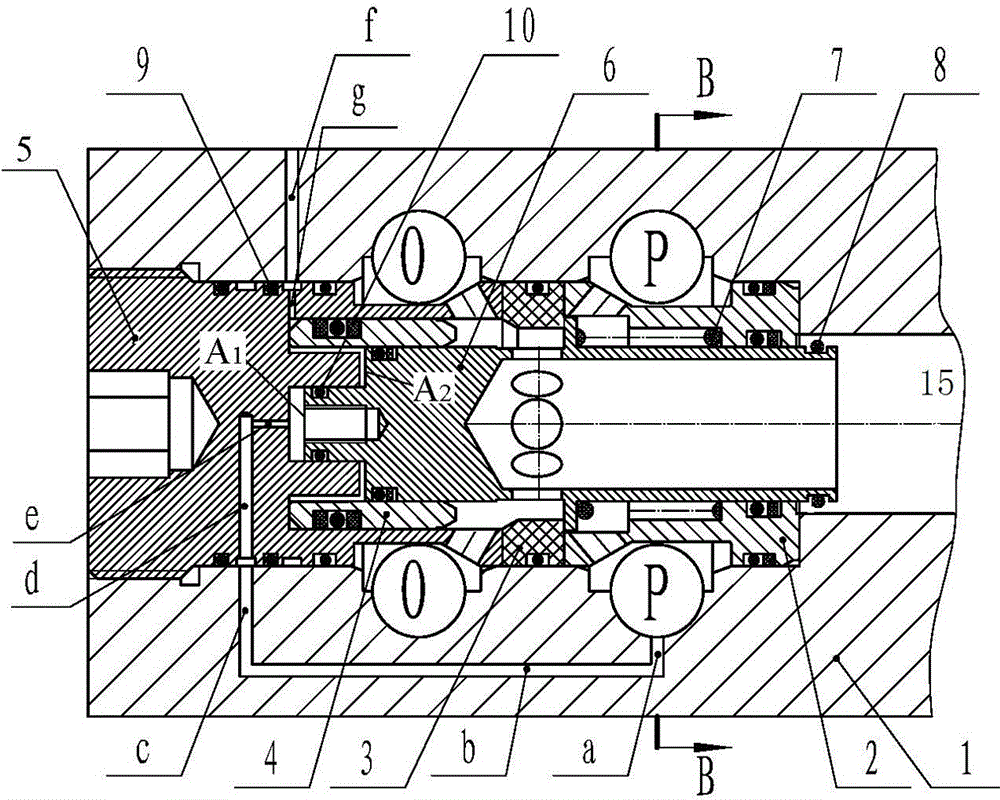

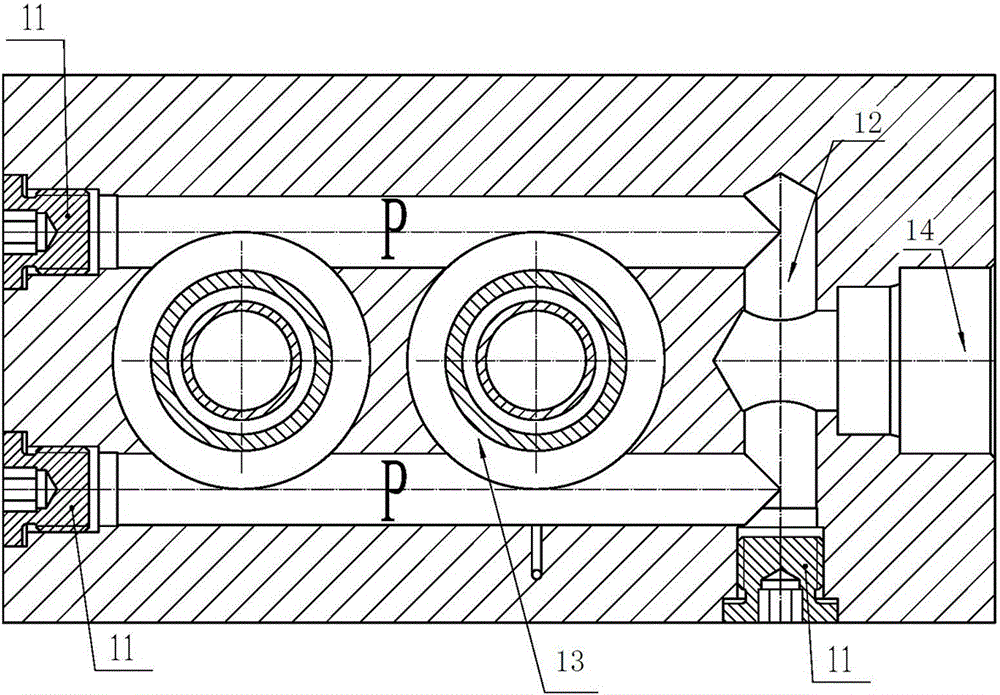

[0015] Such as figure 1 , a double-channel thousand-upgrade high-flow reversing valve, including a valve body 1, a liquid inlet valve sleeve 2, a valve seat 3, a liquid return valve core 4, a liquid return valve sleeve 5, a liquid intake valve core 6, and a return spring 7 , metal retaining ring 8, sealing ring 9,10, screw plug 11. Inside the valve body, there is a double-sided symmetrical liquid supply main channel P that supplies liquid to the valve core. Symmetrical liquid return channel O, one end of the two-sided liquid return channel communicates through the auxiliary flow channel. Symmetrical dual channels reduce the radial unbalanced force of the spool and solve the problem of reversing hysteresis and deflection wear of large flow reversing valves.

[0016] The valve sleeve includes a liquid inlet valve sleeve 2 and a liquid return valve sleeve 5. The valve core includes a liquid inlet valve core 6 and a liquid return valve core 4. The liquid inlet valve core 6 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com