Wire stranding device of welding wire stranding machine and welding wire stranding machine

A technology of stranding machine and welding wire, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., can solve the problem that the size of the welding wire reel is restricted by the inner space of the twisted wire drum, and achieve compact structure, reduce downtime, The effect of small radial vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

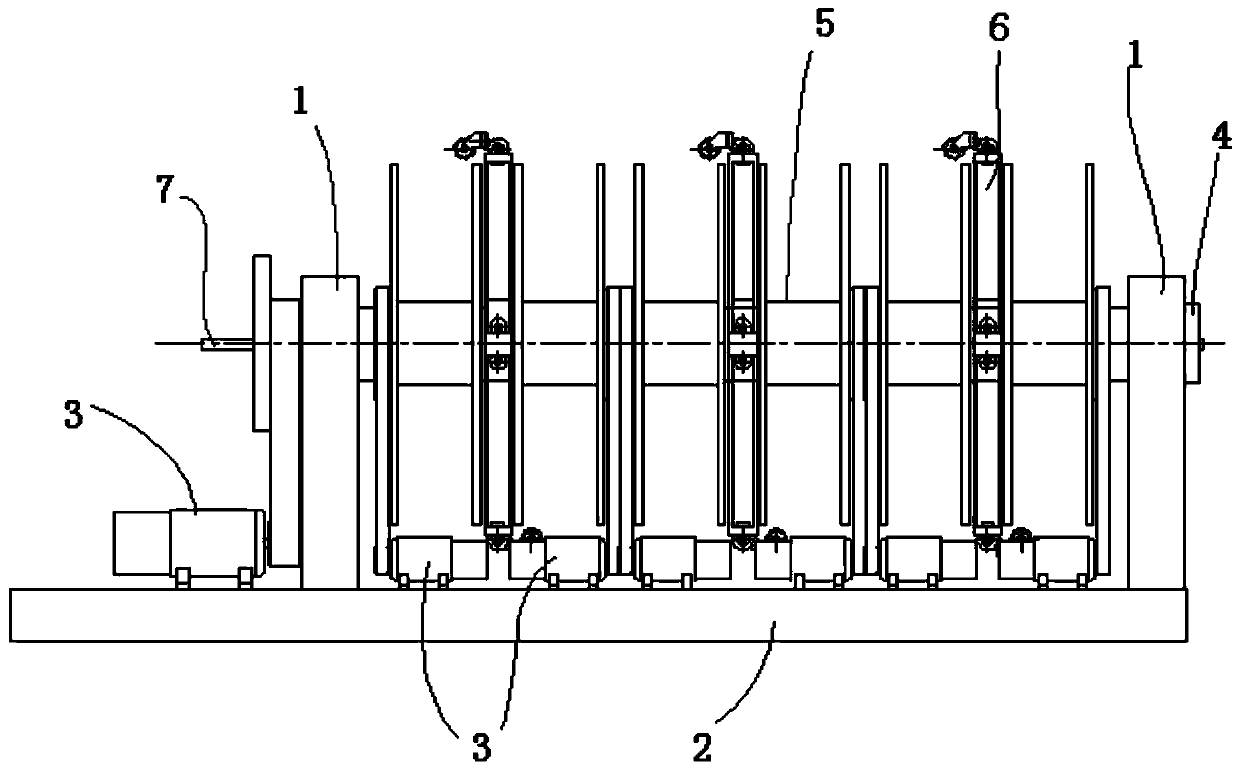

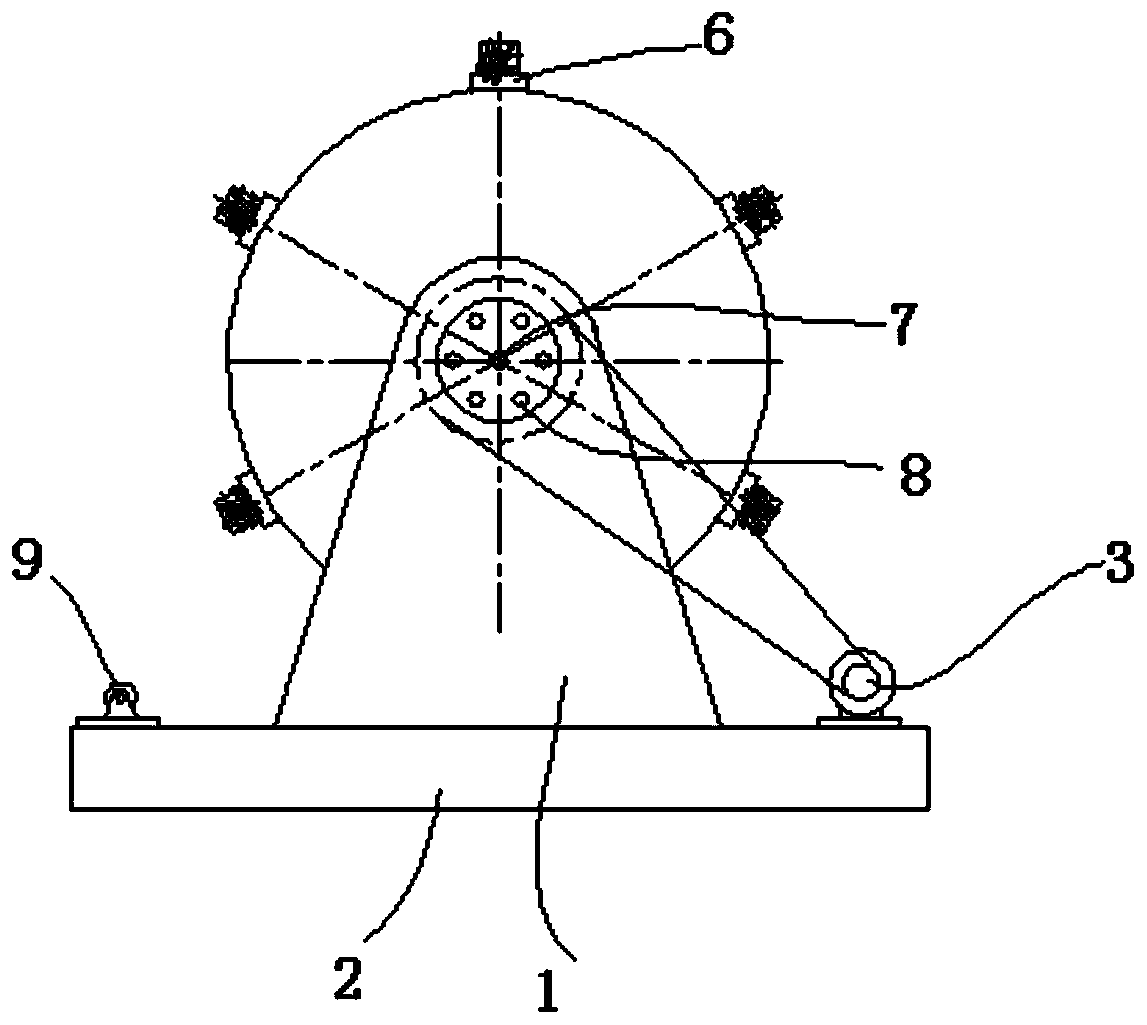

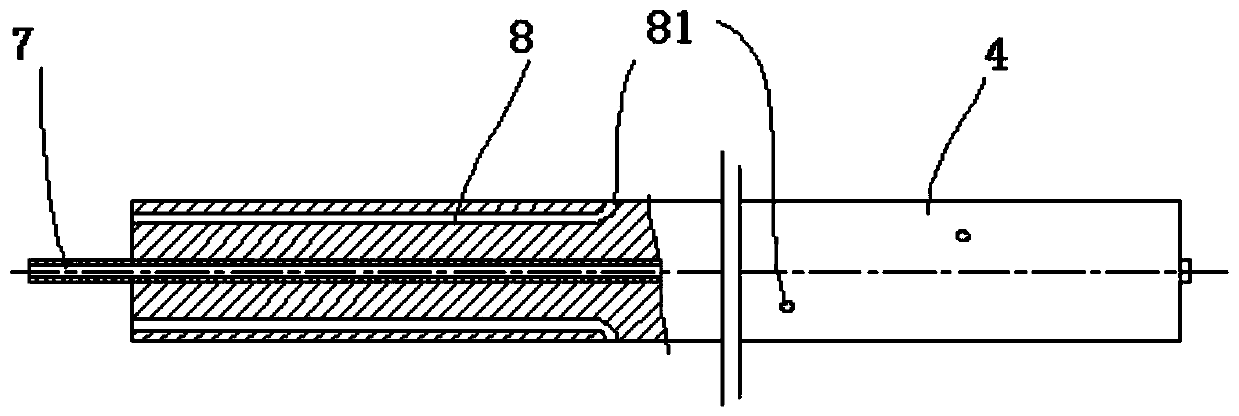

[0056] like Figure 1-2 A specific embodiment of the wire stranding device of the shown welding wire stranding machine includes a stranding cylinder 4, which is rotatably arranged on the support 1; a plurality of welding wire reels 5, including a central welding wire reel and peripheral welding wire The wire reel, the peripheral welding wire reel is pivotably sleeved on the outside of the said wire reel 4; the wire reel is arranged in the said reel 4, including the peripheral welding wire reel 8 and the central welding wire reel Pipe 7; a wire taking device, which guides the welding wire on the wire reel 5 into the corresponding wire feeding tube; a driving device, which drives the wire twisting drum 4 and the wire reel 5 to rotate respectively. Because the peripheral welding wire reel is pivotably sleeved on the outside of the wire reel 4, the diameter of the wire reel 5 is not restricted by the space of the wire reel 4, so the diameter of the wire reel 5 can be increased, an...

Embodiment 2

[0067] A welding wire stranding machine, comprising the stranding device described in the above-mentioned embodiments, a wire leveling device, a stress relief straightening device, and a wire receiving device are arranged at the outlet end of the stranding cylinder, and the welding wire stranding machine welding wire The size of the reel is not restricted by the space of the wire reel, the weight of the welding wire loaded on the wire reel is relatively large, and the production efficiency is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com