Patents

Literature

32results about How to "Ensure constant tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

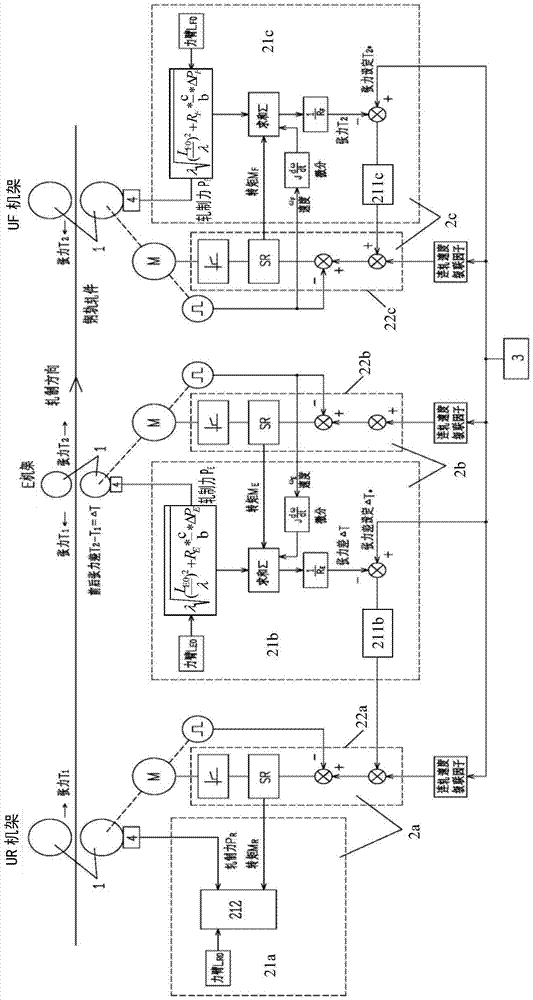

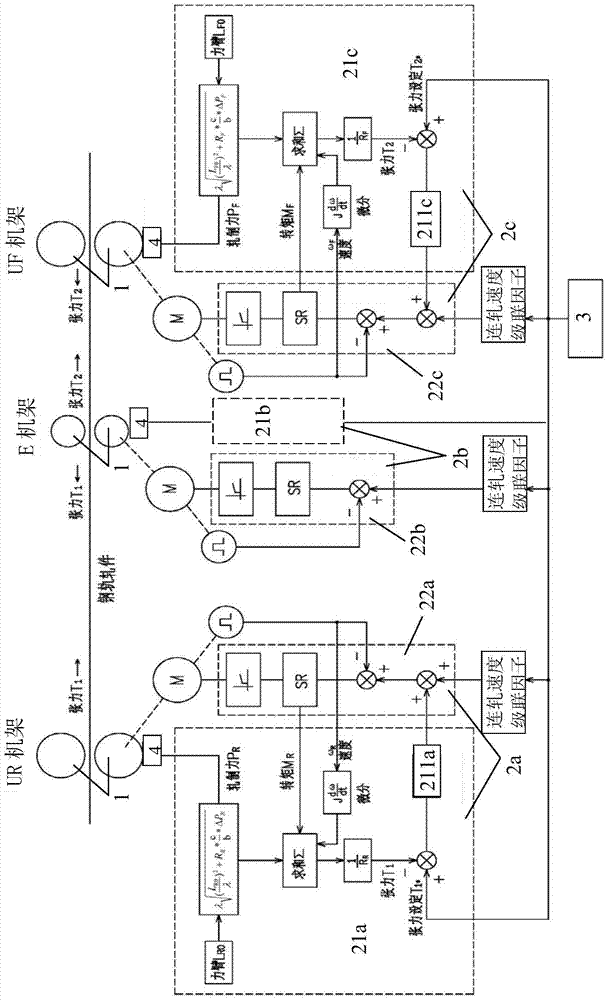

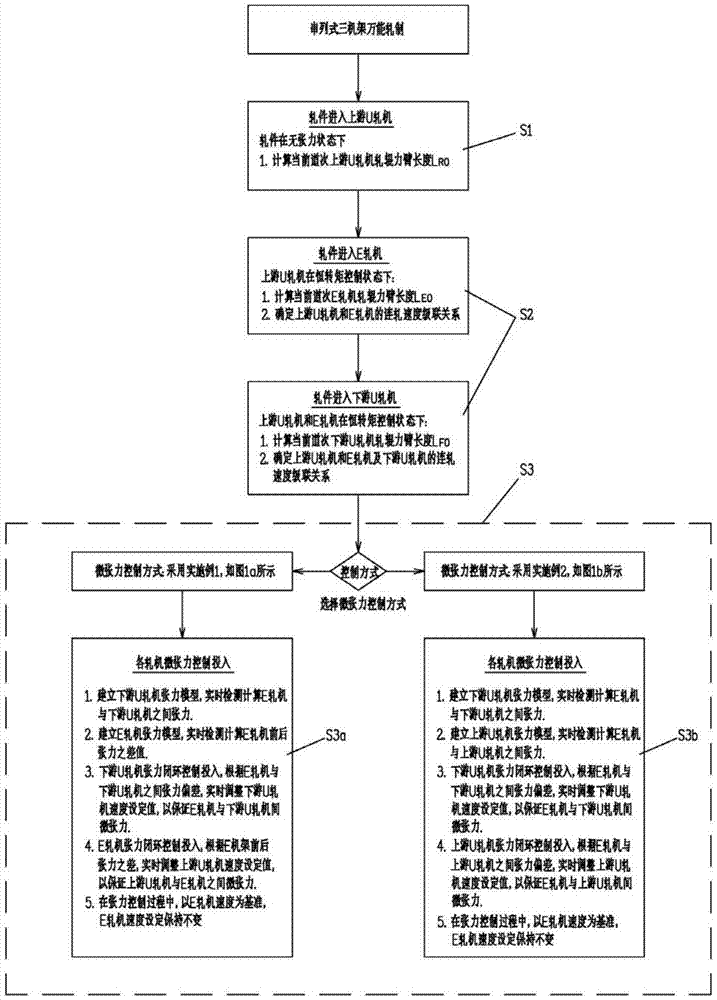

Micro-tension control system and method

ActiveCN103567230AGuaranteed tension control accuracyGeometry out-of-tolerance reductionMeasuring devicesTension/compression control deviceLoop controlClosed loop

The invention discloses a micro-tension control system and method. In the hot continuous rolling process, when a rolled piece enters a current machine frame and is stably bitten, the current machine frame is kept under speed control, speed control of main motors of machine frames on the upstream of the current machine frame is switched to constant torque control, on the basis, the torque and the rolling force of a main motor of the current machine frame are sampled to calculate the initial length of a rolling force arm, and the tension measurement calculating accuracy is improved. Each machine frame is provided with a pressure measuring head device to directly detect the rolling force, and consideration is given to the situation that the length of the rolling force arm is changed along with changes of the rolling force. Tension between the machine frames is obtained in real time through tension calculating models to form micro-tension closed-loop control to adjust the speeds of the machine frames so as to correct the tension deviations between the machine frames. As for a serial type universal rolling mill, the speed of the E machine frame serves as a standard, the rolling speed of the E machine frame is kept unchanged while speed set values of the other machine frames are adjusted, and real-time control is carried out on dynamic instantaneous values of the tension difference of the E machine frame before and after the adjustment process to guarantee micro-tension rolling of series universal rolling.

Owner:BERIS ENG & RES CORP

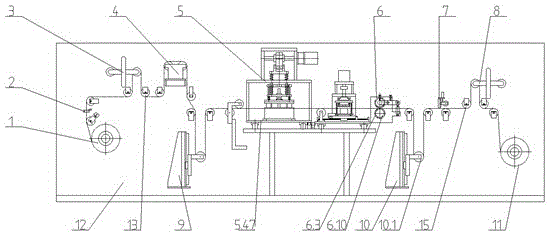

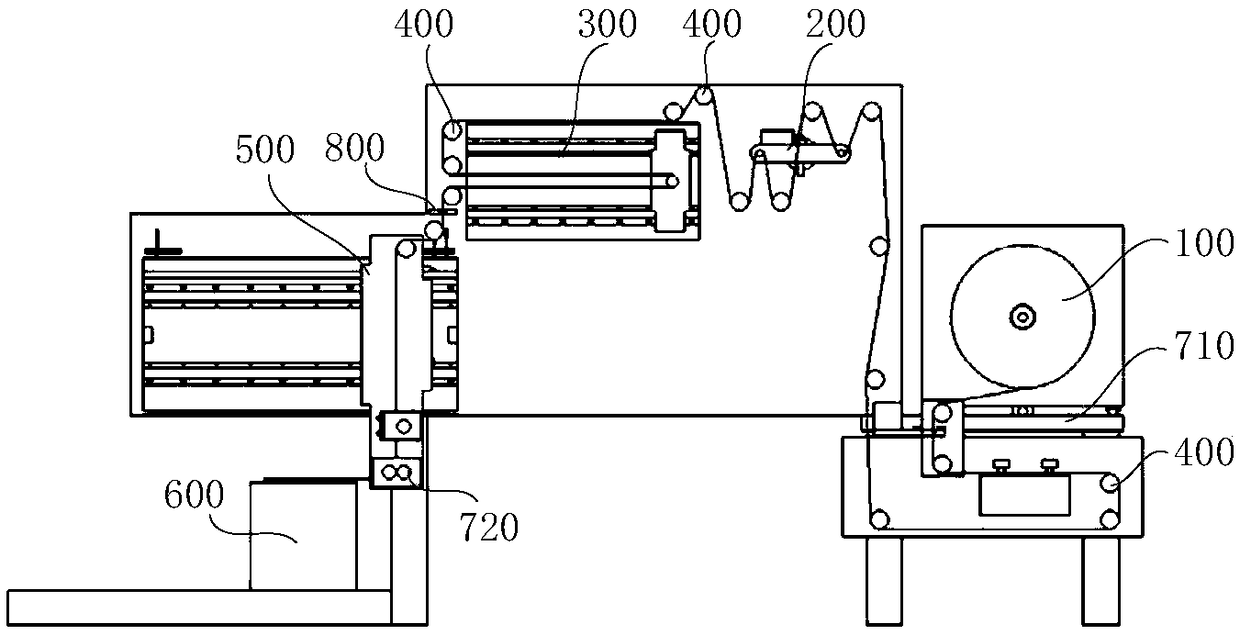

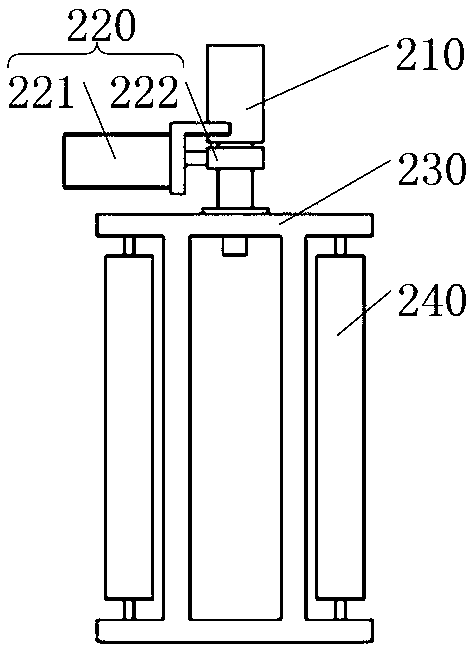

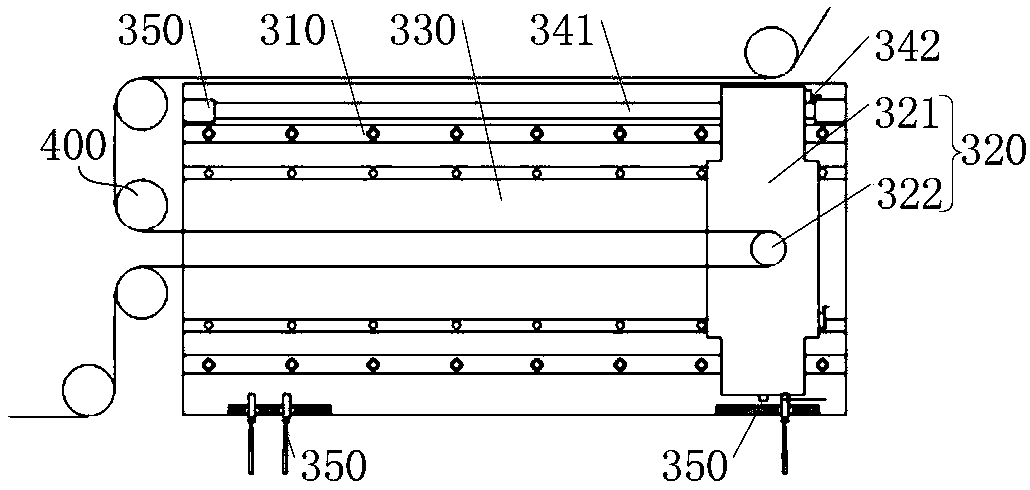

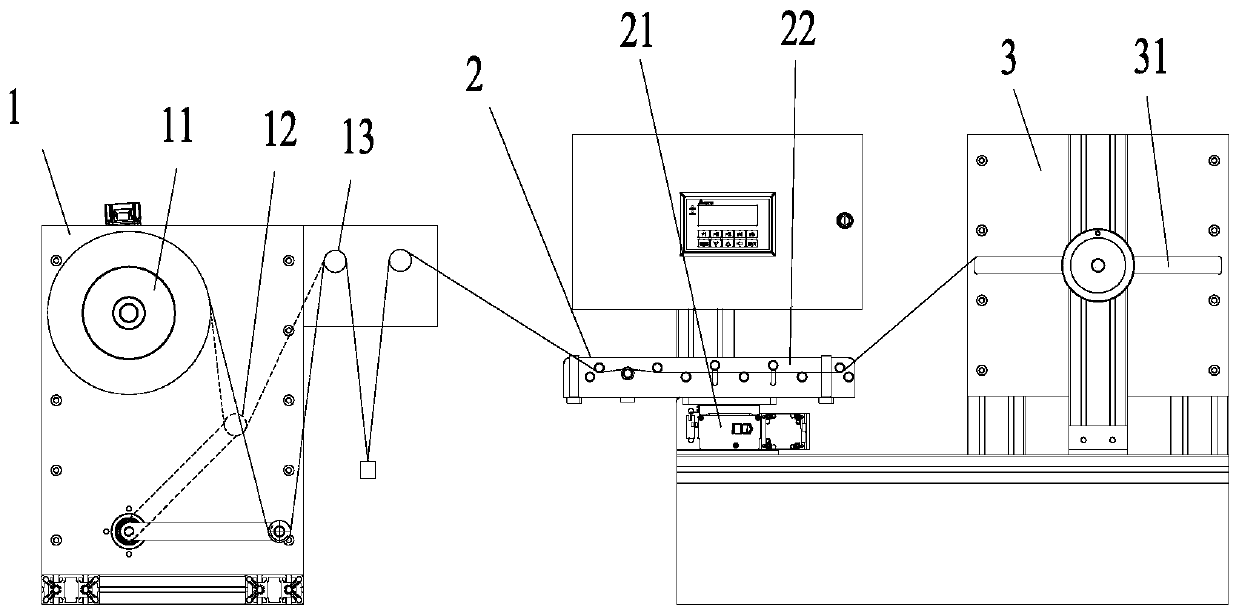

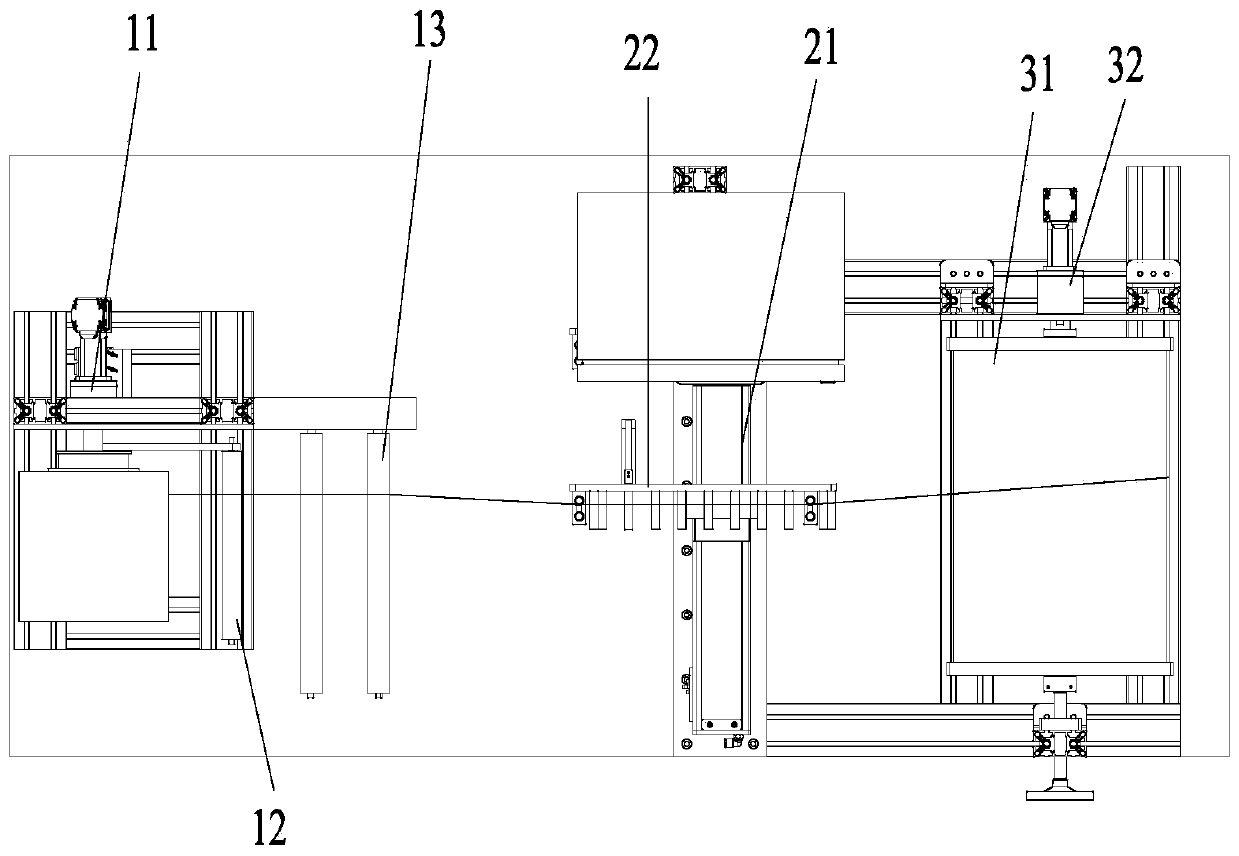

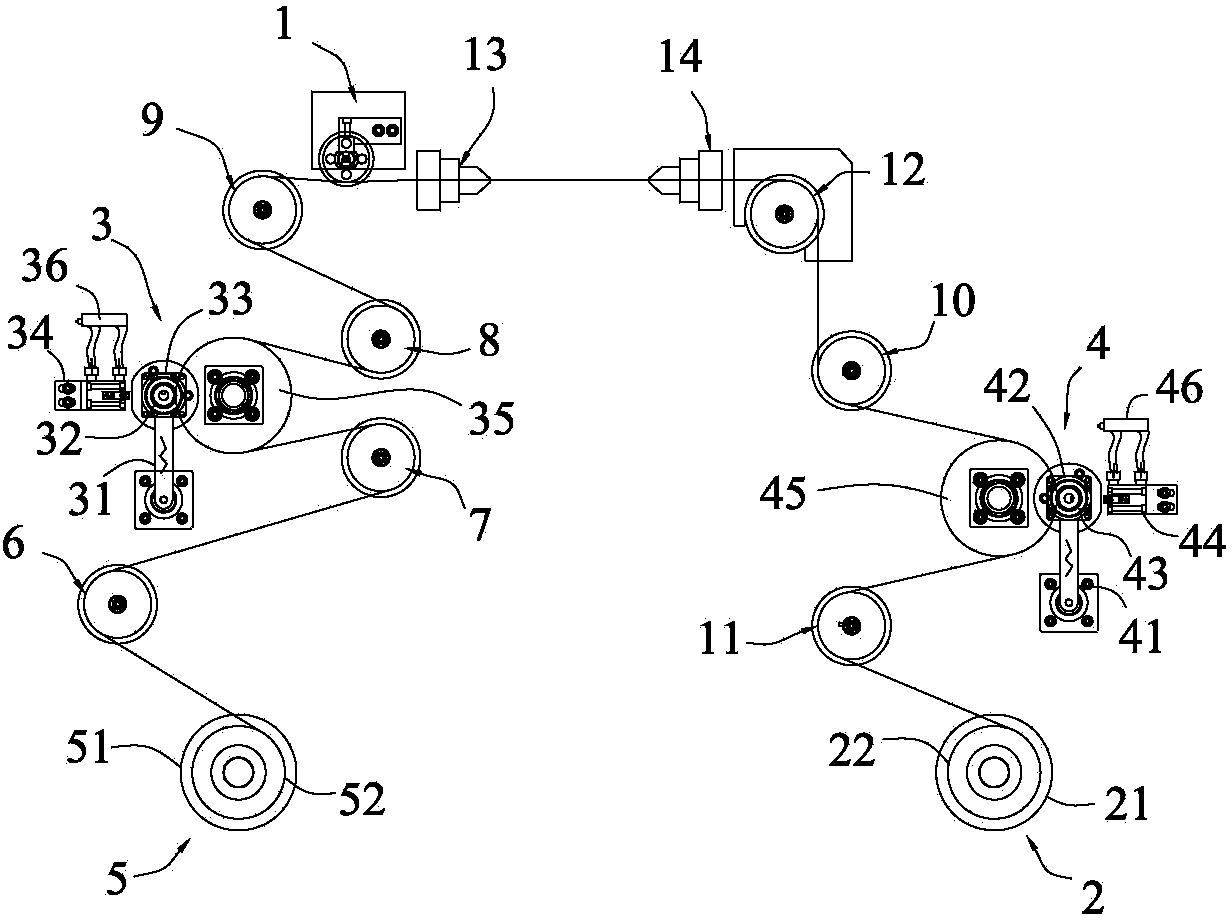

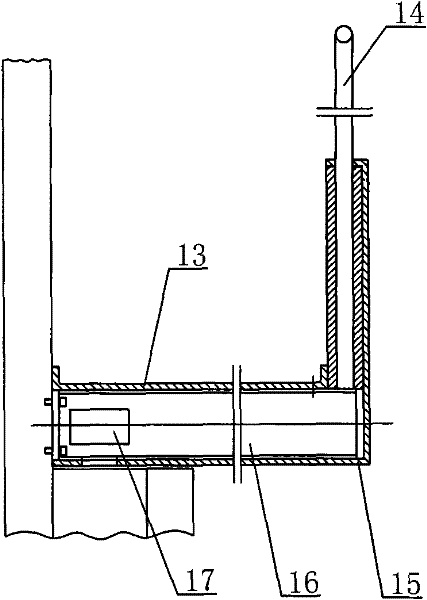

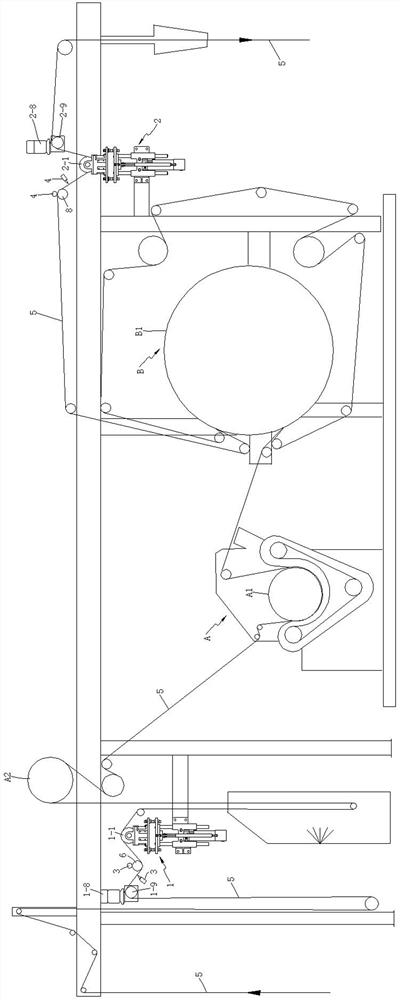

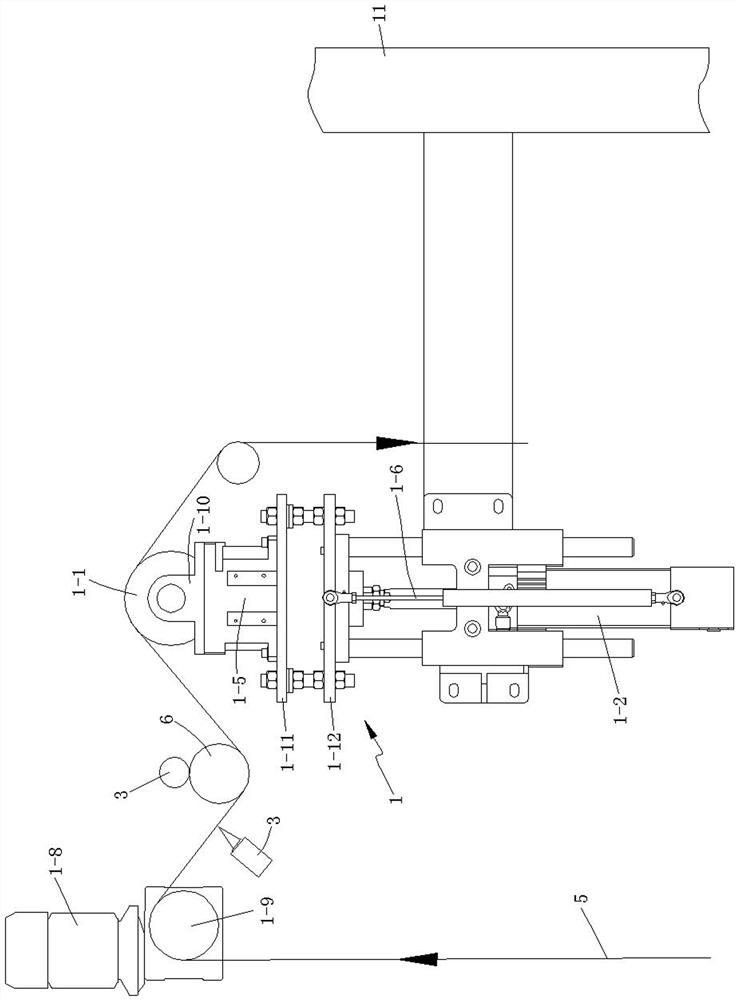

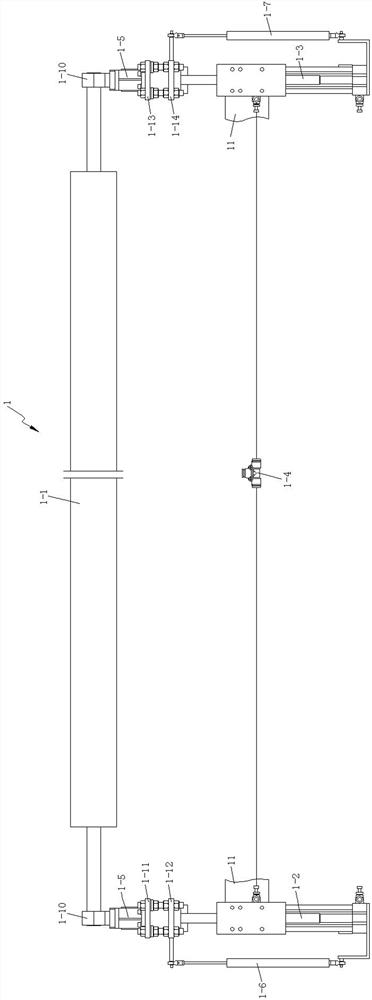

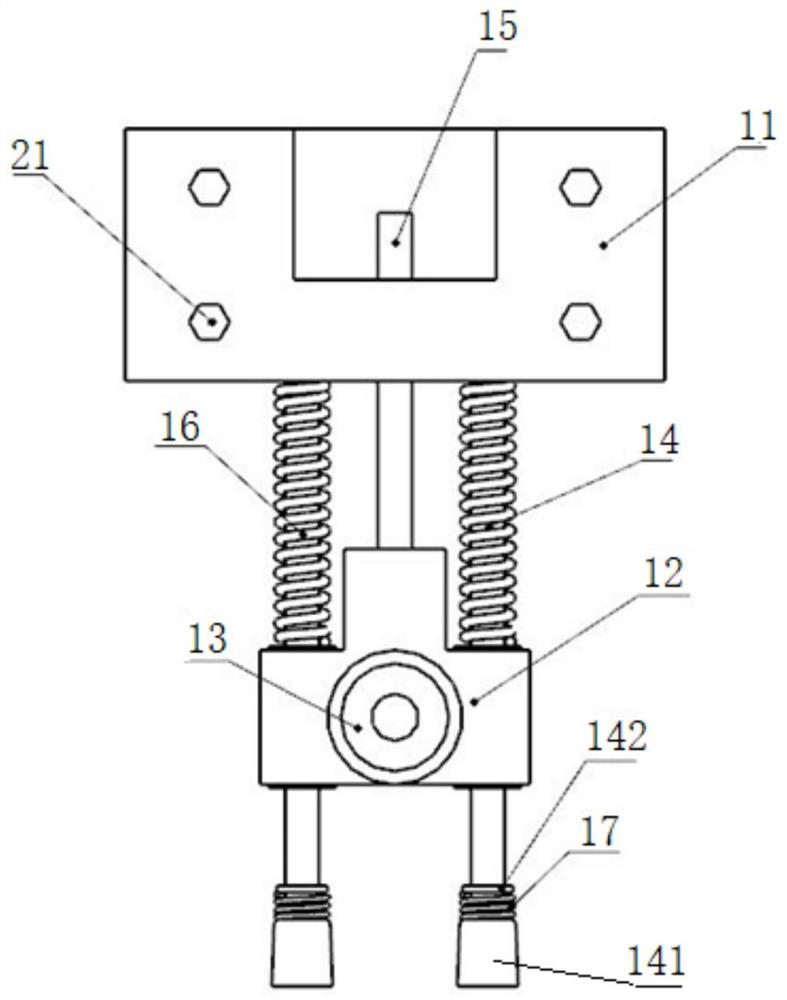

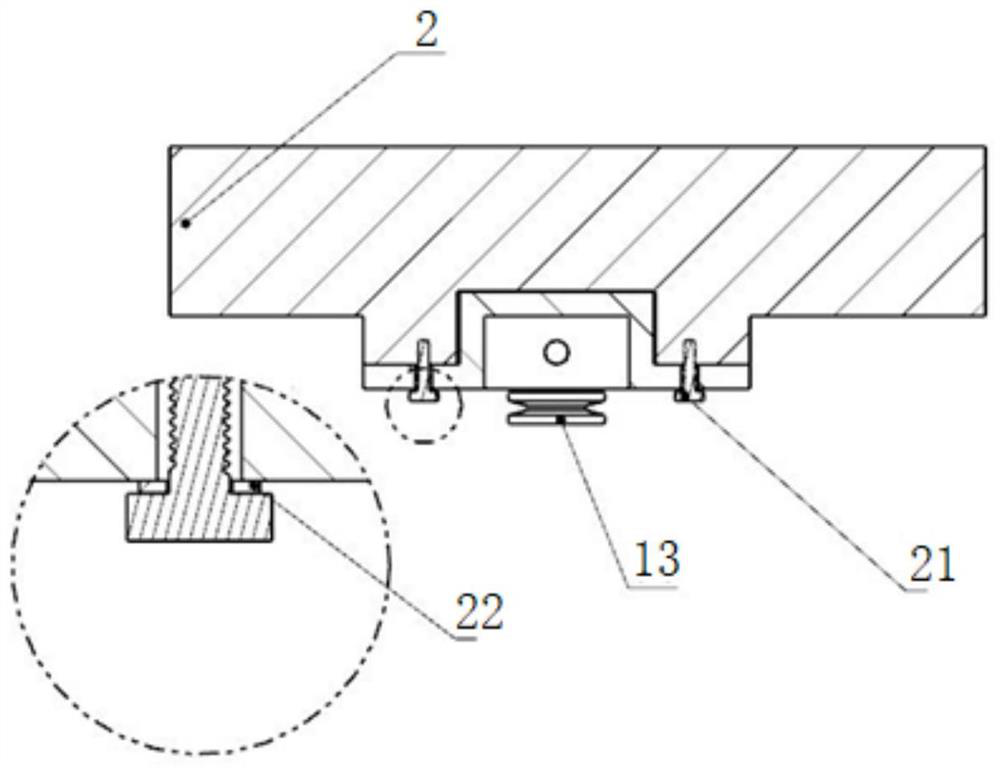

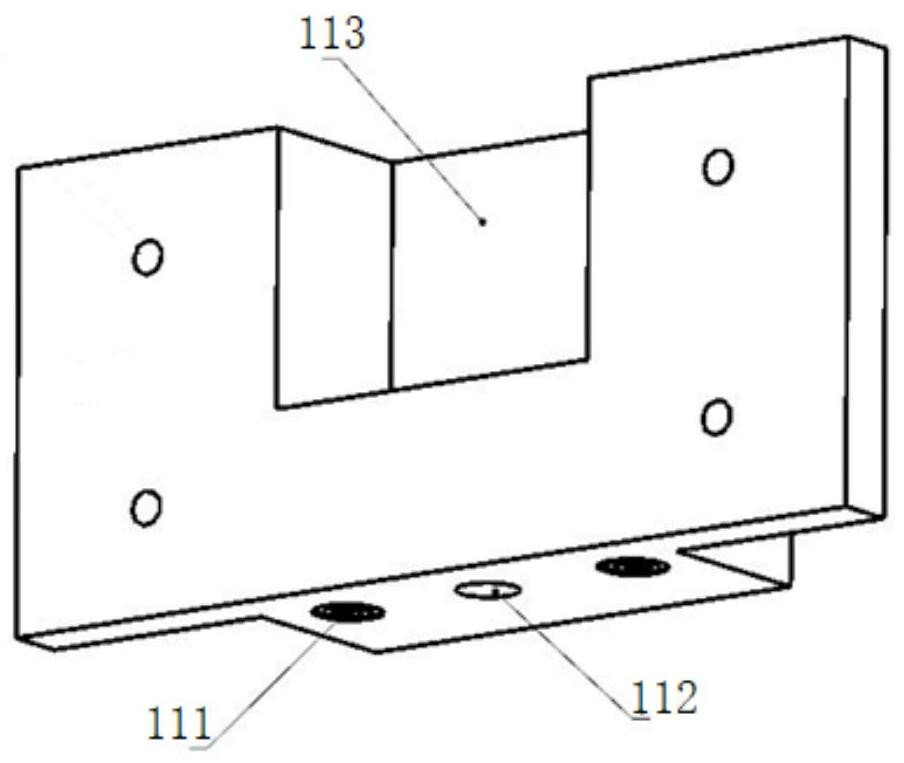

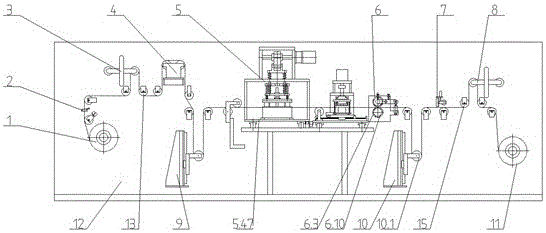

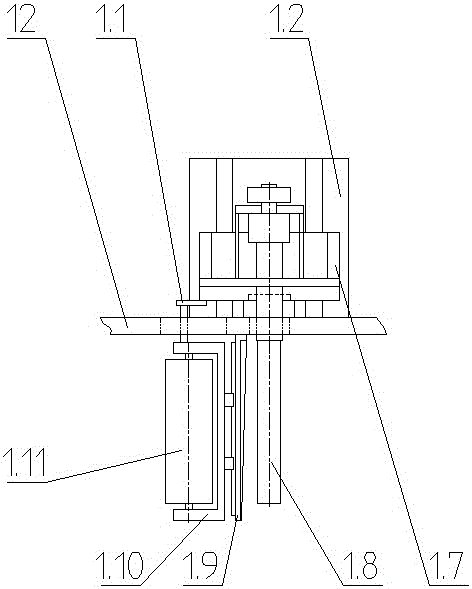

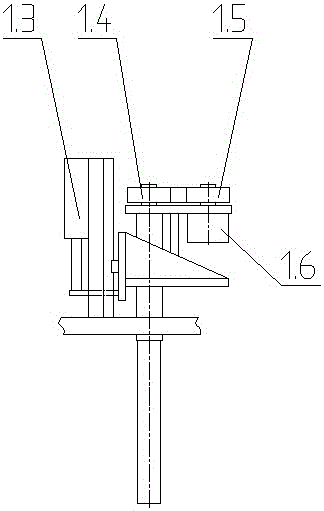

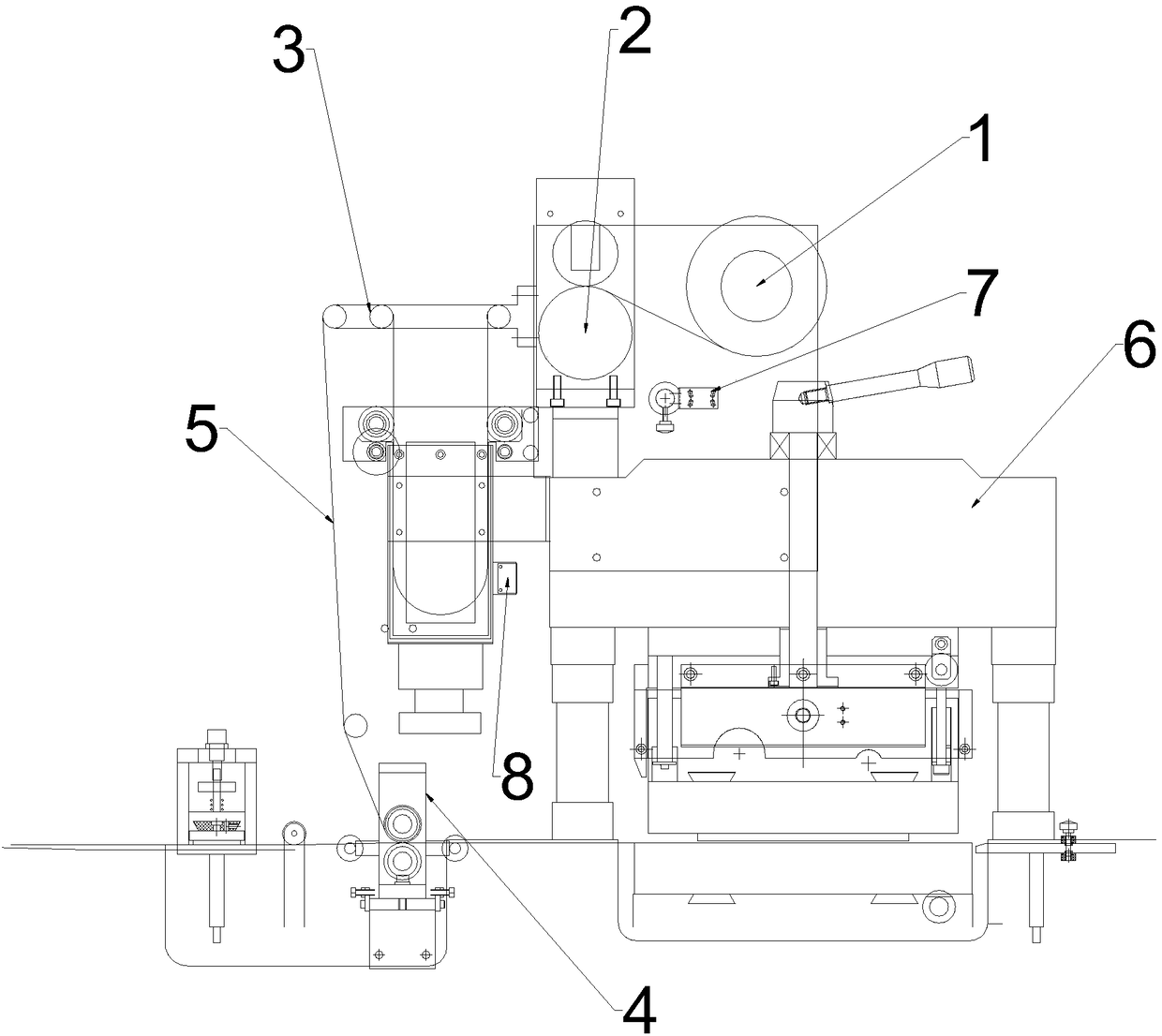

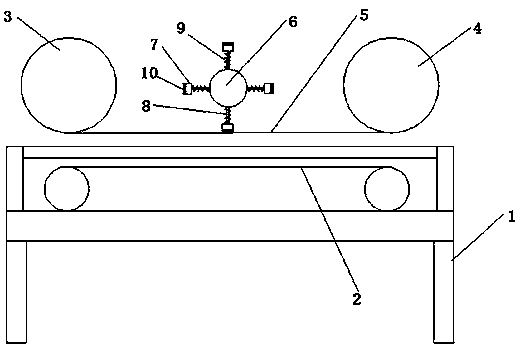

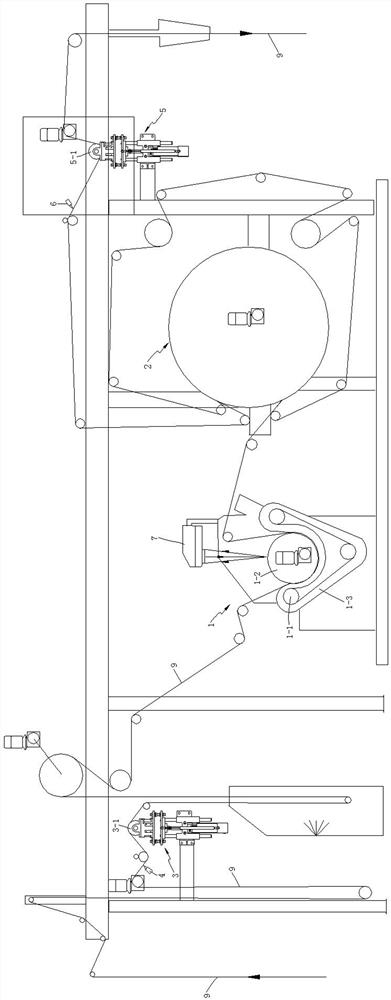

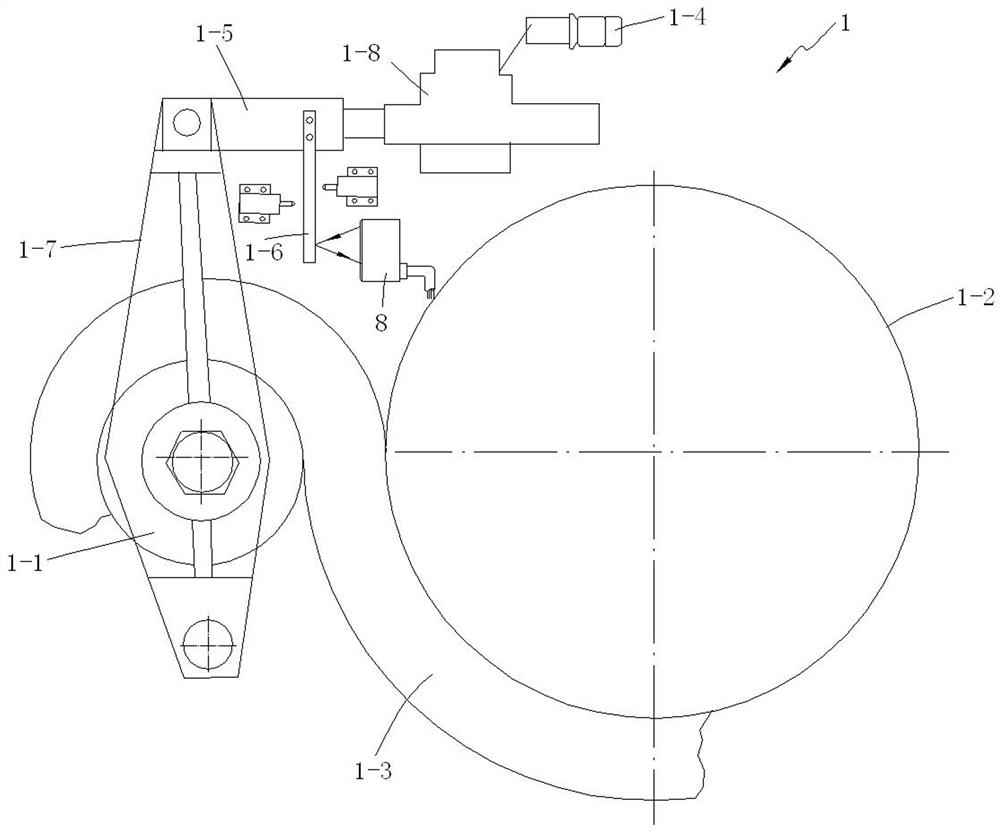

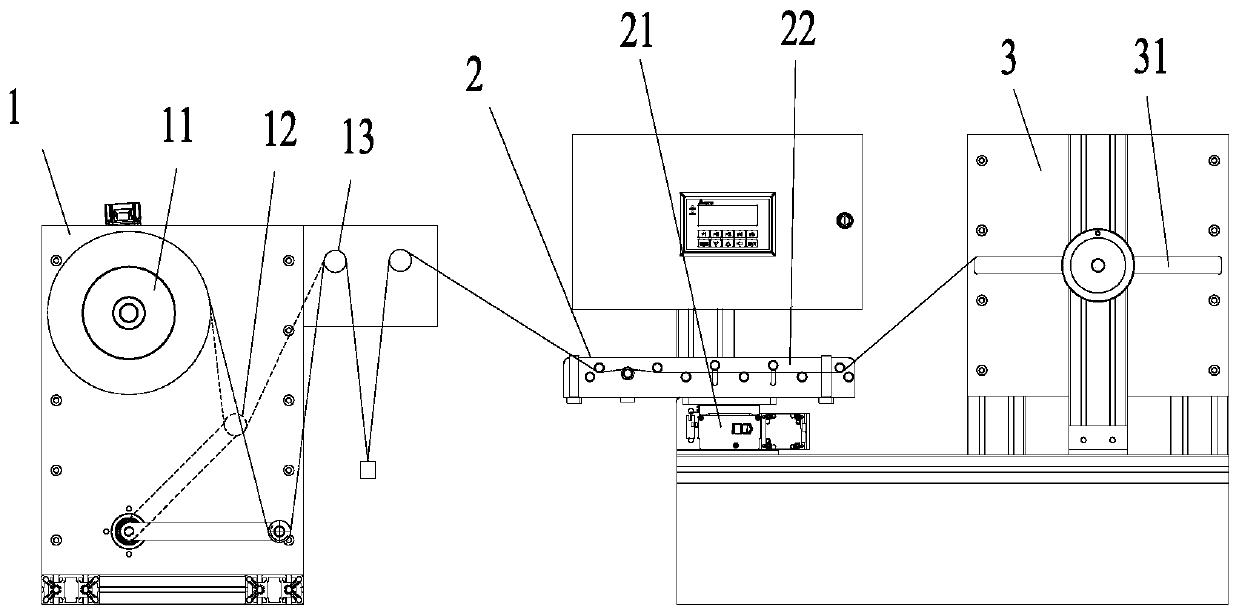

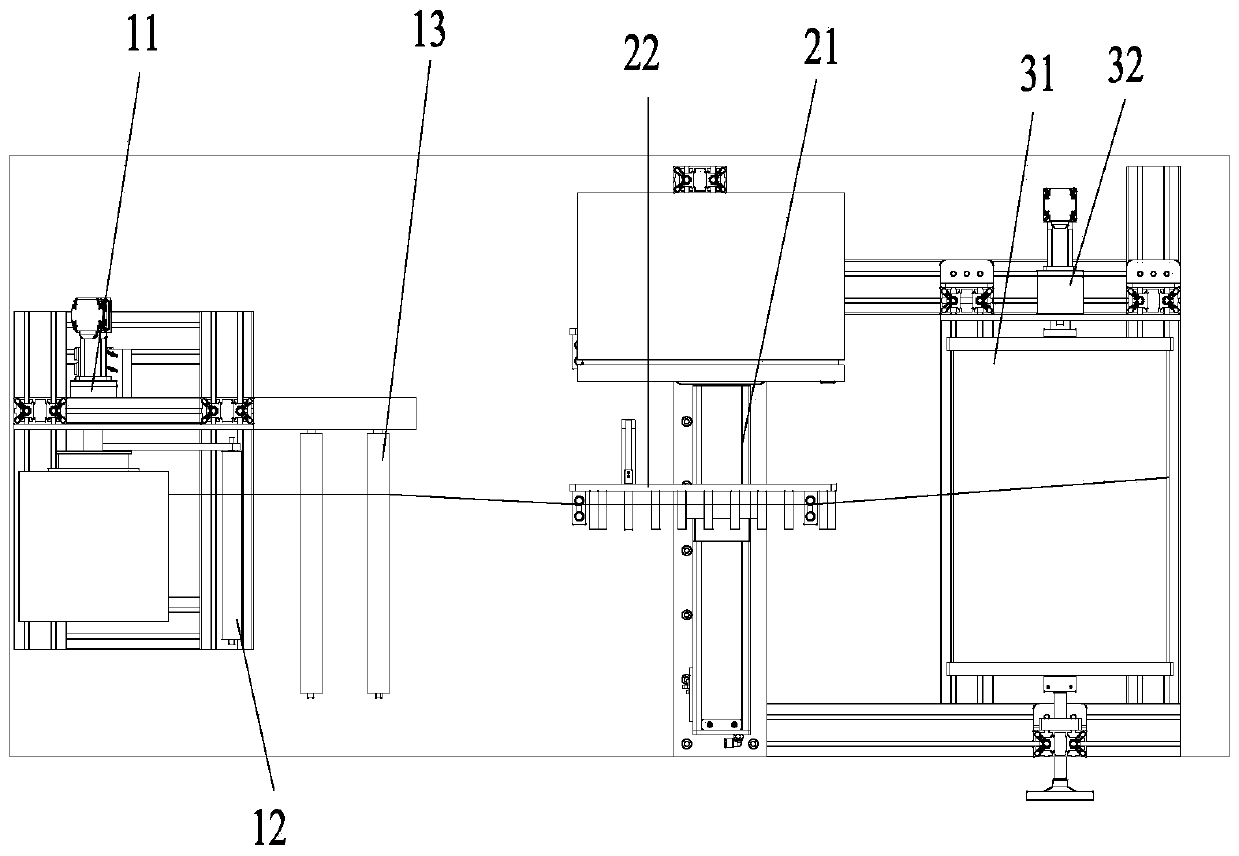

Full-automatic die cutting machine for pole piece

ActiveCN105033017AEnsure constant tensionImprove efficiencyMetal-working feeding devicesPositioning devicesEngineeringPole piece

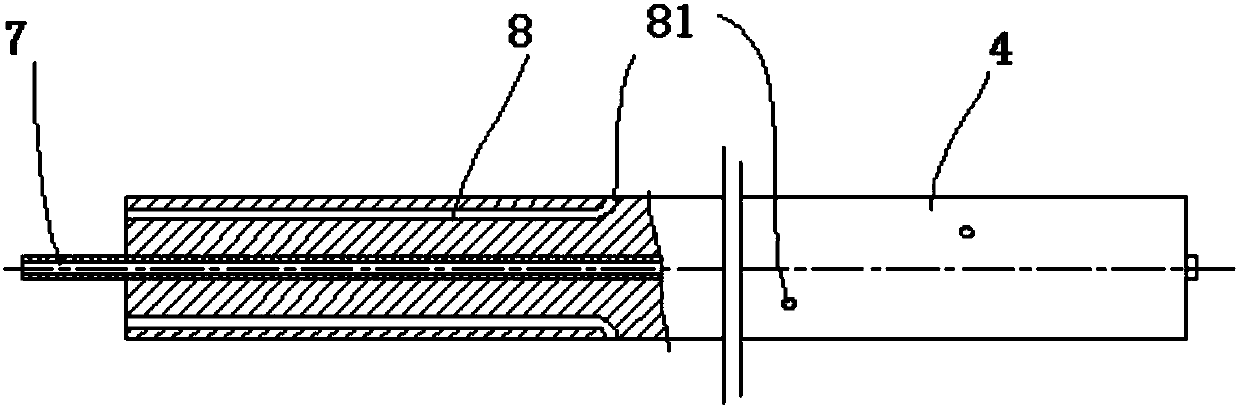

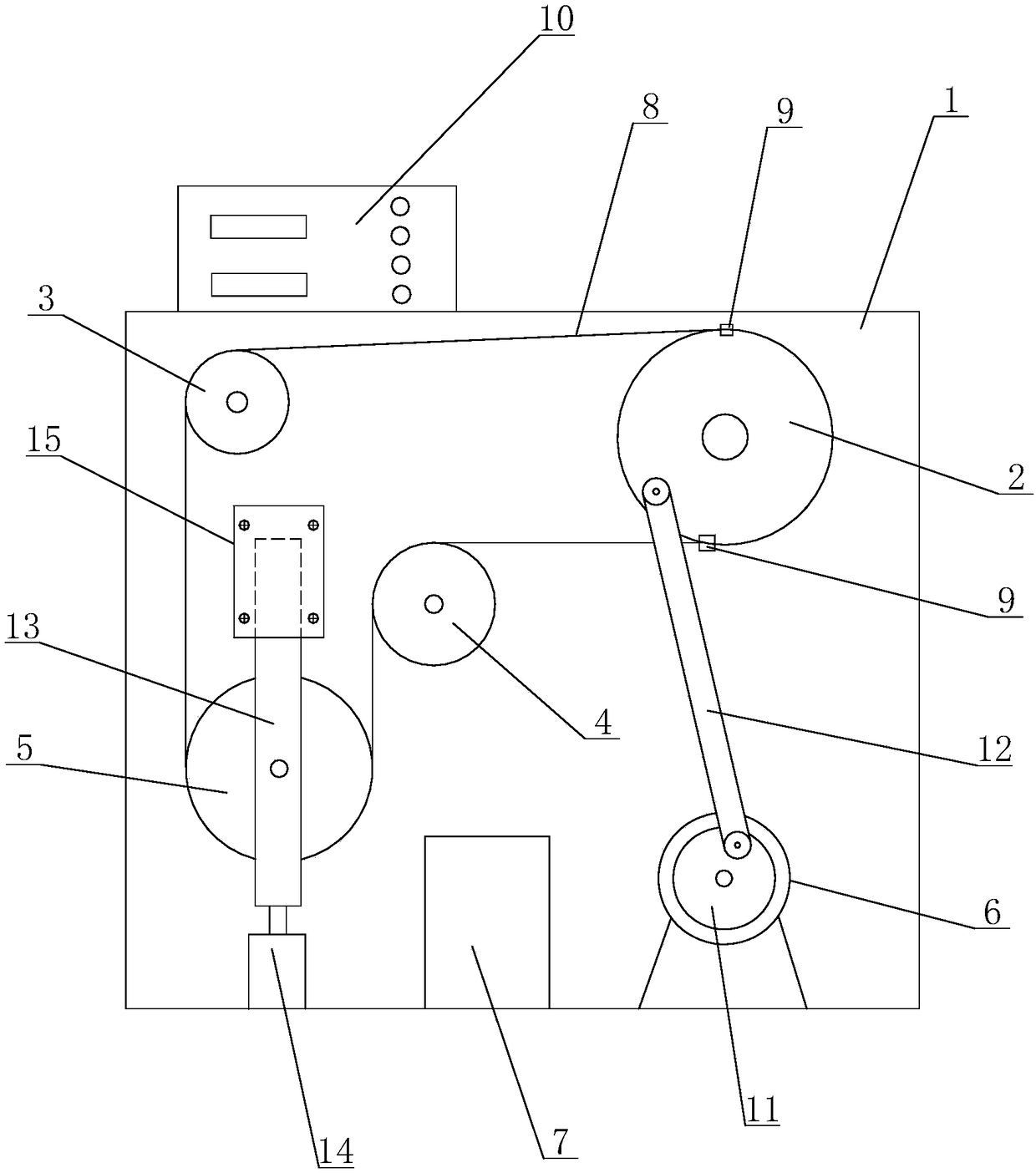

The invention relates to a full-automatic die cutting machine for a pole piece. The full-automatic die cutting machine comprises a front die cutting mechanism and a rear die cutting mechanism, wherein the front die cutting mechanism comprises an unreeling device, a deviation correcting sensor, a first tension regulating device, first transition rollers, a deviation correcting device and a pole piece blanking cutting die device, and the rear die cutting mechanism comprises a main driving device, a length measuring device, second transition rollers, a second tension regulating device and a reeling device; a first material storing device is arranged between the deviation correcting device and the pole piece blanking cutting die device, and a second material storing device is arranged between the main driving device and the length measuring device; the first material storing device comprises a first storage piece floating roller and a first lifting mechanism, and the first storage piece floating roller can be driven to move upwards or downwards by the first lifting mechanism; the second material storing device comprises a second storage piece floating roller and a second lifting mechanism, and the second storage piece floating roller can be driven to move upwards or downwards by the second lifting mechanism. Through the use of the full-automatic die cutting machine disclosed by the invention, the pole piece blanking efficiency is improved, and the efficiency of blanking pole pieces of lithium batteries is ensured.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

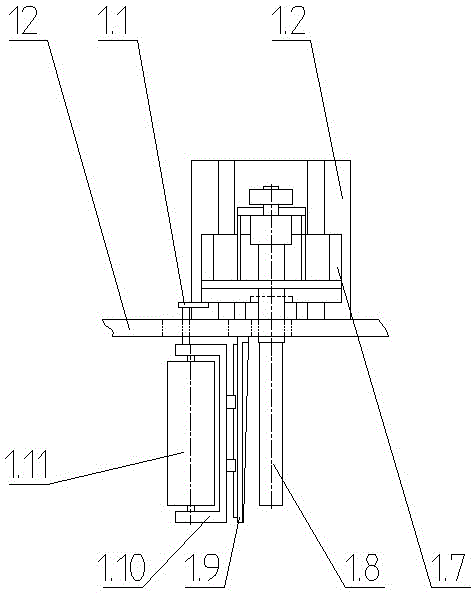

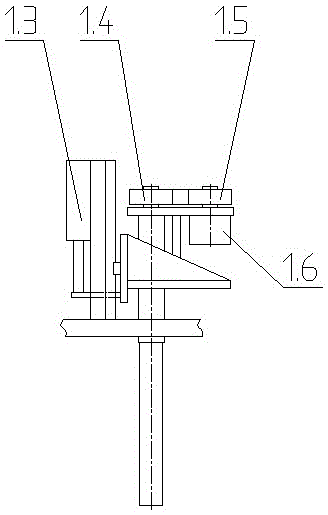

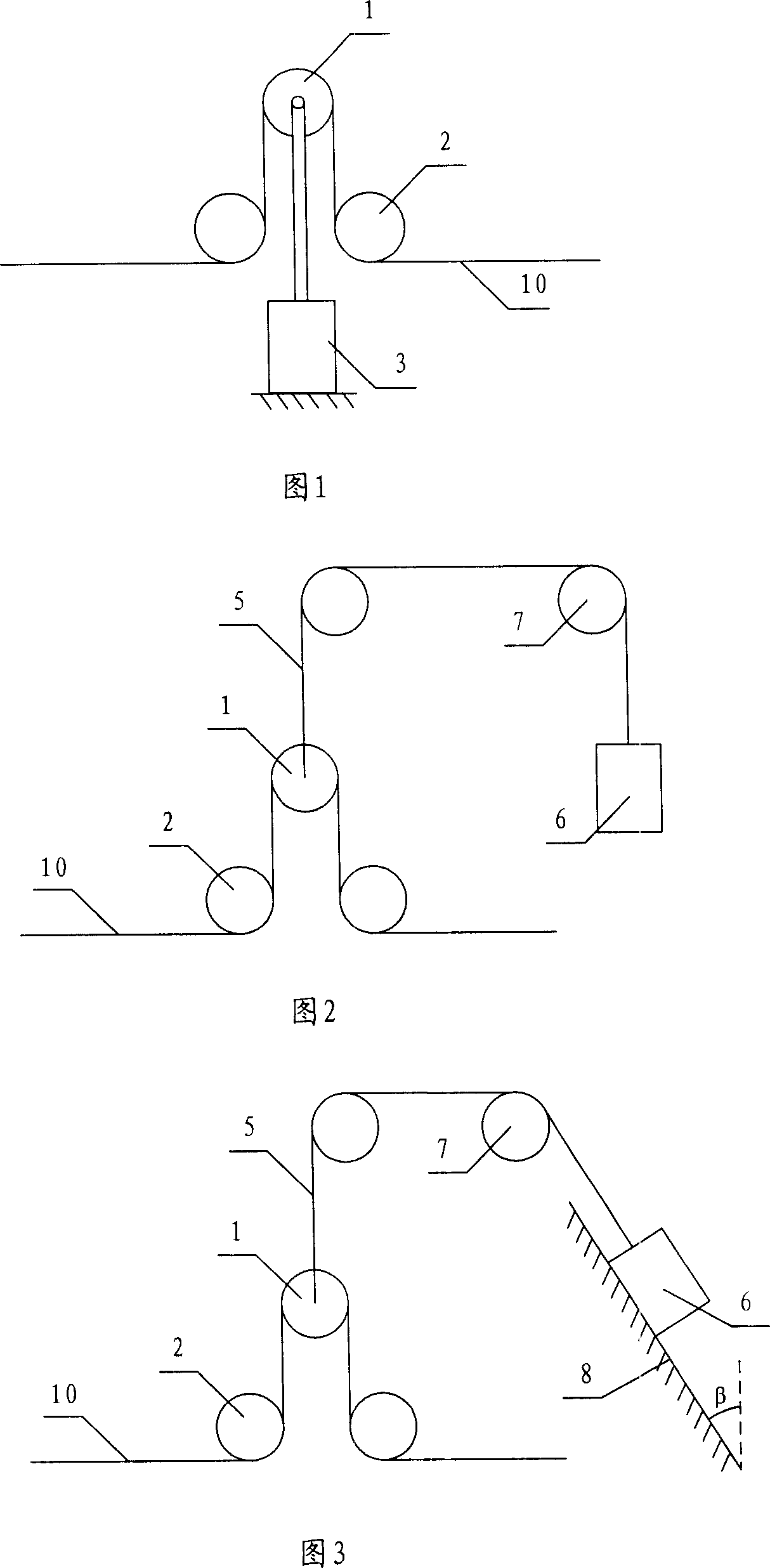

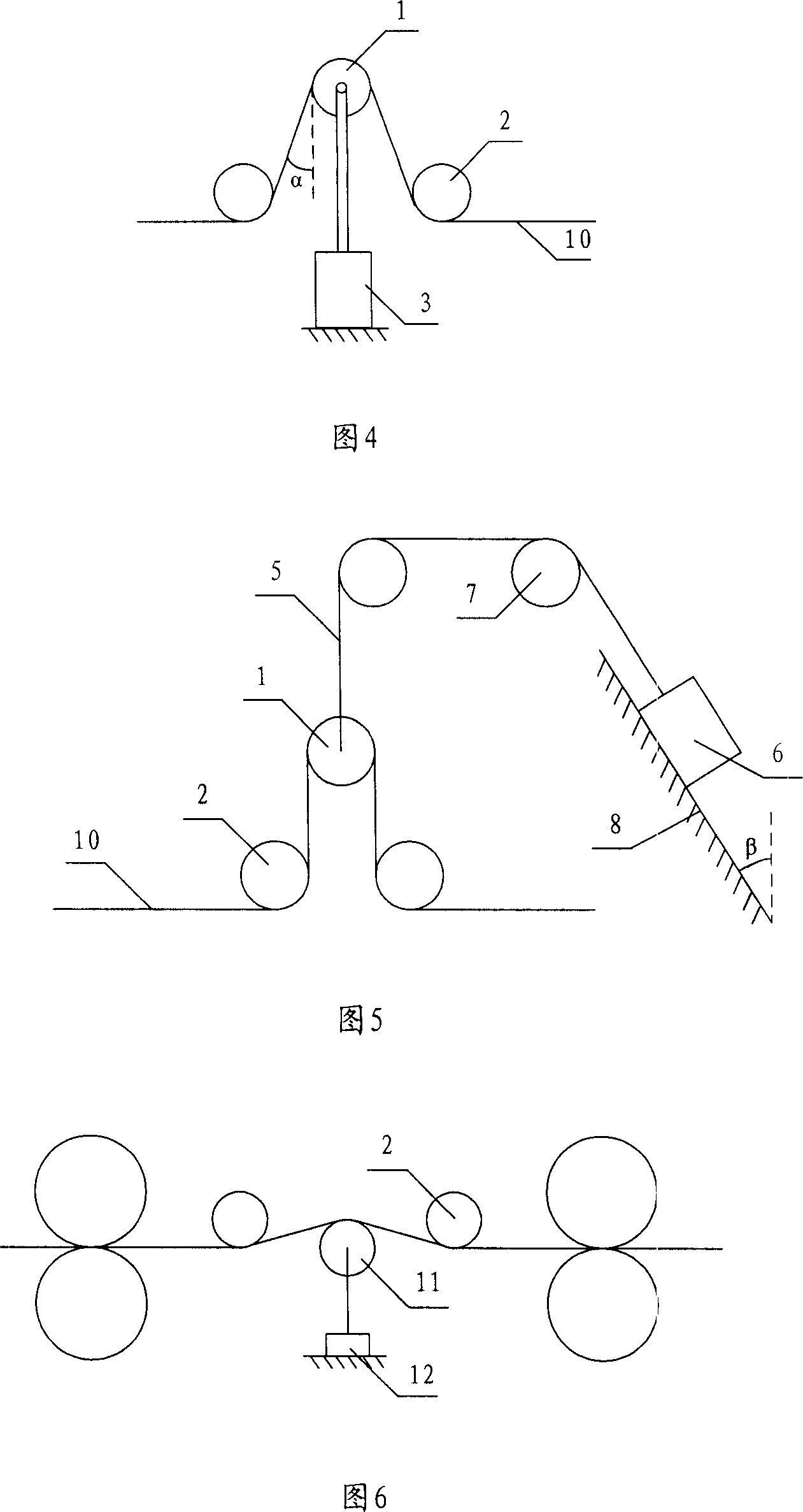

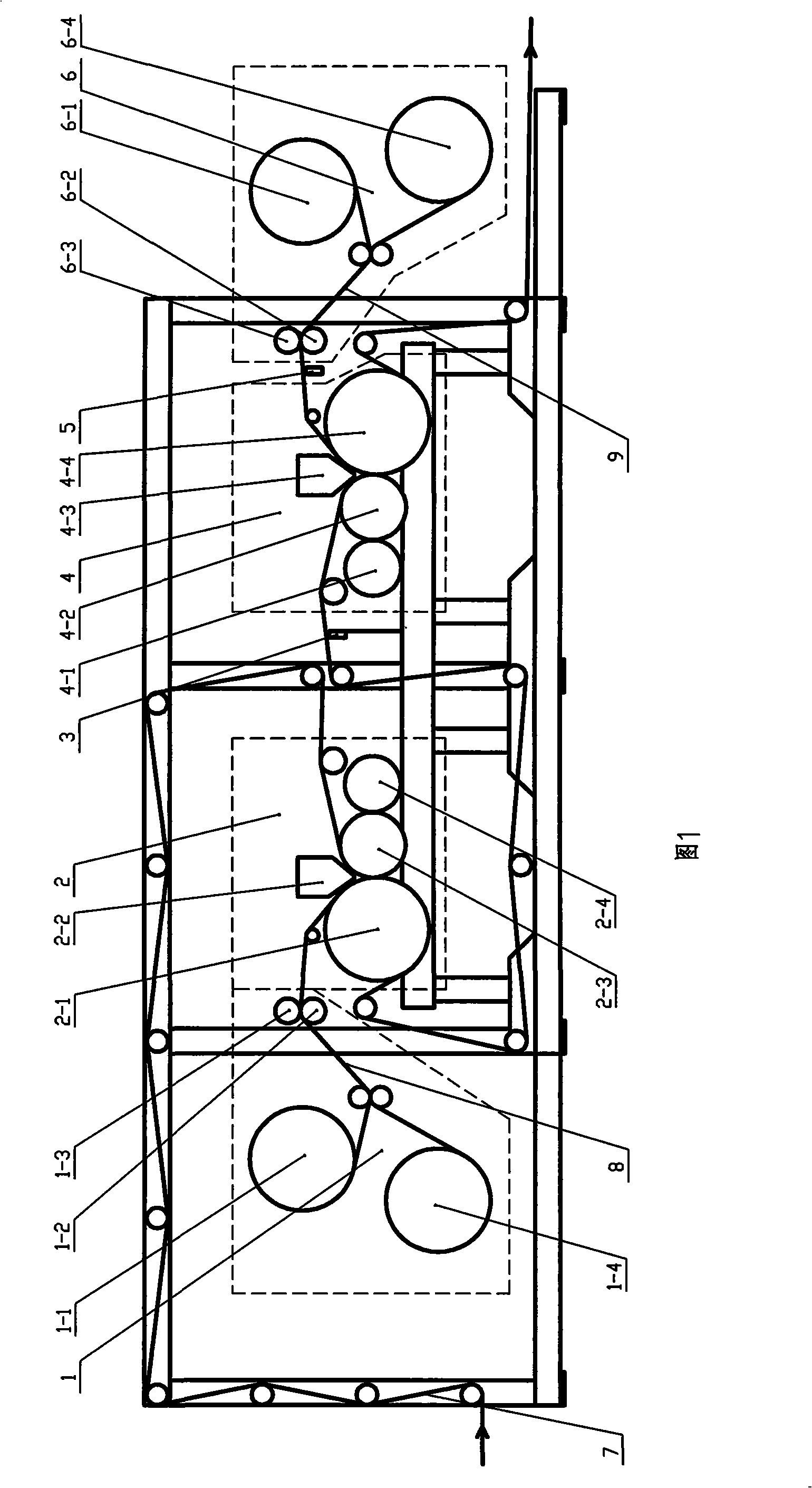

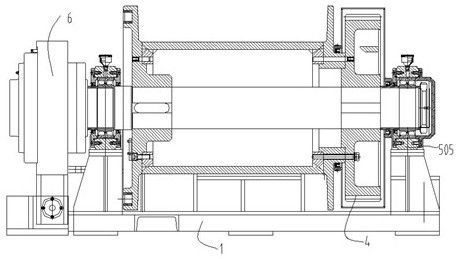

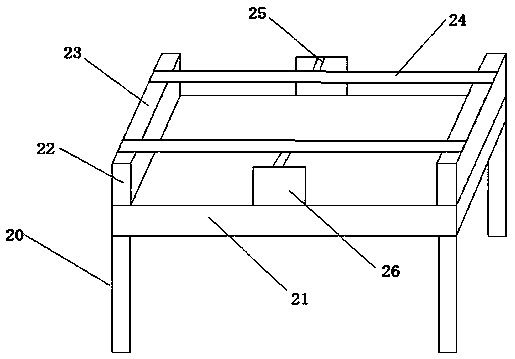

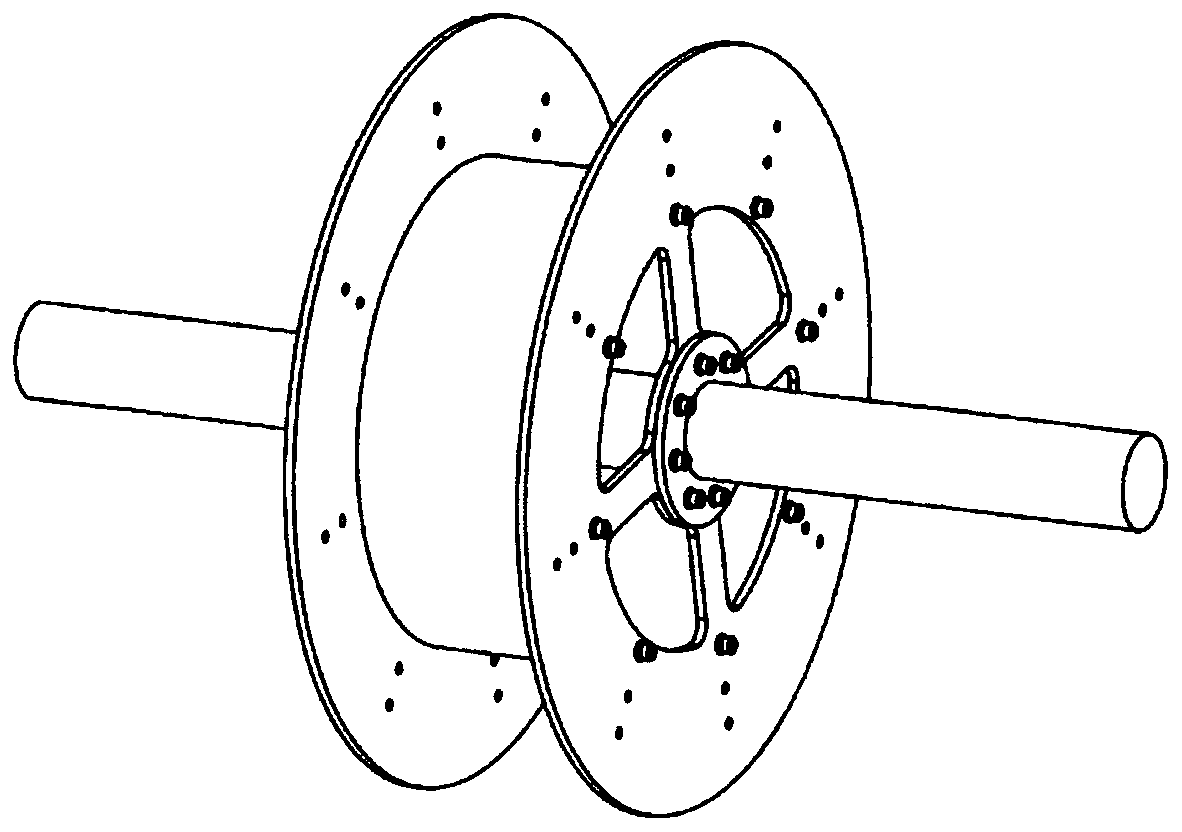

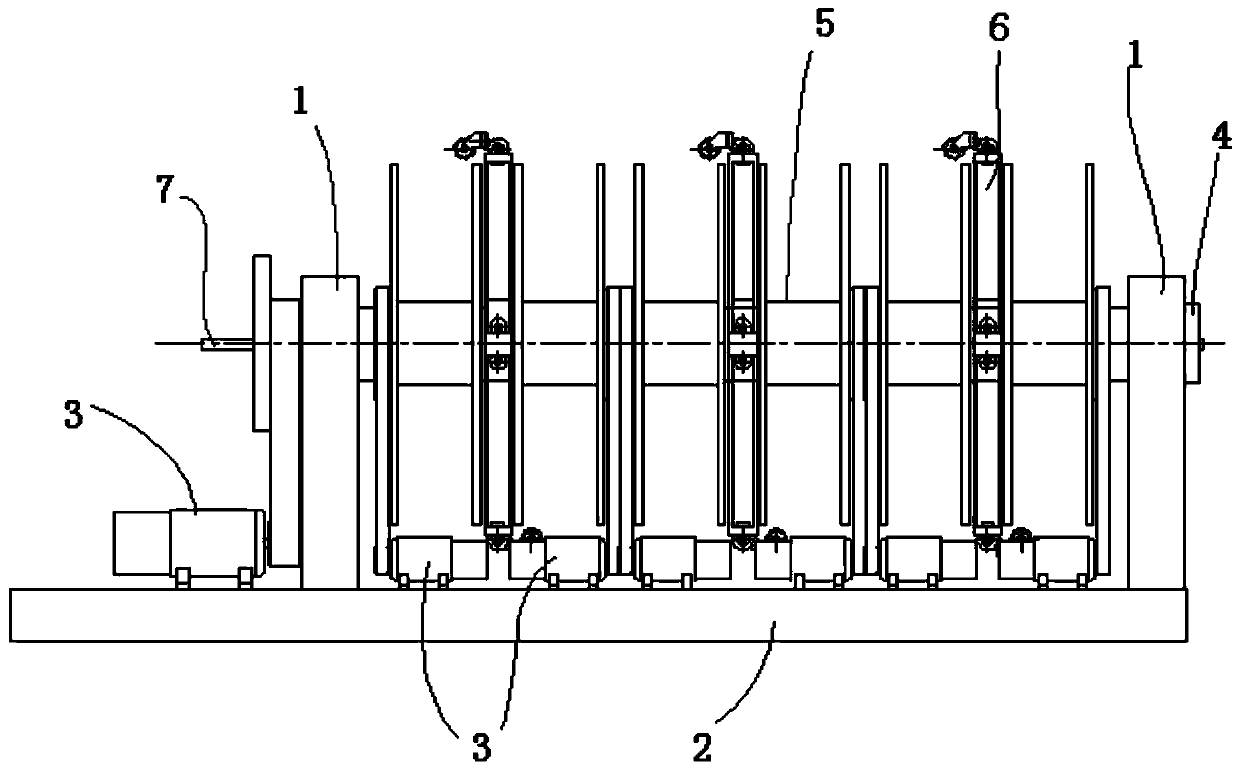

Tension equipment of continuous mill system

InactiveCN101007321AEnsure constant tensionHigh control precisionTensioning/braking arrangementsTension/compression control devicePull forceForce constant

The invention involves a tension device of tandem rolling system. It includes two guide rollers guiding rolling pieces move, floating roller is equipped between said two guide rollers and supports rolling pieces with constant force and makes the rolling pieces stretching force constant through moving up and down, the rolling pieces between said floating roller and said two guide rollers is vertical. Said floating roller can be connected with a hydraulic means which has constant support force, also can be connected with a counterweight body with constant stretching force through hanger rope. The invention proposes a technology program which ensures rolling pieces stretching force constant in rolling plant through changing storage rolling pieces length in rolling mill plant, has characteristics of simple structure, separately adjustment, fast dynamic response and high control precision, etc, it effectively solves the enormous puzzle and technical difficulty stopping tandem rolling technique development for years and years.

Owner:郑红专 +1

Film coating machine for two-sided automatic register

InactiveCN101269552AIncrease productivityRealize automatic version matching functionMechanical working/deformationRelative displacementMotor drive

The invention relates to a film coating machine, in particular to a two-sided automatic plate-alignment film coating machine, which is provided with a basic cloth delivery-furl mechanism, a first basic material delivery-furl mechanism, a first composite mechanism, a second basic material delivery-furl mechanism, a second composite mechanism, a first color mark sensor, a second color mark sensor, a processor, a servo controller, and a servo motor; the second basic material delivery-furl mechanism is provided with a second basic material delivery-furl shaft, a second pressing roll, and a second basic material guiding roll which are driven by a second basic material delivery-furl motor; the servo motor drives the second basic material guiding roll; the processor is connected with the servo controller; and the servo controller is connected with the servo motor. The film coating machine has the automatic plate-alignment function of two-sided design, and the delivery-furl composite speed is rapid, the productivity effect is high, even though the basic material adopts an OPP film with very thin thickness, the highest delivery-furl composite speed of the OPP film can reach 80 meters per minute, the relative displacement of the color mark combined on the OPP films of the two sides of the same plastic braided cloth can be controlled within 3 mm.

Owner:CHANGZHOU HUASHENG PLASTIC MACHINERY

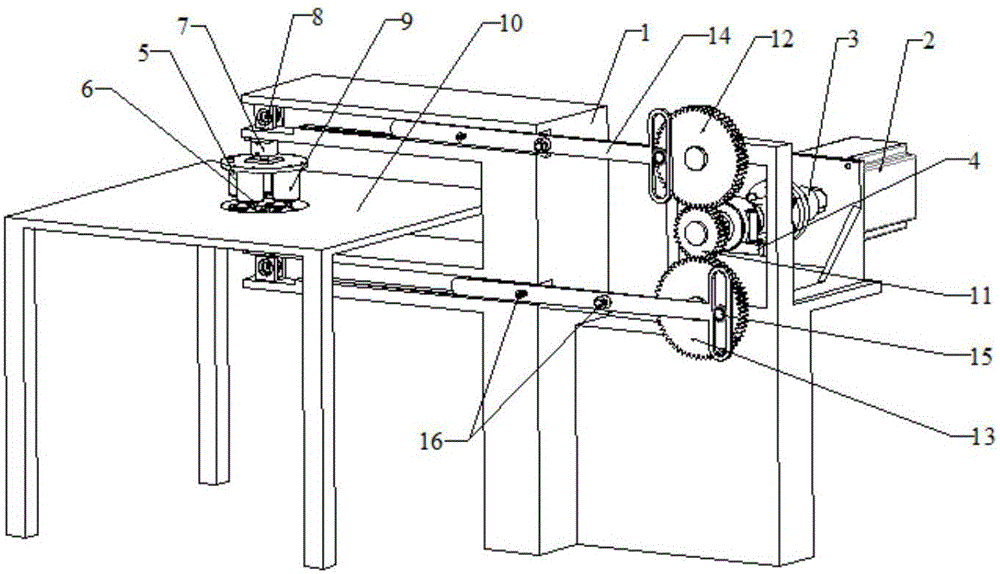

Manual emery wire cutting machine

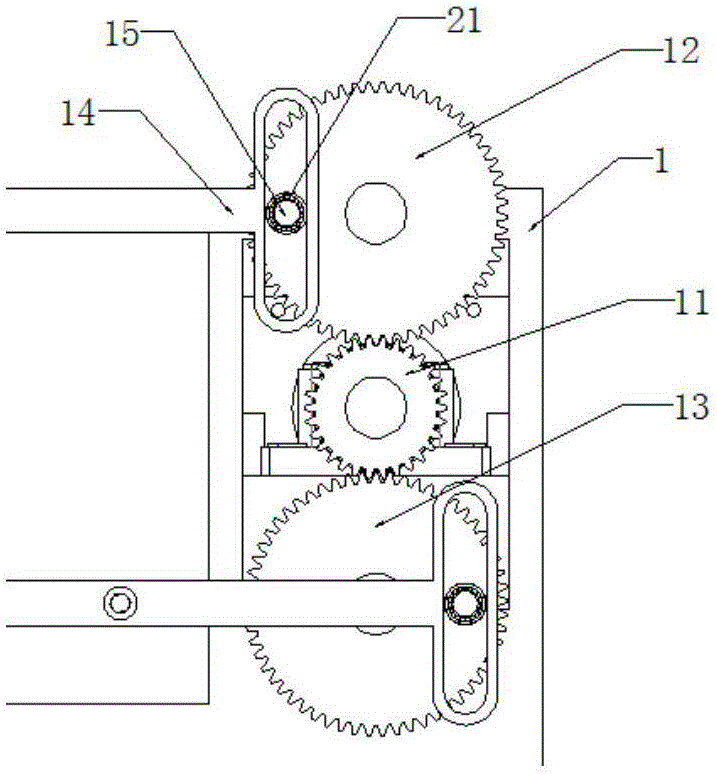

PendingCN107520892AImprove working environmentConstant lengthMetal working apparatusWire cuttingGear transmission

The invention provides a manual emery wire cutting machine. The manual emery wire cutting machine comprises a machine body, a gear transmission device, a crank slide block guide rod mechanism, wire winding and unwinding devices, a fixed supporting and float pressing device, a wire carrying mechanism and a fixed worktable. The whole working process is as follows: a motor drives a driving gear to rotate to enable two working gears, engaged with the driving gear up and down and with the same geometric sizes, to rotate; crank shafts with a phase difference of 180 degrees and the same eccentric distance are respectively mounted on the working gears; through connection of rolling bearings and slide block guide rods, the rotating motion of the working gears is converted to the linear reciprocating motion of the upper and lower slide block guide rods; meanwhile, the slide block guide rods are provided with the wire winding and unwinding devices for fixing, replacing and changing working sections of emery wires; and nonmetal plates are pressed by the float pressing and fixed supporting device, so that the instant advancing motion distance and speed of the emery wires mounted on the upper and lower slide block guide rods are equal to the instant retreating motion distance and speed, and the reciprocating cutting of nonmetal workpieces is finished.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

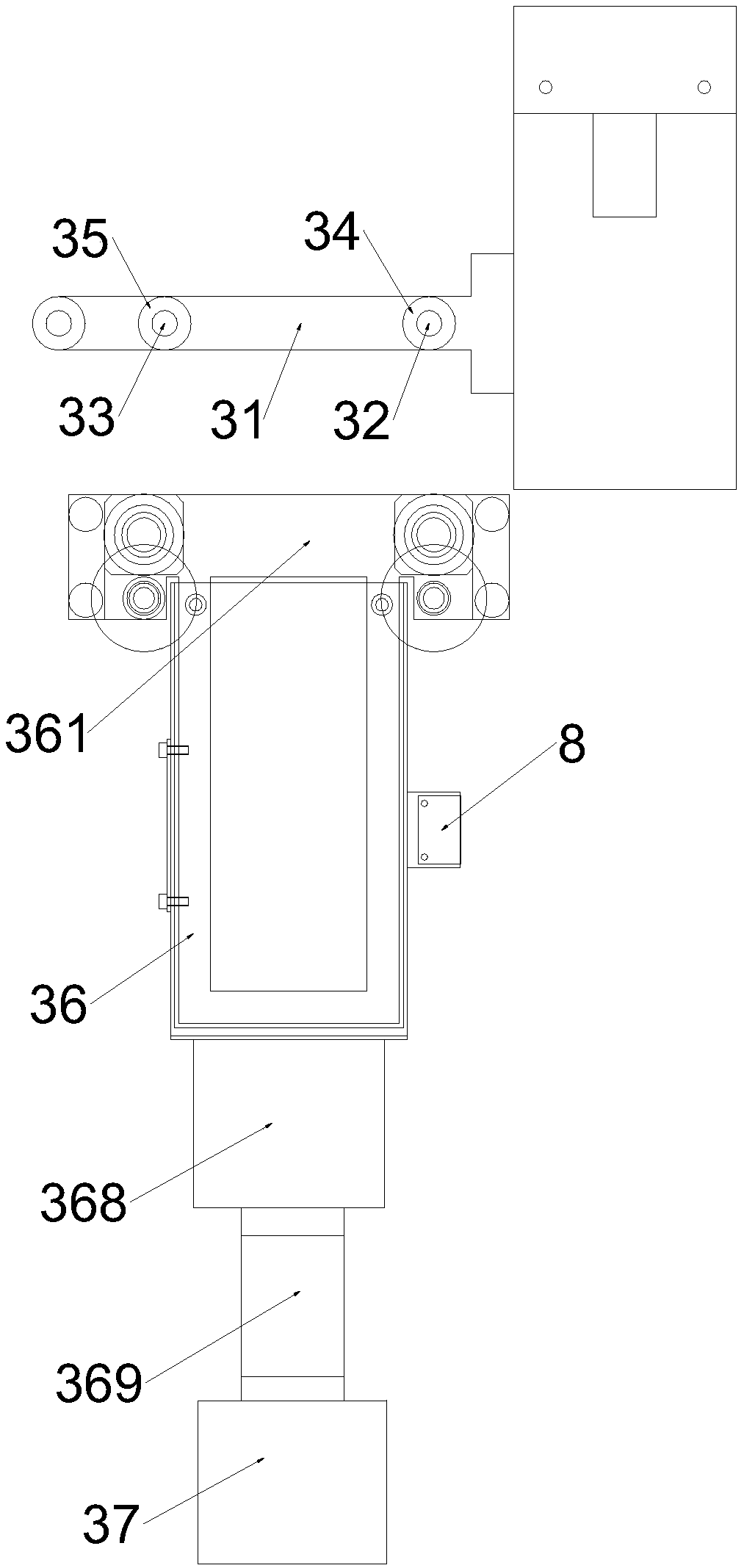

Unreeling device and laminating machine

PendingCN109494416AImprove lamination efficiencyAchieve Z-foldFinal product manufactureSecondary cellsEngineeringTension control

The invention provides an unreeling device and a laminating machine and relates to the technical field of lithium battery manufacturing equipment. The unreeling device comprises an unreeling mechanismfor releasing a diaphragm in a material coil, a tension control mechanism for adjusting the tension of the transported diaphragm, a caching mechanism for caching the transported diaphragm, and a plurality of via rollers for guiding, supporting and tensioning the transported diaphragm. The diaphragm released by the unreeling mechanism enters a laminating mechanism through the via rollers, the tension control mechanism and the caching mechanism and the laminating mechanism drives the diaphragm to move in a reciprocating manner to laminate in a Z shape. The laminating machine comprises the unreeling device. The invention aims to provide the unreeling device and the laminating machine to alleviate the problem that the laminating efficiency is affected when the tension of the diaphragm is controlled improperly in the prior art.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

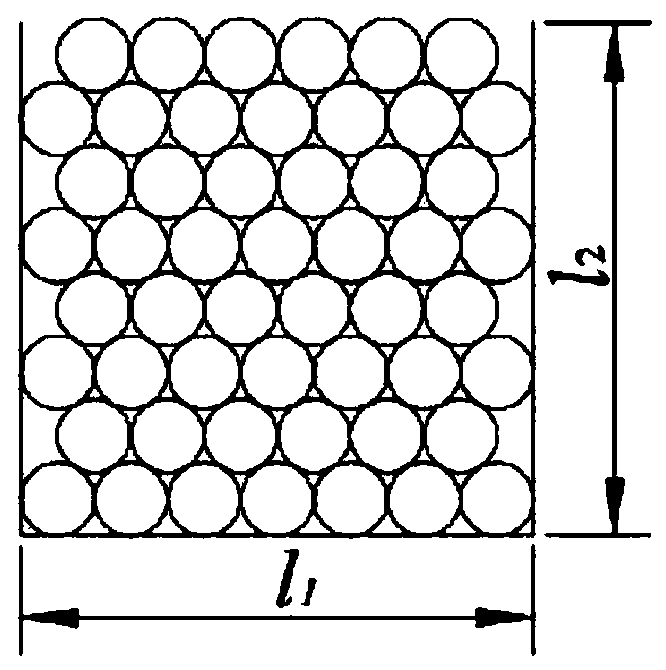

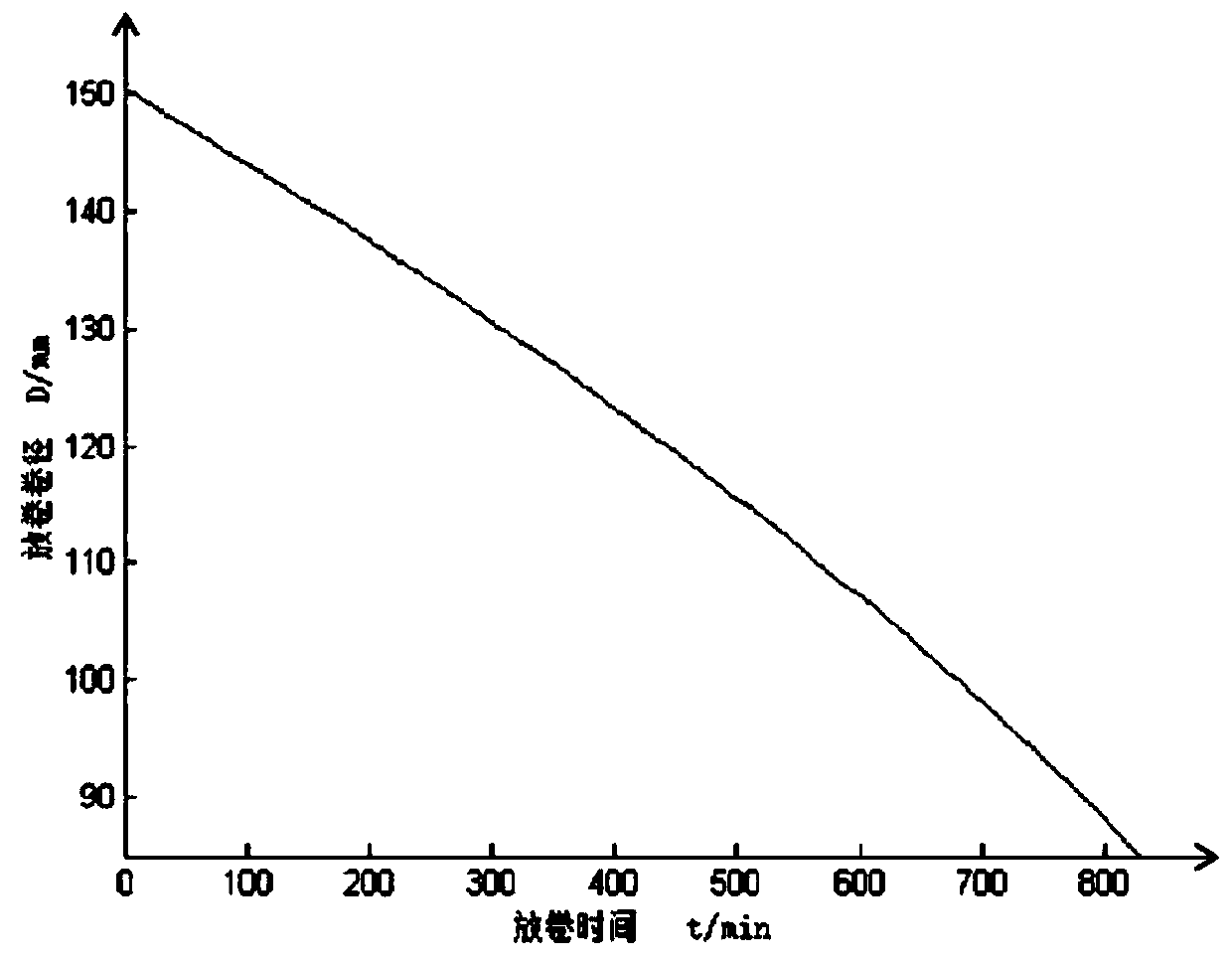

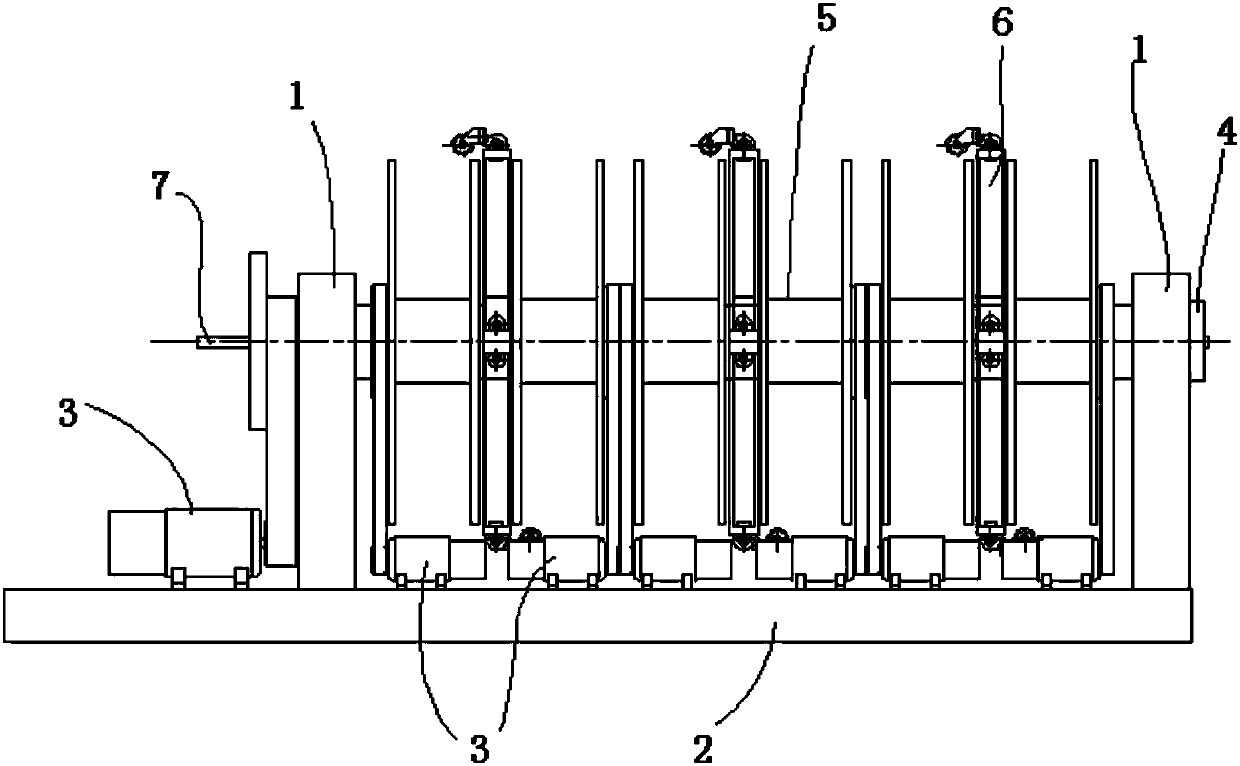

Calculation method for basket-type rope-forming machine stranded rope

InactiveCN109829999AQuality improvementExtended service lifeRegistering/indicating working of machinesRope making machinesNon linear functionsEngineering

The invention provides a calculation method for a basket-type rope-forming machine stranded rope. The method comprises the steps of: the change of the winding diameter of a rope-making machine duringthe pay-off process is detailedly analyzed, and providing a stranded rope cross-winding model used by the rope-forming machine in the unwinding process; establishing a calculation method of filling coefficients [lambda]1 and [lambda]2 of winding of a stranded rope when the arrangement number n of the stranded rope is even and odd and a calculation method of an instant radius D(t) of the axis of apay-off wheel; and determining the filling coefficient of winding of the stranded rope and the winding diameter, namely a non-linear function relation of the instant radius of the axis of the pay-offwheel and the time to achieve the accurate control of tension of the stranded rope of the rope-forming machine in the unwinding process so as to improve the quality of the steel rope spinning and prolong the service life of the steel rope.

Owner:UNIV OF SCI & TECH LIAONING

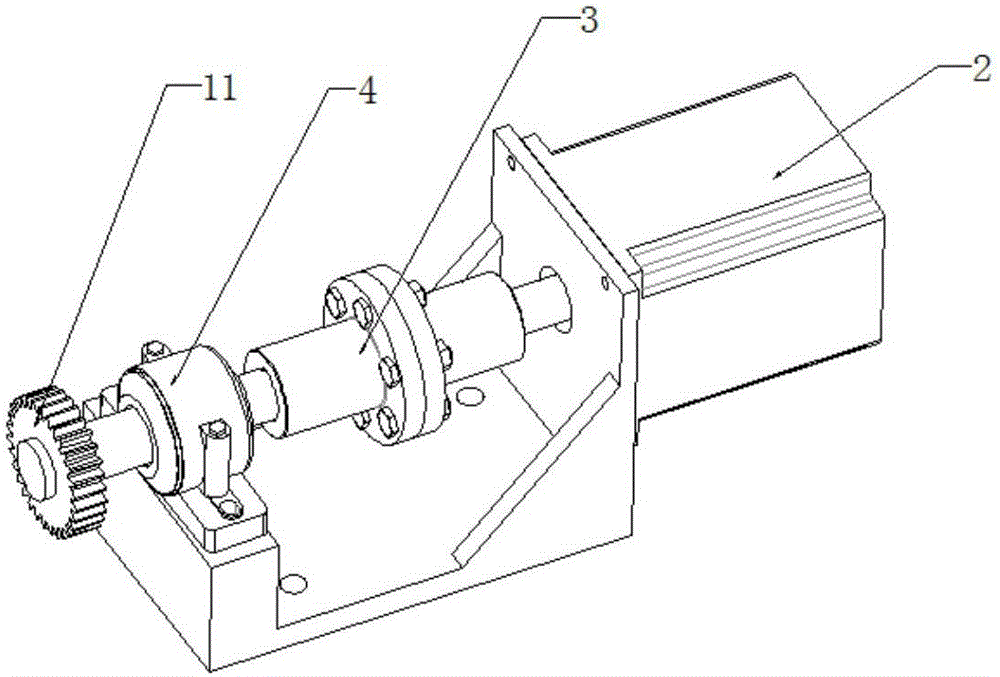

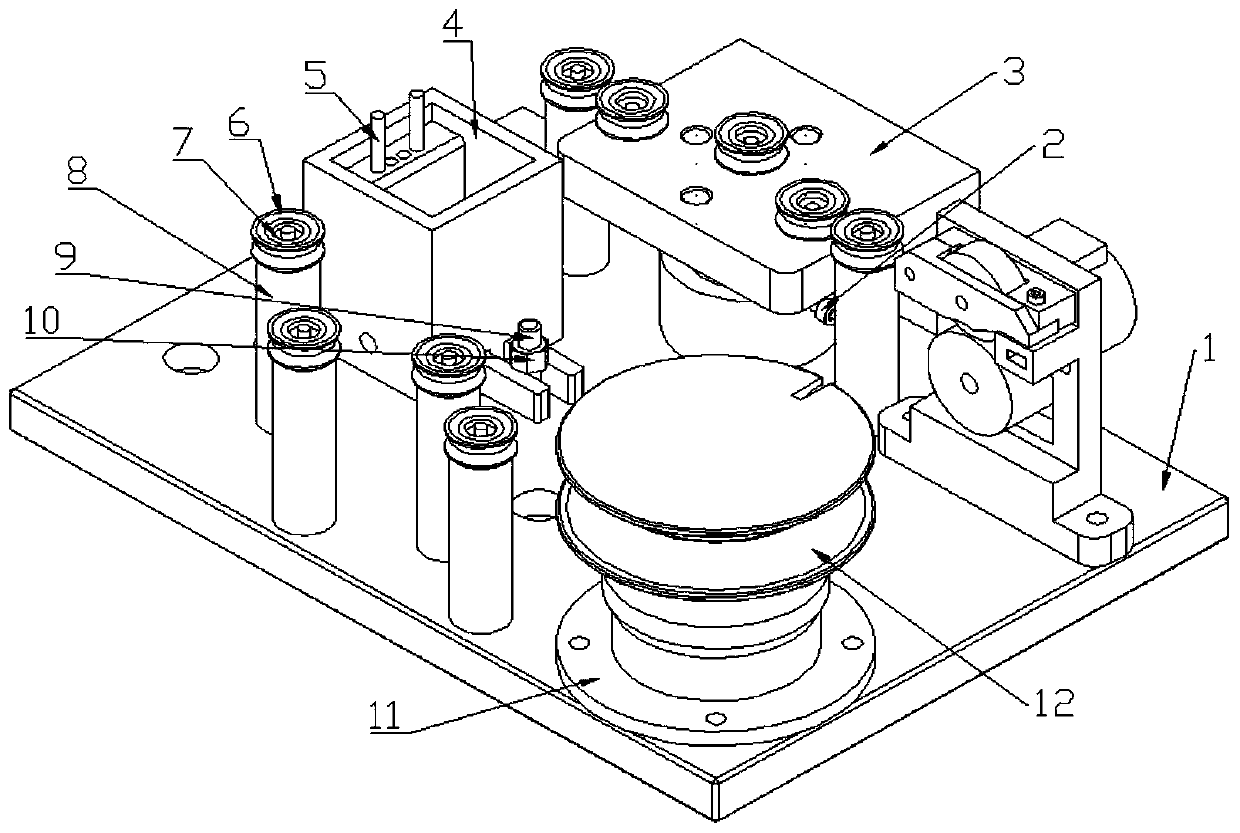

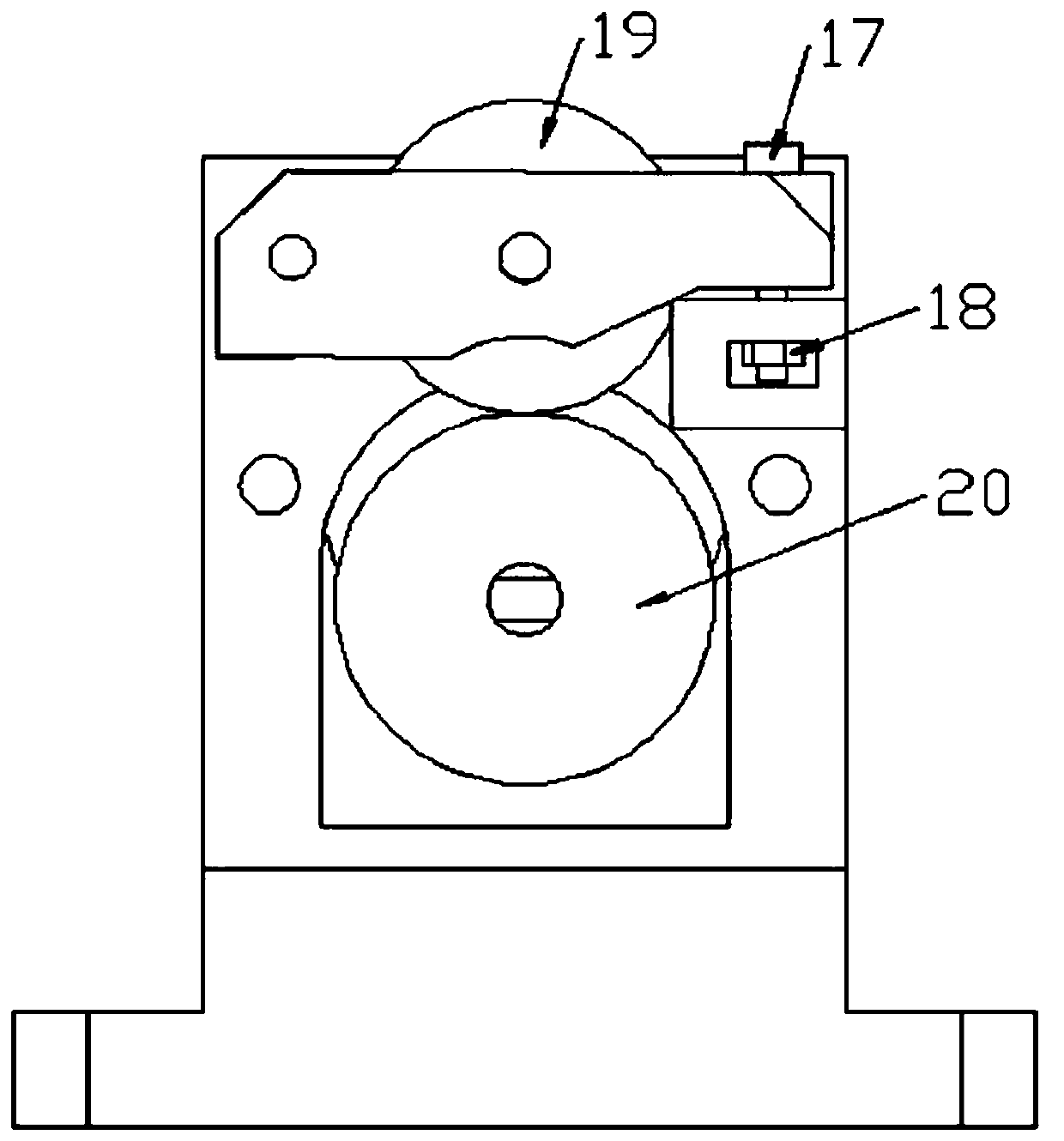

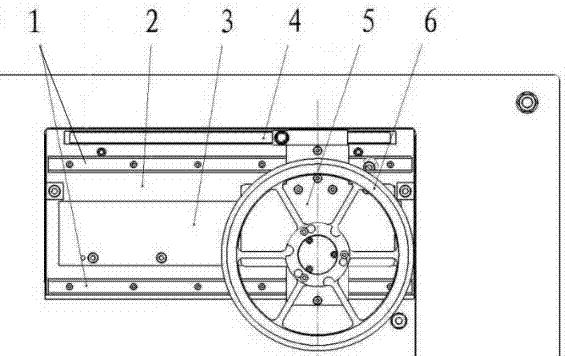

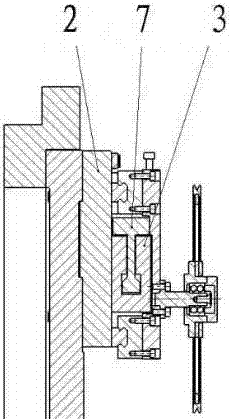

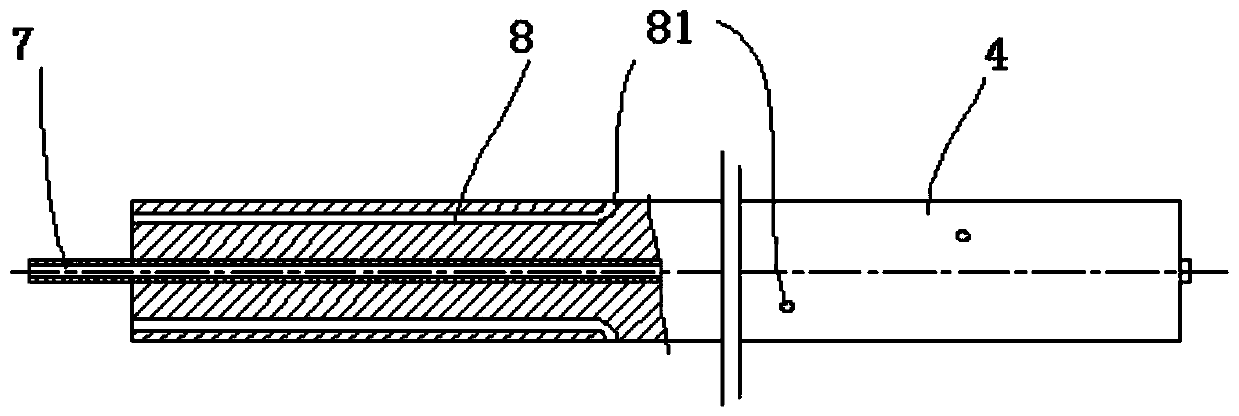

Line electrode constant tension control electric spark grinding machining device

PendingCN111390312AEnsure constant tensionPrevent looseningElectrical-based machining electrodesDrive wheelElectric machine

The invention discloses a line electrode constant tension control electric spark grinding machining device which comprises a base. A wire pay-off mechanism, a wire feeding mechanism and a wire take-upmechanism are arranged on the base. The wire pay-off mechanism comprises a magnetic powder brake installed on the base and a pay-off wheel fixedly connected with a rotating shaft of the magnetic powder brake. The magnetic powder brake is electrically connected with a controller. The wire feeding mechanism comprises a constant tension sensing mechanism, ceramic bars and a plurality of conveying rod mechanisms. The constant tension sensing mechanism comprises a supporting frame and a plurality of tension detection guiding wheels rotationally arranged on the supporting frame, wherein one tensiondetection guiding wheel is connected with a tension sensor, a working solution groove is formed in the base, the two ceramic bars are arranged in the working solution groove in parallel, and the distance between the two ceramic bars can be adjusted. Each conveying rod mechanism comprises a guiding rod and a wire guiding wheel. The wire take-up mechanism comprises a wire take-up support, a wire take-up motor, a driving wheel and a driven wheel. It can be ensured that the tension of a wire electrode in the electric spark grinding machining process is constant.

Owner:LINGNAN NORMAL UNIV

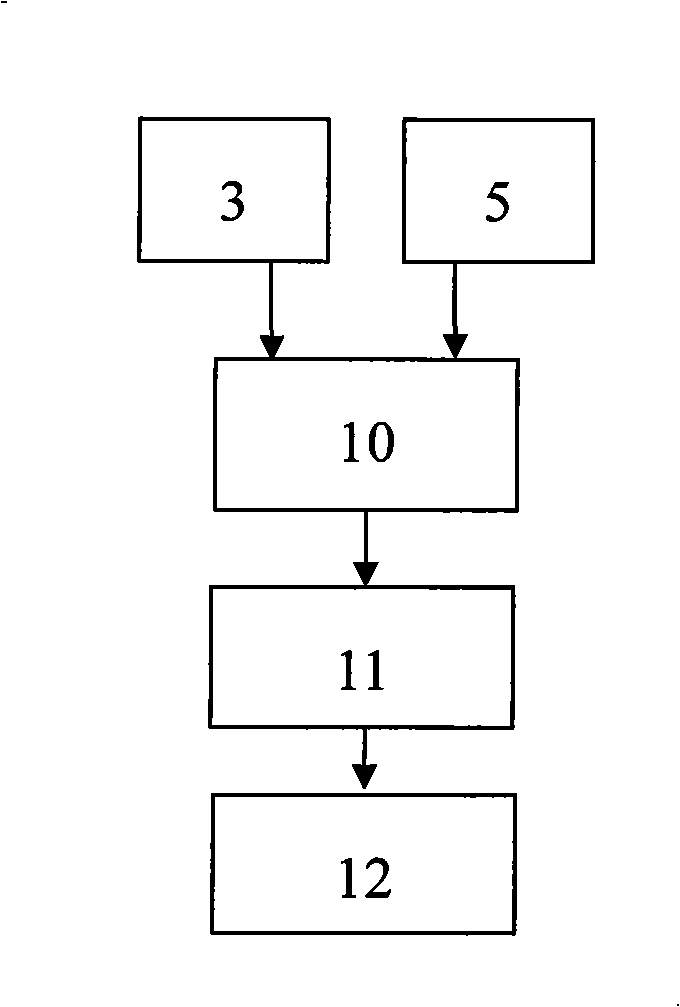

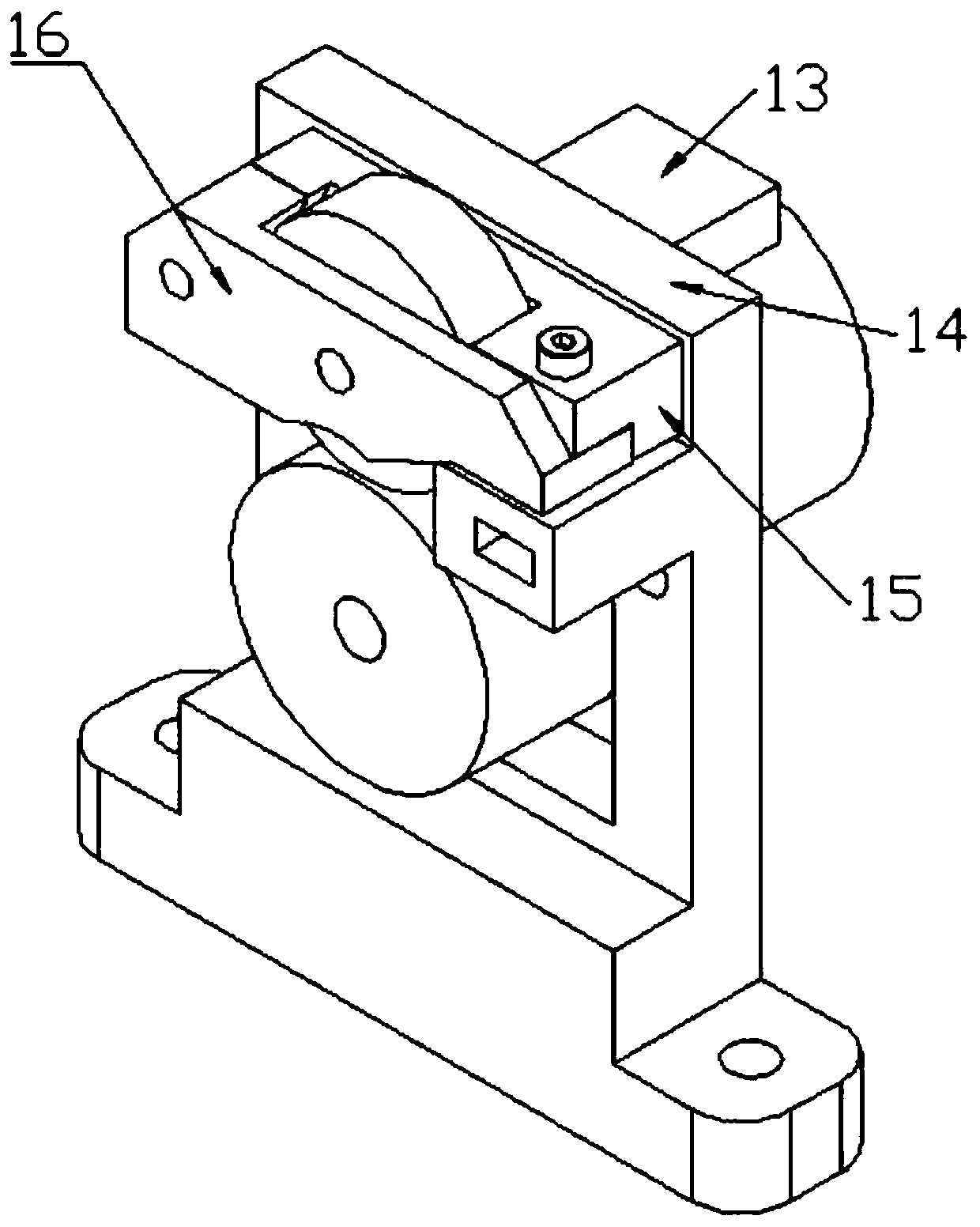

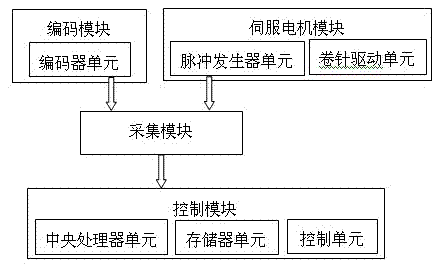

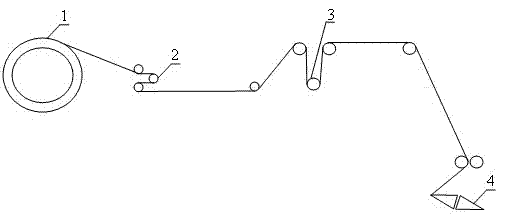

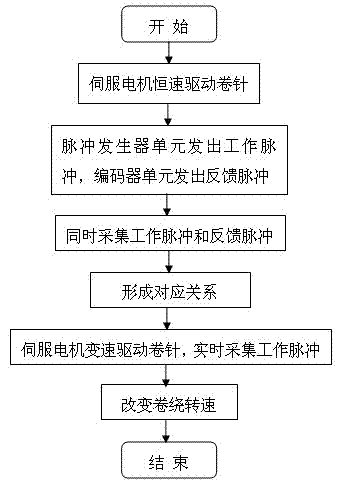

A system and method for variable speed winding of a square winder

ActiveCN102290608AReduce distortionIncrease wind speedFinal product manufactureSecondary cellsEngineeringConductor Coil

The invention provides a square winder variable-speed winding system and a method. The square winder variable-speed winding system comprises a servomotor module, a coding module, an acquisition module and a control module, the servomotor module comprises a winding pin-driving unit and a pulse generator unit, and the pulse generator unit outputs the working pulses of the servomotor module; the coding module adopts a coder unit to periodically interrupt and output feedback pulses; the acquisition module simultaneously acquires the working pulses and the feedback pulses; the control module comprises a central processor unit, a memory unit and a control unit, the central processor unit is used for calculating the winding speed corresponding to the feedback pulses and storing the corresponding relation between the winding speed, the working pulses and the feedback pulses into the memory unit, and the control unit changes the winding speed of the system according to the corresponding relation between the working pulses and the corresponding relation.

Owner:GEESUN AUTOMATION TECH

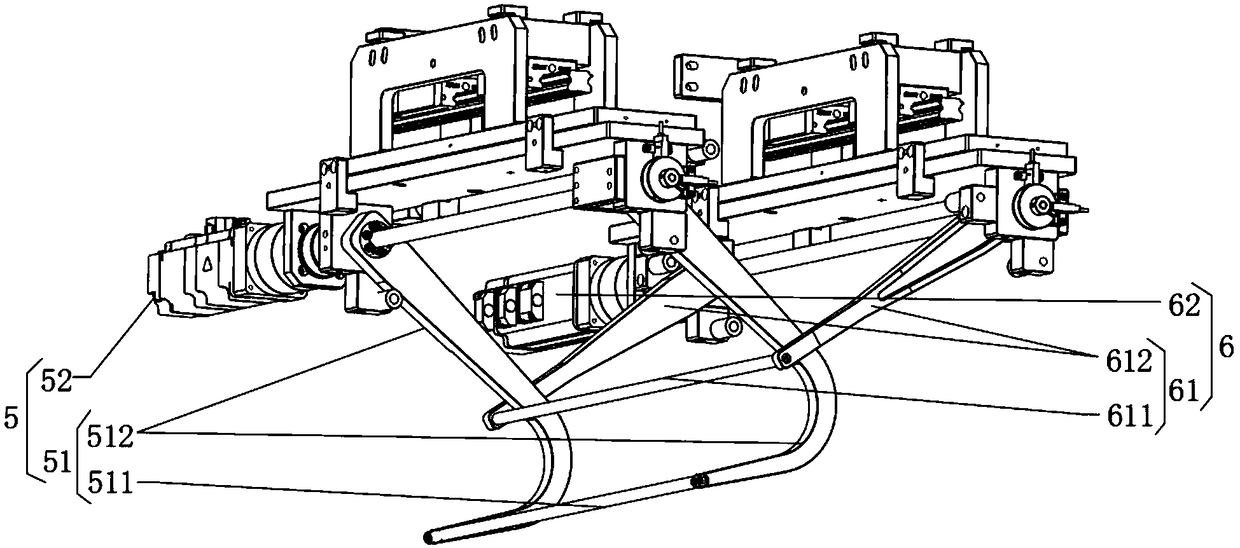

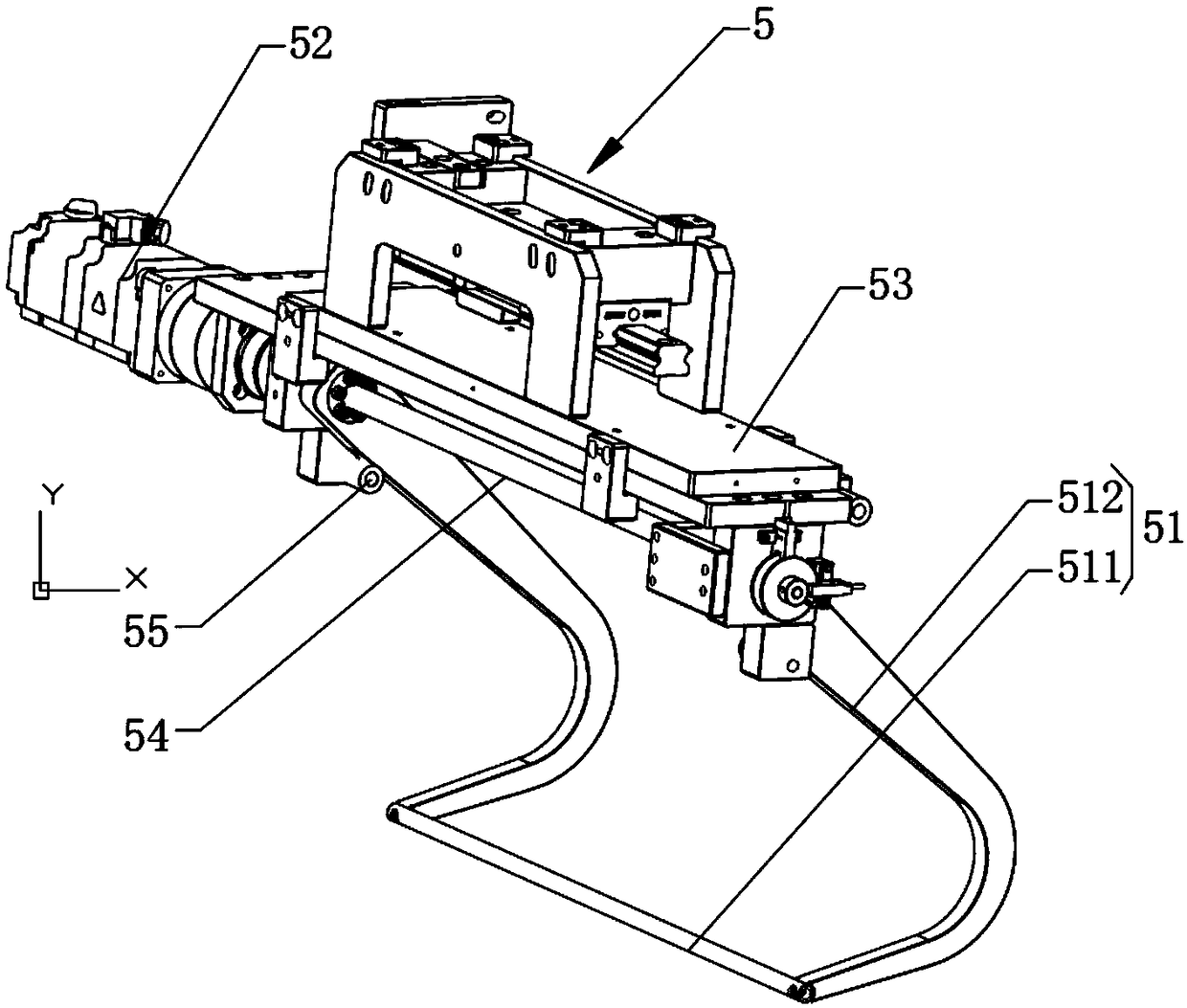

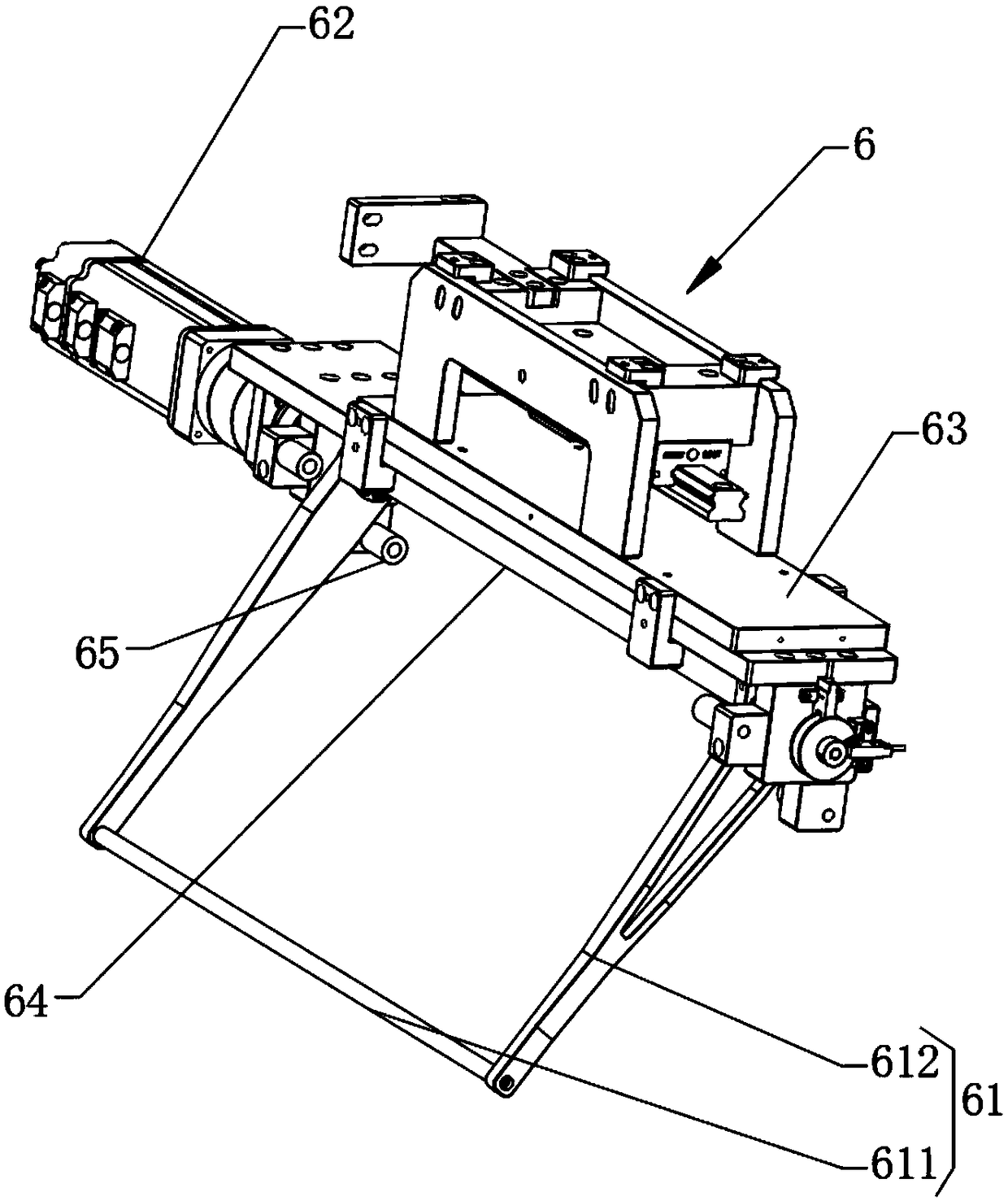

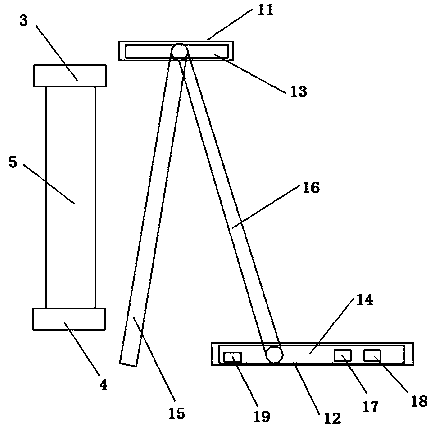

A double-swing arm type tension control device and a double-swing arm type lamination machine

ActiveCN109119701AEliminate the problem of length mutationEnsure constant tensionFinal product manufactureSecondary cellsTension control

The invention relates to the technical field of tension control, in particular to a double-swing arm type tension control device and a double-swing arm type lamination machine, the double-swing arm type tension control device comprises a first swing arm mechanism and a second swing arm mechanism, the diaphragm is guided and folded in a Z form by swinging the first swing arm mechanism and the second swing arm mechanism, the second swing arm mechanism tensions the diaphragm when the first swing arm mechanism guides the diaphragm to one side, and the first swing arm mechanism tensions the diaphragm when the second swing arm mechanism guides the diaphragm to the other side. The diaphragm is carried out in the Z form by swinging the first swing arm mechanism and the second swing arm mechanism,specifically, when the first swing arm mechanism guides the diaphragm to one side, the second swing arm mechanism tensions the diaphragm, controls the tension of the diaphragm, and eliminates the problem of sudden change of the diaphragm length in the lamination process, thereby avoiding problems such as diaphragm loosening and tearing in the high-speed lamination process.

Owner:DONGGUAN CHAOYE PRECISION EQUIPMENT CO LTD

Yarn winding system and control method

ActiveCN110040578AEnsure constant tensionOvercoming the problem of unstable tensionFilament handlingFiberCarbon fibers

The invention relates to the technical field of carbon fiber spreading, in particular to a yarn winding system. The yarn winding system comprises an unwinding device, a yarn translation device and a flat plate winding device, wherein the unwinding device is used for unwinding yarns on a yarn barrel under constant tension; the yarn translation device is used for changing the positions of the yarnsreleased from the unwinding device in the direction perpendicular to the conveying direction of the yarns; and the flat plate winding device is used for winding and forming the yarns; a weight is hungbetween two yarn storage rods, and the yarn tension is ensured to be constant while yarn storage is carried out by using the weight of the weight, so that the problem that the yarn tension is not constant due to the fact that a core mold is plate-shaped and the yarn tension is not constant is solved, and the yarns uniformly wind the plate-type core mold. Meanwhile, the invention further relates to a yarn winding control method. According to the control method, the moving speed of a yarn guide part and the rotating speed of the plate-type core mold are reasonably set, so that the uniform and seamless winding of the yarns on the plate-type core mold is realized, and the mechanical property of a finally-formed carbon fiber product is good.

Owner:NEWTRY COMPOSITE

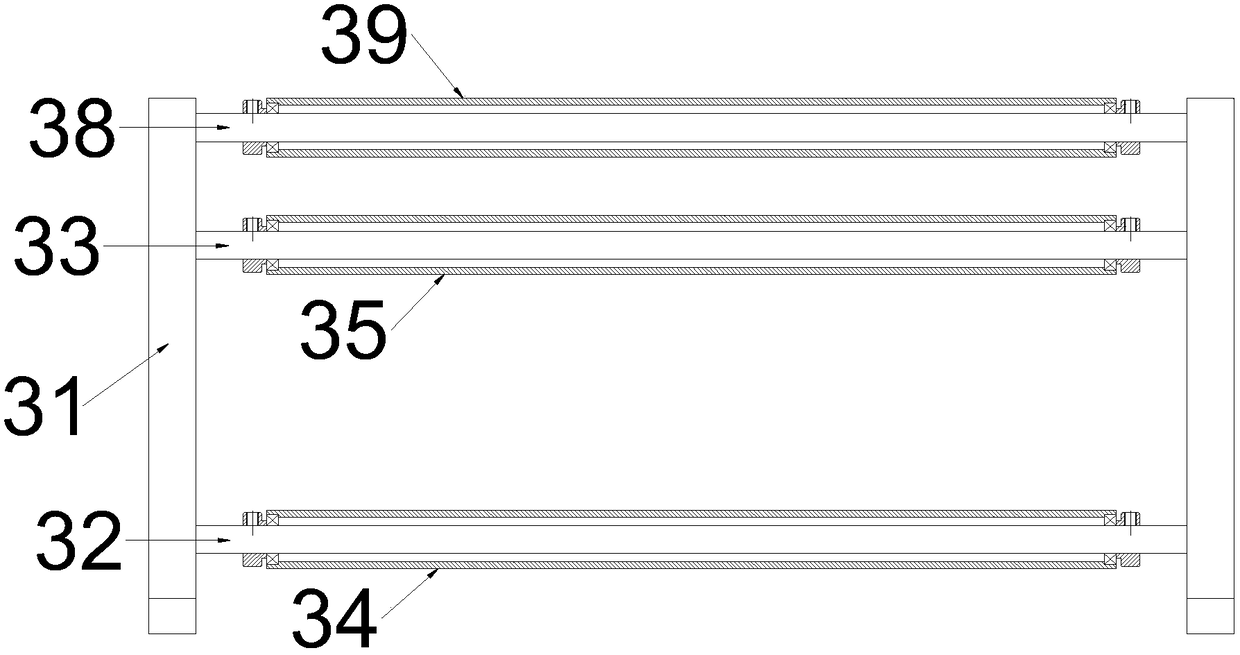

Tension adjusting mechanism for multi-wire cutting machine

The invention discloses a tension adjusting mechanism for a multi-wire cutting machine. The tension adjusting mechanism for multi-wire cutting machine comprises linear guide rails, a machine frame, a stator assembly, a magnetic grid ruler, a moving assembly, a sliding wheel assembly and a mover. The linear guide rails are fixed on the frame, and the stator assembly is also fixed on the frame and is positioned in the middle of the two linear guide rails. The magnetic grid ruler is fixed on the frame along one side of the linear guide rails. The moving assembly is slidably mounted on the linear guide rails and connected with the sliding wheel assembly. The mover is connected with and drives the moving assembly. The tension adjusting mechanism of the multi-wire cutting machine can ensure constant tension on the diamond line and reduce disconnection rate of the equipment.

Owner:SUZHOU HRT ELECTRONICS EQUIP TECH

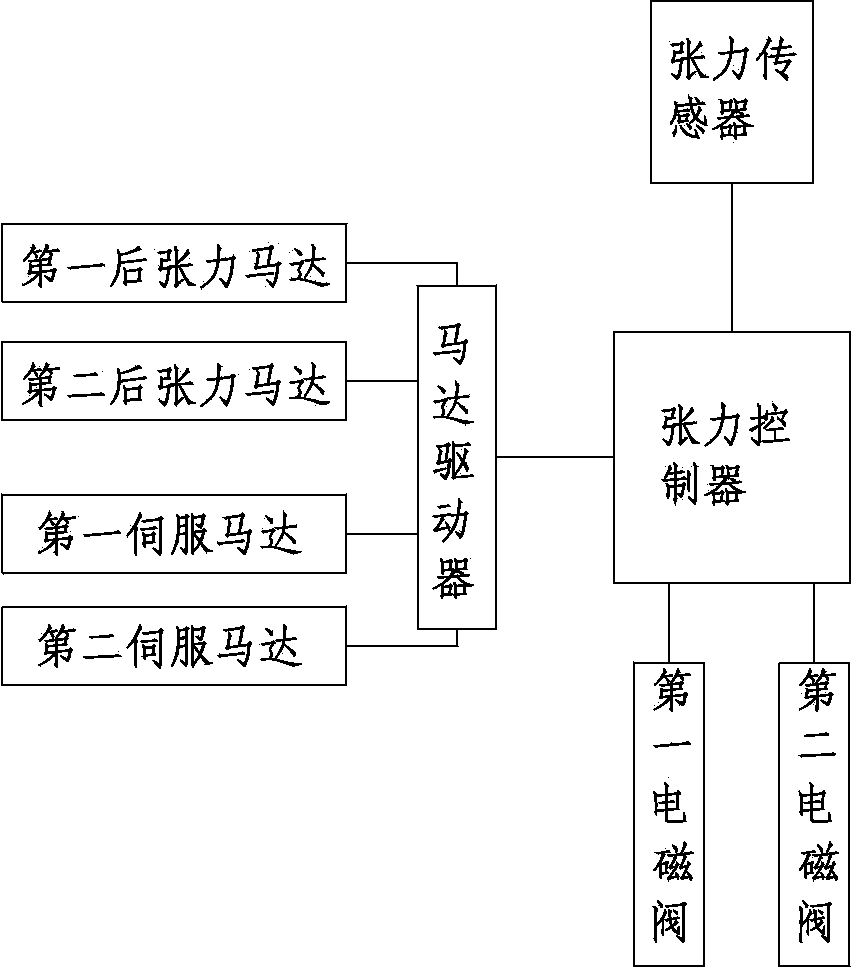

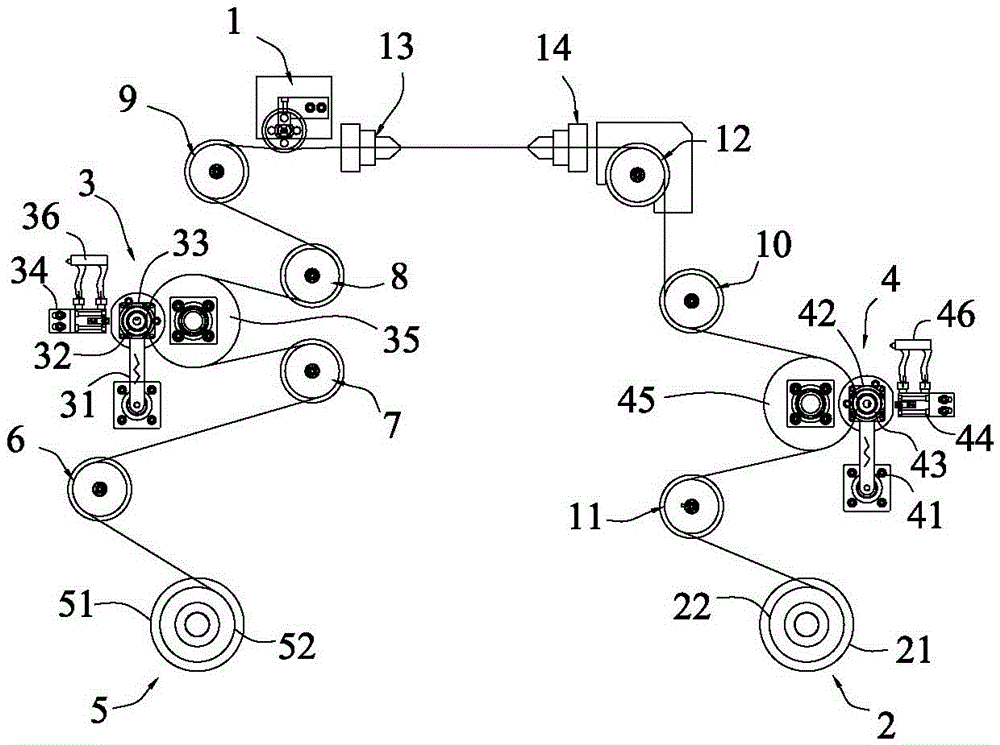

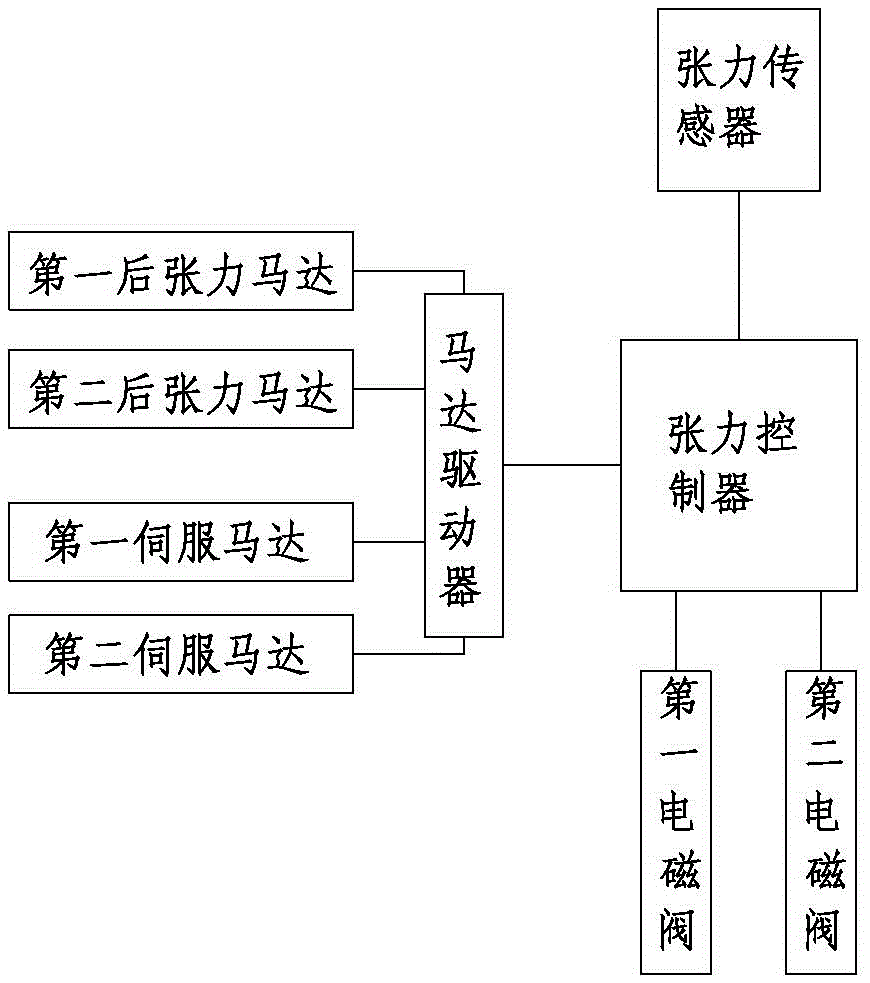

Static constant-tension control system for reciprocation high-speed wire traveling

ActiveCN104028865ASolving resonance problemsFix jitterElectrical-based machining electrodesControl systemEngineering

The invention discloses a static constant-tension control system for reciprocation high-speed wire traveling. The system comprises first guiding wire wheels A-D, second guiding wire wheels A-B, a wire entering guiding pulley, a tension controller, a tension sensor, a first wire feeding wheel taking-up and paying-off device, a second wire feeding wheel taking-up and paying-off device, a first constant tension adjusting device and a second constant tension adjusting device, wherein the tension sensor, the first wire feeding wheel taking-up and paying-off device, the second wire feeding wheel taking-up and paying-off device, the first constant tension adjusting device and the second constant tension adjusting device are respectively connected with the tension controller. The structural design is ingenuous and reasonable, the wire feeding wheel structure is adopted for replacing traditional wire winding drums, the problem that because the wire drums are not concentric, a wire electrode resonates and shakes is solved, it is effectively guaranteed that the tension of the wire electrodes is constant, and machining efficiency is improved; moreover, original positions of a tension wheel and the wire electrode do not need to be adjusted, people only need to control rotation speed of a servo motor, and therefore operation is easy; meanwhile, a symmetrical structure design is adopted, so that matched wire loosening and reciprocation operation on the two sides are achieved, the problem that because single-side wire loosening and reciprocation operation are adopted, the tension is not constant is effectively solved, constancy of the tension is further kept, and machining precision is improved.

Owner:广州静粤态科技有限公司

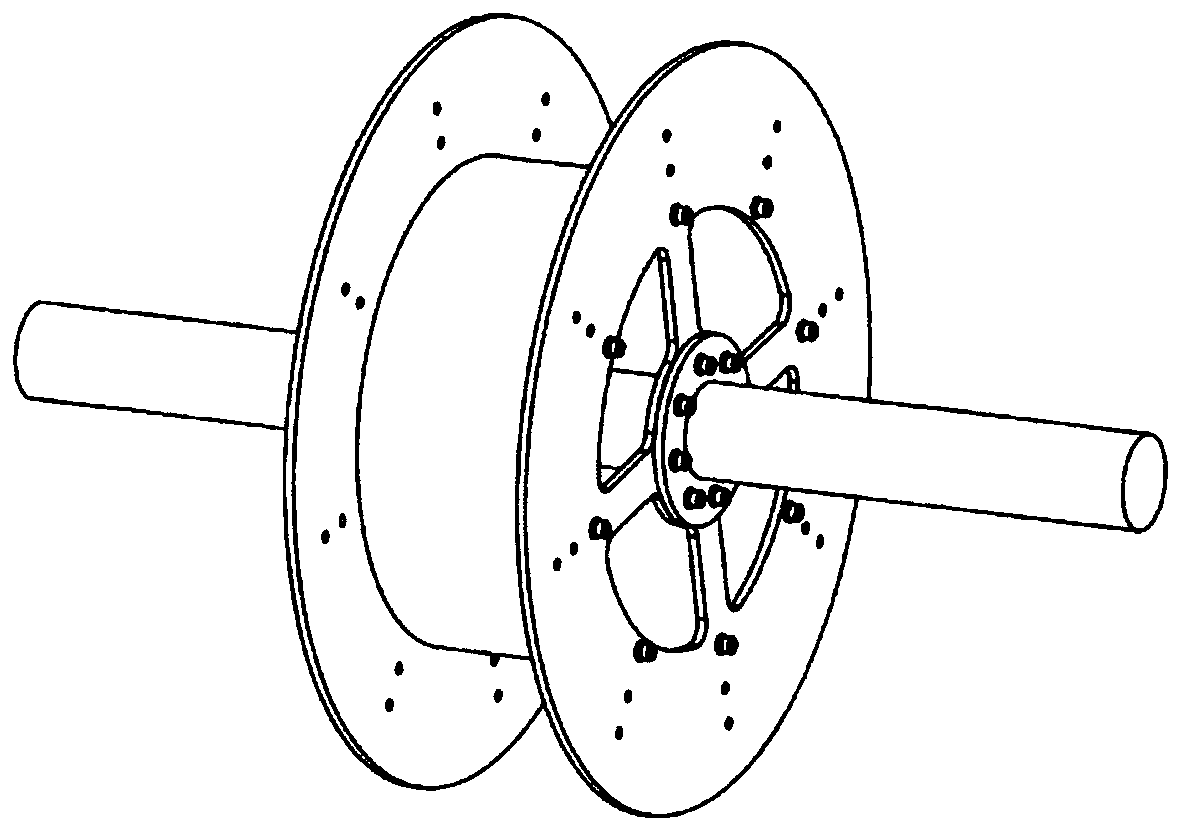

Wire twisting device of welding wire twisting machine and welding wire twisting machine

ActiveCN107717263ALarge diameterReduce downtimeWelding/cutting media/materialsSoldering mediaEngineeringConductor Coil

The invention provides a wire twisting device of a welding wire twisting machine and the welding wire twisting machine. The wire twisting device comprises a wire twisting cylinder, a plurality of welding wire reels, wire winding tubes, a wire taking device and a driving device, wherein the wire twisting cylinder is rotatably arranged on a bracket; at least peripheral welding wire reels pivotally sleeve the outer side of the wire twisting cylinder; the wire winding tubes are arranged in the wire twisting cylinder, and comprise peripheral welding wire winding tubes and a central welding wire winding tube; the wire taking device is used for guiding welding wires on the welding wire reels into the corresponding wire winding tubes; and the driving device is used for driving both the wire twisting cylinder and the welding wire reels to rotate. As the peripheral welding wire reels are arranged on the outer side of the wire twisting cylinder, the diameters of the welding wire reels are not limited by the space of the wire twisting cylinder and can be increased, the welding wires loaded on the welding wire reels are relatively heavy, the idle hour caused by the replacement of the welding wire reels can be greatly shortened, and the production efficiency can be greatly improved.

Owner:江苏科融新材料有限公司

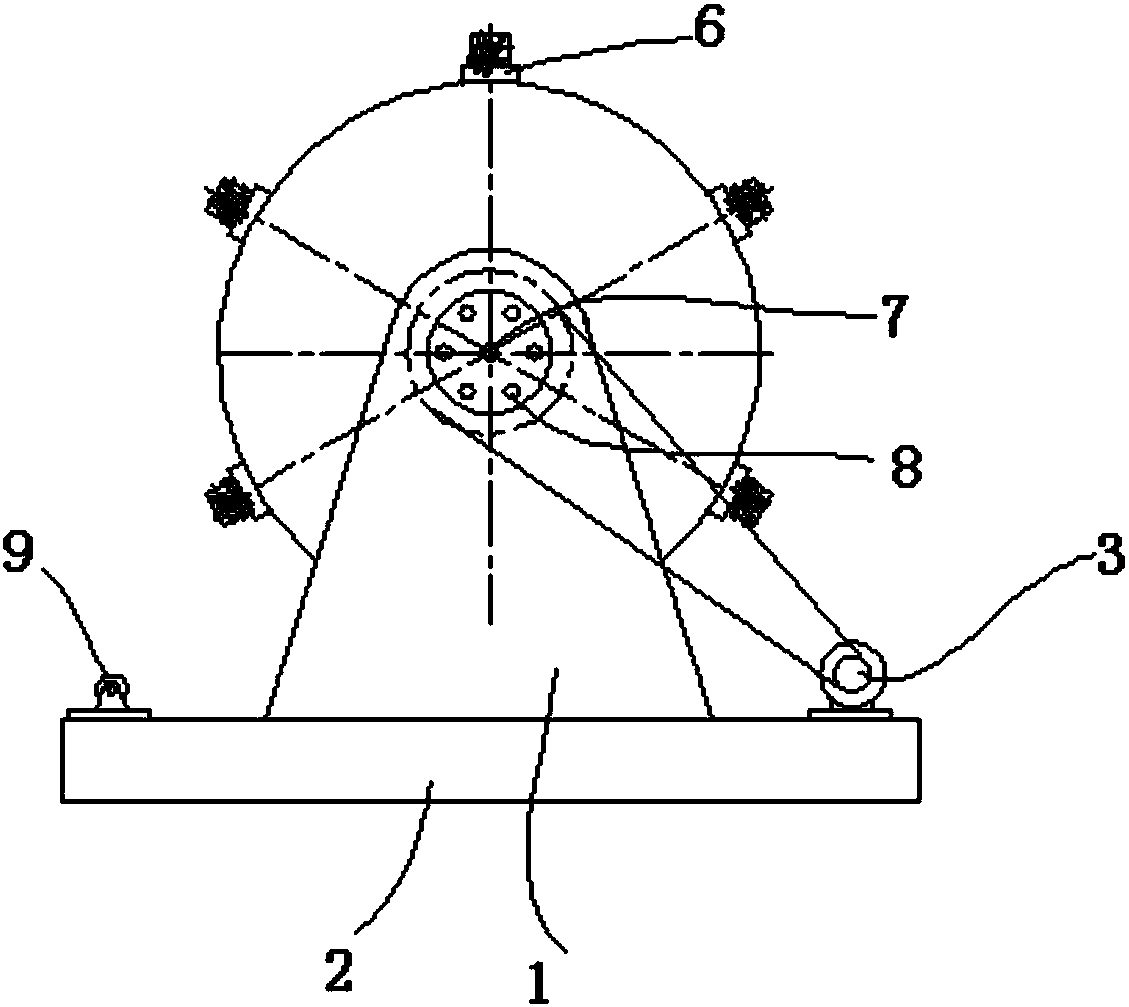

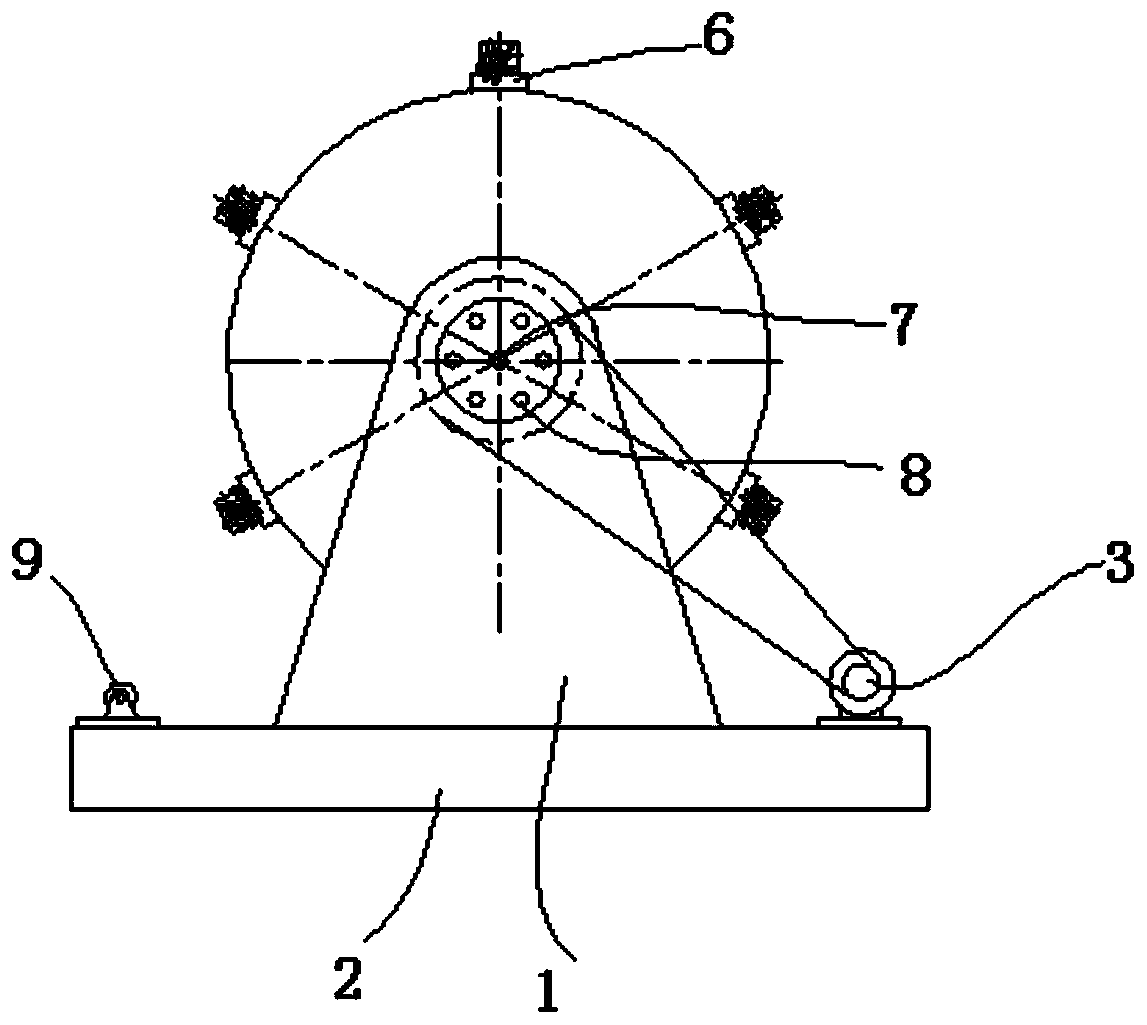

Steel wire rope bending fatigue testing apparatus

PendingCN109142038AEnsure constant tensionHigh precisionMaterial strength using repeated/pulsating forcesDrive wheelEngineering

The invention discloses a steel wire rope bending fatigue testing apparatus which comprises a rack, a driving wheel, a test wheel, a guide wheel, a counterweight wheel, a control box and a driving device, wherein the driving device is used for driving the driving wheel; the counterweight wheel is mounted on a wheel stand; a fixing block is arranged on the rack and positioned above the counterweight wheel; a chute is formed in the fixing block along the vertical direction; the upper end of the wheel stand is connected into the chute in a sliding manner; the lower end of the wheel stand is connected with a servo driving device used for driving the wheel stand to move up and down; the servo driving device is electrically connected with the control box; a tension sensor is arranged on the testwheel; and the tension sensor is electrically connected with the control box. According to the testing apparatus disclosed by the invention, the tension stressed by a to-be-tested steel wire rope isacquired in real time by the tension sensor, the wheel stand is driven to move up and down by a servo electric cylinder so as to give a certain compensation in the process of enabling the to-be-testedsteel wire rope to slide up and down, and the tension stressed by the to-be-tested steel wire rope in the testing process is further kept constant, so that the accuracy of test data is improved.

Owner:WUXI UNIVERSAL STEEL ROPE

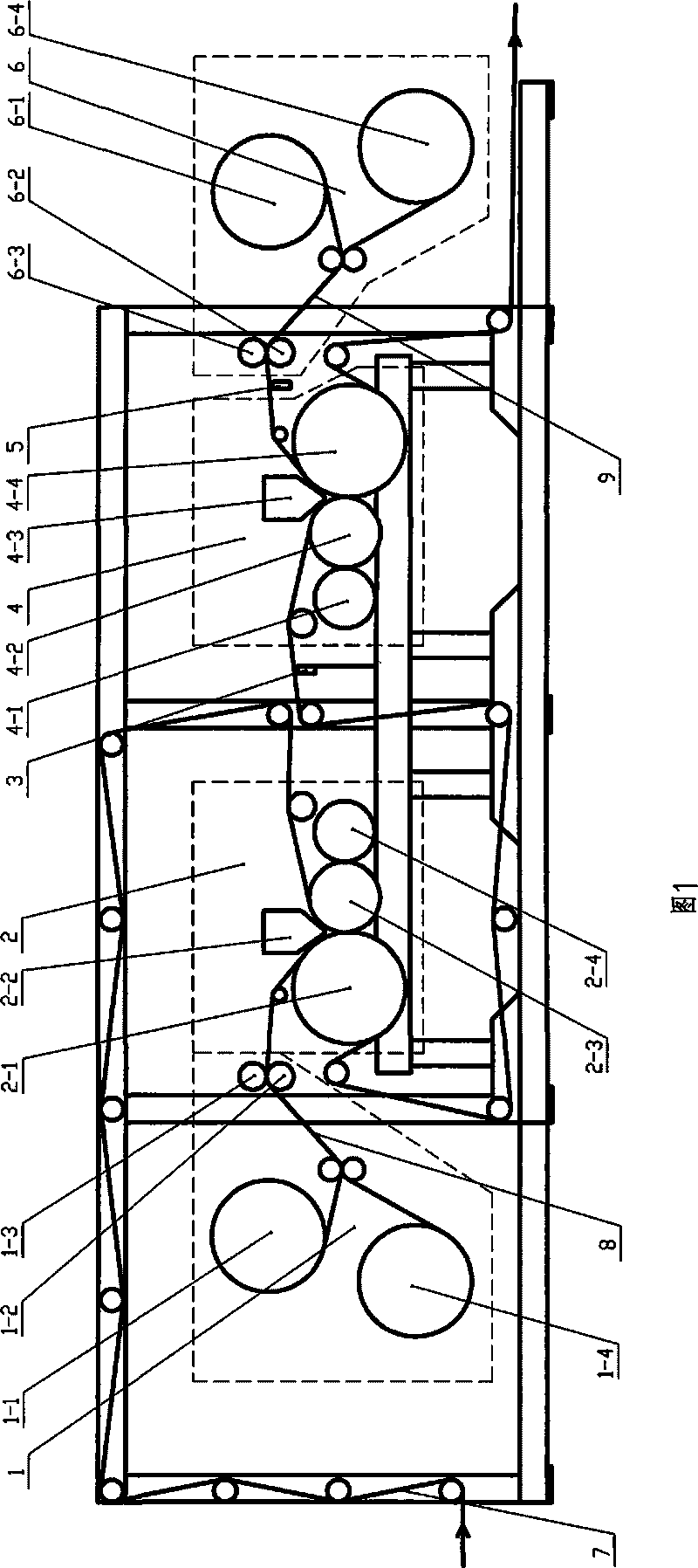

Gravure printing machine

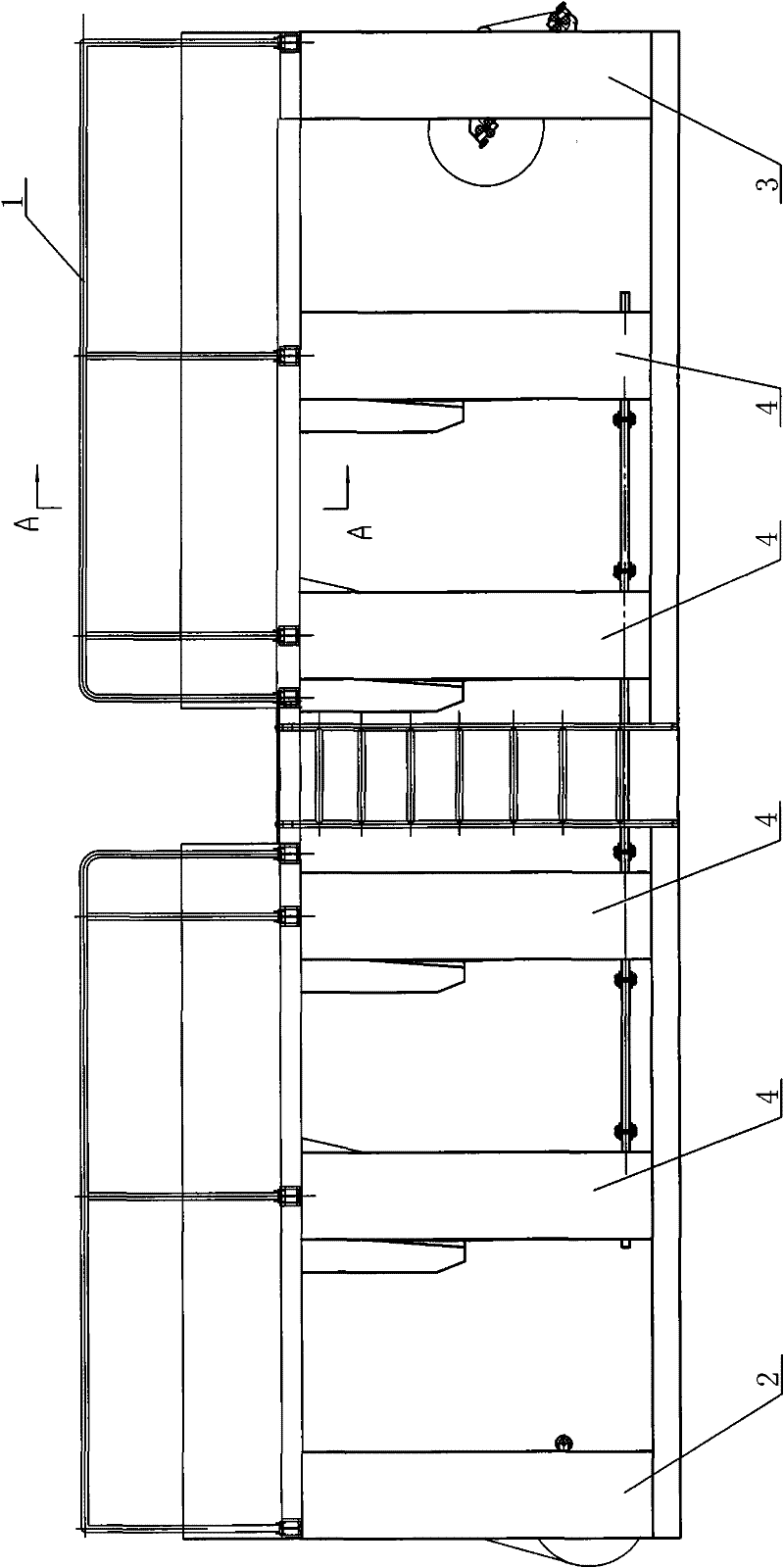

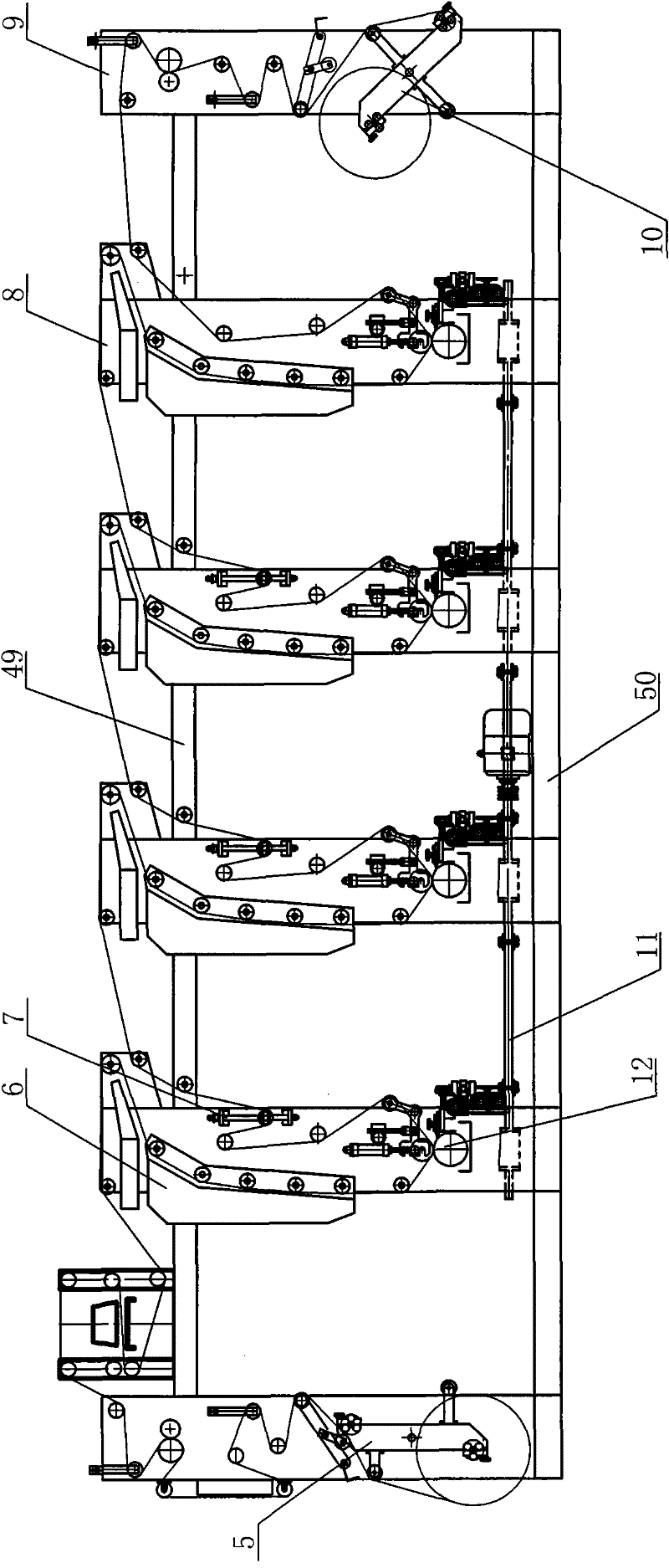

InactiveCN101698369BImprove appearance qualityImprove overprint accuracyRotary intaglio printing pressPrinting press partsDrive shaftThrough transmission

The invention discloses a gravure printing machine. The gravure printing machine comprises a winding group, a unwinding group and a middle color group, wherein the groups are connected together though cross beams and based which are fixed on wall boards of the groups, an operating corridor is arranged outside the wall boards, the winding group and the unwinding group are separately provided with a winding device and an unwinding device, the middle color group owns a plurality of groups, each color group is provided with a coining device and an oven heating device, and the coining devices of the color groups are connected together through transmission shafts in a synchronous manner. The gravure printing machine has good appearance and quality, compact structure and high installation precision, can ensure continuous roll-changing without stopping the machine, and is characterized by energy saving, high efficiency and low consumption.

Owner:WENZHOU GUOWEI PRINTING MACHINERY

Method and device for detecting pre-shrinking rate of preshrunk woven fabric

PendingCN112110261AAccurate length percentageLength percentage trueTextile testingUsing optical meansMechanical engineeringIndustrial engineering

The invention discloses a method and device for detecting a pre-shrinking rate of a preshrunk woven fabric. The method for detecting the pre-shrinking rate of the preshrunk woven fabric comprises a first fabric tension adjusting mechanism arranged on a cloth inlet side of a rubber blanket cloth shrinking unit, a second fabric tension adjusting mechanism arranged on a cloth outlet side of a wool blanket drying unit and a central processing unit. A first length measuring mechanism for measuring an operating length of the fabric is arranged on the cloth inlet side of the rubber blanket cloth shrinking unit, a second length measuring mechanism for measuring the operating length of the fabric is arranged on the cloth outlet side of the wool blanket drying unit, and the first fabric tension adjusting mechanism, the second fabric tension adjusting mechanism, the first length measuring mechanism, the second length measuring mechanism and the central processing unit are connected. By arrangingthe first fabric tension adjusting mechanism and the second fabric tension adjusting mechanism and carrying out regulation and control, it is ensured that tensile forces at two length measuring placesare equal when lengths of the fabric before and after preshrinking settle are measured. According to the invention, length percentages of the fabric before and after preshrinking settle can be preshrunk accurately and truly, and a current accurate fabric preshrinking rate is calculated.

Owner:CHANGZHOU HONGDA INTELLIGENT EQUIP IND DEV RES INST CO LTD

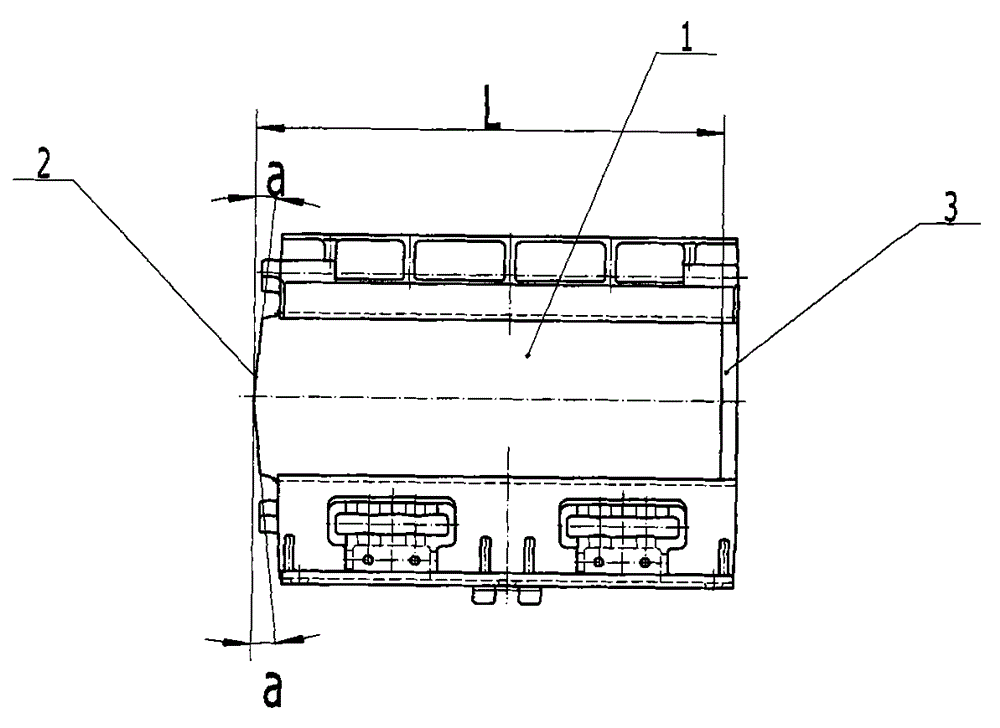

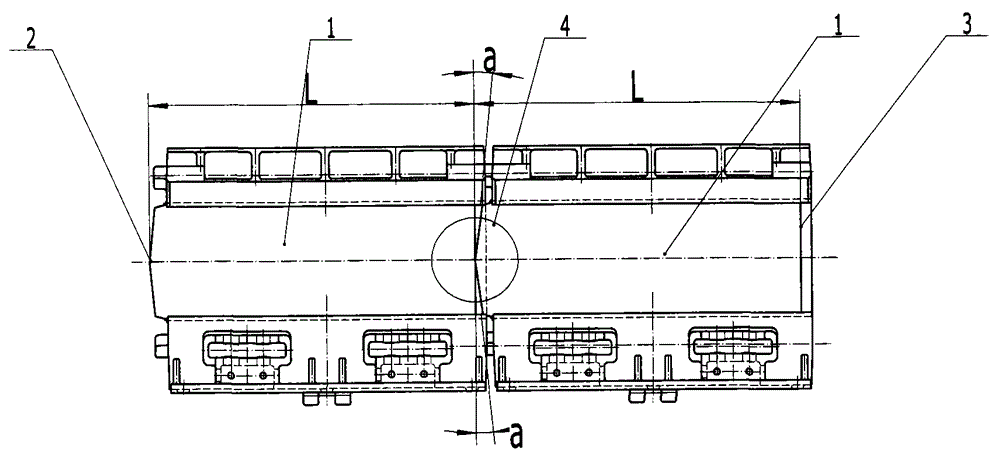

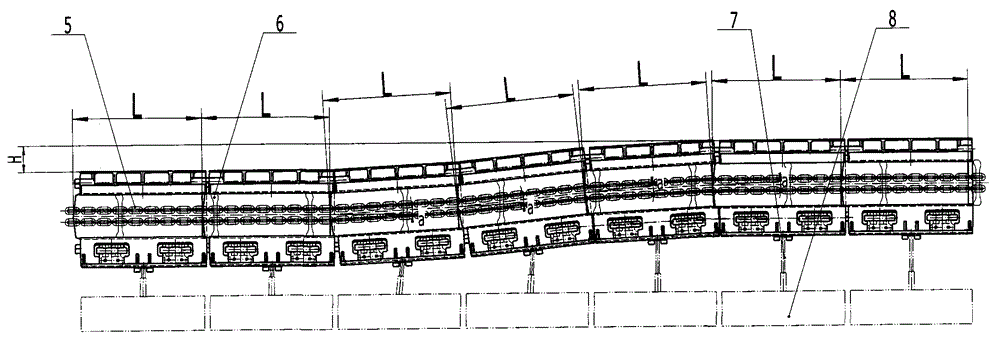

V-shaped geometric form of middle plate structure of middle groove

InactiveCN105292940AMeet corner needsTo achieve the purpose of constant tensionConveyorsGeometric formLateral displacement

The invention discloses a V-shaped geometric form of a middle plate structure of a middle groove. A head end (2) of a middle plate (1) of a middle groove part of a traditional scraper conveyer is designed as a V-shaped edge port with an outward obtuse angle; the V-shaped port is corresponding to a vertical surface of a center line of the middle plate to form an included angle a; a traditional straight port is remained at a tail end (3); meanwhile, the length from a sharp angle at a V end (2) of the head end of the middle plate to a flat port (3) at the tail end is a standard section length L; the shape and size consistency of the middle groove part is kept in operation; in installation and linkage, a K-shaped connecting form is formed in the head-tail connecting place of the middle plate in the middle of each section of the middle groove, so that a gap included angle is formed; and no-gap linkage is realized through head-tail leaning of the middle plate. The no-gap linkage can guarantee constant tension of a ring chain, so that the displacement and the impact of the middle groove in a working state are effectively controlled, and the turning demands needed by the formation of an S-shaped curved line in lateral displacement of the middle groove are guaranteed.

Owner:史庆丰

Conveyor belt tensioning device of belt conveyor

The invention provides a conveying belt tensioning device of a belt conveyor. The conveying belt tensioning device comprises a base, a permanent magnet variable frequency motor, a planetary reducer connected to the permanent magnet variable frequency motor, a gear set connected to the planetary reducer, a winding drum connected to one end of the gear set, a brake connected to the winding drum, a first power-off protection device and an electric cabinet. The designed device is more reasonable in structural layout, small in occupied space, capable of adapting to various complex installation environments and easy to install and transport.

Owner:TAIAN ENDLESS MECHANICAL & ELECTRICAL TECH CO LTD

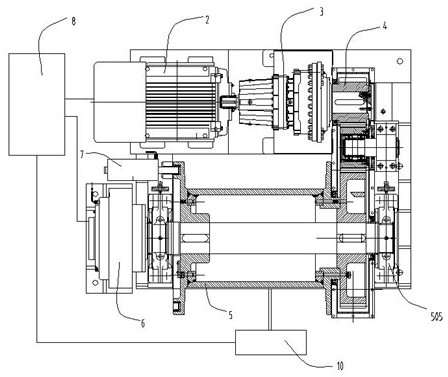

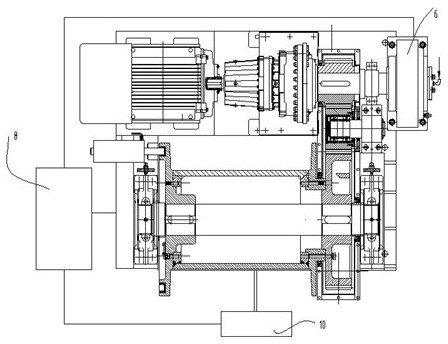

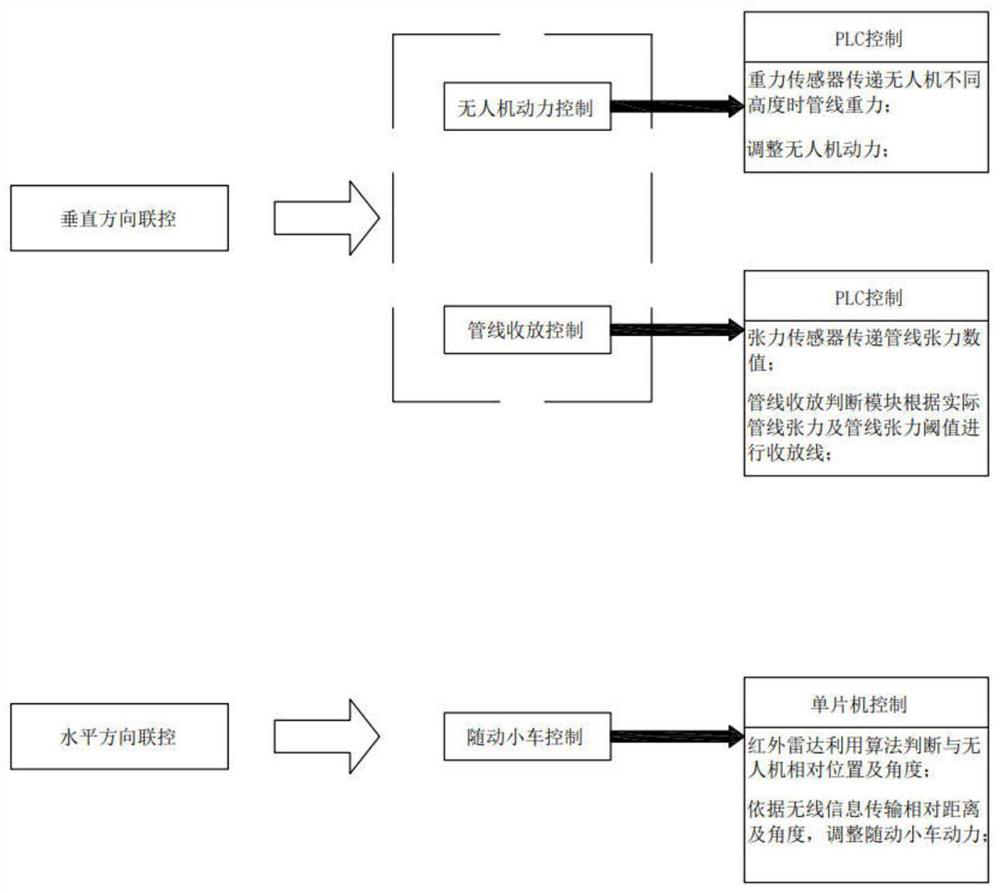

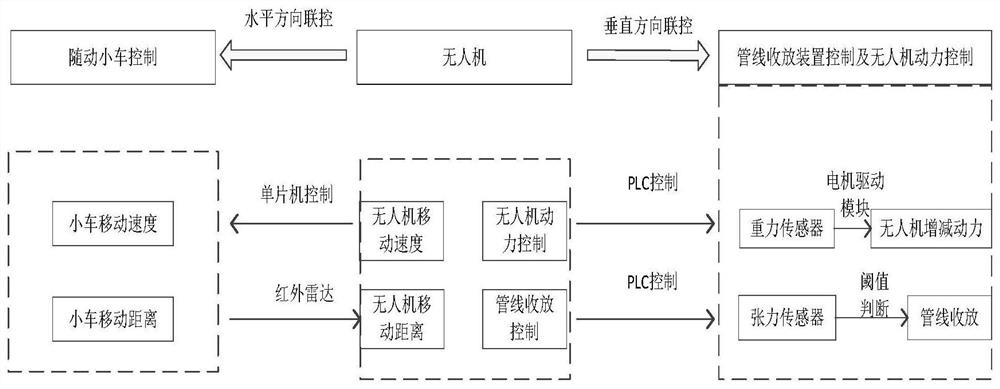

Joint control method and system for unmanned aerial vehicle and follow-up trolley

ActiveCN112748745APoor deliveryEnsure uniform motionPosition/course control in three dimensionsUncrewed vehicleControl theory

The invention discloses a joint control method and system for an unmanned aerial vehicle and a follow-up trolley. The method comprises a vertical direction joint control process and a horizontal direction joint control process which are carried out at the same time. The vertical direction joint control process comprises the following steps of 100, enabling a gravity sensor to measure pipeline gravity loaded by an unmanned aerial vehicle, and enabling a tension sensor to measure a pipeline tension value, 110, controlling a pipeline winding and unwinding device to wind and unwind the pipeline according to the pipeline tension value, so that the pipeline is kept in a tensioned state, and 120, adjusting power output of the unmanned aerial vehicle according to the change of the gravity of the pipeline, and enabling the unmanned aerial vehicle to keep moving at the constant speed. The horizontal direction joint control process comprises the following steps that 200, the distance sensor measures the relative distance and angle between the follow-up trolley and the unmanned aerial vehicle; and 210, the speed of the follow-up trolley is adjusted according to the relative distance and angle, so that the distance and angle between the follow-up trolley and the unmanned aerial vehicle are maintained at the preset distance and angle. The joint control method ensures that the unmanned aerial vehicle moves at a constant speed in the spraying process, and the spraying quality is improved.

Owner:JIANGSU UNIV OF SCI & TECH

Special wire tightening device for linear cutting machine and linear cutting machine

PendingCN112719489ASimple structureEasy to operateElectrical-based machining electrodesWire cuttingEngineering

The invention provides a special wire tightening device for a linear cutting machine tool and the linear cutting machine tool. The special wire tightening device comprises a supporting base, a slide supporting base and a guide wheel, wherein the supporting base is fixedly arranged on a wire rack of the linear cutting machine tool; the slide supporting base is positioned below the supporting base, and can be assembled on the supporting base in a sliding mode vertically relative to the supporting base; and the guide wheel is assembled on the slide supporting base, and can move vertically along with the slide supporting base relative to the supporting base. According to the special wire tightening device, the supporting base on the special wire tightening device is improved, so that the special wire tightening device is better matched with a machine tool, and constant tension of a molybdenum wire cutting line is ensured; the quality and efficiency problems that when the linear cutting machine works, the surface of a part is rough, the cutting efficiency is low, the wire breaking cost is increased and the like due to molybdenum wire tension relaxation are solved; and the special wire tightening device is simple in structure and convenient to operate, and improves the cutting efficiency.

Owner:SHANXI JIANGHUAI HEAVY IND

Automatic Pole Die Cutting Machine

ActiveCN105033017BEnsure constant tensionImprove efficiencyMetal-working feeding devicesPositioning devicesPole pieceEngineering

The invention relates to a full-automatic die cutting machine for a pole piece. The full-automatic die cutting machine comprises a front die cutting mechanism and a rear die cutting mechanism, wherein the front die cutting mechanism comprises an unreeling device, a deviation correcting sensor, a first tension regulating device, first transition rollers, a deviation correcting device and a pole piece blanking cutting die device, and the rear die cutting mechanism comprises a main driving device, a length measuring device, second transition rollers, a second tension regulating device and a reeling device; a first material storing device is arranged between the deviation correcting device and the pole piece blanking cutting die device, and a second material storing device is arranged between the main driving device and the length measuring device; the first material storing device comprises a first storage piece floating roller and a first lifting mechanism, and the first storage piece floating roller can be driven to move upwards or downwards by the first lifting mechanism; the second material storing device comprises a second storage piece floating roller and a second lifting mechanism, and the second storage piece floating roller can be driven to move upwards or downwards by the second lifting mechanism. Through the use of the full-automatic die cutting machine disclosed by the invention, the pole piece blanking efficiency is improved, and the efficiency of blanking pole pieces of lithium batteries is ensured.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Laminating device of die cutting machine

ActiveCN108177194AProper bufferEnsure constant tensionMetal working apparatusEngineeringWind direction

The invention discloses a laminating device of a die cutting machine. A film guiding roller device comprises film guiding roller upper side plates, a first film guiding roller shaft, a second film guiding roller shaft, a first film guiding roller, a second film guiding roller, a tension air bellow and a draught fan. The film guiding roller upper side plates are oppositely arranged. The first filmguiding roller shaft and the second film guiding roller shaft are sequentially arranged between the film guiding roller upper side plates. The two ends of the first film guiding roller shaft and the two ends of the second film guiding roller shaft are connected with the film guiding roller upper side plates through bolts. The first film guiding roller and the second film guiding roller are correspondingly in cup joint to the first film guiding roller shaft and the second film guiding roller shaft through bearings. An interval is reserved between the first film guiding roller and the second film guiding roller. The tension air bellow is arranged under the interval between the first film guiding roller and the second film guiding roller. The draught fan is arranged at the lower end of the tension air bellow. The wind direction of the draught fan acts on the interval between the first film guiding roller and the second film guiding roller. The draught fan and the tension air bellow applydownward pressure to a laminating material, constant tension of the laminating material is guaranteed, and main material bending and deforming after laminating and combining are avoided.

Owner:SHENZHEN REBORN PRECISION MACHINERY CO LTD

Marking machine

InactiveCN111099104AEnsure constant tensionGuaranteed continuous operationLabelling machinesWebs handlingElectric machineryEngineering

The invention discloses a marking machine, and belongs to the technical field of machinery. The marking machine comprises a machine frame, a conveying belt is arranged on the machine frame, an unwinding roller and a winding roller are arranged at the upper end of the conveying belt, the unwinding roller and a winding roller are controlled through a motor, labels are wound on the unwinding roller,a marking device is arranged above the labels between the unwinding roller and the winding roller, the marking device comprises a pressing roller, the pressing roller is driven by the motor to rotate,a plurality of pressing blocks are evenly arranged in the circumferential direction of the pressing roller at intervals, the pressing blocks are connected with the pressing roller through telescopicshafts, and springs are wound around the telescopic shafts. According to the marking machine, the marking process can be completed at a time, baking and manual mark tearing are not needed, the markingprocess can be continuously conducted on products, the production efficiency is greatly improved, and manpower and material resources are saved.

Owner:湖北奥斯龙科技有限公司

Reciprocating high-speed wire walking static constant tension control system

ActiveCN104028865BSolving resonance problemsFix jitterElectrical-based machining electrodesControl systemWire wheel

Owner:广州静粤态科技有限公司

Intelligent control method and device for preshrinking rate of preshrinking woven fabric

PendingCN113911800AHigh control precisionGuaranteed stabilityApparatus for force/torque/work measurementFullingControl engineeringElectric machinery

The invention discloses an intelligent control method and device for the preshrinking rate of a preshrinking woven fabric. The control device comprises a rubber blanket cloth shrinking unit, a wool blanket drying unit and a central processing unit, the rubber blanket cloth shrinking unit comprises a pressing roller, a pressure bearing roller, a rubber blanket and a pressing motor, a first fabric tension adjusting mechanism and a first length measuring mechanism are arranged on the cloth inlet side of the pressure bearing roller, a second fabric tension adjusting mechanism and a second length measuring mechanism are arranged on the cloth outlet side of the pressure bearing roller, and the first fabric tension adjusting mechanism, the first length measuring mechanism, the second fabric tension adjusting mechanism, the second length measuring mechanism and the pressing motor are connected with the central processing unit. A temperature sensor for detecting the temperature of the pressure bearing roller and a displacement measuring mechanism for detecting the displacement of the pressing roller are arranged on the rubber blanket cloth shrinking unit, and the temperature sensor and the displacement measuring mechanism are connected with the central processing unit. According to the intelligent control method and device, the fabric preshrinking rate can be accurately detected online, and the deviation between the actually-measured preshrinking rate and the target preshrinking rate can be avoided or greatly reduced.

Owner:CHANGZHOU HONGDA INTELLIGENT EQUIP IND DEV RES INST CO LTD

A yarn winding system and control method

ActiveCN110040578BEnsure constant tensionOvercoming the problem of unstable tensionFilament handlingFiberCarbon fibers

The invention relates to the technical field of carbon fiber spreading, in particular to a yarn winding system. The yarn winding system comprises an unwinding device, a yarn translation device and a flat plate winding device, wherein the unwinding device is used for unwinding yarns on a yarn barrel under constant tension; the yarn translation device is used for changing the positions of the yarnsreleased from the unwinding device in the direction perpendicular to the conveying direction of the yarns; and the flat plate winding device is used for winding and forming the yarns; a weight is hungbetween two yarn storage rods, and the yarn tension is ensured to be constant while yarn storage is carried out by using the weight of the weight, so that the problem that the yarn tension is not constant due to the fact that a core mold is plate-shaped and the yarn tension is not constant is solved, and the yarns uniformly wind the plate-type core mold. Meanwhile, the invention further relates to a yarn winding control method. According to the control method, the moving speed of a yarn guide part and the rotating speed of the plate-type core mold are reasonably set, so that the uniform and seamless winding of the yarns on the plate-type core mold is realized, and the mechanical property of a finally-formed carbon fiber product is good.

Owner:NEWTRY COMPOSITE

Film coating machine for two-sided automatic register

InactiveCN101269552BGood control effectIncrease productivityMechanical working/deformationRelative displacementMotor drive

Owner:CHANGZHOU HUASHENG PLASTIC MACHINERY

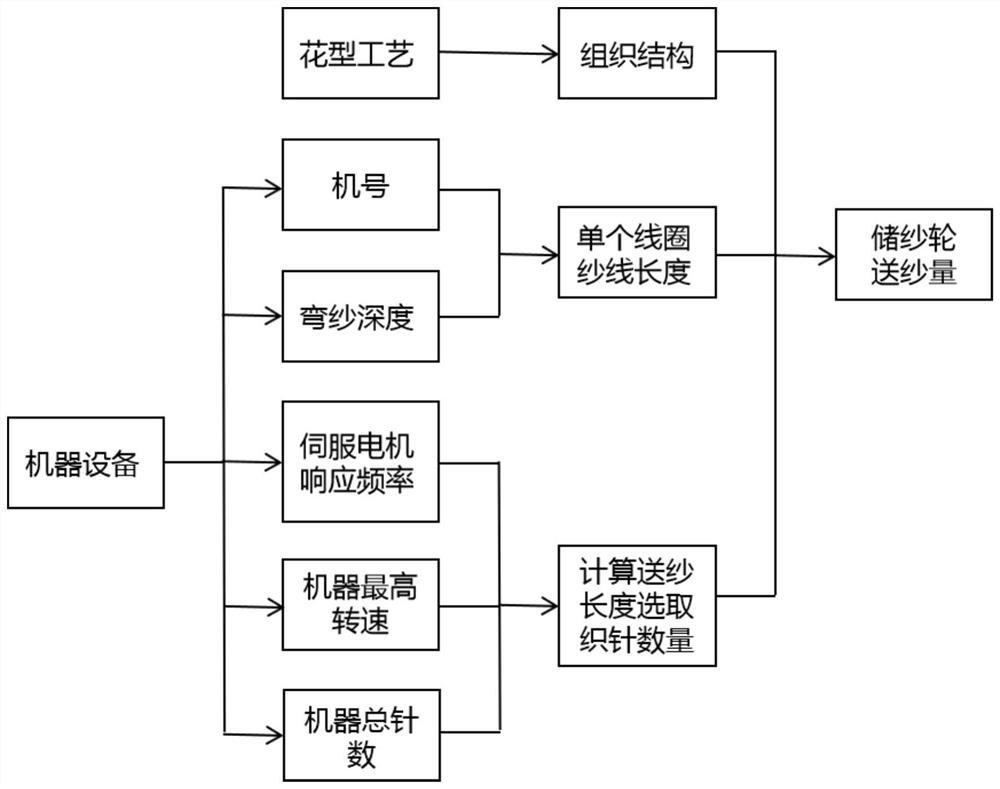

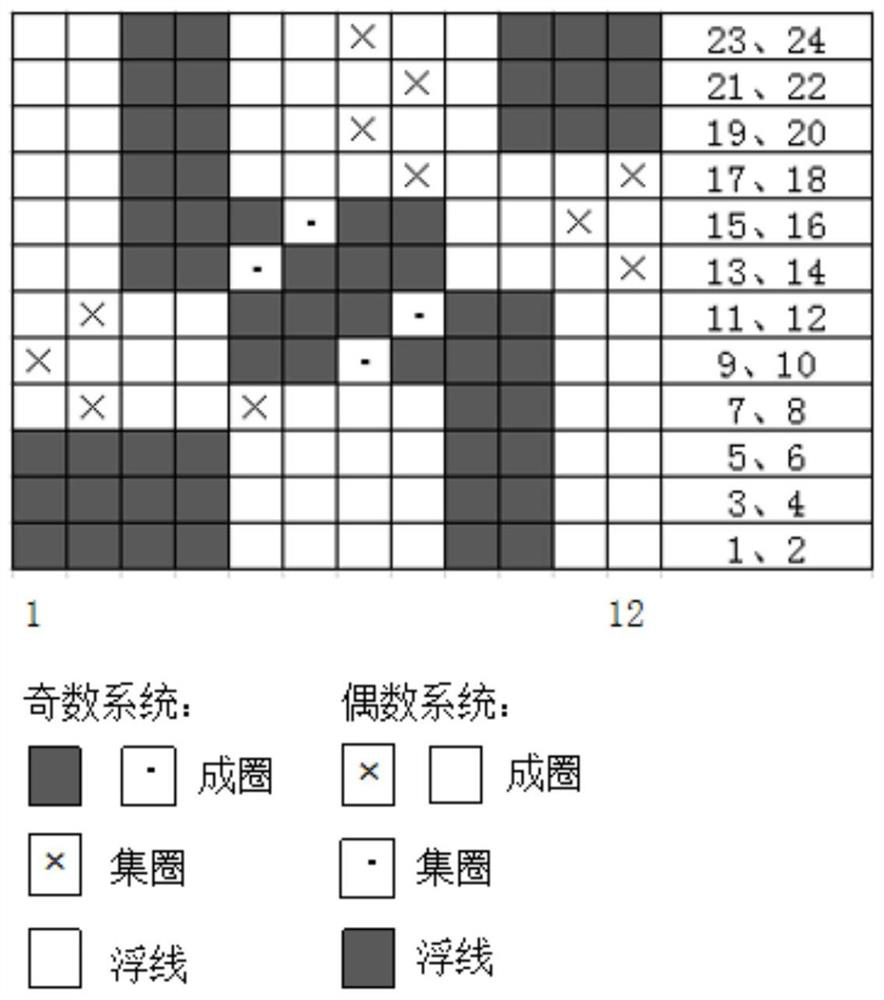

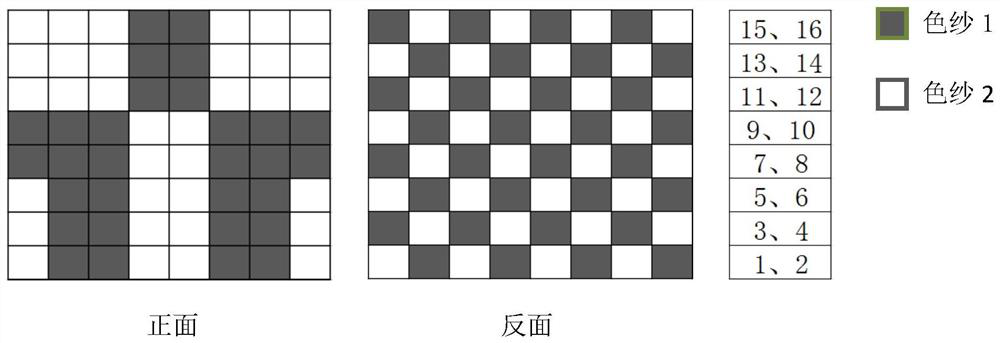

A Calculation Method of Yarn Feed Volume in Positive Yarn Feed Mode of Circular Weft Machine

The invention discloses a calculation method of the yarn feeding amount a positive yarn feeding mode of a circular weft knitting machine. By calculating the yarn length of a certain number of knittingneedle knitting loop structures, a yarn storage wheel can change the yarn feeding amount according to the yarn length needed by knitting in the knitting process, it is ensured that the tension is constant when yarns enter a knitting area, the size difference between the same loops is reduced, patterns can be clearer, the cloth cover is flatter, and the quality and aesthetic degree of a fabric aregreatly improved.

Owner:JIANGNAN UNIV

Wire stranding device of welding wire stranding machine and welding wire stranding machine

ActiveCN107717263BLarge diameterReduce downtimeWelding/cutting media/materialsSoldering mediaStructural engineeringWelding

The invention provides a wire twisting device of a welding wire twisting machine and the welding wire twisting machine. The wire twisting device comprises a wire twisting cylinder, a plurality of welding wire reels, wire winding tubes, a wire taking device and a driving device, wherein the wire twisting cylinder is rotatably arranged on a bracket; at least peripheral welding wire reels pivotally sleeve the outer side of the wire twisting cylinder; the wire winding tubes are arranged in the wire twisting cylinder, and comprise peripheral welding wire winding tubes and a central welding wire winding tube; the wire taking device is used for guiding welding wires on the welding wire reels into the corresponding wire winding tubes; and the driving device is used for driving both the wire twisting cylinder and the welding wire reels to rotate. As the peripheral welding wire reels are arranged on the outer side of the wire twisting cylinder, the diameters of the welding wire reels are not limited by the space of the wire twisting cylinder and can be increased, the welding wires loaded on the welding wire reels are relatively heavy, the idle hour caused by the replacement of the welding wire reels can be greatly shortened, and the production efficiency can be greatly improved.

Owner:江苏科融新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com