Full-automatic die cutting machine for pole piece

A die-cutting machine, fully automatic technology, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems that affect the efficiency of punching pole pieces, and the actions of winding and punching pole pieces cannot be carried out at the same time, to achieve The effect of constant tension and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific drawings and embodiments.

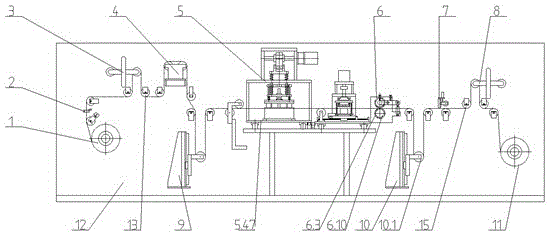

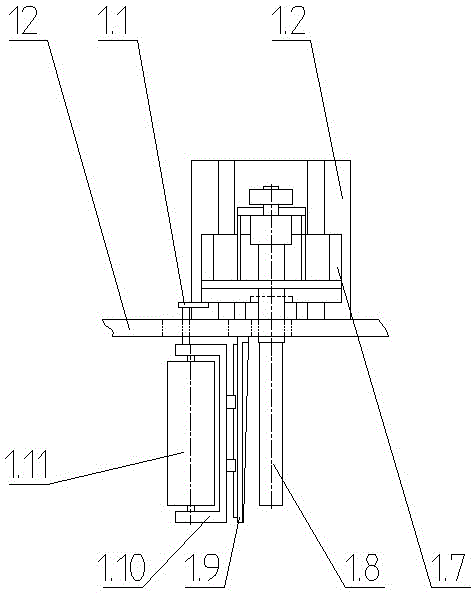

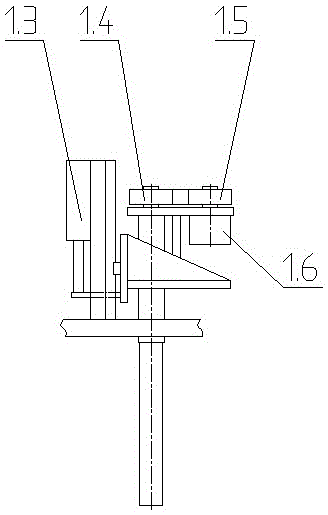

[0028] Such as figure 1 As shown, the present invention includes a pre-die-cutting mechanism and a post-die-cutting mechanism, wherein the pre-die-cutting mechanism includes an unwinding device 1, a deviation correction sensor 2, a first tension adjustment device 3, a deviation correction device 4, and a pole piece punching knife die device 5. The first transition roll 13, the unwinding device 1, the deviation correction sensor 2, the first tension adjustment device 3, the deviation correction device 4 and the pole piece punching knife die device 5 are sequentially arranged on the first mounting plate 12, the first The transition roller 13 is used for transitional transmission of the pole piece, the unwinding device 1 is used for unwinding the pole piece to be punched, the first tension adjustment device 3 is used for adjusting the tension of the pole piece, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com