Calculation method for basket-type rope-forming machine stranded rope

A technology for stranding and forming ropes, which is applied in the field of rope calculation of basket-type rope forming machines, can solve problems such as rapid measurement of coil diameter, and achieve the effect of improving quality and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific embodiments provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0044] A method for calculating the strands of a basket-type rope forming machine includes the calculation of the winding filling factor of the strands and the calculation of the winding diameter of the strands. Non-linear function relationship, so as to realize the precise control of the yarn tension during the unwinding process of the rope forming machine. It includes the following steps:

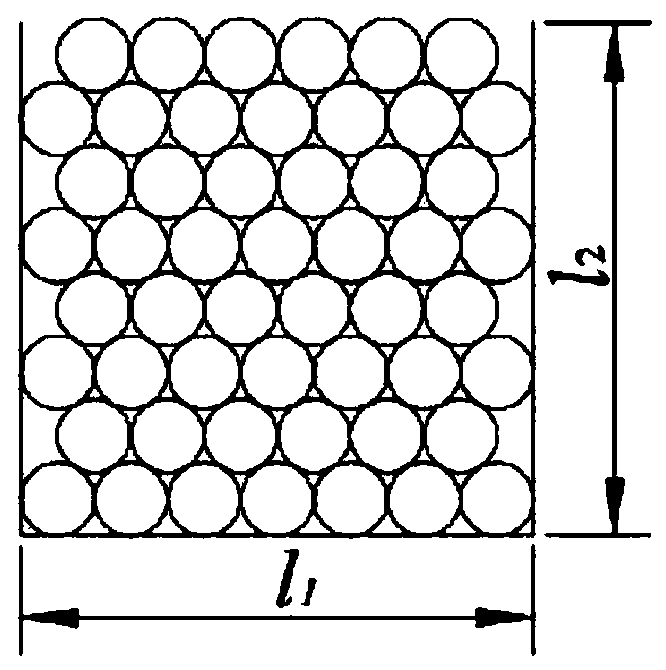

[0045] Step 1. Establish a cross-winding model of strands. There are m columns and n rows of wire ropes that are cross-wrapped. The diameter b of the strands is uniform. In an ideal case, the window length is l. 1 =m×b, window width l 2 =(n-1)×b×sin60°+b, m is the number of turns of each layer of the strands wound on the pay-off wheel, and n is the number of layers of strands arranged;

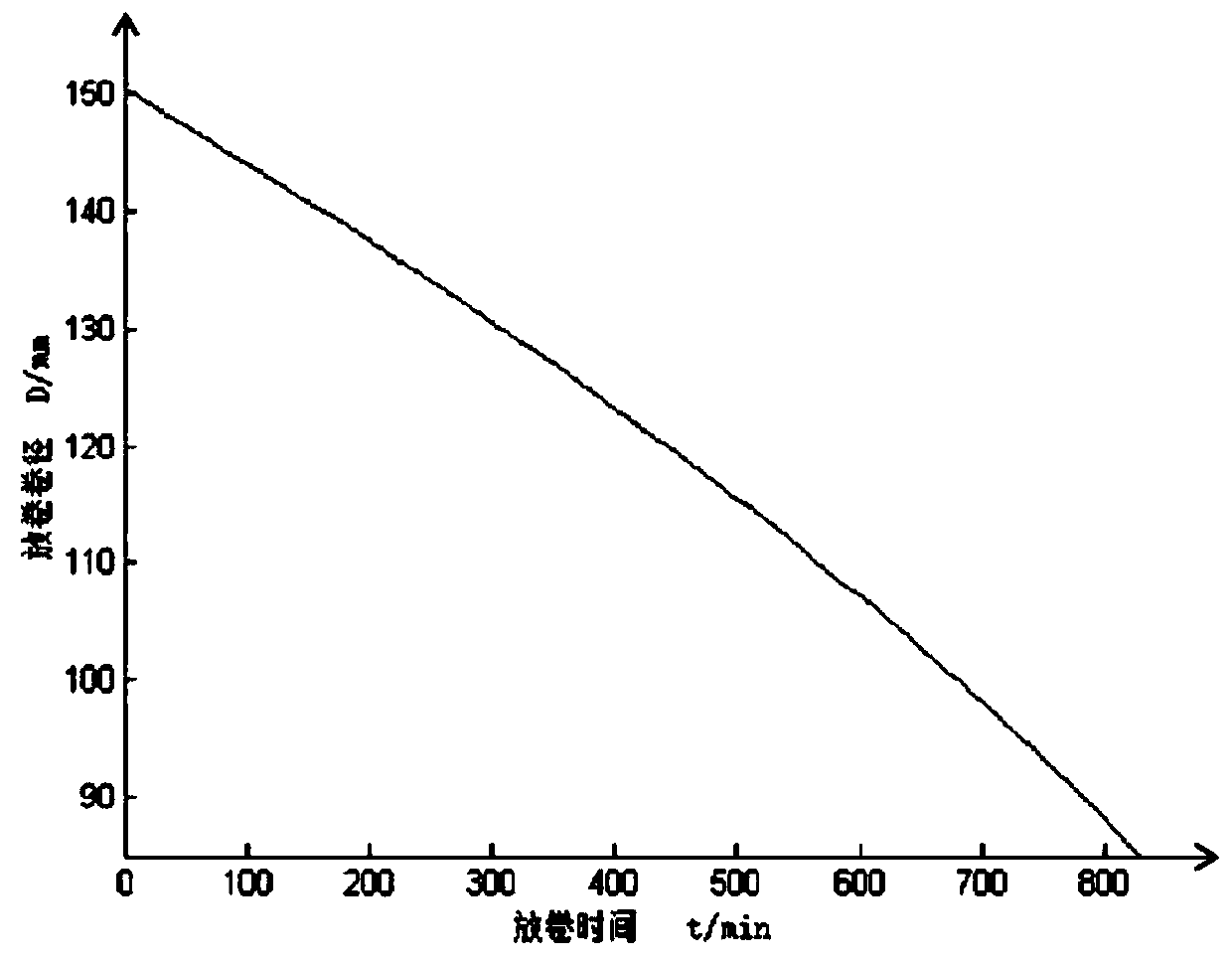

[0046] The maximum diameter of the pay-off reel is D ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com