Novel winding machine

A winding machine, a new type of technology, applied in the field of winding machines with servo winding and torque motor winding, it can solve problems such as complicated procedures, mismatch between winding speed and winding speed, difficult adjustment of winding pitch, etc. Achieve the effects of convenient adjustment, reduced product bumps, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and specific embodiments.

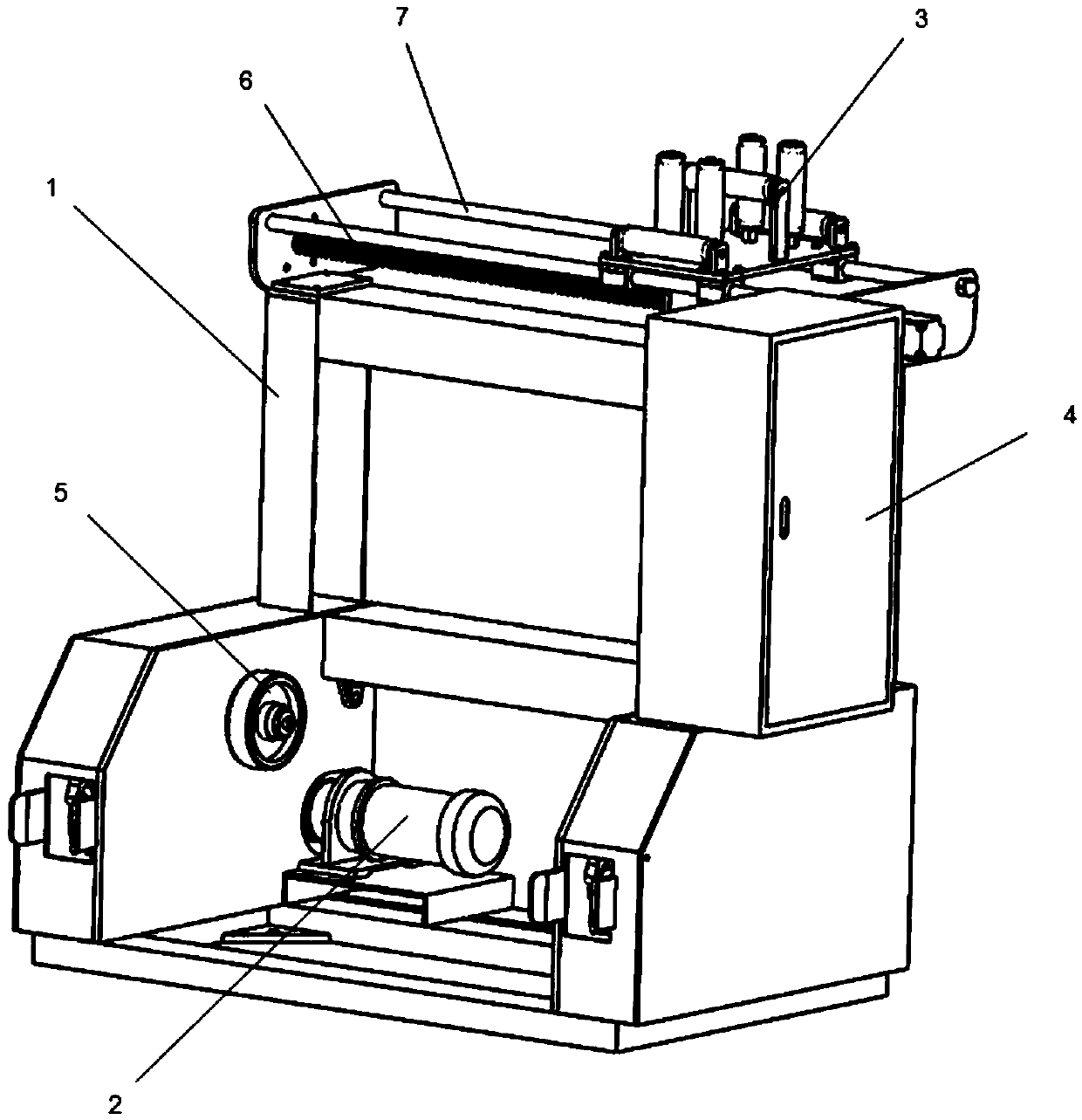

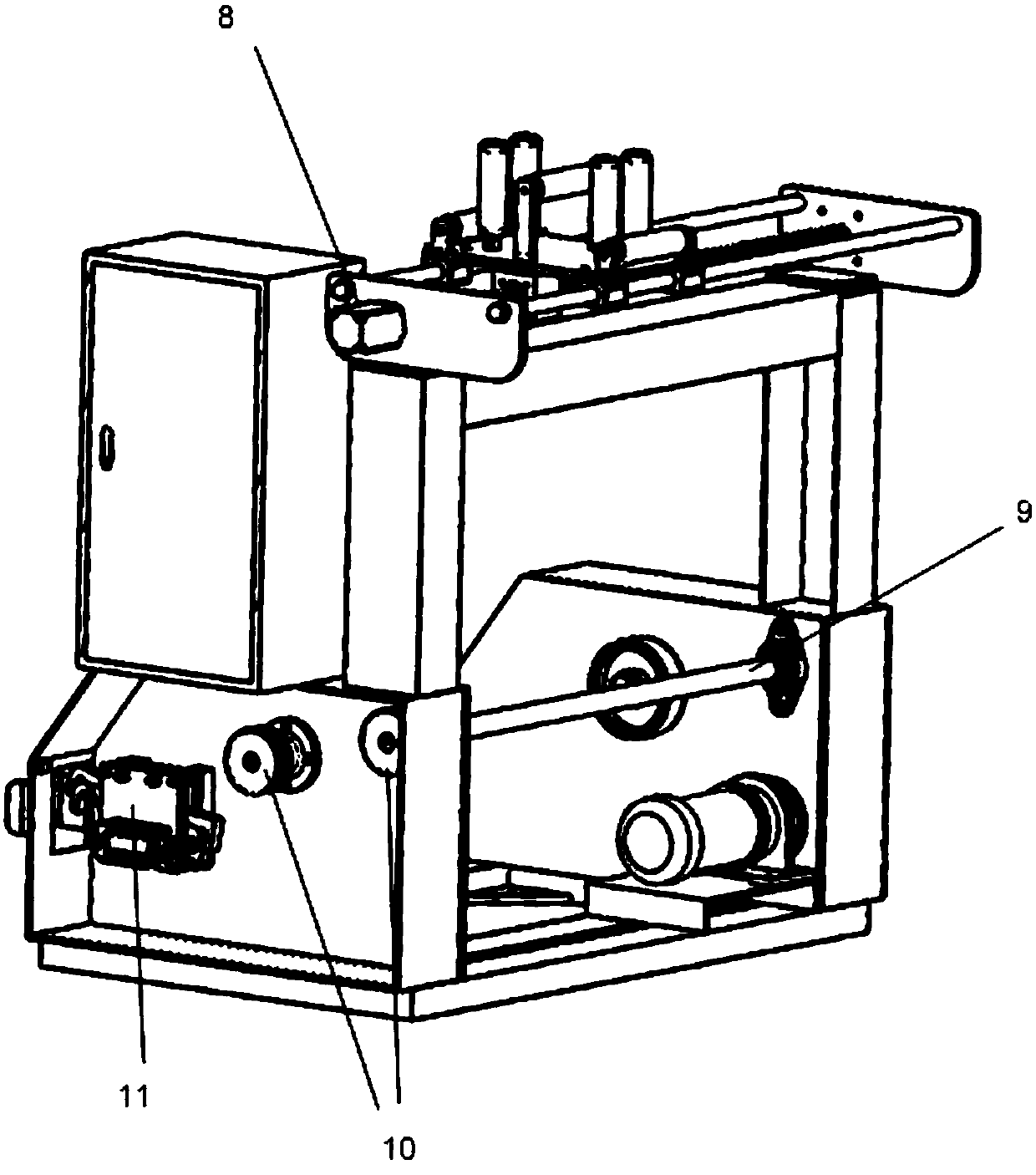

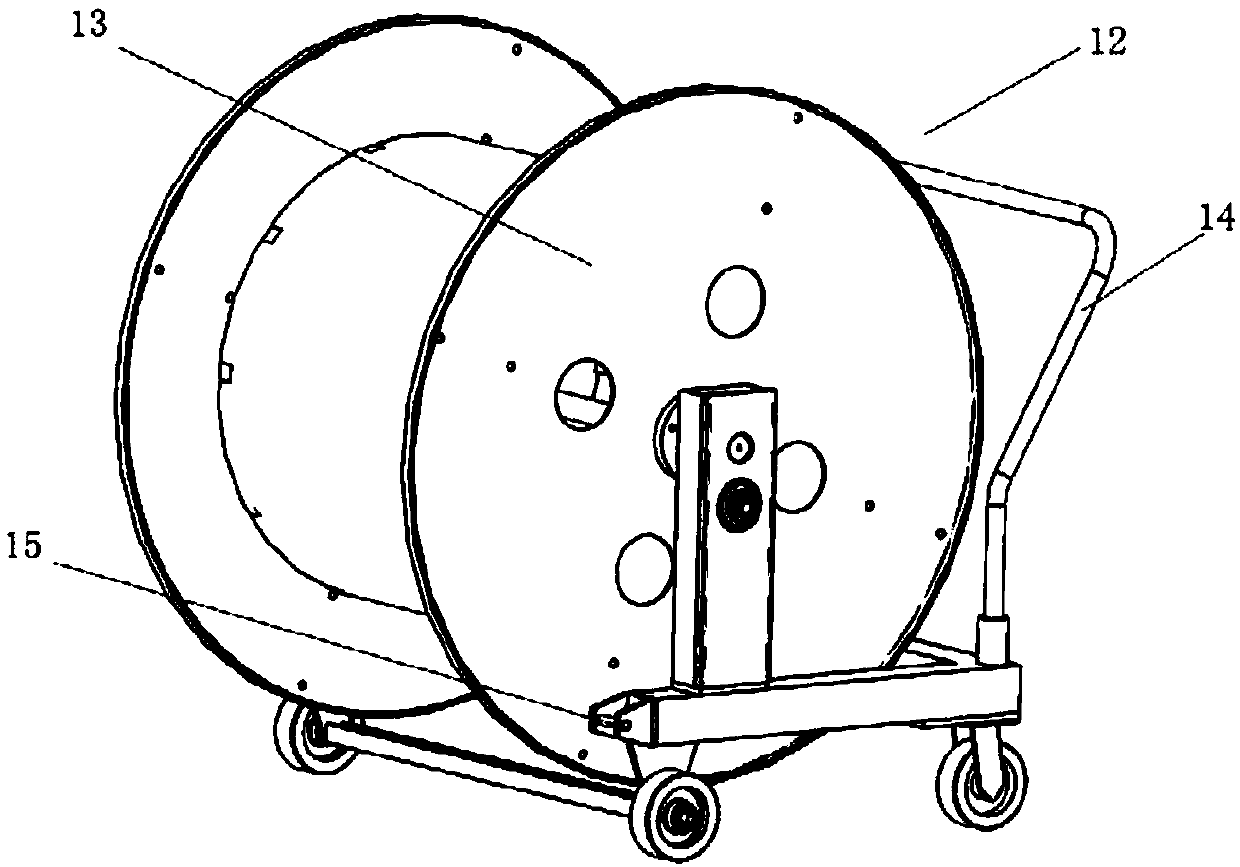

[0019] Such as Figure 1 to 3 As shown, a new type of winder includes a frame 1 and an electric box 4, and also includes a cable pitch adjustment mechanism located above the frame 1, a hub drive mechanism located below the frame 1, and located in front of the frame 1. The small wheel hub 12; the cable pitch adjustment mechanism includes a servo motor 8, a screw rod 6 and a guide wheel set 3. The screw rod 6 is connected to the servo motor 8, and the guide wheel set 3 is connected to the nut on the screw rod 6 , The servo motor 8 drives the lead screw 6 to drive the guide wheel set 3 to move; the hub drive mechanism includes a torque motor 2, a transmission shaft 9, a synchronization wheel 10 and a friction support wheel 5, the synchronization wheel 10 and the friction support wheel 5 are coaxial Connected, the torque motor 2 drives the synchronous wheel 10 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com