Soft touch switch press fitting device

A soft-touch switch, press-fit device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to control the installation height of screws on both sides, unreliable work, low efficiency, etc., to save product replacement Time, reduce labor intensity, quick replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

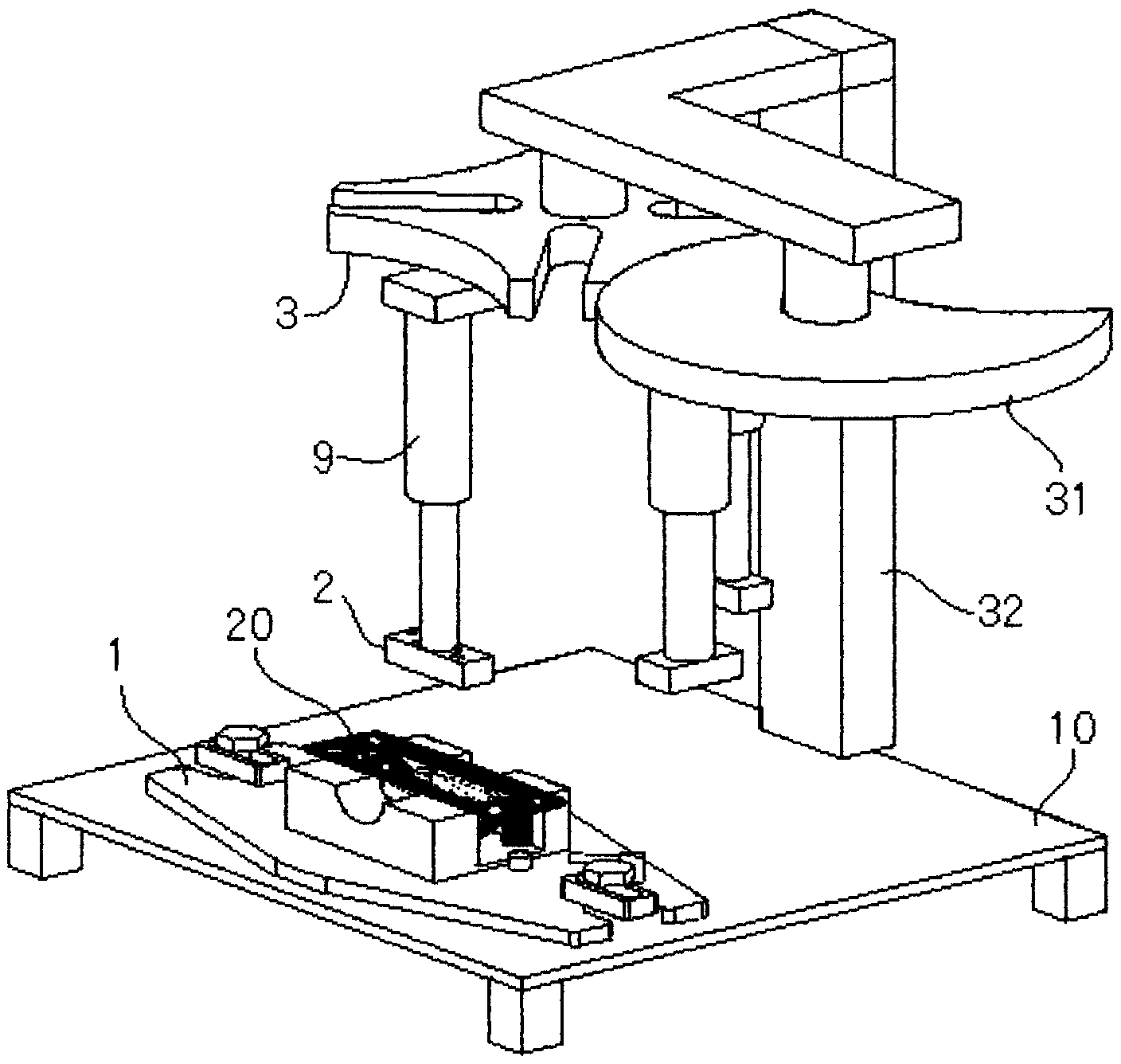

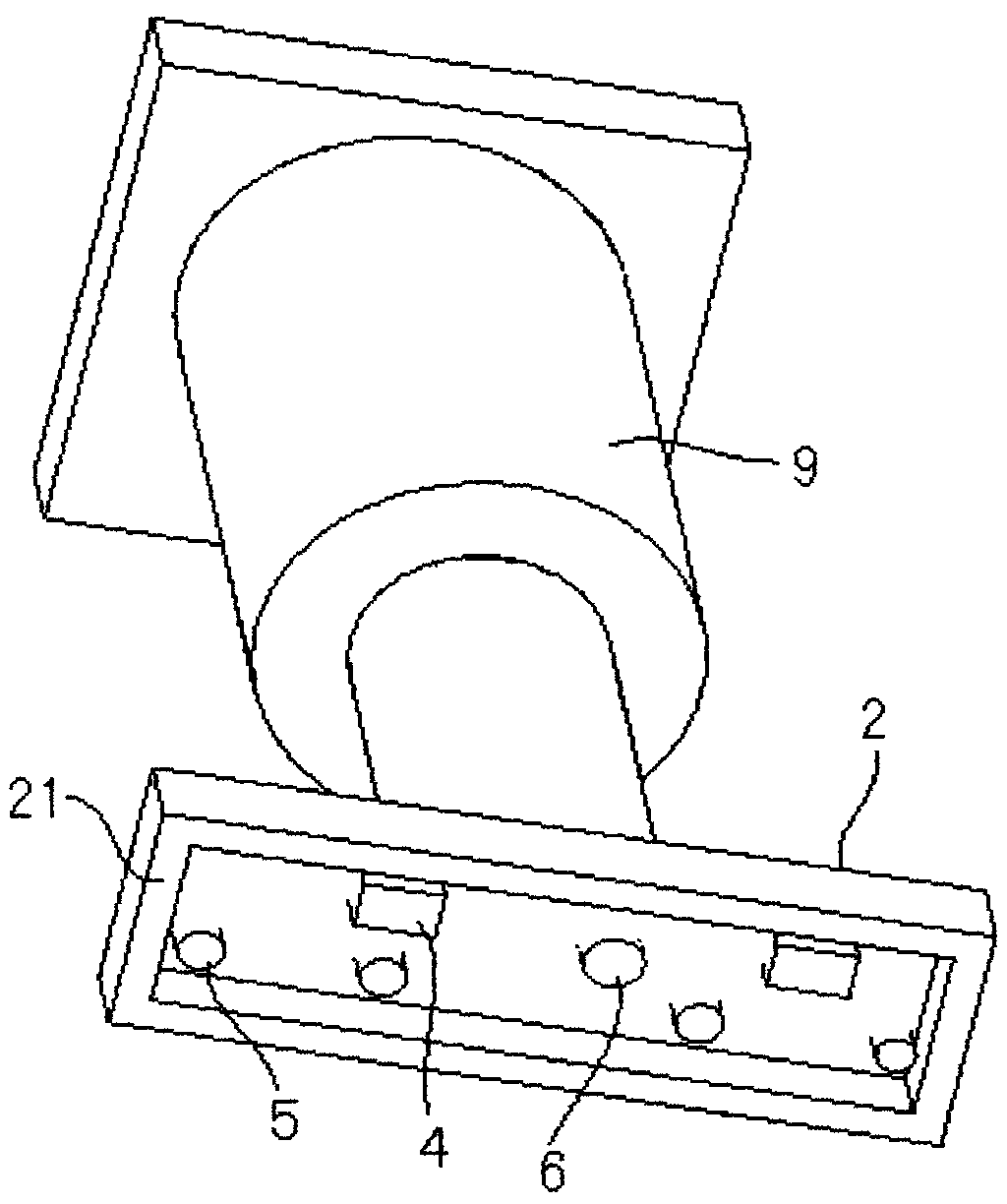

[0019] refer to figure 1 As shown, a press-fitting device for a soft-touch switch includes a working surface 10 , on which a replaceable jig 1 is connected, and the jig 1 is used to fix the housing 20 of the soft-touch switch.

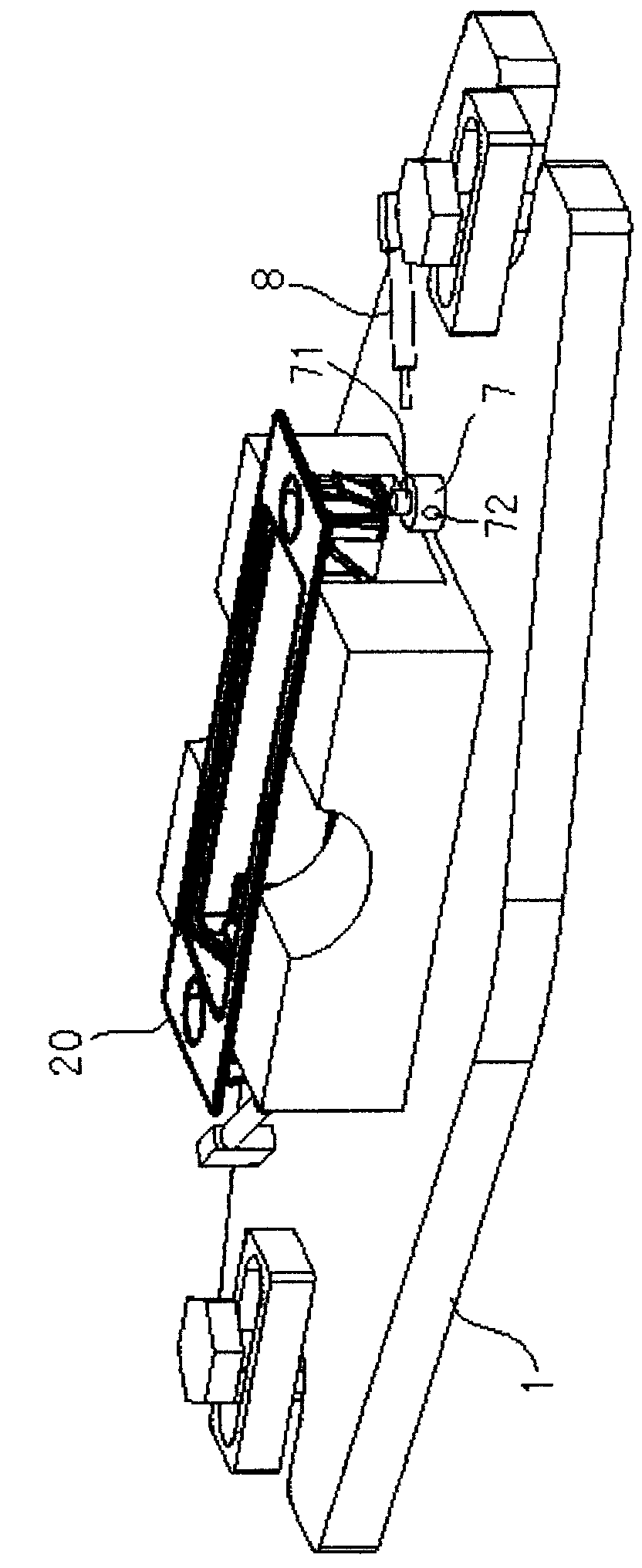

[0020] refer to figure 2 As shown, the two sides of the soft touch switch housing 20 are provided with a screw limiting device 7, the screw limiting device 7 includes an adjustable limiting block 71 and a locking screw 72, and one side of the screw limiting device 7 is provided with a useful To detect the linear displacement sensor 8 of the screw installation situation.

[0021] refer to figure 1 As shown, a sheave mechanism 3 is provided above the soft touch switch housing 20, and the sheave mechanism 3 cooperates with an arc-shaped locking dial 31 to realize rotation and transposition. The compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com