Automatic pneumatic saw web replacing device

An automatic and saw blade technology, which is applied in the manufacture of sawing machine tools, metal sawing equipment, metal processing equipment, etc., can solve problems such as poor processing accuracy, affecting the quality of saw blade processing, and saw blade positioning errors, etc., to achieve structural Compact and reasonable, shorten the replacement time, good processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings and specific embodiments.

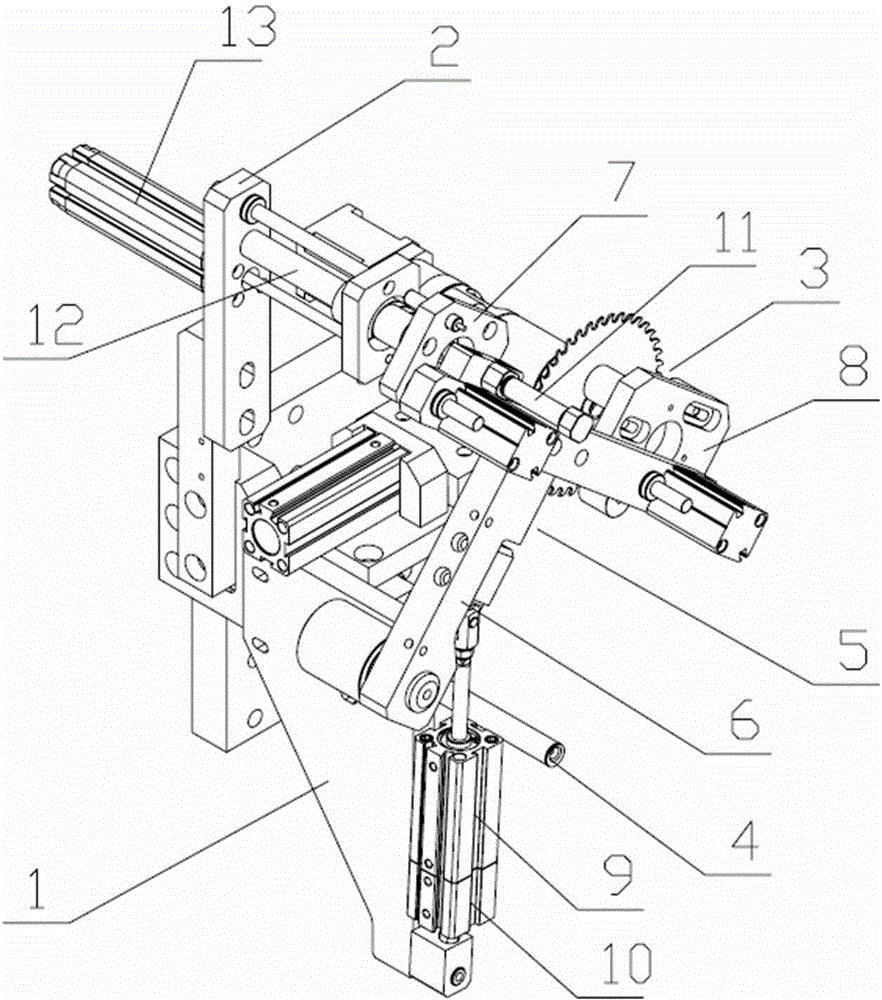

[0016] Such as figure 1 The present invention shown includes a frame 1. The frame 1 is provided with a base pushing mechanism 2, a saw blade rotating mechanism 3, and a finished product hanging rod 4; the frame 1 is also equipped with a swing arm mechanism 5, so The swing arm mechanism 5 includes a swing arm 6, one end of the swing arm 6 is connected to the frame 1 through a rotating shaft, and a first suction cup 7 and a second suction cup 8 are respectively mounted on the other end of the swing arm 6; When the swing arm mechanism 5 swings to one side, the first suction cup 7 corresponds to the position of the film base pushing mechanism 2, and the second suction cup 8 corresponds to the saw blade rotation mechanism 3. Corresponding to the position; when the swing arm mechanism 5 swings to the other side, the first suction cup 7 corresponds to the position o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com