Cable dividing mechanism convenient for feeding of flexible flat cables

A flexible wire arrangement and feeding technology, applied in metal processing and other directions, can solve problems such as affecting processing, long wire installation time, and wrong wire routing, and achieve the effects of improving processing quality, fast wire installation, and avoiding wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

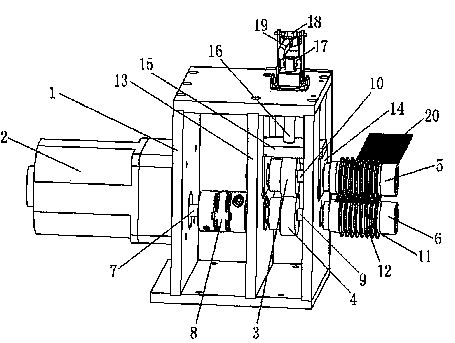

[0014] Such as figure 1 As shown, a branching mechanism for flexible cable feeding, including bracket 1, motor 2, upper gear 3, lower gear 4, upper die 5, lower die 6, fixed plate 13, sliding plate 14, connecting Plate 15, moving shaft 16, connecting arm 17, bearing pin 18 and handle 19, motor 2 is provided with on support 1 side, is provided with two parallel fixed plates 13 in support 1, and described lower rotating shaft 9 passes through two Fixed plate 13, and lower gear 4 and lower die 6 are sleeved on lower rotating shaft 9, lower gear 4 is arranged between two fixed plates 13, lower die 6 is arranged on the outside of fixed plate 13, motor 2 output shaft 7 is connected with the lower rotating shaft 9 through a coupling 8,

[0015] Be provided with the opening that is used to place sliding plate 14 on every fixed plate 13 tops, described upper rotating shaft 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com