Electric control hydraulic reversing method, electric control hydraulic reversing system and engineering machinery

An electronically controlled hydraulic and reversing system technology, which is applied in the field of construction machinery, can solve the problems of gearbox parts damage, long time consumption, and large shifting strokes, so as to reduce shifting impact, simplify operation difficulty, and avoid coordination errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

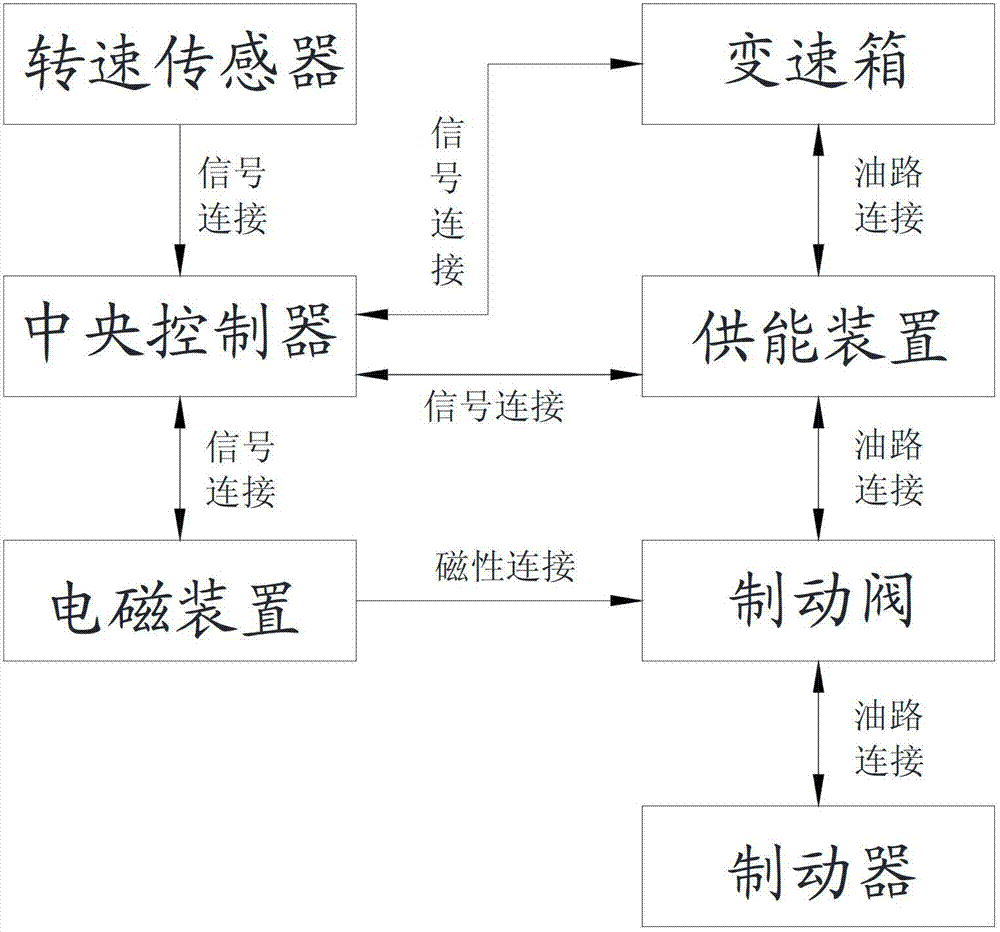

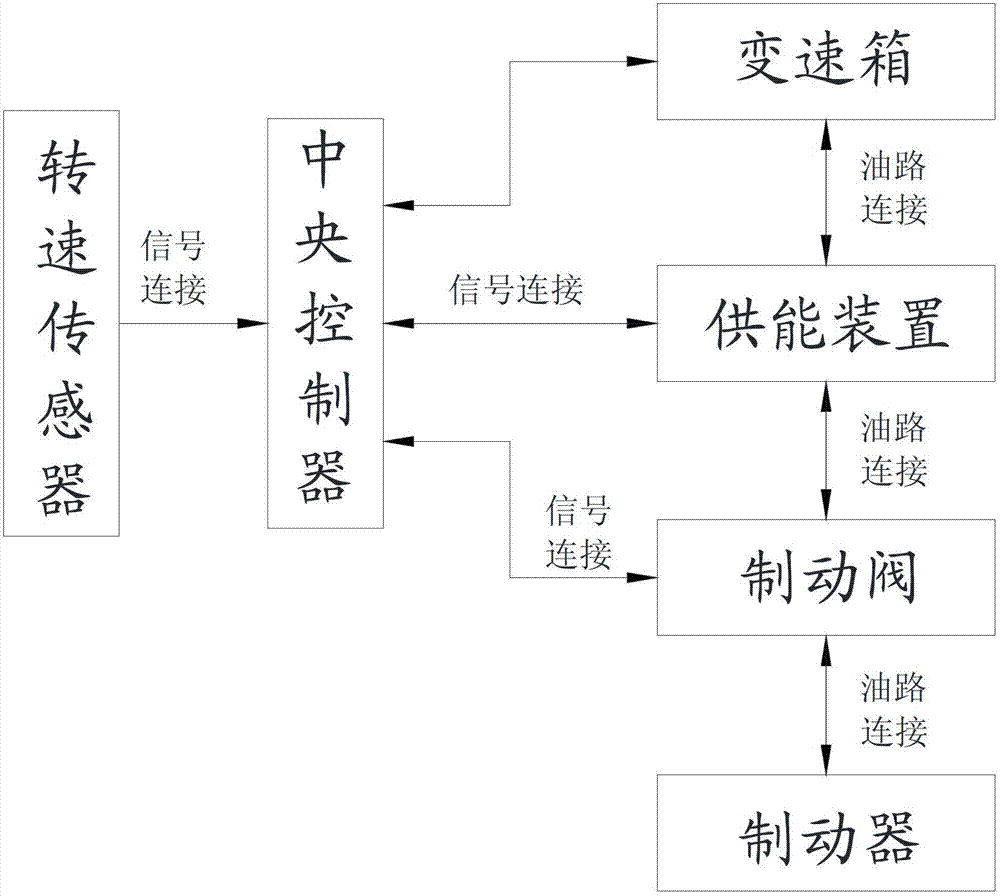

[0023] In the electronically controlled hydraulic reversing method described in the embodiment of the present invention, when the central controller receives the reversing command, it first controls the gearbox to perform a neutral action, and at the same time controls the brake valve to make the brake start to perform a braking action. When the speed sensor monitors in real time that the vehicle speed drops to the shifting condition, the central controller controls the brake valve to release the brake, and then controls the gearbox to perform the shifting and shifting action. In this way, the brake deceleration action, neutral gear action, and shifting and reversing action after deceleration can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com