Cam following tension control device for lithium battery winder

A tension control and winding machine technology, applied in non-electric variable control, mechanical pressure/force control, electrical program control, etc., can solve problems such as failure to meet process requirements, short circuit of cells, inconsistent tension, etc., and achieve product adaptation Strong ability, good performance, and the effect of meeting process requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

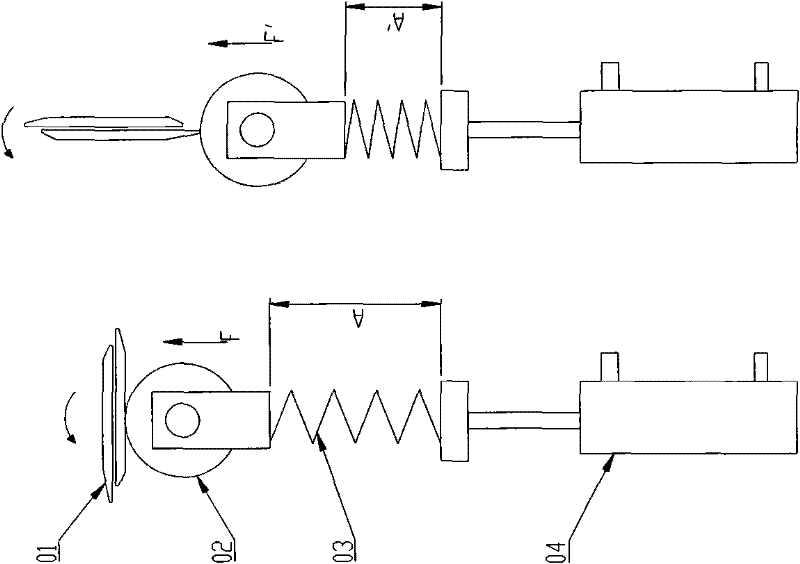

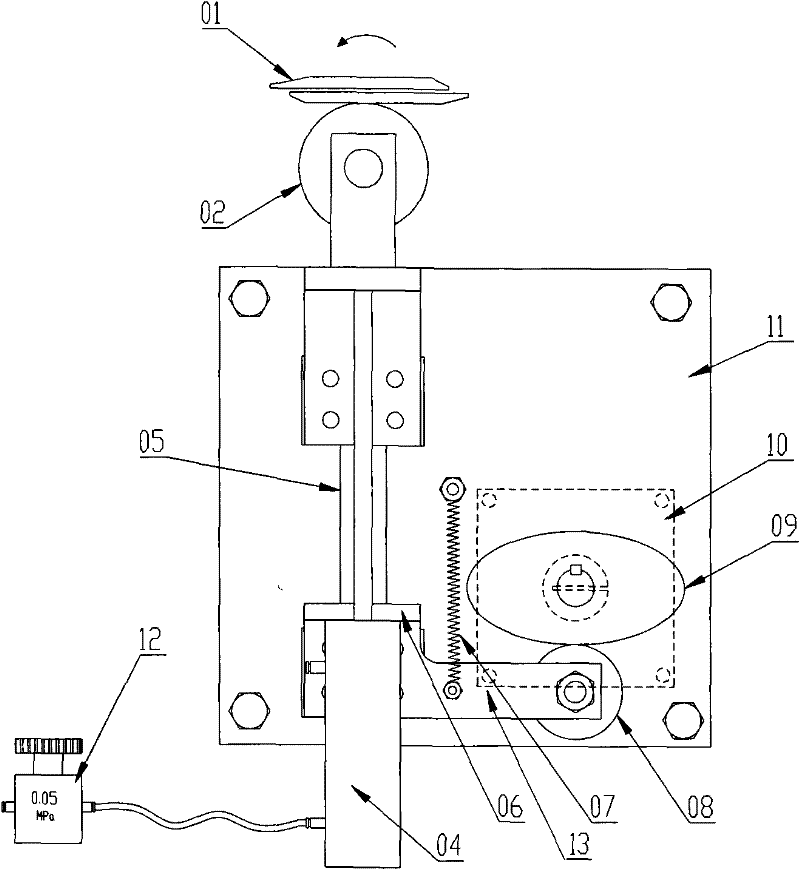

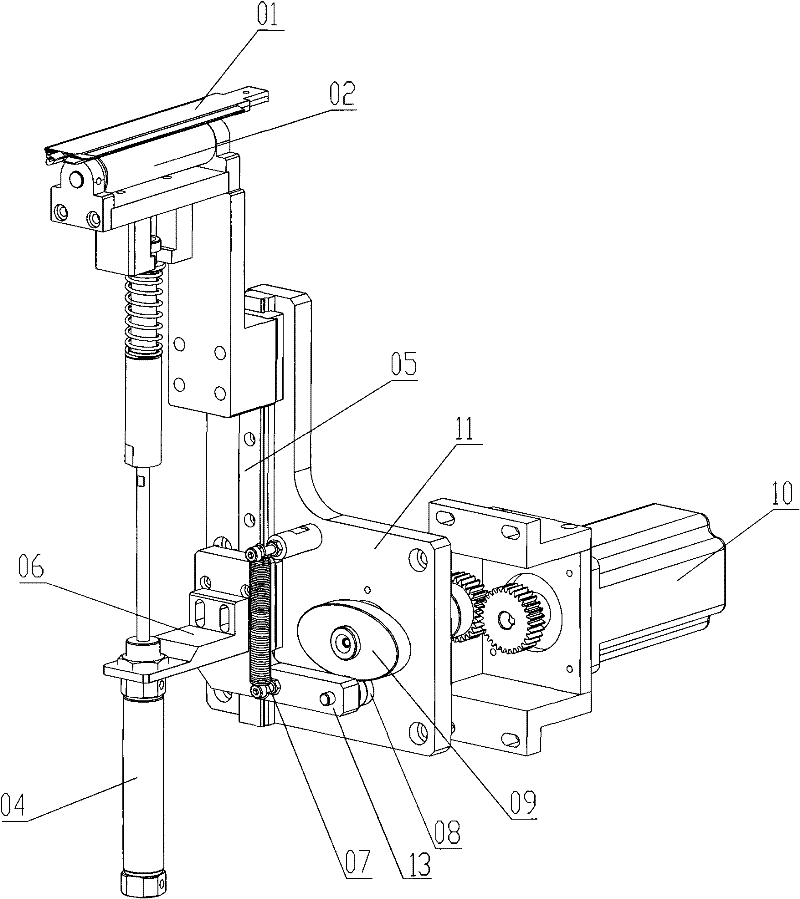

[0023] Such as figure 2 , 3 Shown: a cam follower tension control device of a lithium battery winding machine according to the present invention, including a winding needle 01, a tension roller 02 and an air cylinder 04, characterized in that: between the tension roller 02 and the air cylinder 04 A cam follower mechanism is provided, and the rotation speed of the cam follower mechanism is consistent with the rotation speed of the winding needle 01.

[0024] The cam follower mechanism includes a stepper motor 10, a follower cam 09, a positioning bearing 08, a follower plate 13, a tension spring 07, a cylinder mounting plate 06, and a linear guide rail 05, and is characterized in that: the follower The outer edge of the cam 09 is closely contacted with the outer edge of the locating bearing 08, and the front end of the follower plate 13 is installed with the linear guide 05, and the locating bearing 08 is installed at the tail end, and the middle part is connected with the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com