V-shaped geometric form of middle plate structure of middle groove

A technology of plate structure and form, applied in the field of new "V" geometric form, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

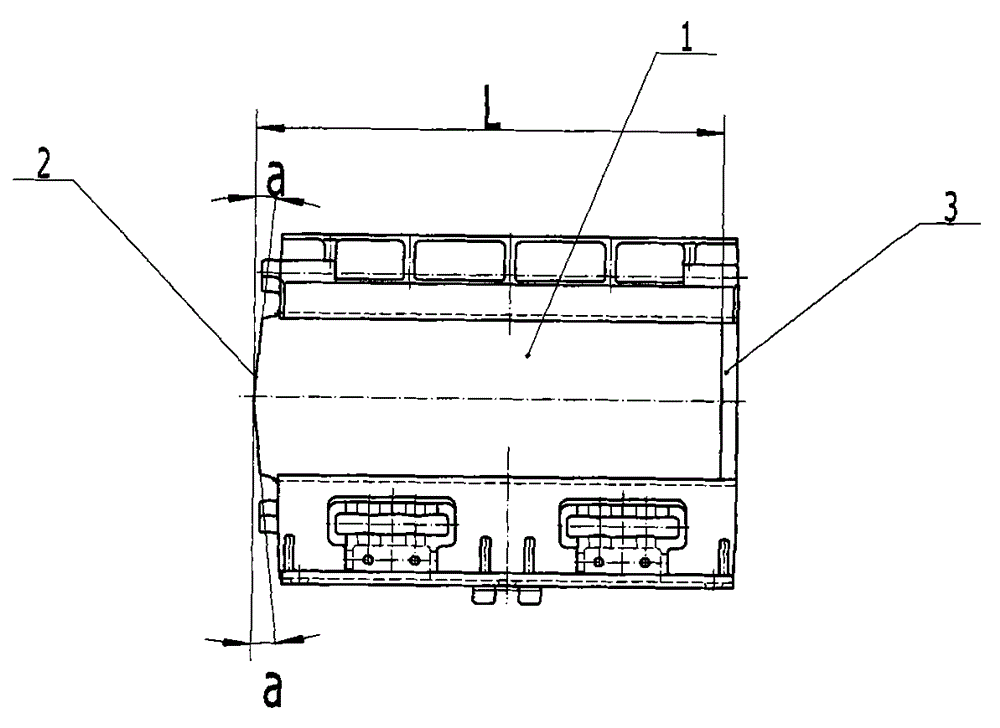

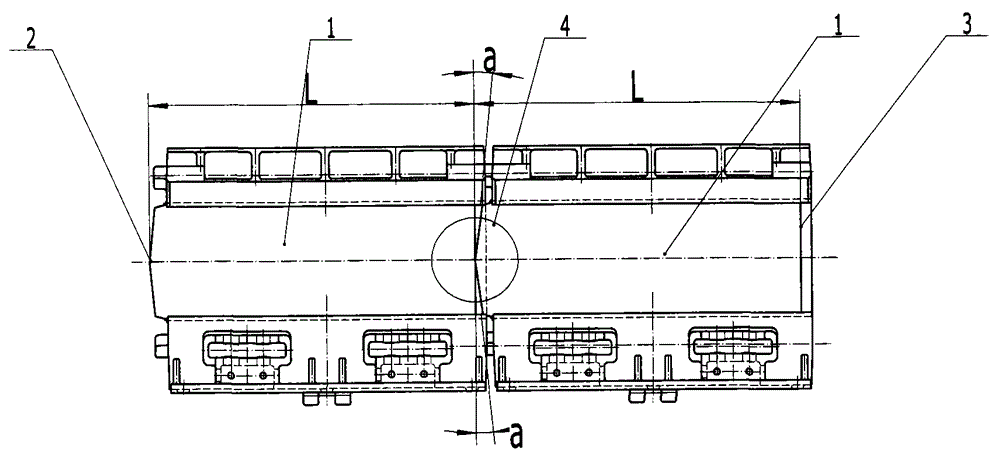

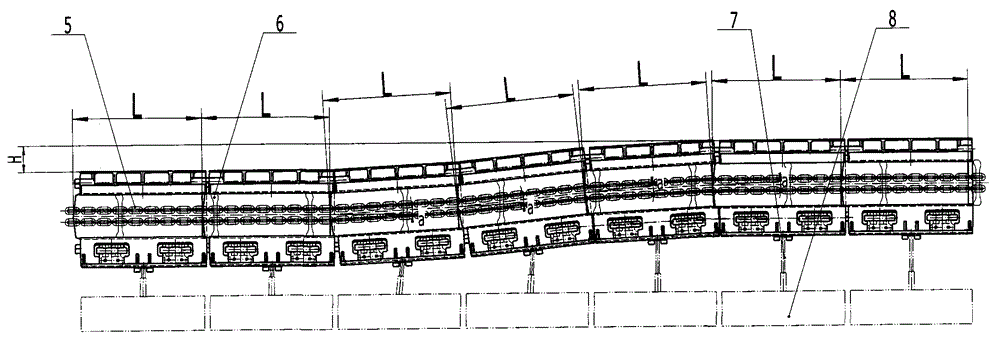

[0012] In the figure, 1. The plate in the middle groove, 2. The front end of the plate in the middle groove is an obtuse "V"-shaped edge facing outward, 3. The straight opening at the end of the plate in the middle groove, 4. The correspondence between the middle grooves when installing the link The "K" type connection form, 5, circular chain, 6, scraper, 7, push cylinder, 8, hydraulic support.

[0013] exist figure 1 In the embodiment shown in , the head end (2) of the middle plate (1) in the middle groove part is designed as a "V"-shaped edge facing outward at an obtuse angle, and the "V"-shaped mouth is perpendicular to the center line of the middle plate The angle a is the maximum allowable rotation angle when the middle groove is pushed, and the traditional straight opening is retained at the tail end (3), and at the same time, it is ensured from the sharp corner of the "V"-shaped end of the middle plate to the The length dimension at the flat opening of the tail end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com