Single-sided and double-sided dual-purpose connecting line face-to-face printing offset press and printing method thereof

A printing method and technology of offset printing machine, applied in printing, printing machine, rotary printing machine, etc., can solve the problem of double-sided printing machine that does not have the function of front and back wiring of graphics and text, cannot be used as anti-counterfeiting, and printing accuracy error, etc. problem, to achieve the effect of simple structure, high versatility and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

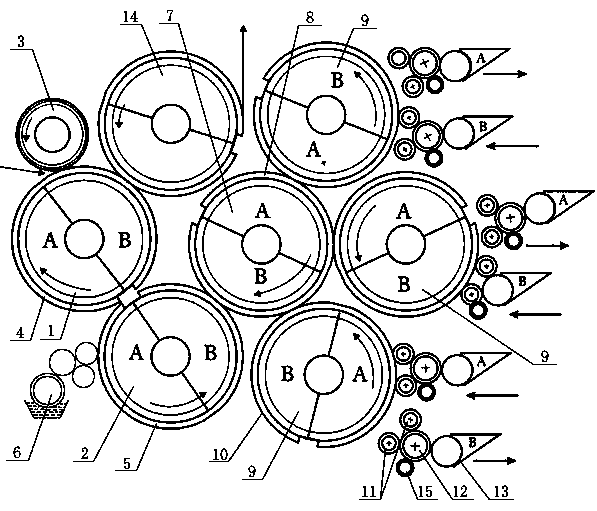

[0057] Embodiment 1: A printing method for a single- and double-sided dual-purpose wiring offset printing machine, including the following printing steps:

[0058] a) Continuously feed the sheet between the embossing / transfer cylinder and the rubber cylinder;

[0059] b) When the single-sided printing function is used, the paper is full-width, and when the paper passes between the embossing / transfer cylinder and the rubber cylinder, the rubber cylinder prints the graphic on it onto one side of the full-width paper, completing one-sided print.

[0060] Wherein, the color stencil of the color mold cylinder is a single-plate two-unit structure, and the diameter of the color mold cylinder after covering the color stencil is equal to that of the color collection cylinder after covering the color collection rubber, and the color stencil on it is the same as the collection The imprint size of the color rubber is equal, and the color stencil of the color mold cylinder accepts the ink...

Embodiment 2

[0062] Embodiment 2: A printing method for a single- and double-sided dual-purpose wiring offset printing machine, including the following printing steps:

[0063] a) Continuously feed the sheet between the embossing / transfer cylinder and the rubber cylinder;

[0064]b) When the double-sided printing function is used, the paper is half-width, and the pattern of a printing unit on the rubber cylinder is transferred to the embossing / transfer cylinder in the paperless state, and then the half-width paper is transferred from the embossing / transfer Pass between the printing cylinder and the rubber cylinder, the rubber cylinder prints the graphics on one side of the half-width paper, and the embossing / transfer cylinder prints the graphics on it onto the other side of the half-width paper to complete double-sided printing .

[0065] Wherein, the printing rubber on the rubber cylinder is a single rubber two-unit structure, and the diameter ratio of the embossing / transfer cylinder to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com