Coil winding machine of coreless motor

A winding machine and hollow cup technology, which is applied in the field of winding machines, can solve problems such as inappropriate wire arrangement methods, low production efficiency, and long production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

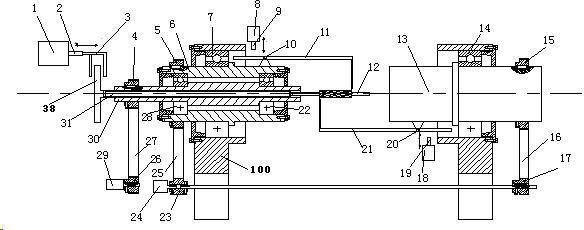

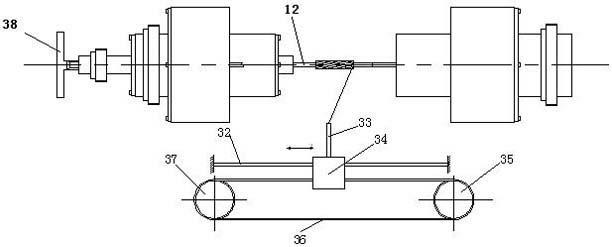

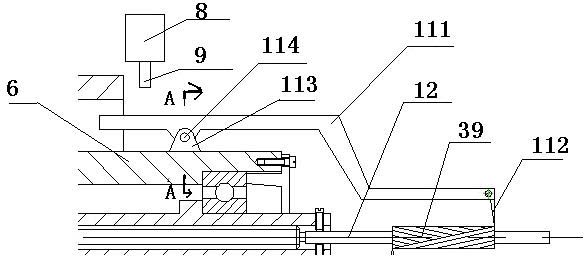

[0022] like figure 1 As shown, the present invention provides a coreless motor coil winding machine with high precision of wire arranging, completes the wire arranging action at the same time of winding, and coherent unwinding action, which includes a frame 100 and a machine mounted on the frame 100 Winding mechanism, wire feeding mechanism and wire withdrawing mechanism.

[0023] In this embodiment, the winding mechanism includes a first cable arrangement 11, a second cable arrangement 21, a first rotating sleeve 6, a rotating sleeve 13, and a second rotating sleeve 30 arranged in the first rotating sleeve 6. , the first power device that drives the rotation of the first rotating sleeve 6 and the operation of the rotating cylinder 13, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com