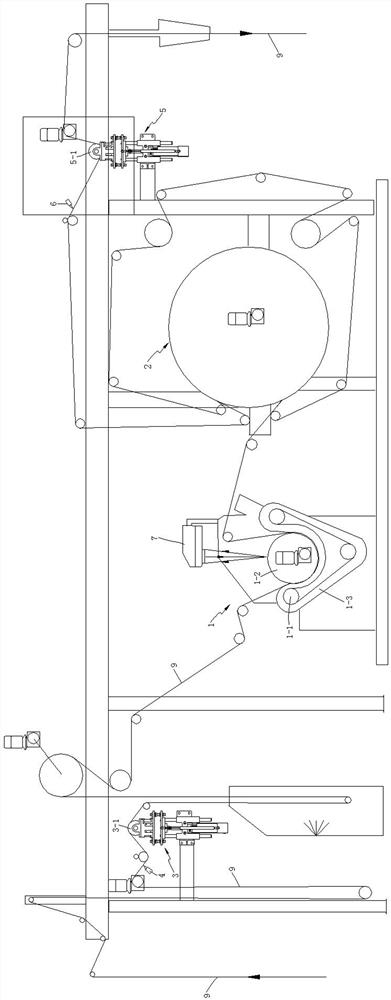

Intelligent control method and device for preshrinking rate of preshrinking woven fabric

A technology of intelligent control and pre-shrinking machine, which is applied in measuring devices, fabric surface trimming, shrinking, etc., can solve problems such as unguaranteed product quality, lagging pre-shrinking rate control, large fluctuations in pre-shrinking rate, etc., to achieve production The effect of improving efficiency, suppressing disturbance, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

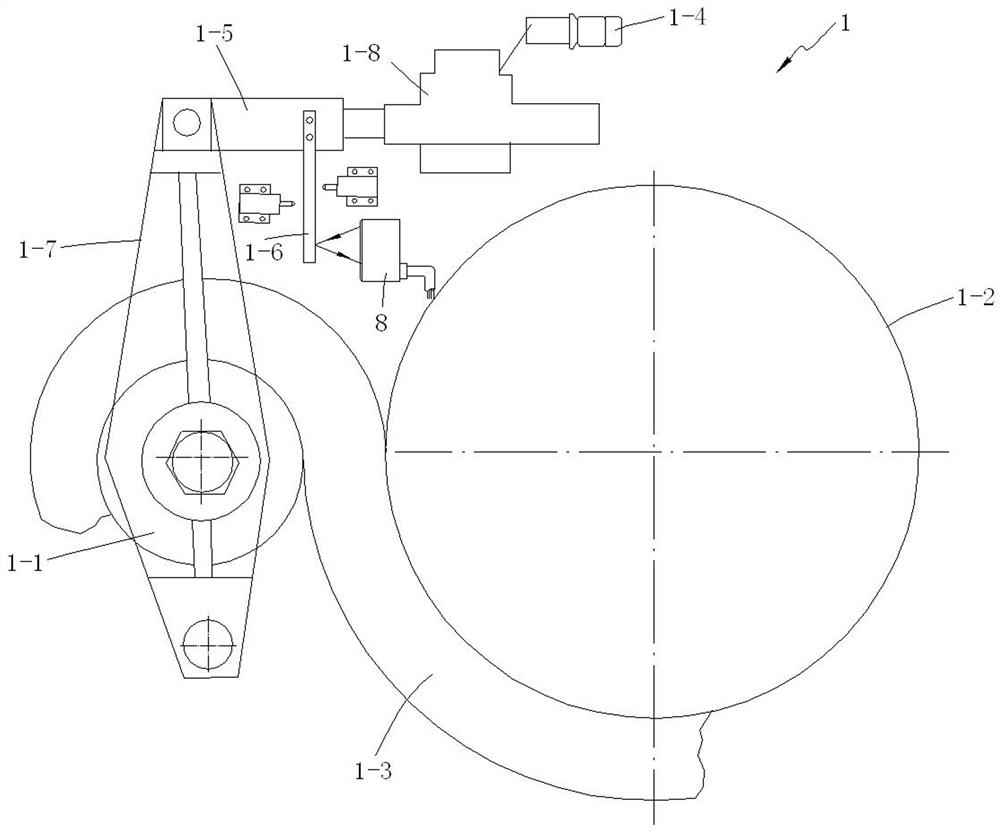

[0037] As a preferred embodiment of the present invention, the central processing unit is a digital controller with a human-machine interface such as a DDC digital controller or an embedded industrial controller or an industrial computer or a PLC programmable controller. Of course, it can also be Other types of controllers are used, and the central processing unit is not shown in the figure.

[0038] After testing, the invention avoids or greatly reduces the deviation between the measured pre-shrinkage rate and the target pre-shrinkage rate, improves the control accuracy of the pre-shrinkage rate, ensures the stability of the pre-shrinkage rate, improves the product qualification rate, and achieves good effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com