Patents

Literature

59results about How to "Improve overprint accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

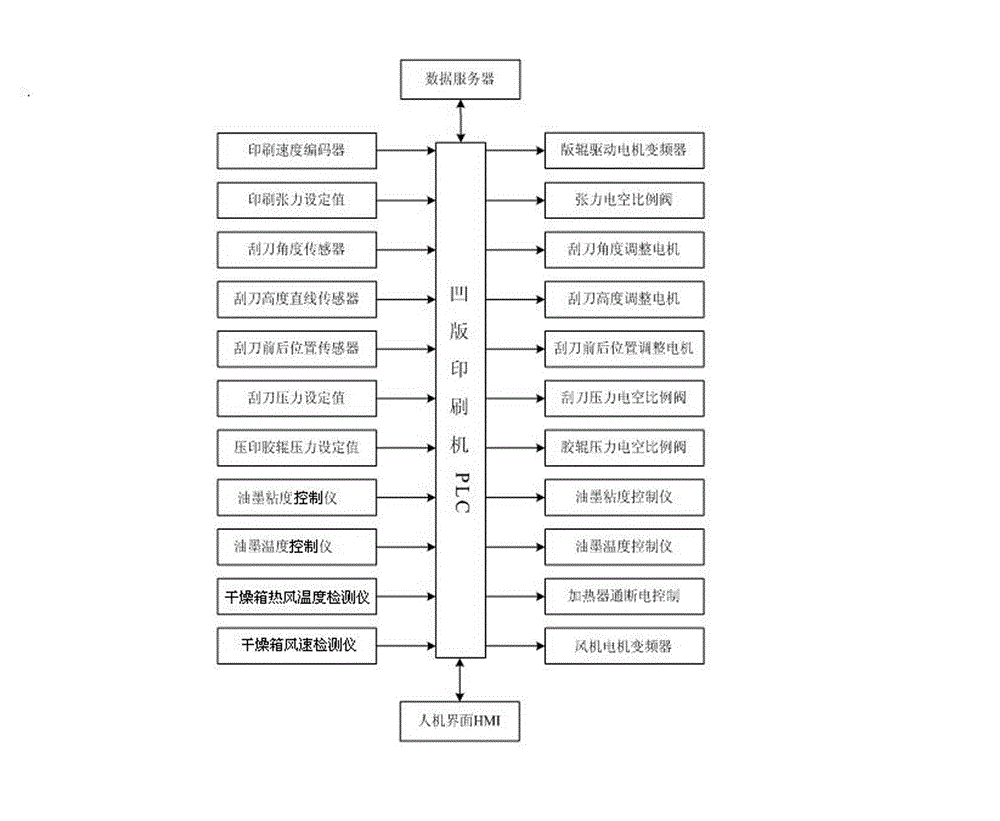

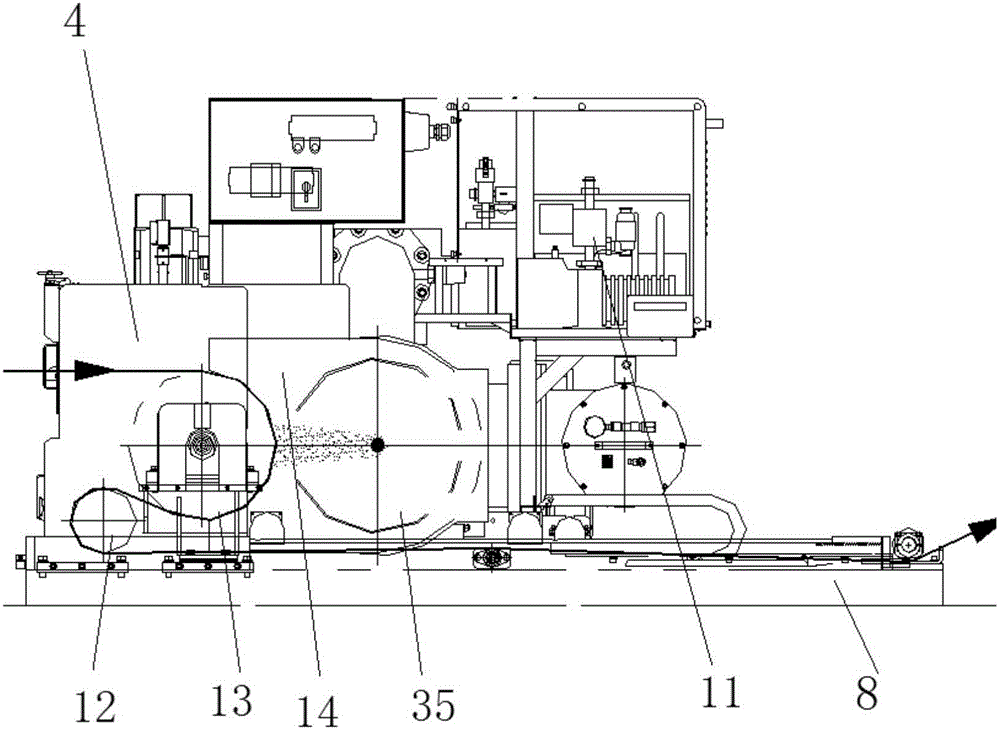

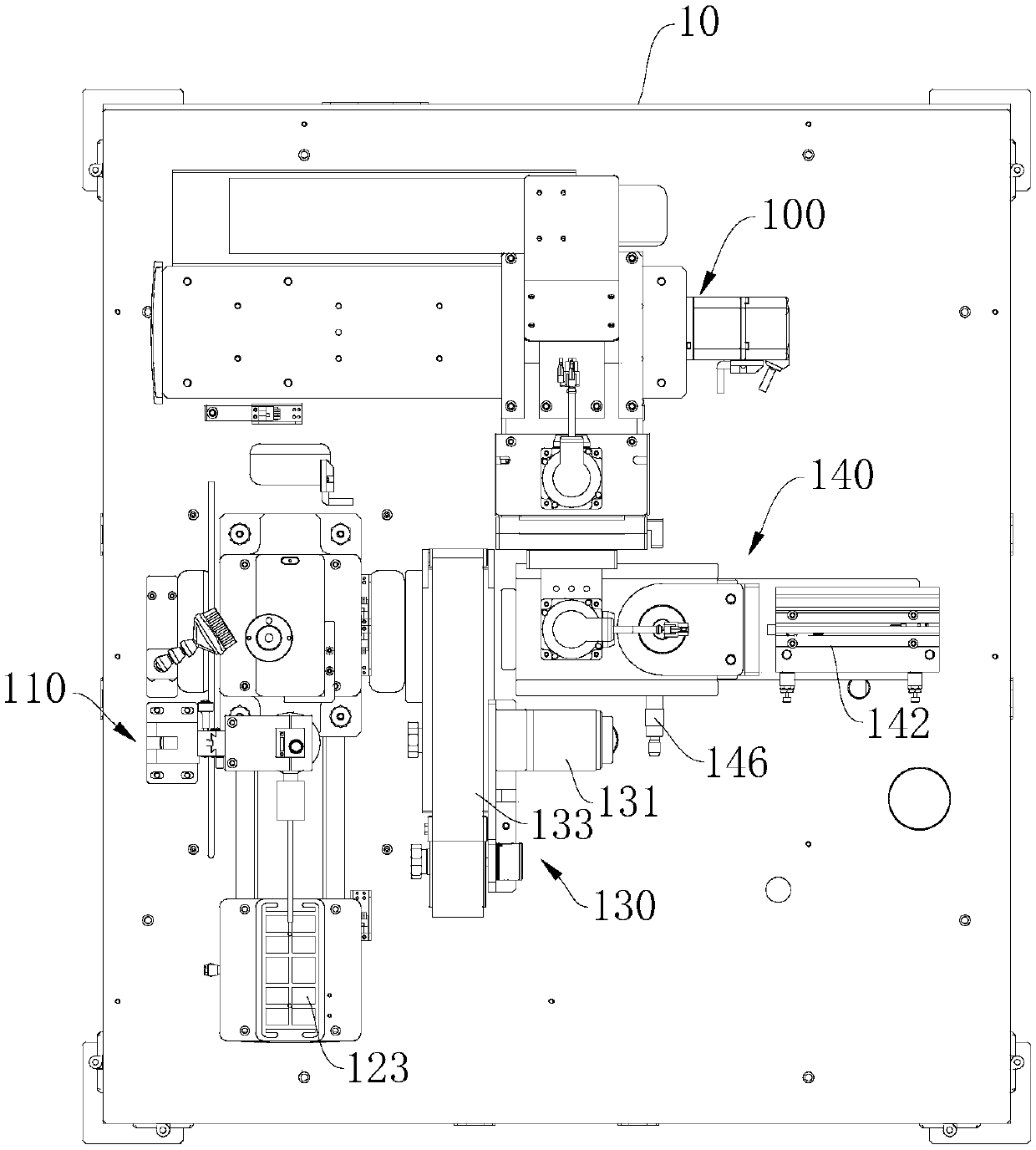

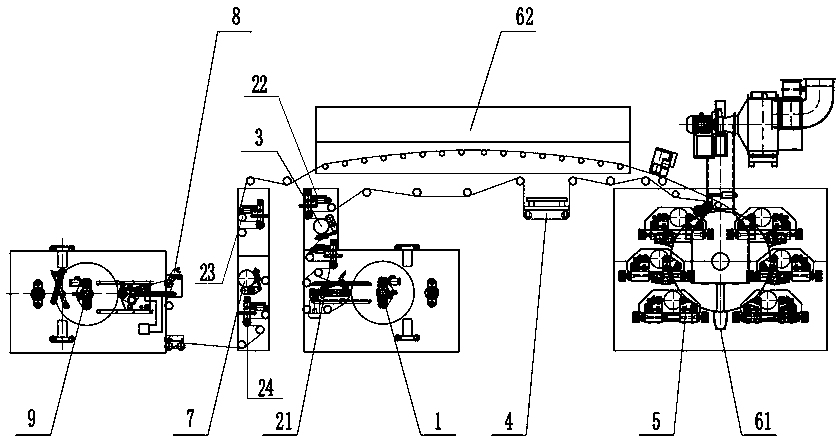

Intaglio press based on color management operation system

ActiveCN102717586ASimplify labor intensityReduce printing costsRotary intaglio printing pressPrinting press partsElectrical controlProgrammable logic controller

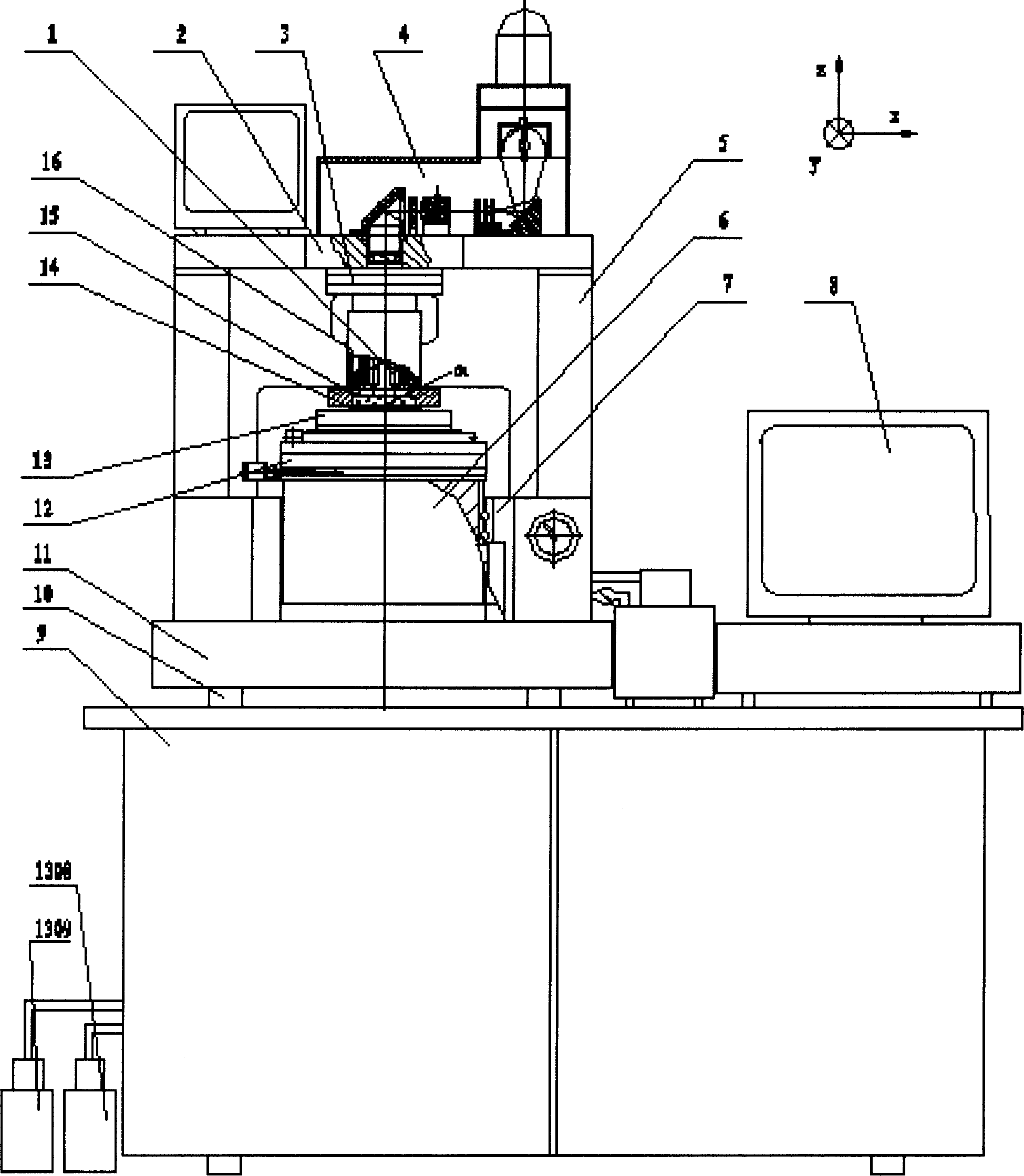

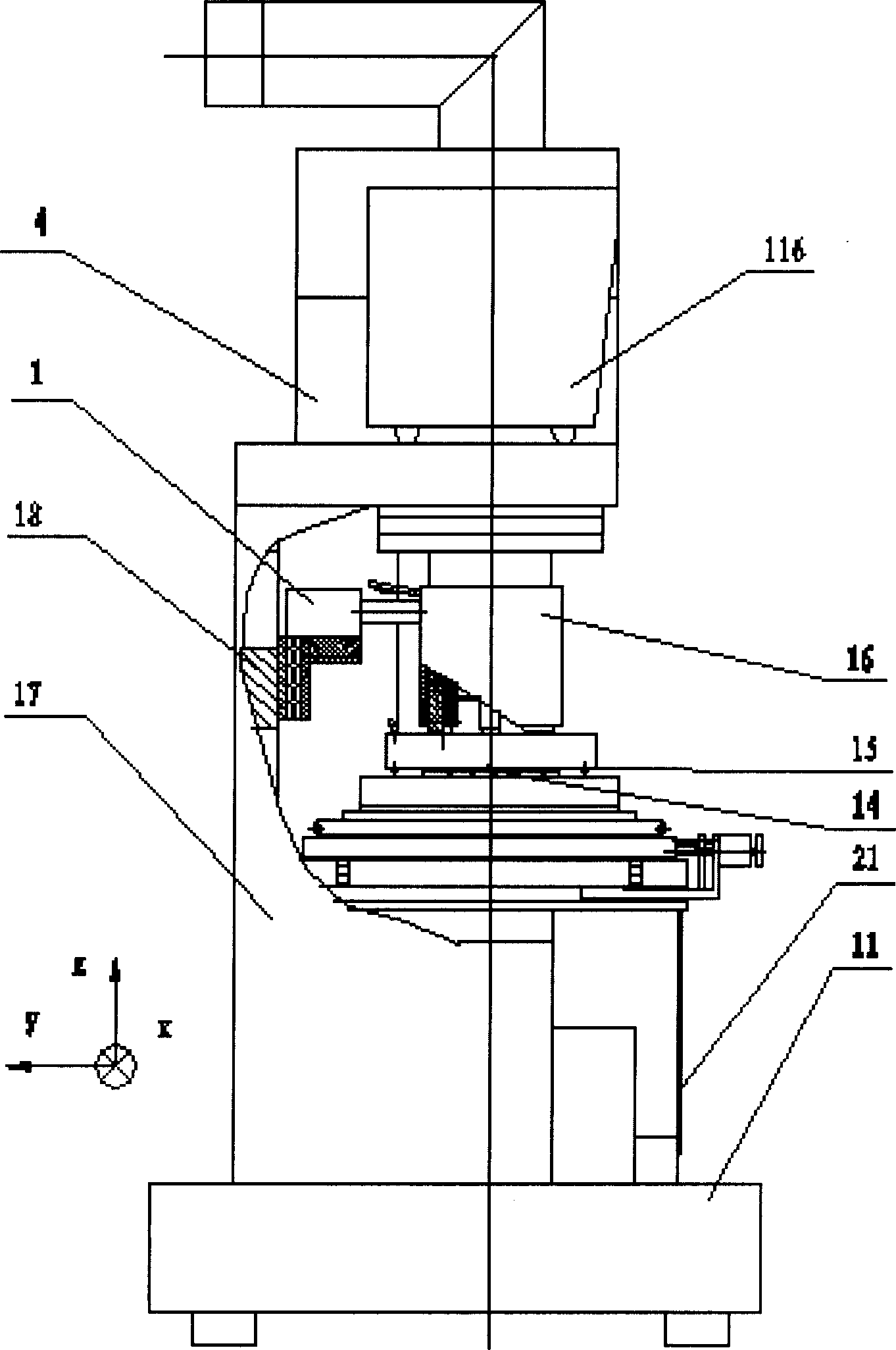

The invention relates to a press, in particular to an intaglio press based on a color management operation system, and solves the problems that labor strength is high, yield is low, printing cost is increased, and the like in the existing intaglio press. The intaglio press comprises an automatic ink feeding device, a scraper height adjusting mechanism, a scraper angle adjusting mechanism, a scraper longitudinal-position adjusting mechanism, a PLC (programmable logic controller) system and an electrical control system composed of a human machine interface and a data server. Ink strength controllers and ink temperature controllers are mounted on the automatic ink feeding device. The scraper height adjusting mechanism is achieved through a pinion and rack mechanism, the scraper angle is adjusted by a worm and gear mechanism, and the longitudinal position of a scraper is adjusted by a screw rod mechanism, so that labor strength of printing operators is simplified, waste of ink and printing stock caused in an initial printing adjusting procedure is reduced, printing cost is reduced, delivery cycle is shortened, speed and registering accuracy of the whole press are increased, and efficiency and yield are high.

Owner:YUNCHENG PLATE MAKING PRINTING MACHINERY MFG

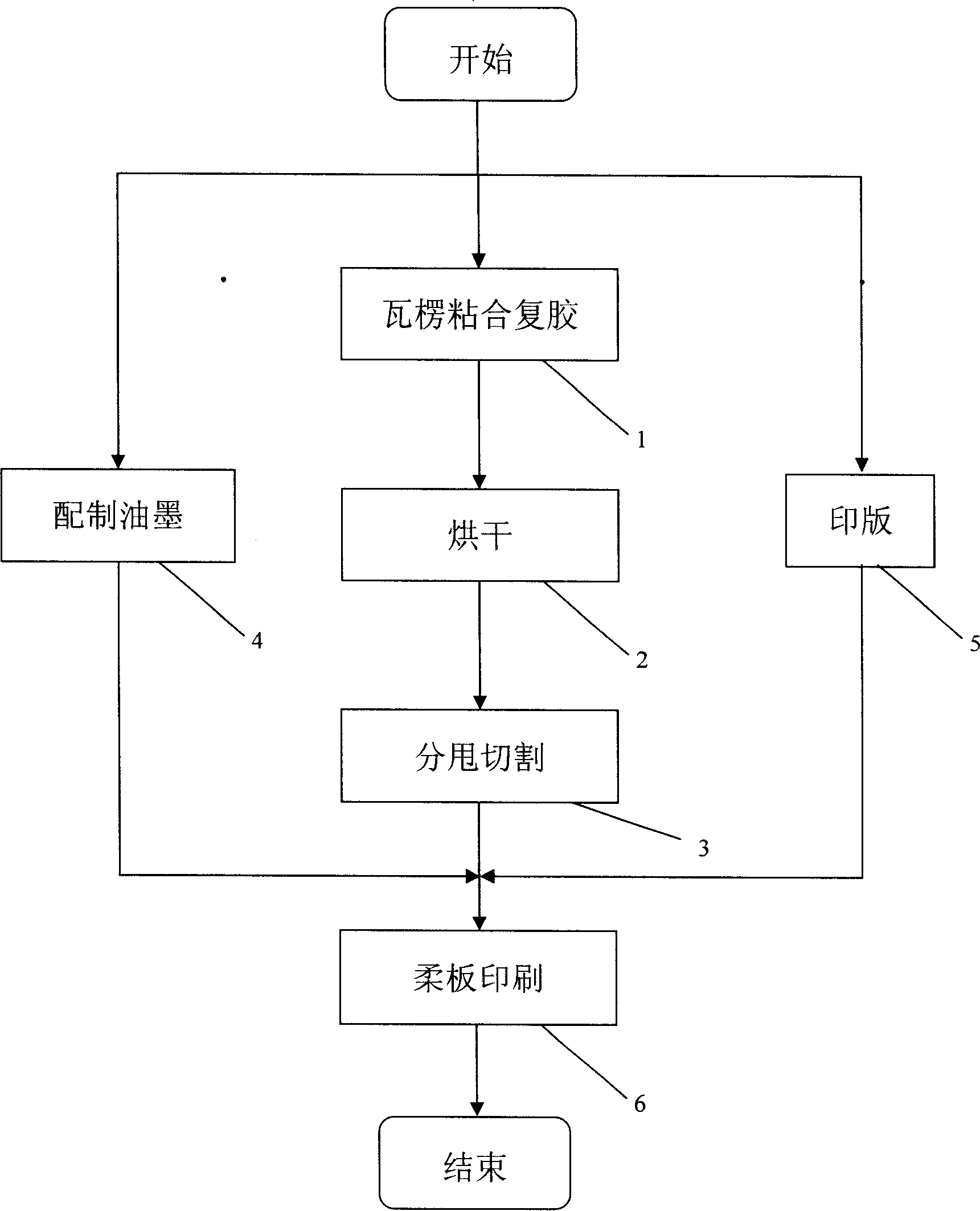

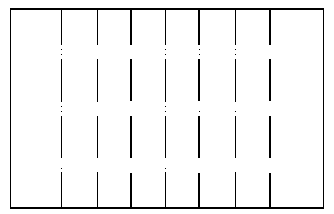

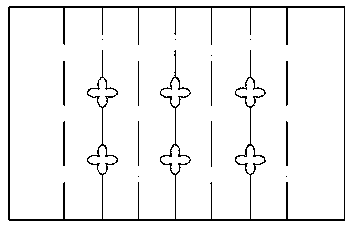

Method for manufacturing colorful flexible printing corrugated paper box

InactiveCN101186123AKeep clearImprove overprint accuracyMechanical working/deformationBox making operationsCardboardEngineering

The invention discloses a manufacture method of a colorful flexible printing corrugated box, comprising six steps such as corrugated bonding, drying, throwing and cutting, preparing ink, forme and flexible printing. A corrugated cardboard with special standard is taken as a printing material, thus leading no settlement phenomenon between the corrugated peak and corrugated valley of the corrugated cardboard to occur and ensuring clear printed patterns. By adopting no-shaft transmission flexible printing, overprinting precision of each color group can be independently adjusted, thus improving the overprinting precision of the printed products, and greatly improving the printing quality. By adopting knurled rolls in grid shape and ceramic material spayed on the surface of the knurled rolls, the surface performance of the knurled rolls is improved, the flexible printing quality is improved, the service life of the knurled rolls is prolonged, and the printing cost is saved. The content of the connecting material in ink is increased and the consistency of dye is increased, thus reaching required ink film thickness under low ink transmission quantity, and reaching the requirement of stable and full colors, high vividness of the printed product and good glossiness.

Owner:俞建虎

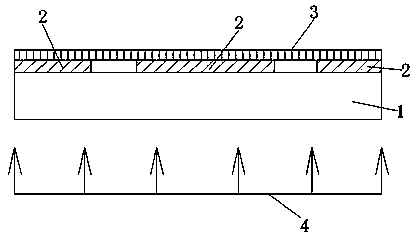

Warm-up flash two-purpose nano impression device

InactiveCN1776526ASimple and efficient operationImprove overprint accuracyDecorative surface effectsPhotomechanical exposure apparatusWarming upOil pressure

The stamping apparatus is composed of CCD alignment system in two way, corrector in Z direction, illumination system in purple light, left and right side plates, oil pressure lifting jack system, heating desk for loaded piece, slant correcting mechanism and control system. Large base plate of host is on equipment cabinet. The large base plate, left and right side plates, backboard and upper transverse plate constitute frame. Corrector in Z direction and slant correcting mechanism with press mold are hung underside of the transverse plate. Oil lifting jack system faced to the press mold is installed at middle. XYtheta micromotion work desk, the heating desk, substrate is lifted by jack system to impact the mold to stamp out Nano graph structure. Illumination system in purple light illumines polymer in stamping layer to solidify it. Heating up and cooling down heating desk solidifies and demoulds the polymer. The invention possesses advantages of two stamping methods.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Process for transfer printing of aluminized or laser patterns on plastic film

InactiveCN101544140AAvoid overprint errorsImprove overprint accuracyPattern printingOther printing apparatusEngineeringPlastic film

The invention disclosed a process for transfer printing of aluminized or laser patterns on a plastic film, which comprises the following steps: a, pre-printing design: adding aluminized or laser patterns or logos to a layout pattern; b, plate making: mounting corresponding plate rollers respectively in accordance with the color of the layout pattern and the aluminized or laser patterns, and carving the corresponding patterns on the plate rollers; and c, simultaneously printing, sizing and affixing aluminized films or laser films: during printing, putting the plate roller caved with color patterns into an ink fountain filled with corresponding colors; putting the plate rollers carved the aluminized or laser patterns into the ink fountain filled with glue water, and colorizing the glue water at the same time for the convenience of tracking by a photoelectric eye during printing; arranging the ink fountain filled with the glue water at the backmost position for printing; and coating a silicone oil layer on guide rollers of a printing machine from a discharge port of a glue water printing machine set to a printing rolling part. The process has the advantages of simplicity, applicability to various materials, high overprinting precision and low cost.

Owner:浙江汇华包装股份有限公司

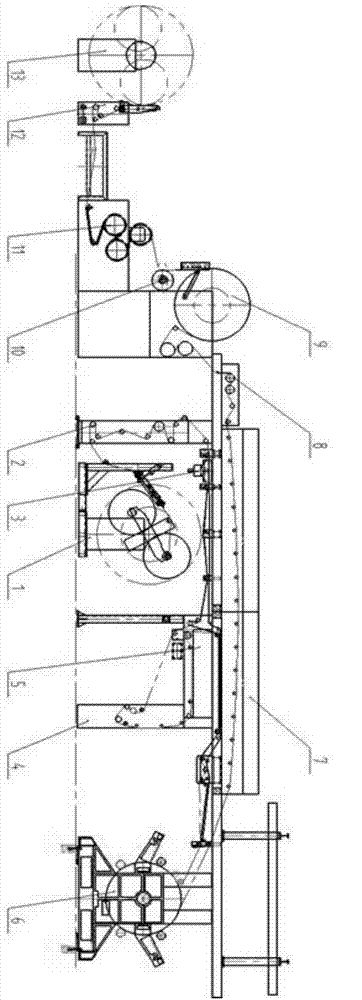

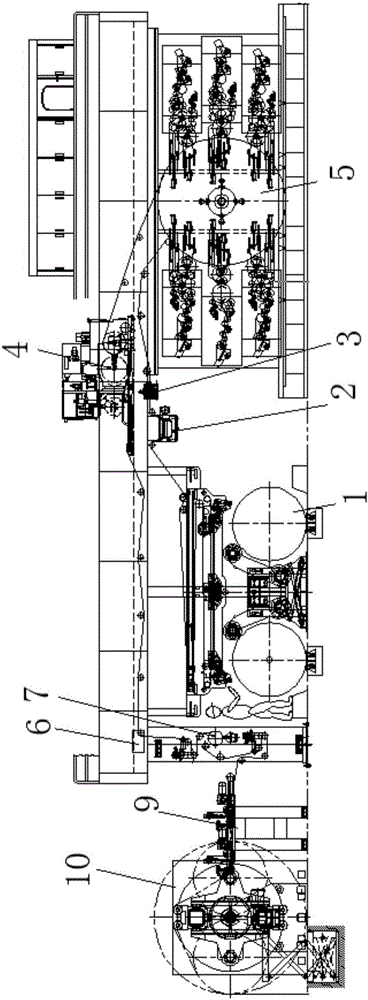

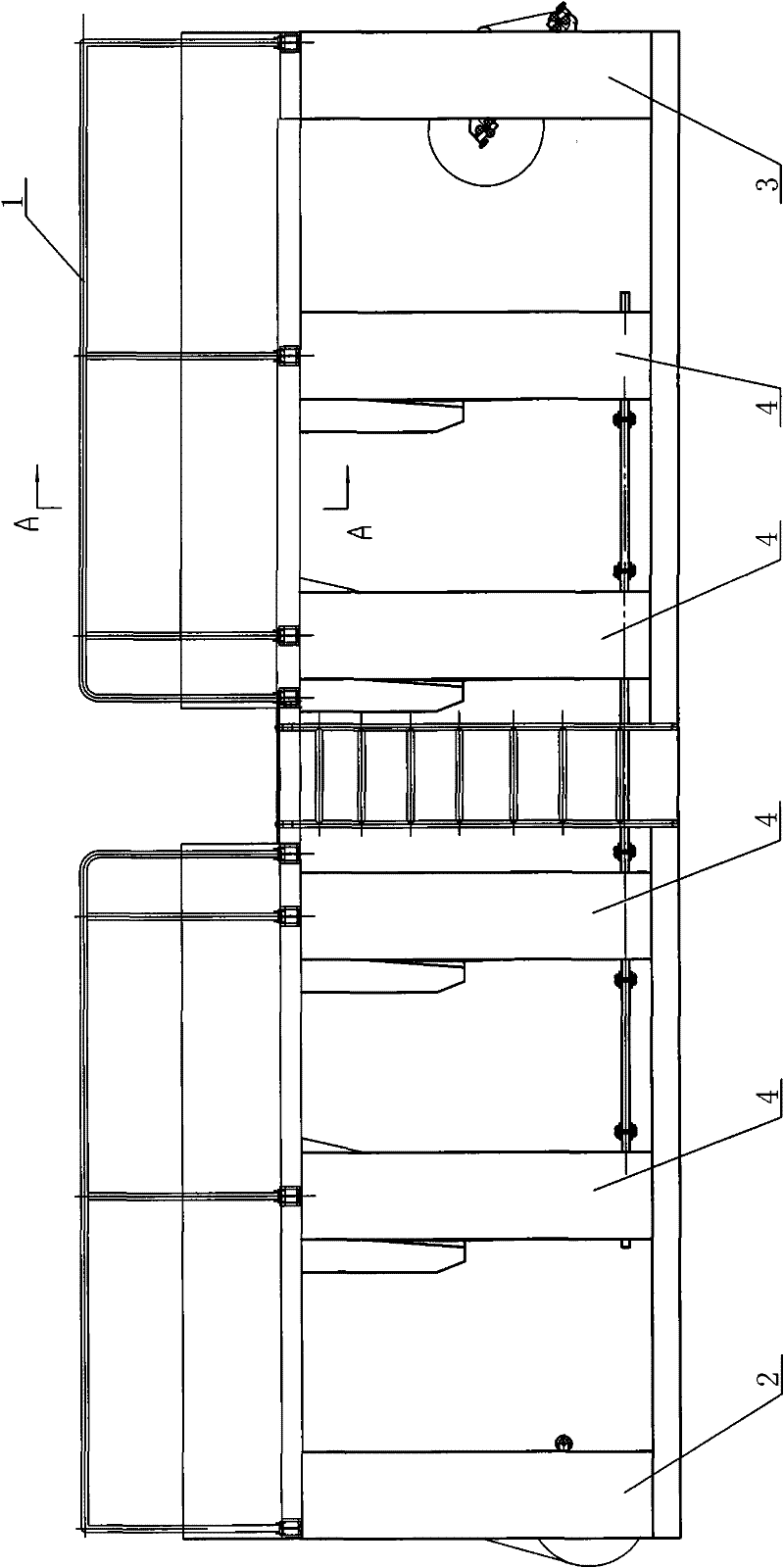

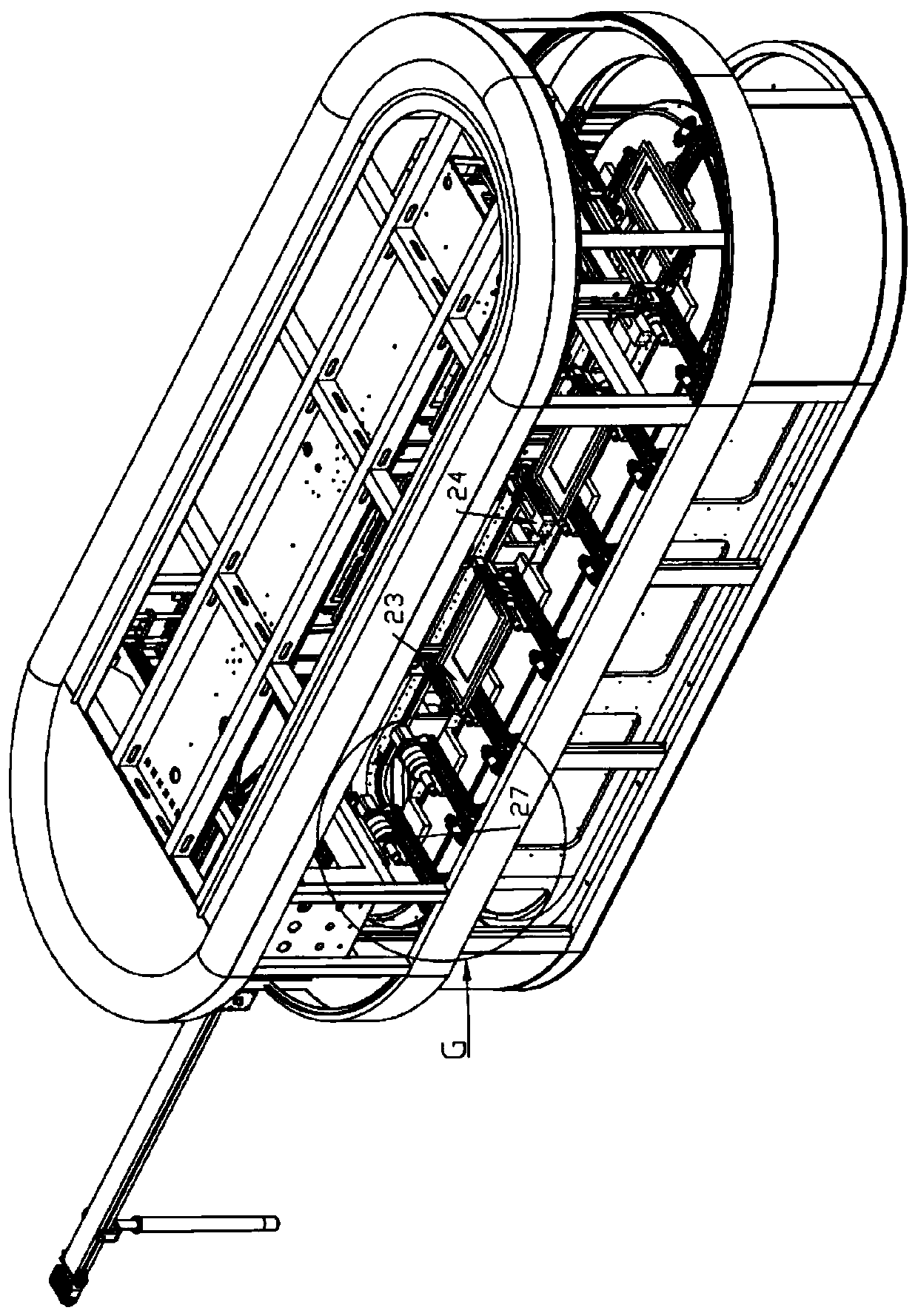

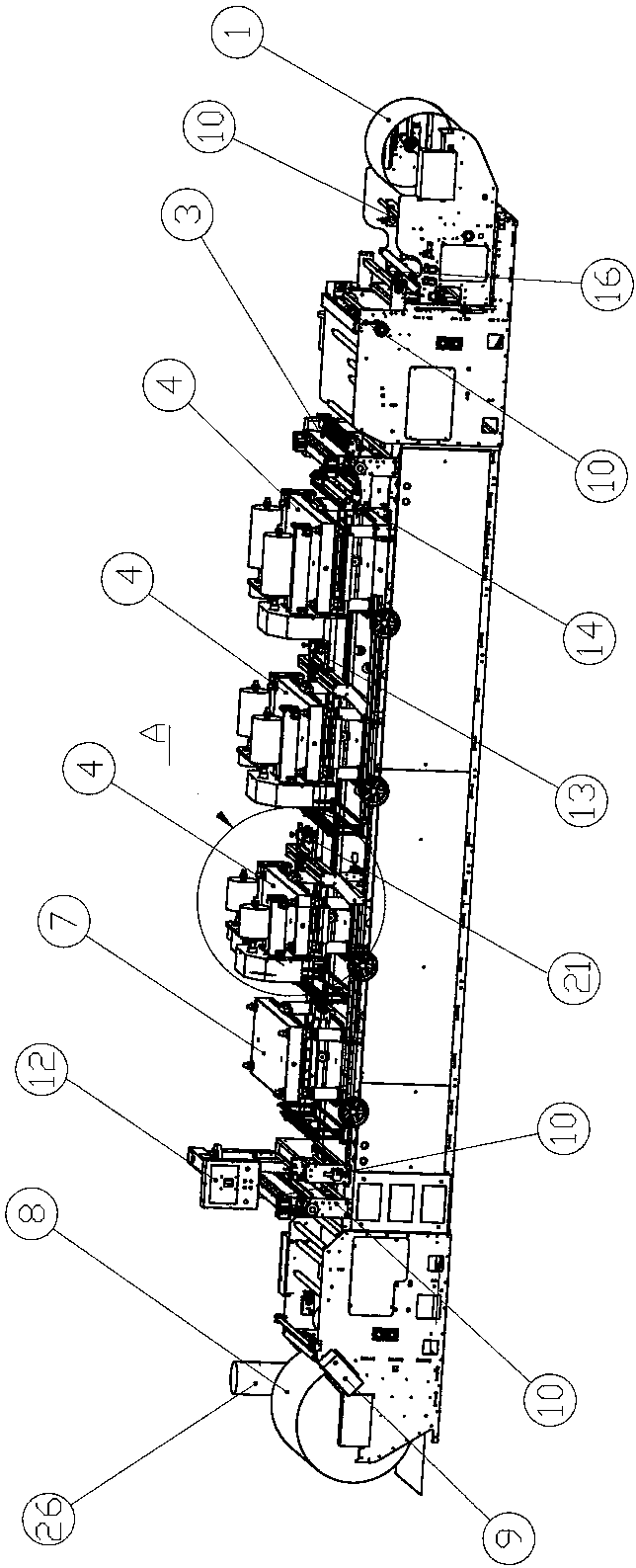

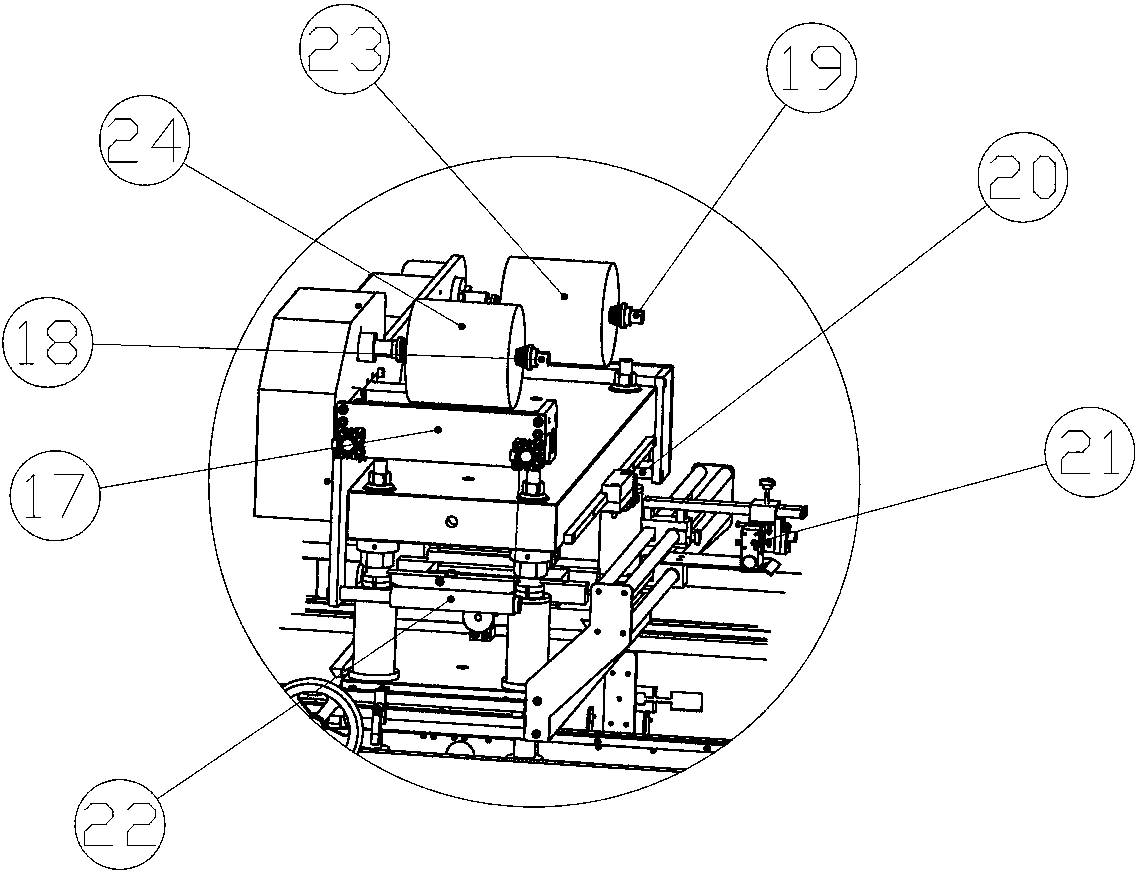

Freezing point printing and holographic gilding printing integrated printing equipment and application method thereof

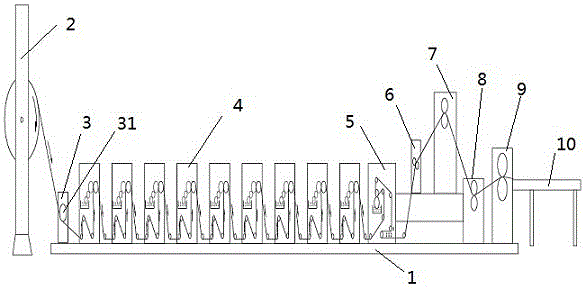

ActiveCN104553292AGuaranteed uptimeGuaranteed compensation for overprint deviationScreen printersBronze printingTension controlPaper sheet

The invention discloses freezing point printing and holographic gilding printing integrated printing equipment and an application method thereof. The freezing point printing and holographic gilding printing integrated printing equipment comprises a base, a paper unwinding device, a paper guide mechanism, flexography units, a gravure freezing point unit, a tension control unit, a holographic gilding device, a concave-convex unit, a cutting unit and a finished paper collecting unit, wherein the paper guide mechanism is disposed on one side of the paper unwinding device, the plurality of flexography units are sequentially disposed on one side of the paper guide mechanism, and the gravure freezing point unit, the tension control unit, the holographic gilding device, the concave-convex unit, the cutting unit and the finished paper collecting unit are sequentially disposed on one side of the flexography units. The freezing point printing and holographic gilding printing integrated printing equipment has the advantages that printing combining multiple working procedures is achieved, freezing point printing and holographic gilding printing are integrated, the printing equipment is high in continuity, high in automation level, convenient to operate, stable in operation, good in printing effect, high in chromatography precision and high in yield, efficient and high-quality printing is achieved, production procedures are reduced, production time is saved, production efficiency is increased, and production cost is lowered.

Owner:KUNMING WEIJIAN KECHUANG PRINTING

Method and device for printing printed material

InactiveCN103660650AQuality improvementImprove overprint accuracyRotary pressesOther printing apparatusPrinting inkEngineering

The invention relates to a method for printing printed material in a rotary printing machine. The roatry printing machine has a first press cylinder and a second press cylinder which are contacted with the printed material in a printing gap. The second press cylinder transmits printed images which are previsouly mounted on the second press cylinder of first ink to the printed material. An ink jet printing device which applies additionally variable printed images made of ink on the printed material. The ink jet printing device is characterized in that the additionally variable printed images are directly applied on an non-ink circumenferential section of a shifting cylinder which is directly conntaced with the second press clindyer or which tranmist the printed images from the second press cylinder to the pinted materal. A cleaning device is also arranged to remove additionally printed imaged applied by the ink jet printing device from the non-ink circumenferential section during the continous brush operation of the rotary printing machine.

Owner:HEIDELBERGER DRUCKMASHINEN AG

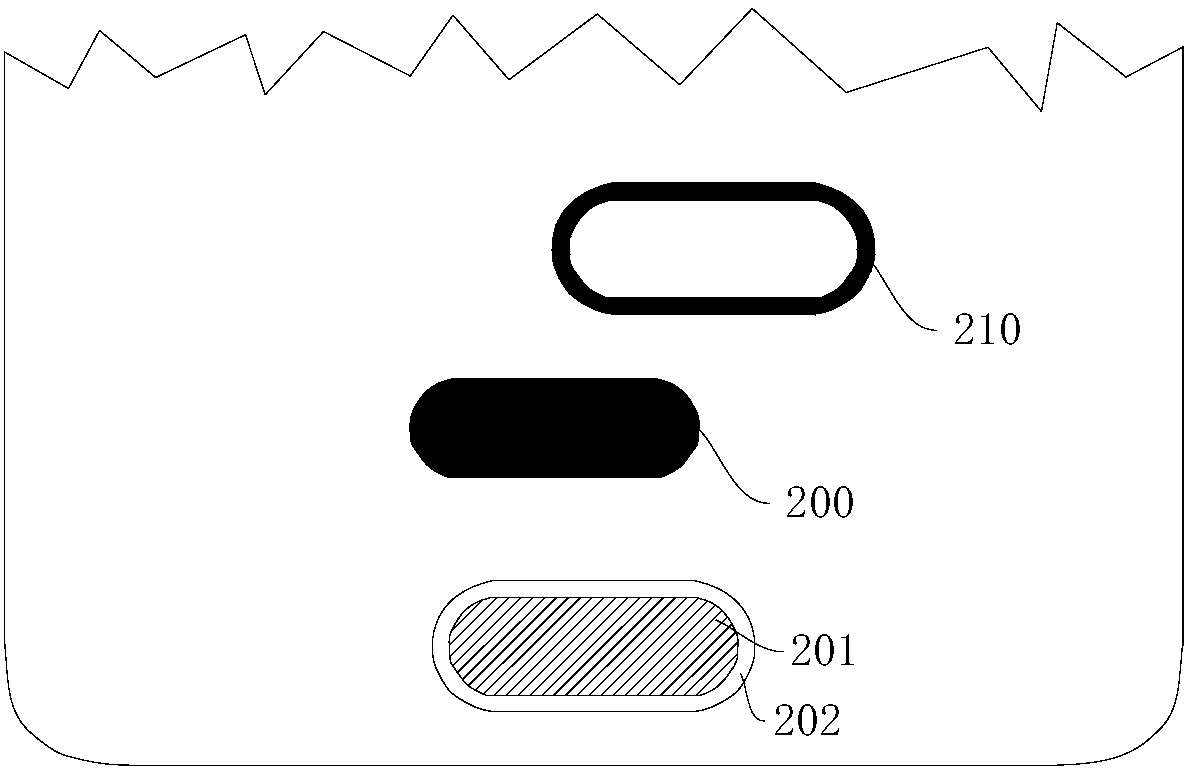

Bottle body automatic screen printing machine

ActiveCN108454224AOutstanding and Beneficial Technical EffectsFast transmissionScreen printersNon-mechanical conveyorsScreen printingUltraviolet

The invention discloses a bottle body automatic screen printing machine. The machine comprises a conveying and loading device, a circular conveying working line and an unloading device; a bottle bodycircular conveying working line comprises the circular conveying working line arranged on a stand; the circular conveying working line comprises an annular guide rail set, a linear motor magnetic suspension motion mechanism and a servo control system; the linear motor magnetic suspension motion mechanism is provided with a mover for circularly moving along annular guide rails; the mover is provided with a bottle body fixture; a screen plate and an ink curing device are arranged beside the linear motor magnetic suspension motion mechanism; a scraper is arranged on the screen plate; the screen plate and the ink curing device are both positioned above a motion trajectory of the bottle body fixture; and the ink curing device is positioned between an ink plate and the unloading device. The machine is precise in repeated positioning, safe, reliable and high in speed, improves the chromatography precision and the printing quality, adopts ultraviolet rays or electronic beams to cur ink on bottle bodies, and is suitable for printing of some glass bottles and cosmetic bottles with complicated shapes.

Owner:台州科迅印刷设备科技有限公司

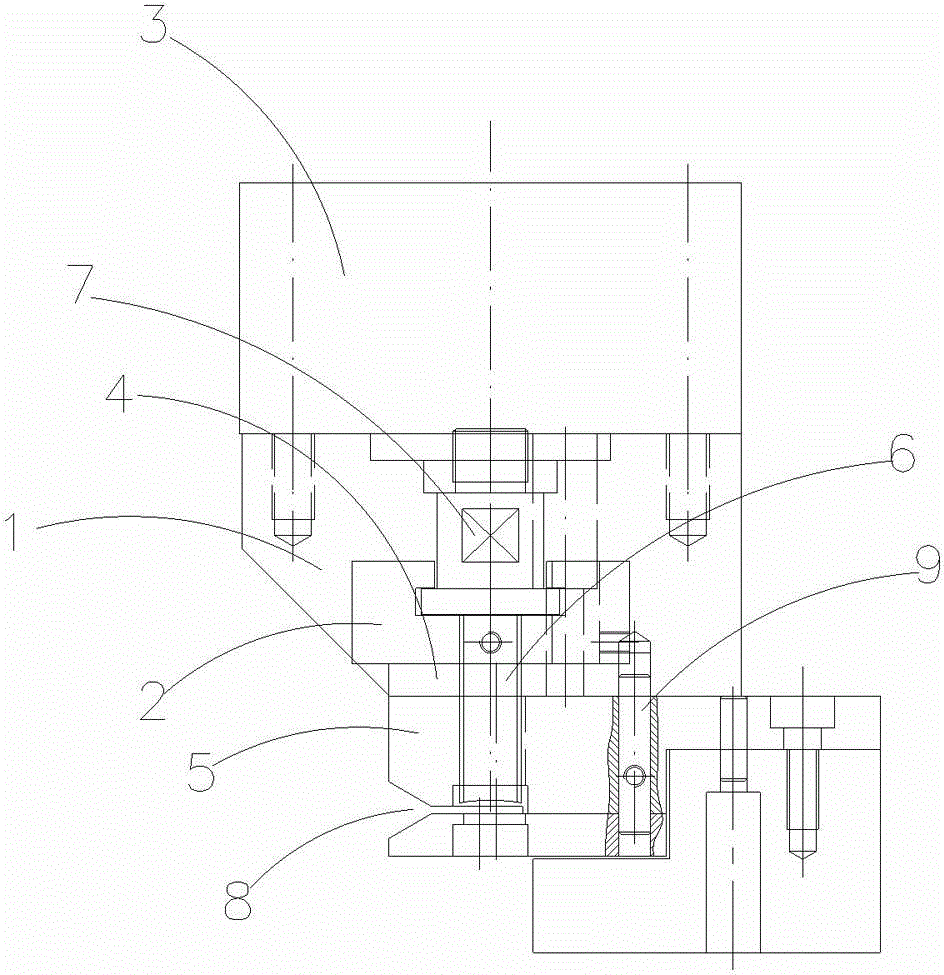

Automatic precise punching device and operation method thereof

ActiveCN104647462AReduce labor costsReduce manual overprint instabilityMetal working apparatusPunchingTransverse groove

The invention relates to a punching device, and particularly relates to an automatic precise punching device and an operation method thereof, which belong to the field of printing machinery. The automatic precise punching device comprises a punching die connecting side plate and a punching air cylinder connecting plate, wherein a punching air cylinder is arranged on the upper end of the punching die connecting side plate, the punching air cylinder connecting plate is arranged on the lower end of the punching die connecting side plate, the bottom of the punching air cylinder connecting plate is fixedly connected with a punching die upper plate, a punching die lower plate is arranged at the bottom of the punching die upper plate, a punch is arranged in the punching die upper plate and the punching die lower plate, the upper end of the punch is fixedly connected with the punching air cylinder through a connecting screw, and a punching positioning transverse groove is formed in the punching die lower plate. The operation method comprises the steps of installation of the punching device, operation during punching and operation after punching. The automatic precise punching device has the advantages of simple structure, precision in punching, high overprinting precision and diversity in punching.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

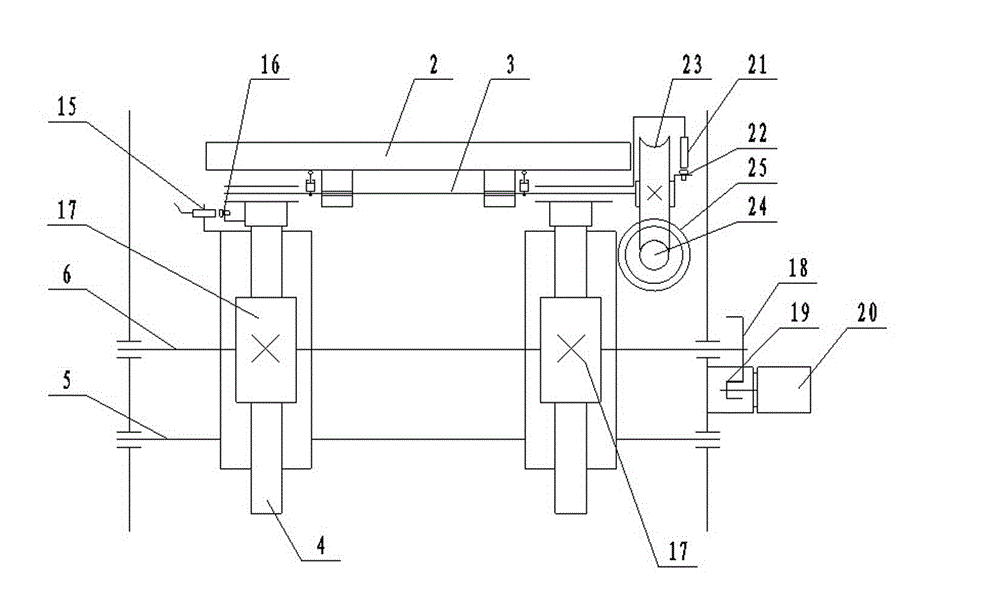

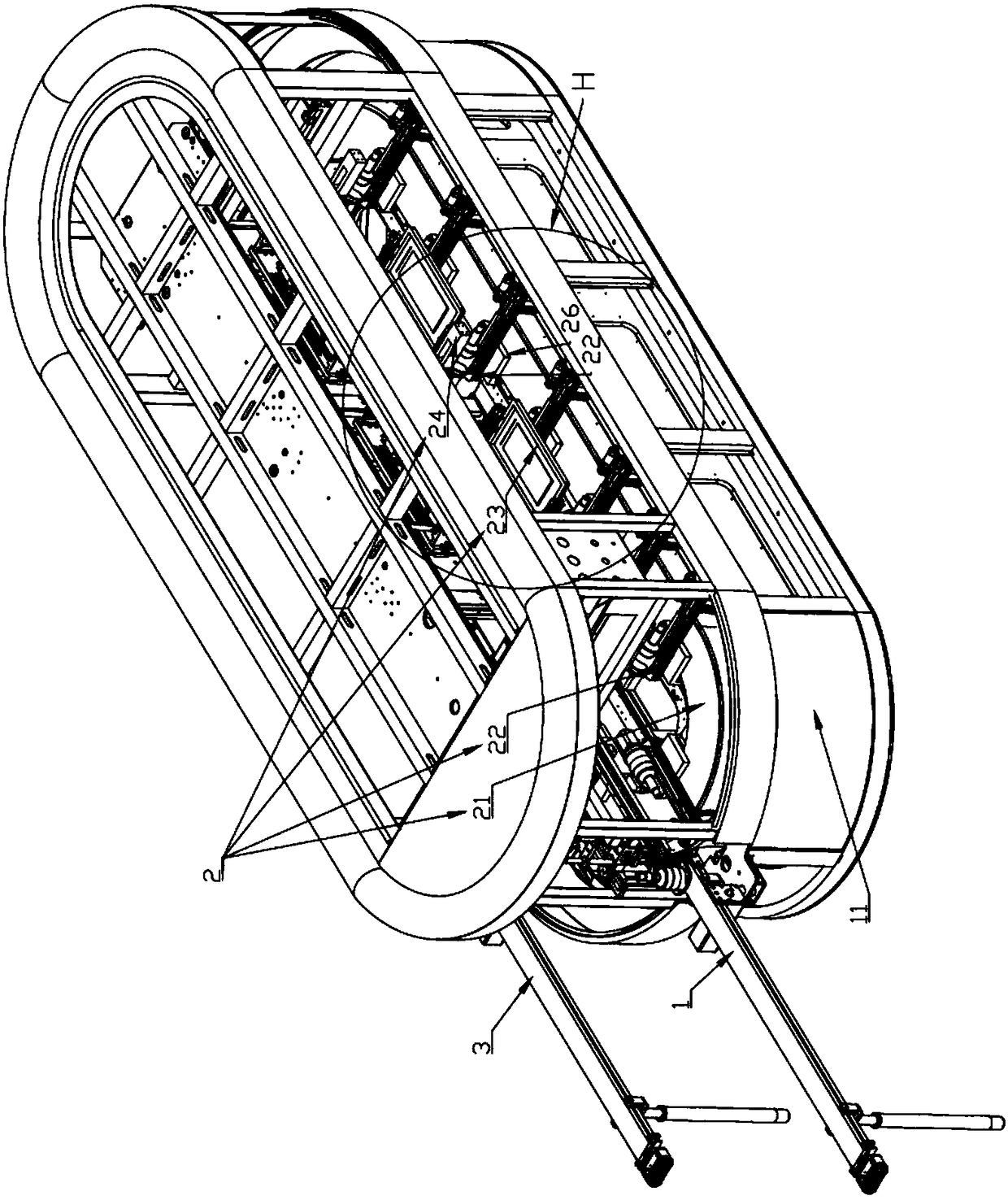

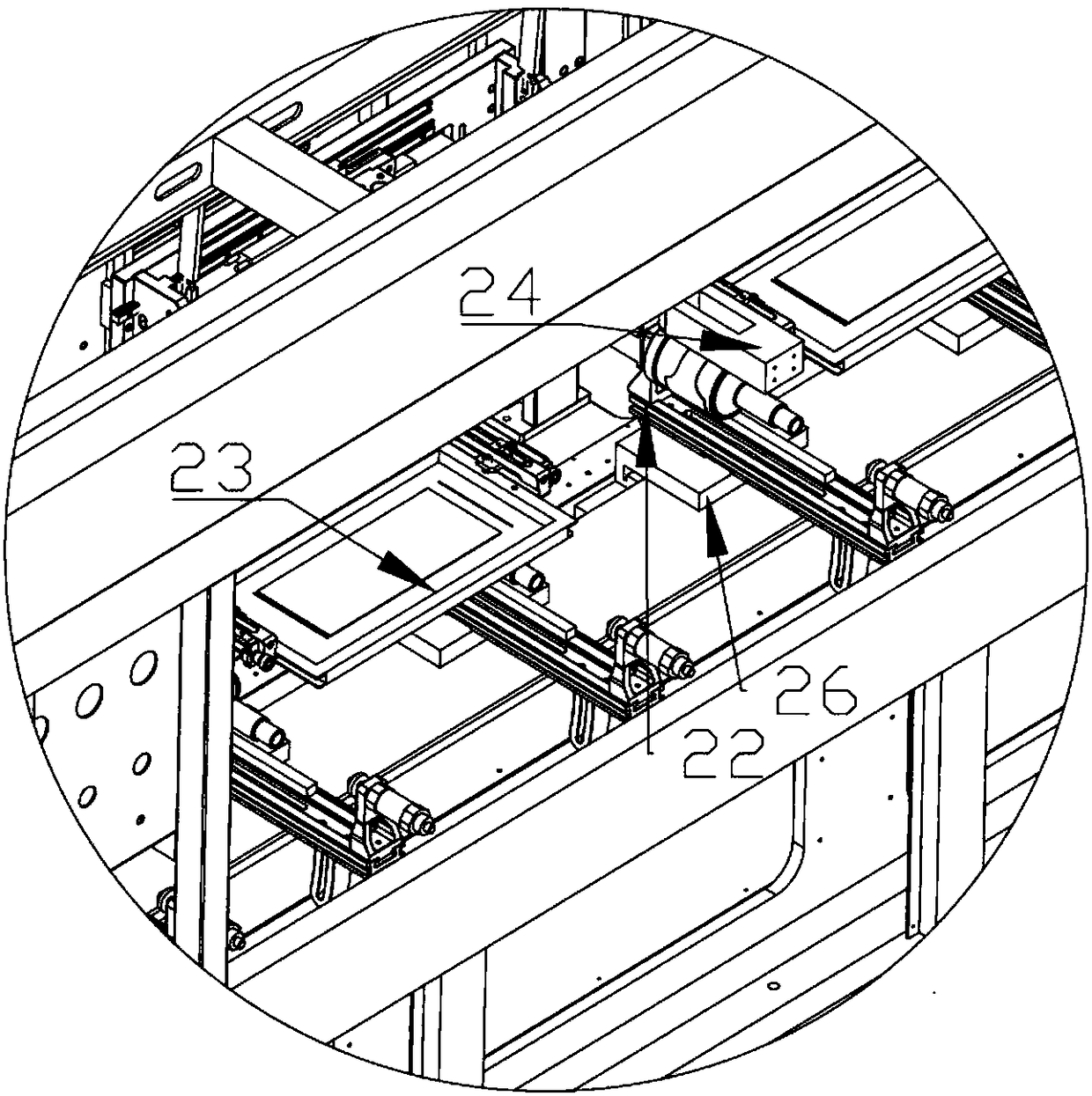

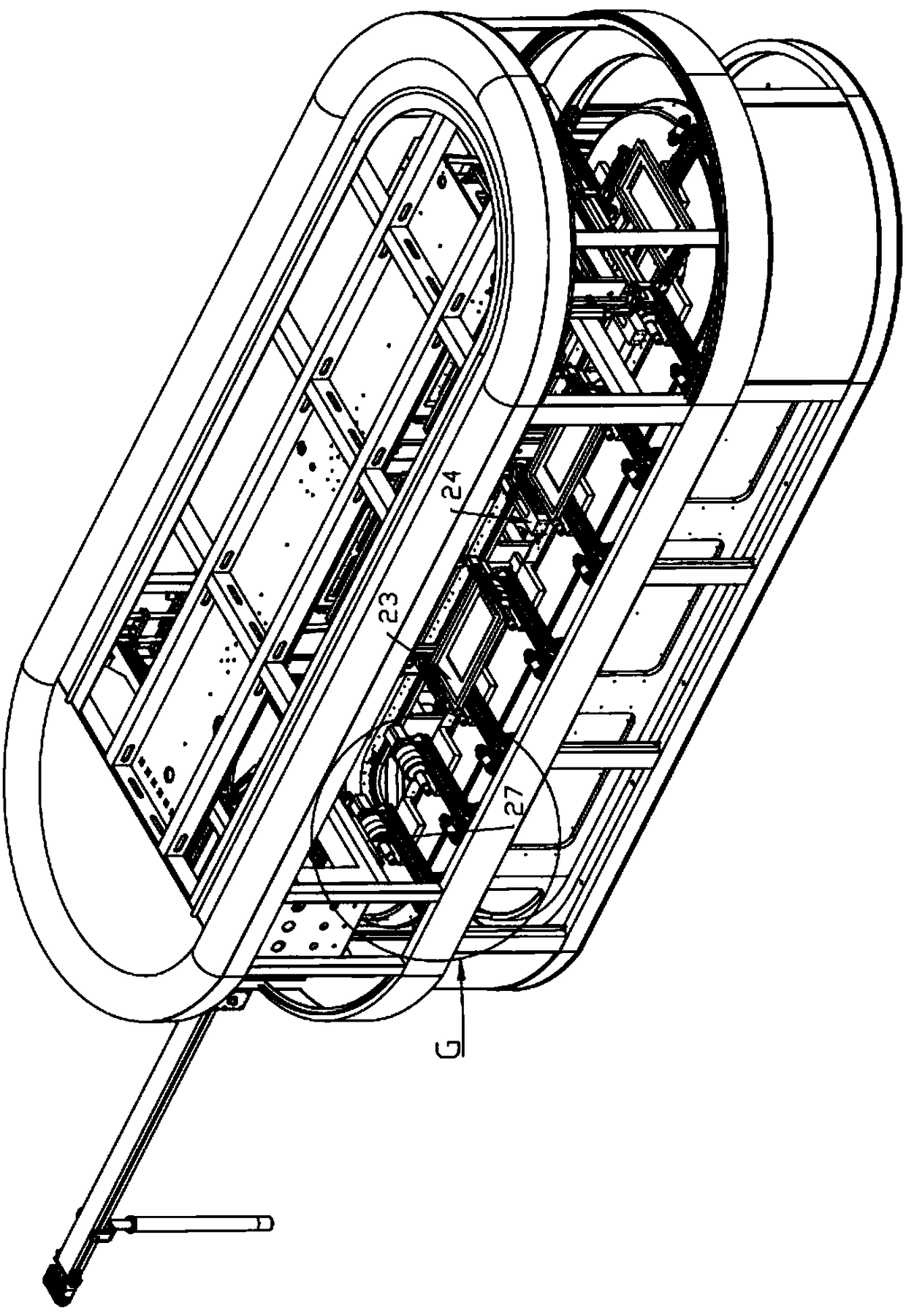

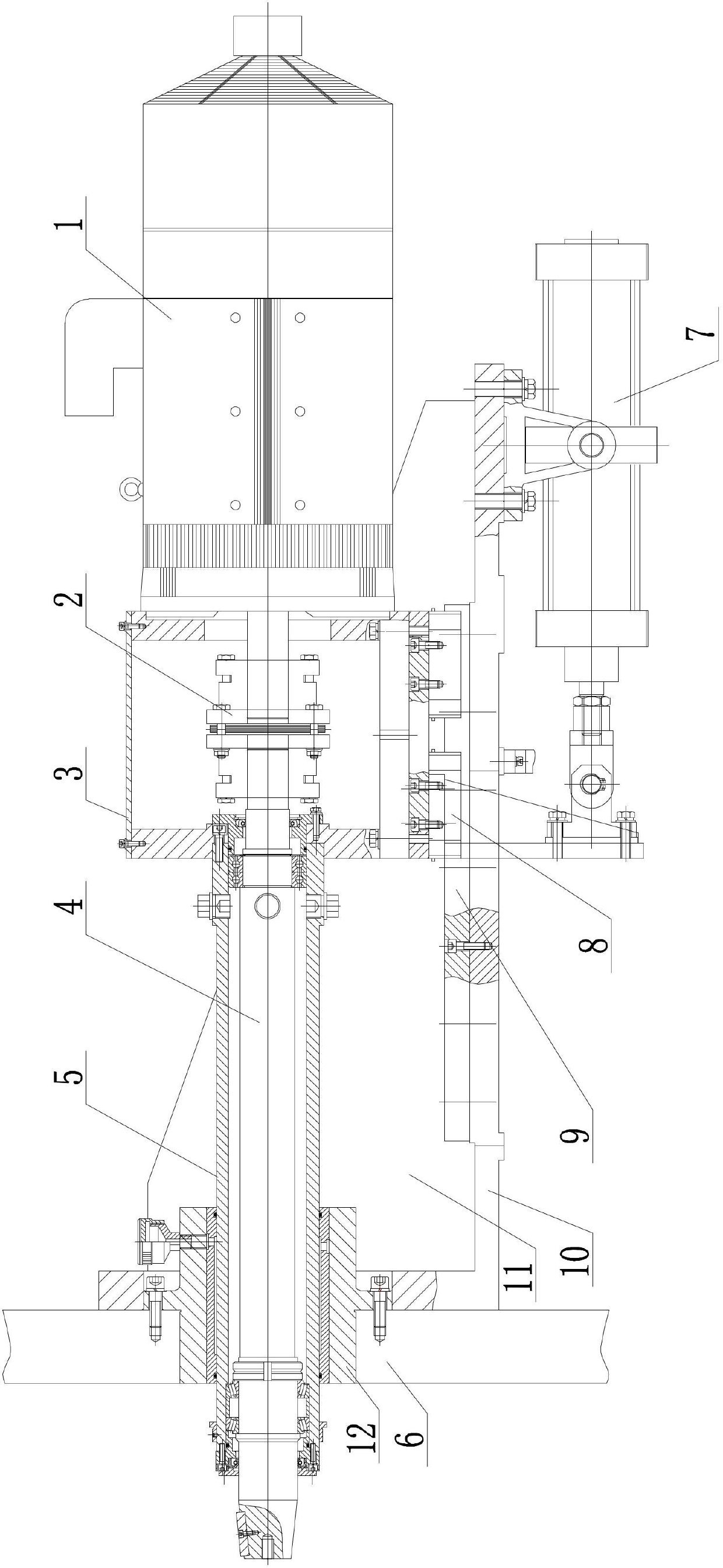

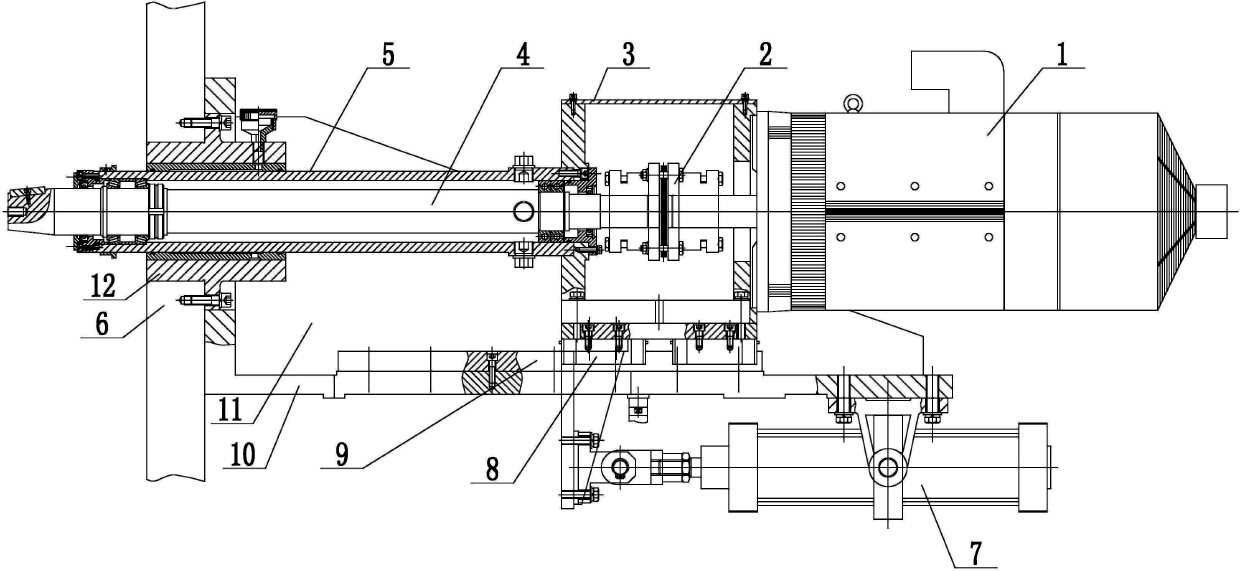

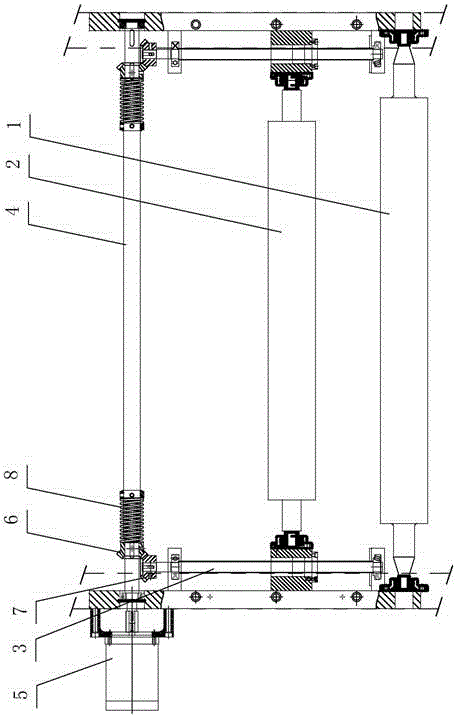

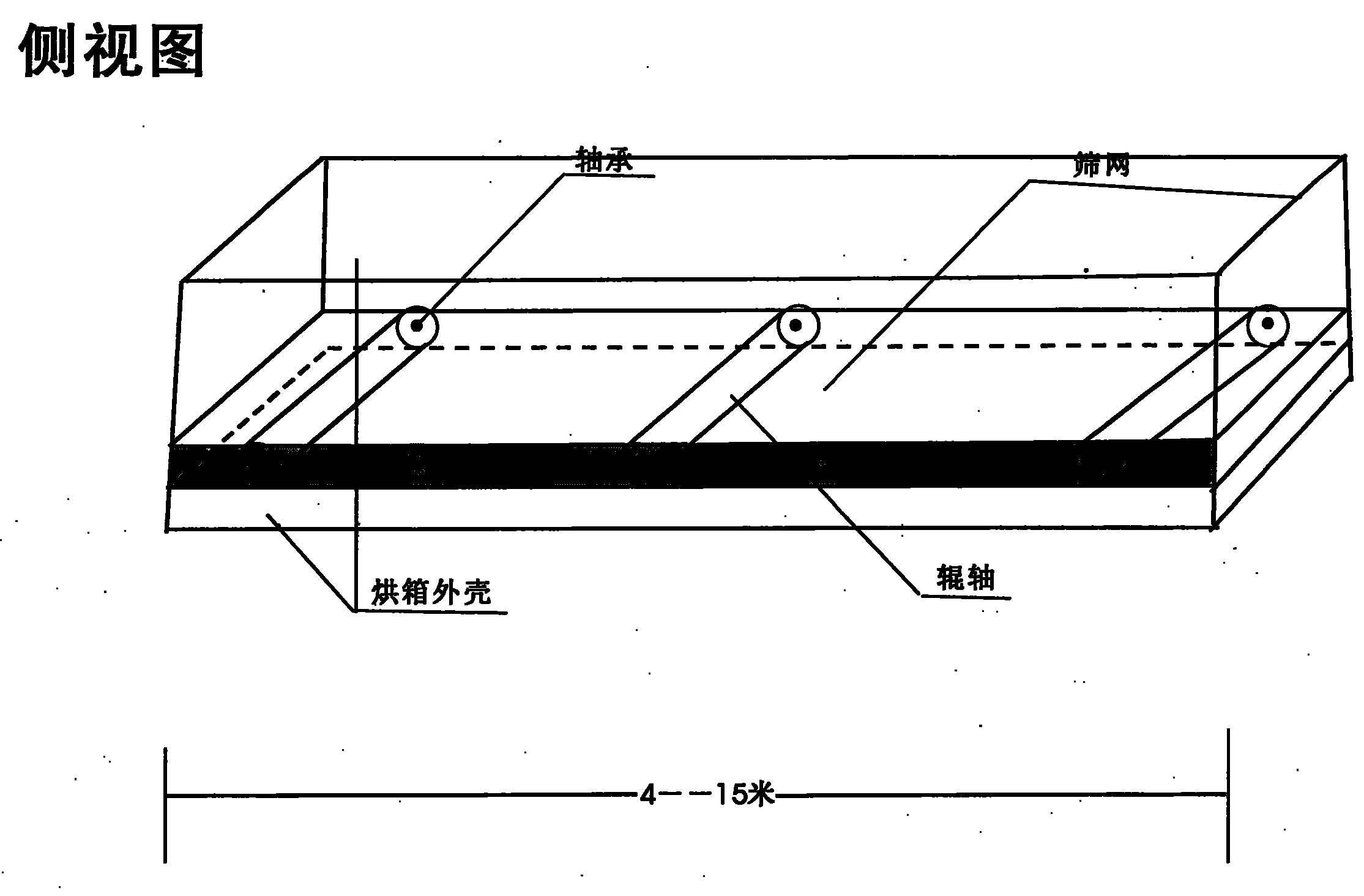

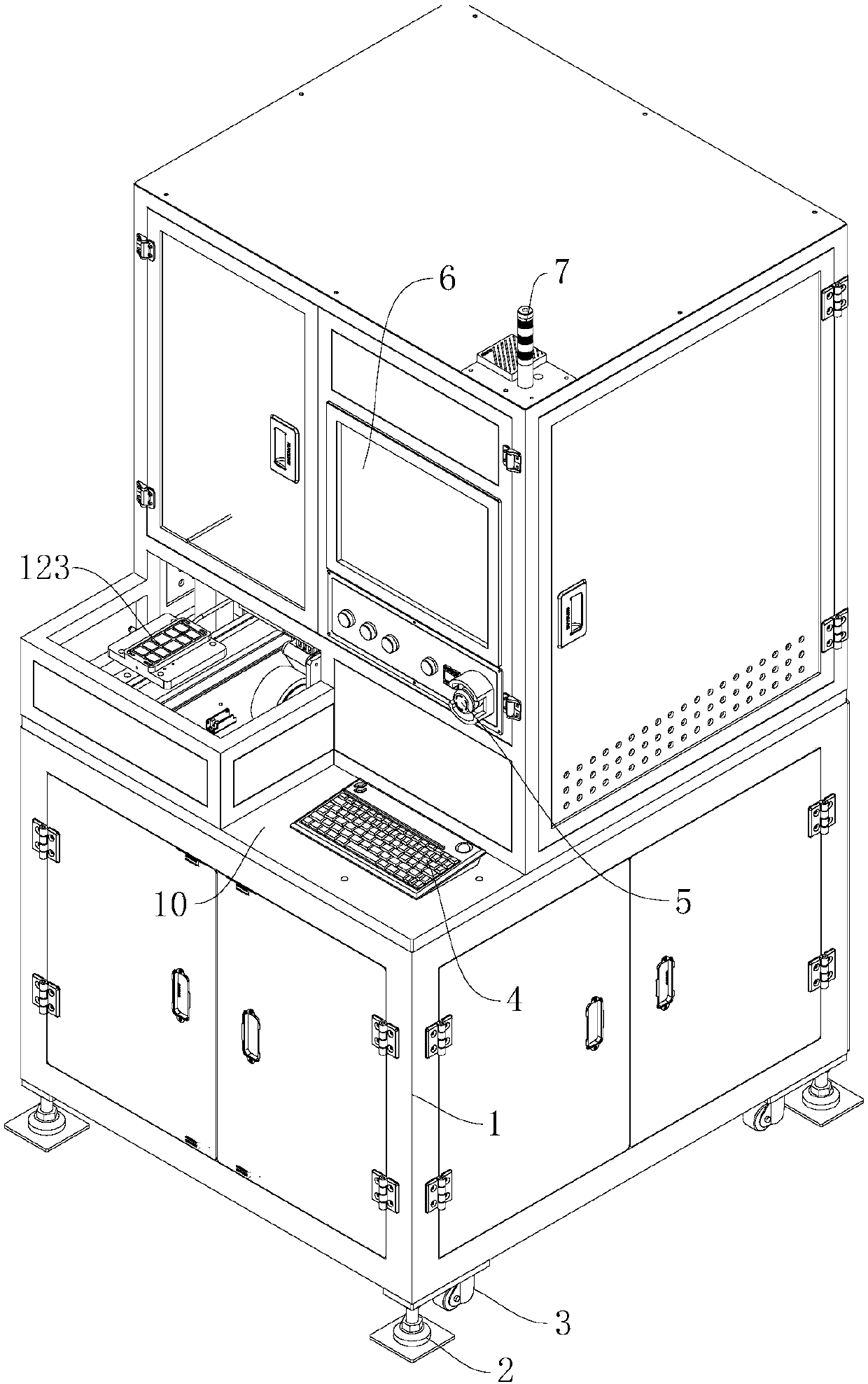

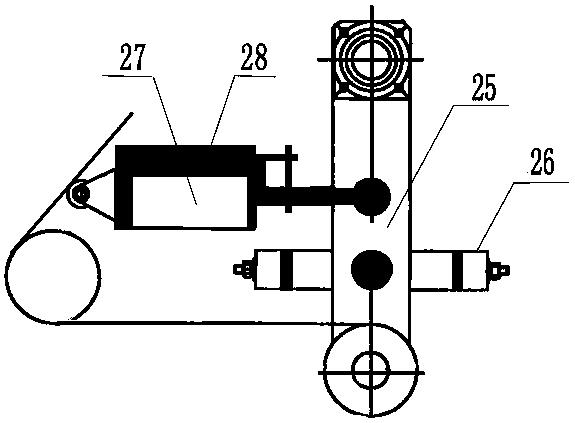

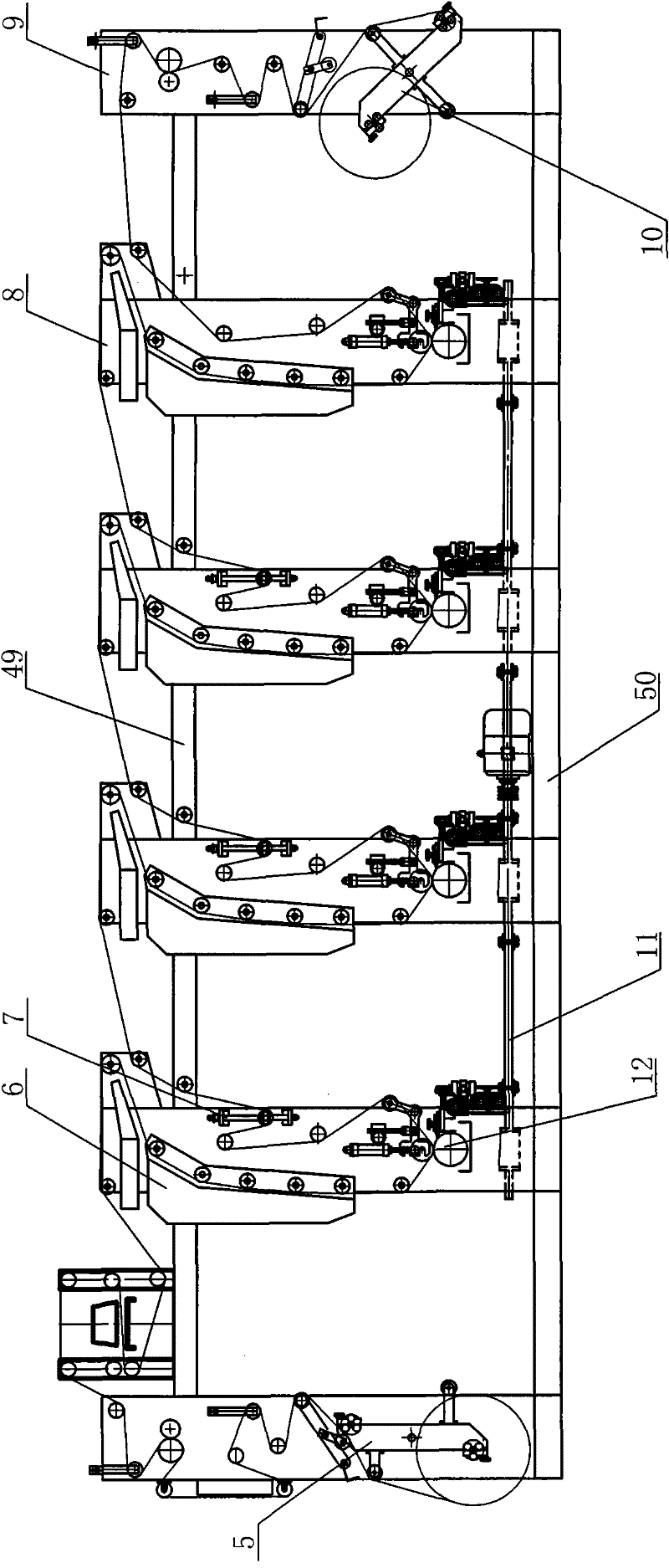

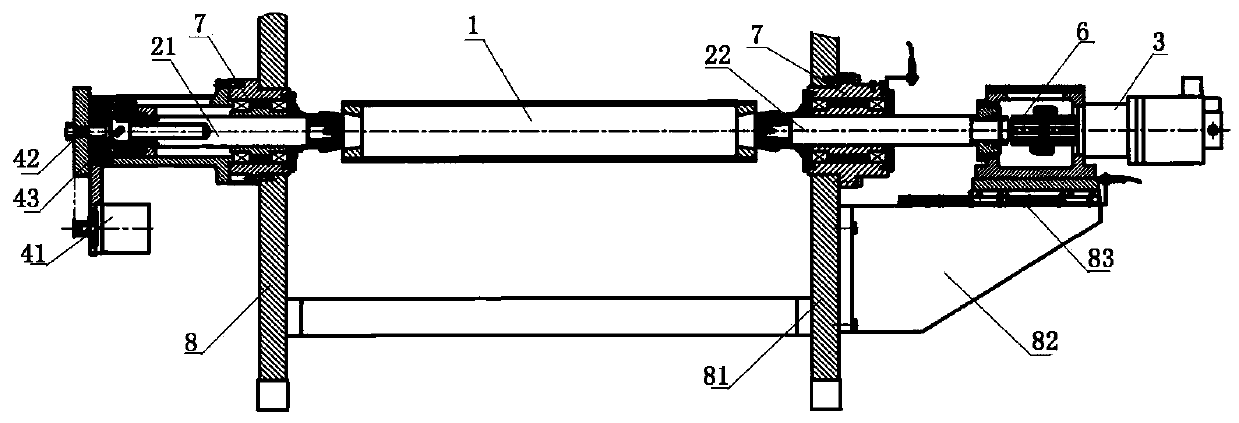

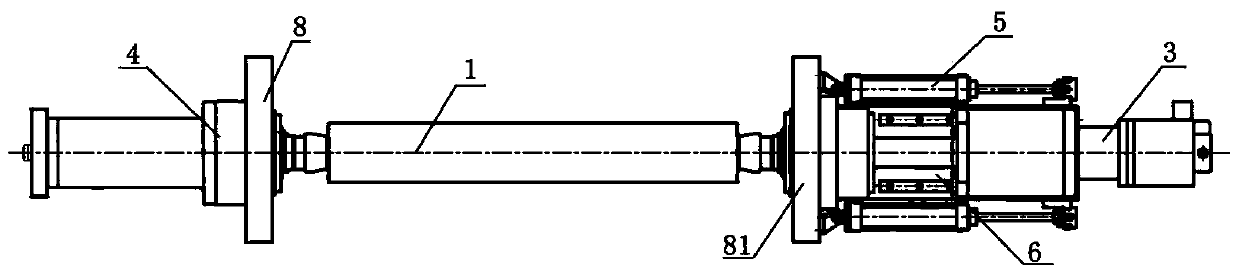

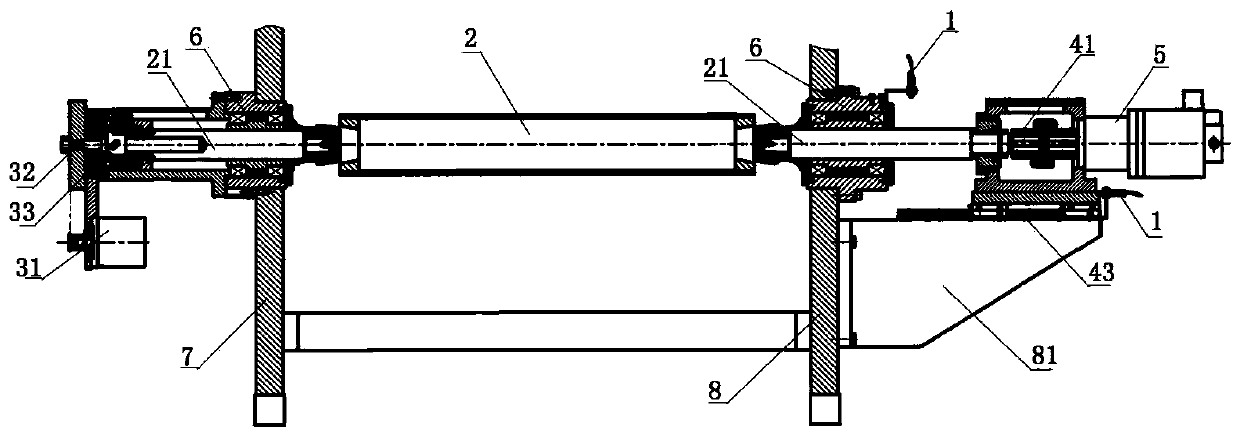

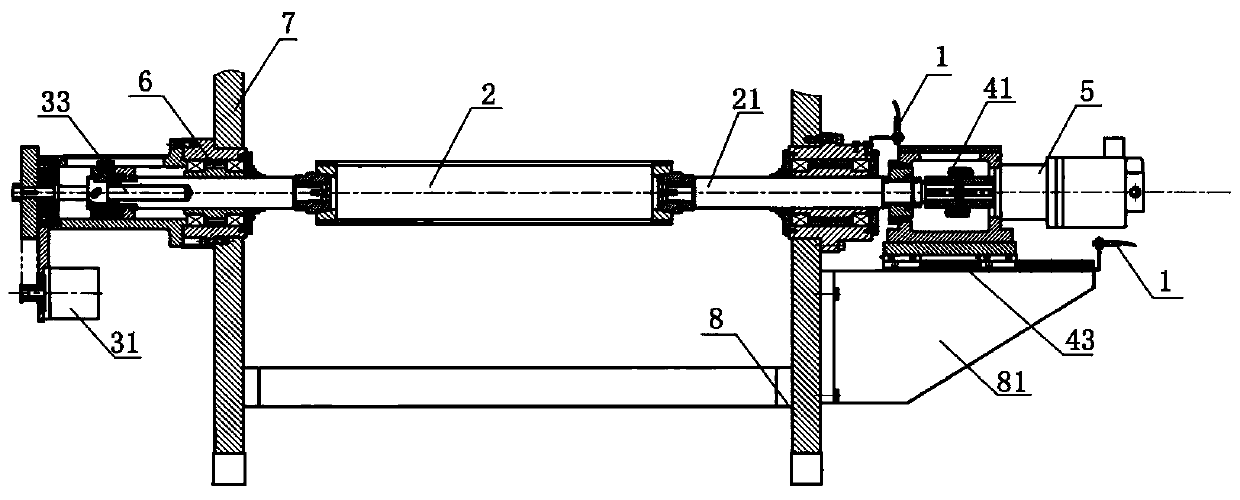

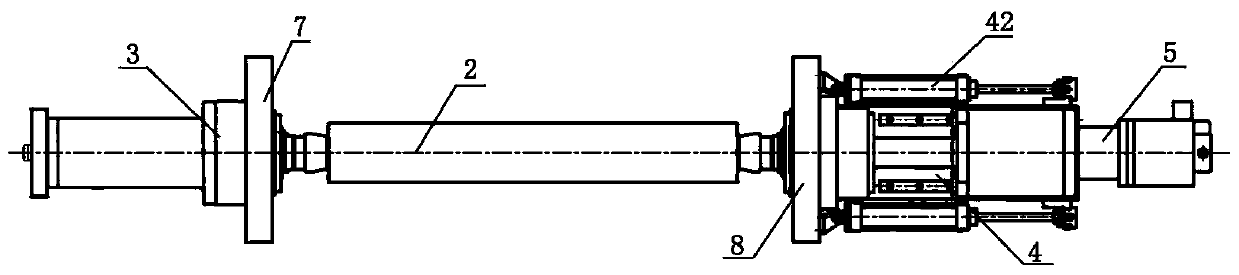

Driving device for printing roll of high-speed electronic shaft transmission printing machine

InactiveCN102673099AReduce error accumulationThere is no problem of slowly decreasing accuracyRotary pressesEngineeringMechanical engineering

The invention discloses a driving device for a printing roll of a high-speed electronic shaft transmission printing machine, which can improve the overprinting precision and make the overprinting precision stable. The driving device for the printing roll of the high-speed electronic shaft transmission printing machine comprises a servo motor (1), a shaft coupler (2), a box body (3) and a printing roll driving shaft (4), wherein the servo motor (1) is connected with the box body (3); the output shaft of the servo motor (1), the shaft coupler (2) and the printing roll driving shaft (4) are connected sequentially; the part between the two ends of the printing roll driving shaft (4) is positioned in a shaft sleeve (5); the printing roll driving shaft (4) is rotationally connected with the shaft sleeve (5); one end of the shaft sleeve (5) is connected with the box body (3); and the shaft sleeve (5) is in sliding fit with a machine frame (6) of the high-speed electronic shaft transmission printing machine.

Owner:NINGBO XINDA PRINTING MACHINERY

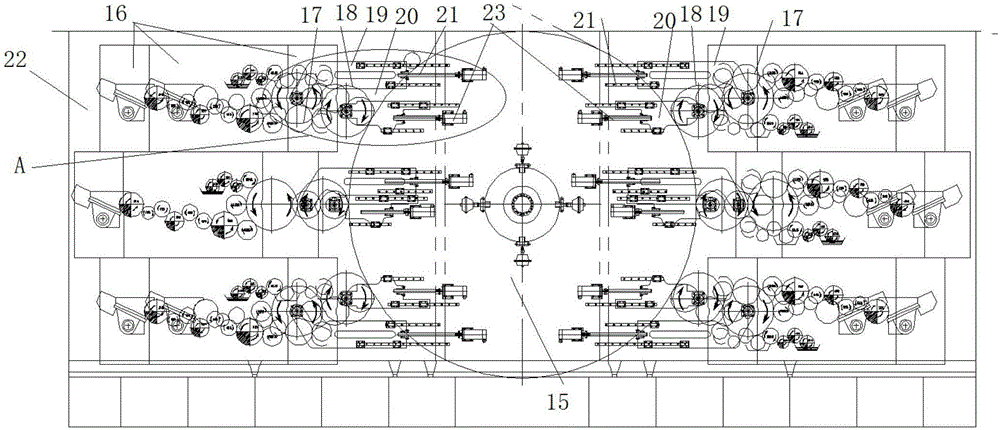

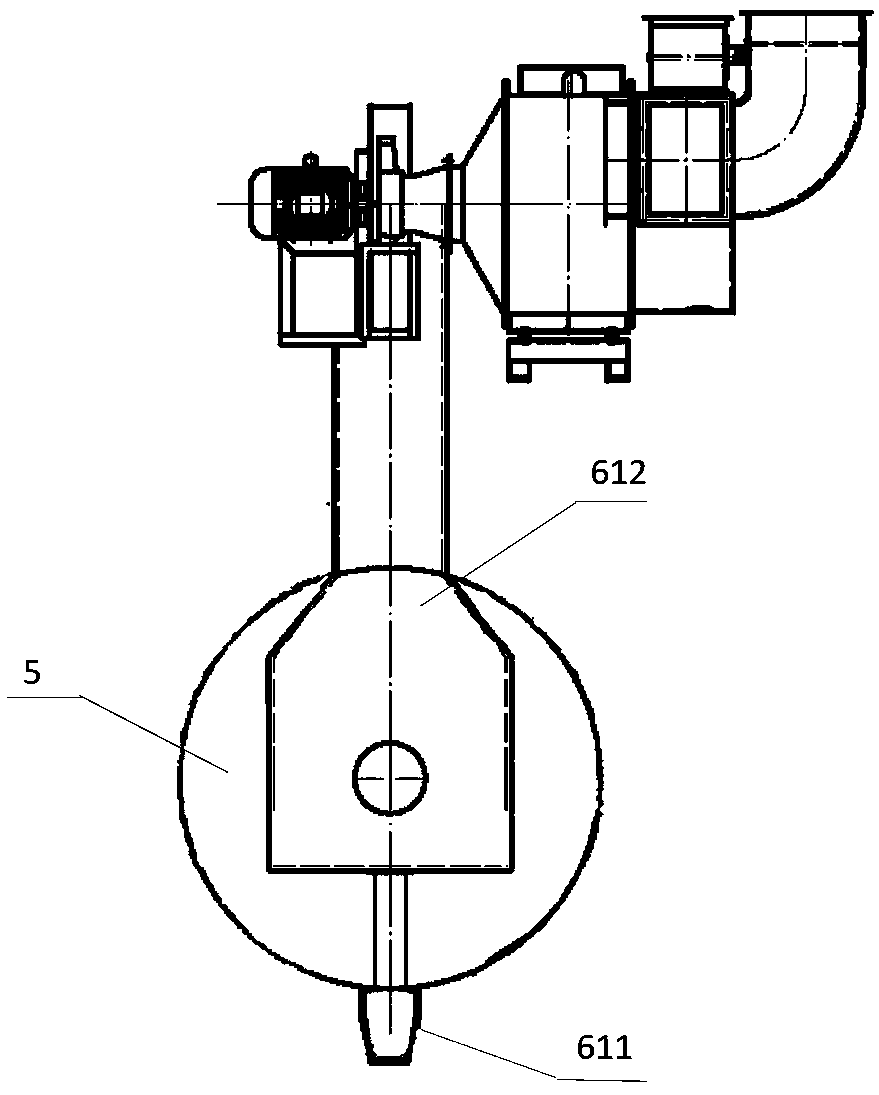

Satellite intaglio printing method

The invention discloses a satellite intaglio printing method, which is performed according to following steps that a printed material passes through a swing roller in a traction unit from a discharging unit and enters a corona treatment unit for corona treatment after tension achieves a preset state, then the printed material is subjected to ground color printing after entering a single coating unit, a coating drying unit dries the printed material, the printed material attached with ground color enters a satellite intaglio printing unit for four-color printing, then a top drying unit bakes the printed material, the temperature of the dried printed material is reduced by a top water cooling unit, the printed material is subjected to deep line embossing treatment by a deep line embossing unit, and a heating unit is used in the deep line embossing process, so the lines of the printed material are clearer, then the printed material passes through a secondary water cooling unit, the printing embossing process is finished, and the well-printed printed material passes through an edge cutting unit, and is coiled by a large coiling unit and shaped. The satellite intaglio printing method solves the problem that the technical requirements of multicolor and precise overprinting of a direct printing process cannot be met.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

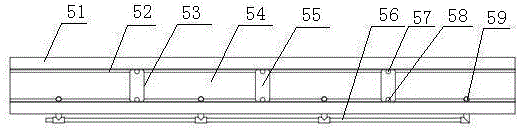

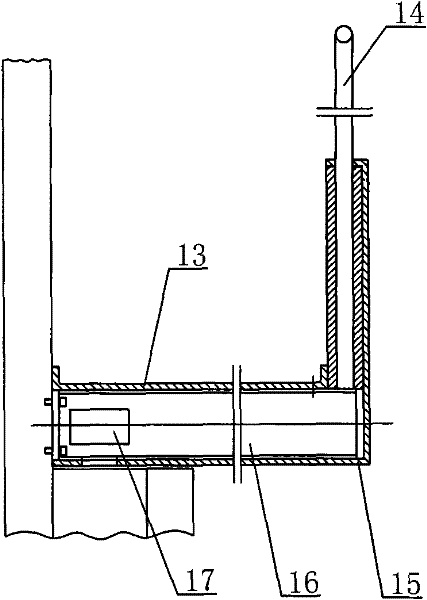

Device capable of improving regulation precision of photogravure press guide roller

InactiveCN104972737AThere will be no meshing virtual position phenomenonImprove overprint accuracyRotary pressesBall screwGear wheel

The invention discloses a device capable of improving the regulation precision of a photogravure press guide roller. The device comprises a material-guiding guide roller, a regulating guide roller, ball screws, a drive rod and a motor as well as a motor, wherein the regulating guide roller is arranged above the material-guiding guide roller, the ball screws are arranged at two ends of the regulating guide roller so as to regulate vertical lifting of the regulating guide roller, the drive rod is connected with the two ball screws by bevel gears so as to drive the two ball screws to synchronously rotate, the motor is used for driving the drive rod to rotate, the bevel gears on the drive rod are axially fixed on the drive rod, each ball screw is provided with a spring; by the springs, bevel gears on the ball screws and the bevel gears on the ball screws can be pressed and meshed. According to the invention, the spring presses the bevel gears on the drive rod and the bevel gears on the ball screws so that the bevel gears on the drive rod and the bevel gears on the ball screws are tightly meshed all the time, the phenomenon of idle meshing of the gears is avoided and the chromatography precision of the photogravure press is effectively increased.

Owner:曾宪雄

Satellite type electron-beam curing ink offset press

InactiveCN106393954AEasy to dryNo emissionsRotary lithographic machinesPrinting press partsEngineeringMechanical engineering

The invention discloses a satellite type electron-beam curing ink offset press. The satellite type electron-beam curing ink offset press comprises an emptying and paper receiving machine device, wherein a printing material in form of a coiling block in the emptying and paper receiving machine device enters a material receiving device through a deviation-correcting device, a dedusting device, a printing unit, an electron-beam curing device, an outlet deviation-correcting device, a material receiving traction device and a material receiving cutting device successively; the printing device comprises a central large roller which is perpendicularly arranged between a pair of wallboards of the offset press; a plurality of pairs of offset print color cell units which are adjustable in position are formed on opposite two sides of the central large roller horizontally; each of the offset print color cell units successively comprises a water-ink system which is arranged close to the central large roller, a printing roller which is quickly disassembled and assembled and a rubber roller which is quickly disassembled and assembled; the printing roller is as same as the rubber roller in structure. The satellite type electron-beam curing ink offset press is small in pollution, the offset print structure can continuously feed, and the overprinting accuracy is high.

Owner:SHAANXI BEIREN PRINTING MACHINERY

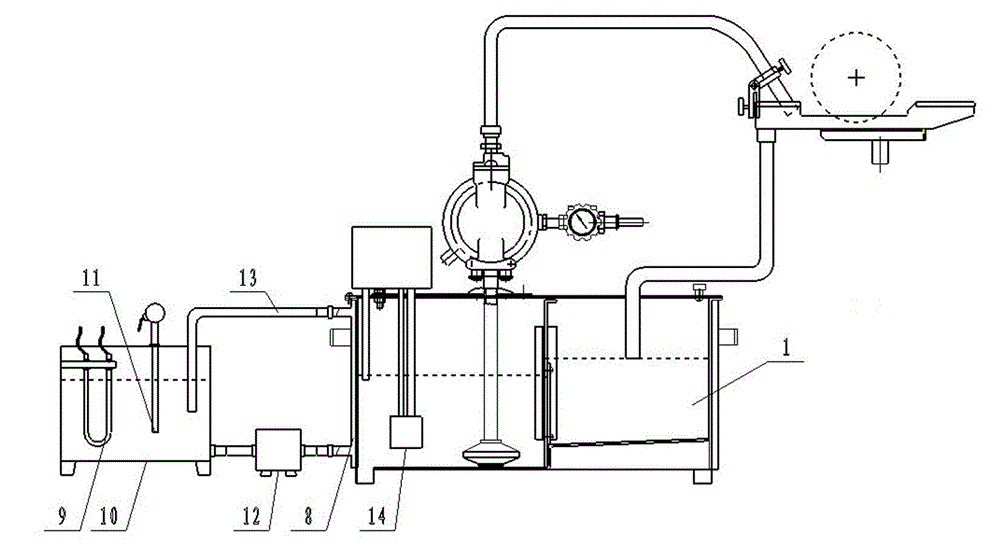

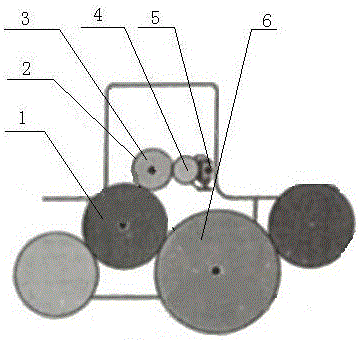

Printing device of plate roller of multi-color gravure printing machine

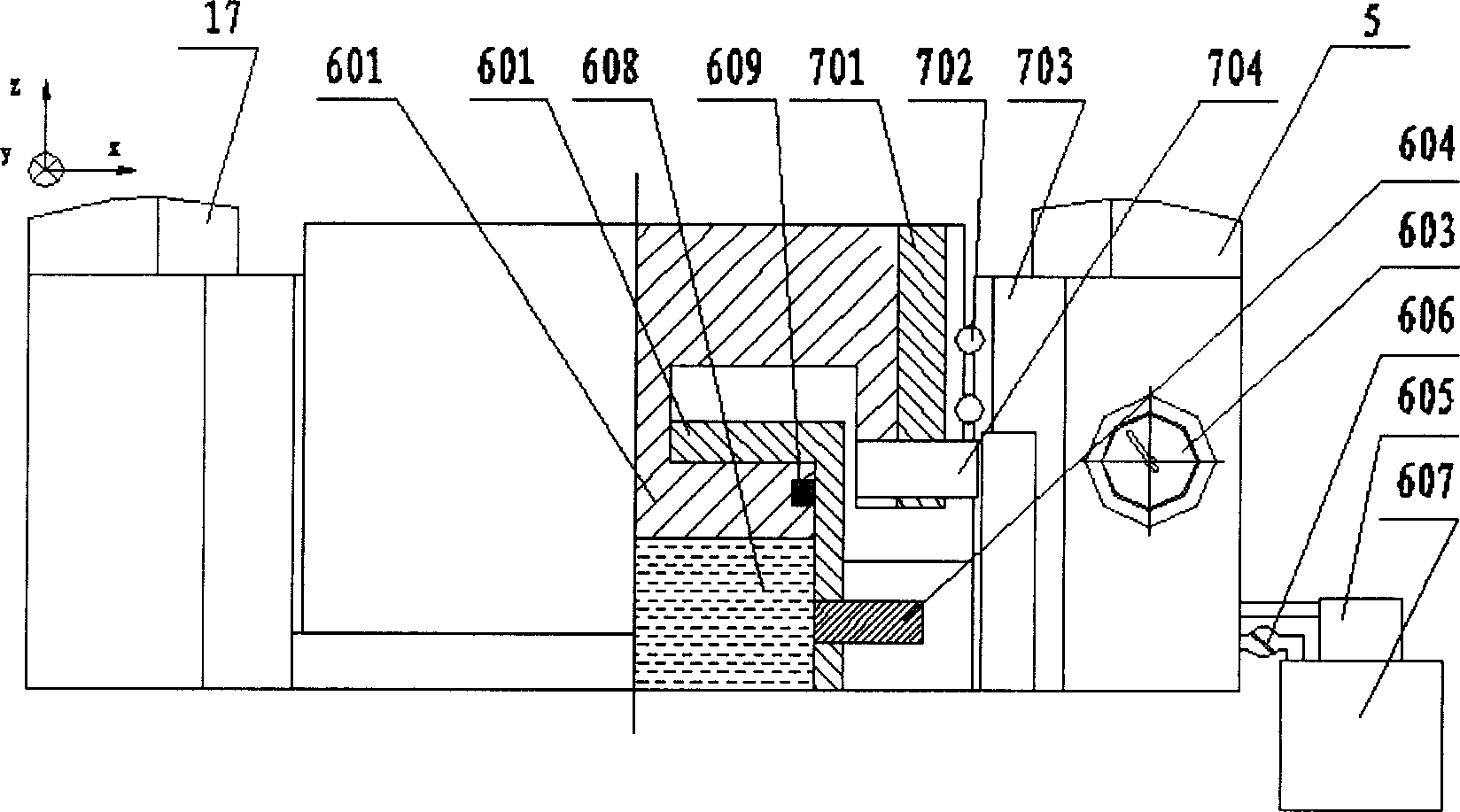

InactiveCN102241182ATransfer evenlyImprove overprint accuracyRotary intaglio printing pressPrinting press partsFiltrationSpray nozzle

The invention discloses a printing device of a plate roller of a multi-color gravure printing machine, which is a main component part of the gravure printing machine. A closed container is arranged according to the size of the printing machine, the printing plate roller, a scraper and a water ink spray nozzle are arranged in the closed container, and a pressure pump with pressure is mounted outside the closed container and further connected with the water ink spray nozzle. One surface of the closed container is set to be a moving surface so as to facilitate the replacement of the plate roller. A feed port and a discharge port are formed on the closed container, a baiting valve is arranged at the bottom of the closed container and filtration is further performed. By the adoption of the printing plate roller, dry plate phenomenon happens hardly, and a printed pattern is clear; compared with the prior art, printing and color registration of the multi-color gravure printing machine are stable, the printing speed is further improved, the working efficiency is improved and the good printing effect is obtained.

Owner:张伟公

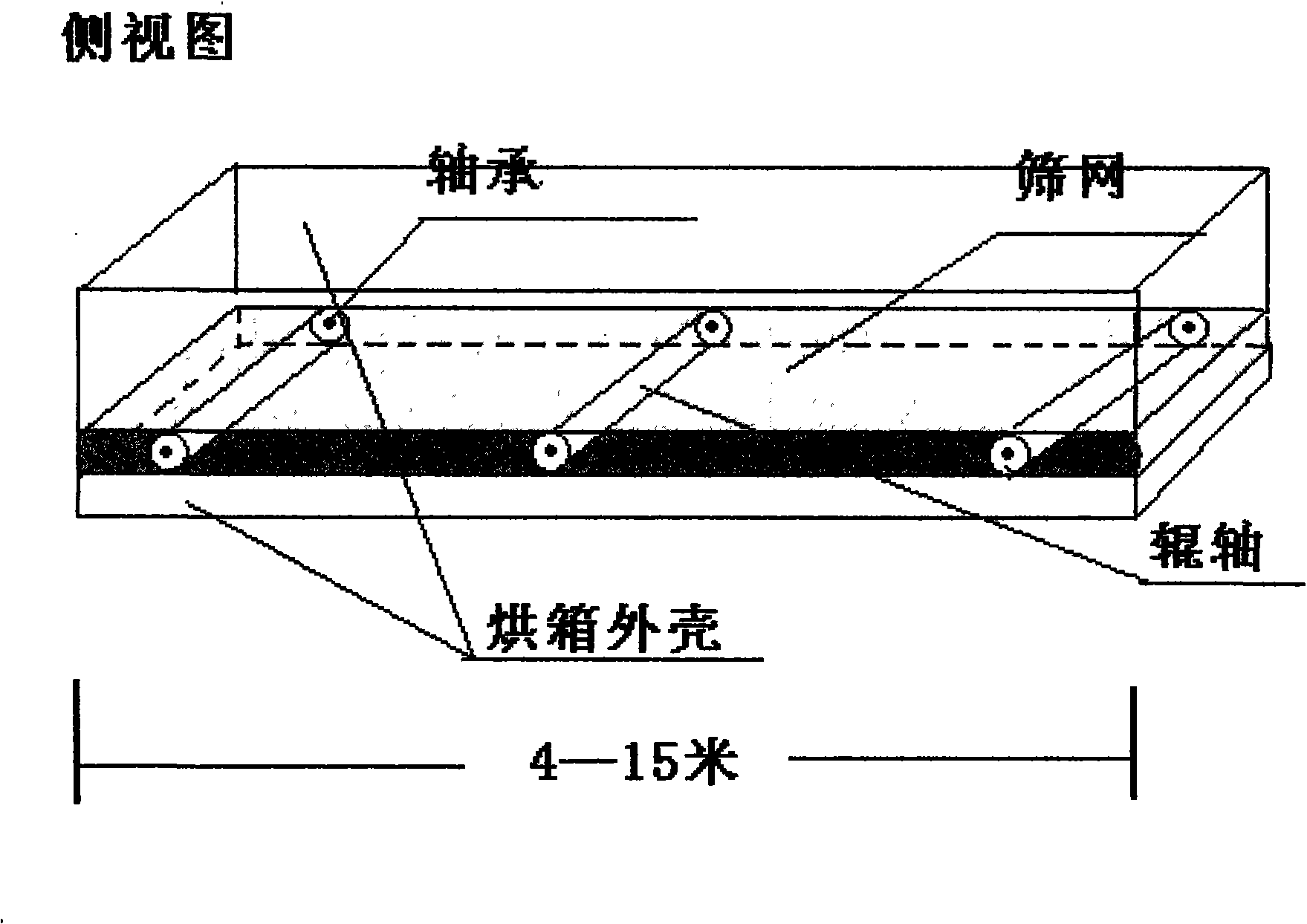

Drying device of multicolor intaglio press oven

InactiveCN101934629AImprove overprint accuracyTransfer evenlyPrinting press partsMicrowaveEngineering

The invention discloses a drying device of a multicolor intaglio press oven, wherein infrared drying and electric heating drying modes or microwave drying mode can be adopted in the oven. The oven is internally provided with a plurality of guide rollers or the guide rollers are arranged to drive a screen to roll along with a web material, and each guide roller is internally provided with a rolling shaft and a bearing. The invention can ensure that tension for printing the web material is stably treated and the material is uniformly stretched under constant tension, thereby achieving uniform drying and avoiding the phenomenon that the materials are not dried during lower surface plating. Compared with the prior art, the invention can ensure that printing casing of the multicolor intaglio press is stable, thereby further improving printing speed and working efficiency and achieving favorable printing effect.

Owner:张伟公

Gloss oil set printing device for optical variable anti-faking ink offset printing and offset printing online printing method

ActiveCN106585087AReduce scratch areaAvoid damagePrinting after-treatmentPrinting press partsEngineeringColor changes

The invention discloses a gloss oil set printing device for optical variable anti-faking ink offset printing. The device comprises a conveying device, a scraper, an anilox roller, a plate roller sleeved with a resin plate, and an impression cylinder; the conveying device is mounted below the impression cylinder for conveying a printed mater onto the impression cylinder; the scraper and the plate roller are mounted on two sides of the anilox roller; the plate roller is mounted above the impression cylinder; the scraper prints optical variable anti-faking ink to the resin plate sleeved on the plate roller through the anilox roller; and under the effect of the impression cylinder, the optical variable anti-faking ink on the resin plate is printed on the printed matter. The invention further discloses an optical variable anti-faking ink offset printing online printing device with the gloss oil set printing device and an optical variable anti-faking ink offset printing online printing method. The printing process and the printing equipment of optical variable anti-faking ink offset printing are simplified; the printing efficiency is improved; the equipment investment and the labor intensity of optical variable anti-faking ink offset printing are reduced; and such technical difficulties as easy color change, blackening and darkening of optical variable anti-faking ink in optical variable anti-faking ink offset printing in the prior art are solved.

Owner:HUNAN FURUI PRINTING CO LTD

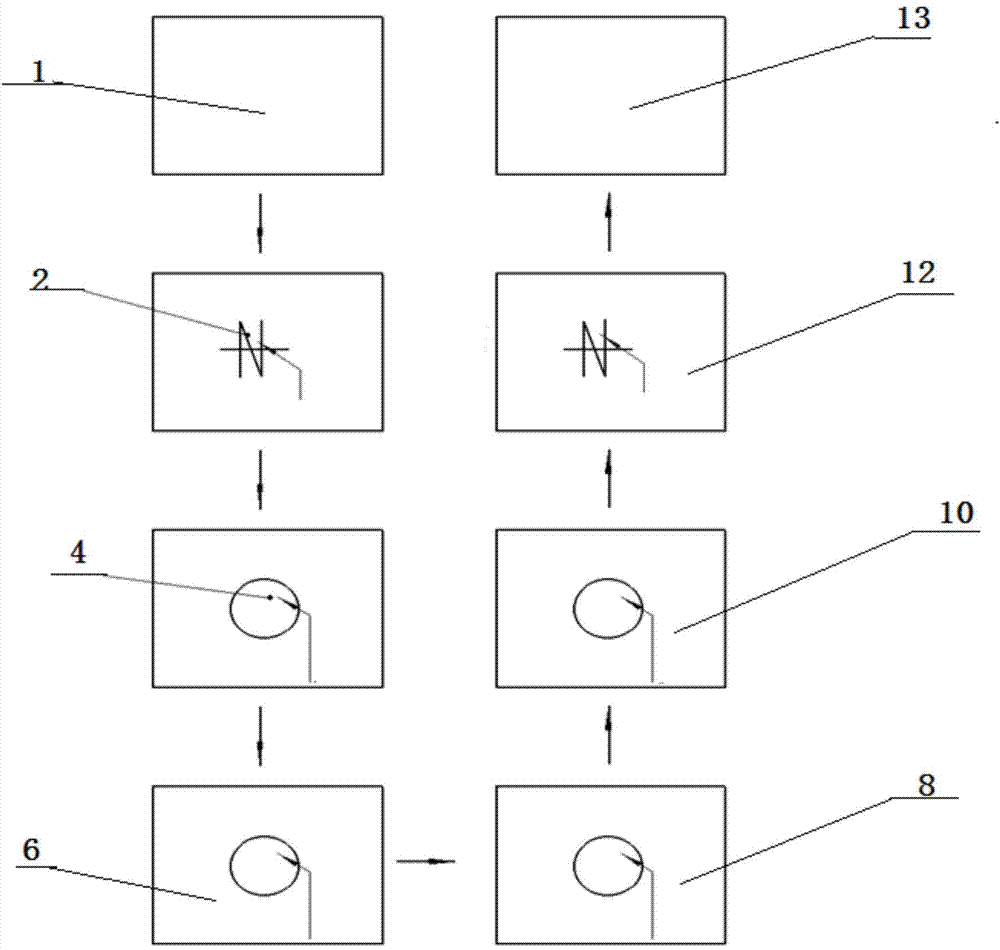

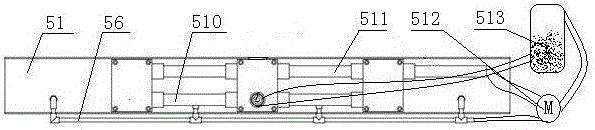

Concave surface high-precision repeated overprinting method and blind hole printing machine

ActiveCN110027332AImprove overprint accuracyRotary pressesOther printing apparatusEngineeringSoft body

The invention provides a concave surface high-precision repeated overprinting method and a blind hole printing machine, and relates to the technical field of blind hole printing. The concave-concave high-precision repeated overprinting method comprises the steps that a blind hole positioning mechanism is used for grabbing the bottom or a hole mouth light ring of a blind hole, and the first centralcoordinates X00, Y00 and R00 of the blind hole are automatically recorded; a first pattern matched with the bottom of the blind hole is collected from an ink taking mechanism, and the first pattern is printed on a cover plate of an electronic product; the blind hole positioning mechanism is used for grabbing data of the second central coordinates X1, Y1 and R1 of the first pattern on the cover plate; and a difference between the second central coordinates X1, Y1 and R1 of the first pattern and the first central coordinates X00, Y00 and R00 is obtained through automatic operation of a soft body, and then the first pattern is printed on the bottom of the blind hole after the difference is automatically compensated. The concave-concave high-precision repeated overprinting method is high in printing precision and capable of enabling the center points of different patterns to be highly overlapped.

Owner:KUNSHAN RUIYONGCHENG PRECISION EQUIP

Manufacturing method of broad-width special holographic mold pressing mother matrix

The invention provides a manufacturing method of a broad-width special holographic mold pressing mother matrix. The manufacturing method comprises the following steps of: dividing the surface of a base material into a plurality of areas; printing a photo-curing ink layer on the first area of the base material, and performing jointing, light illumination and stripping on the photo-curing ink layer and a holographic nickel plate or holographic film which is provided with a background pattern or special edition pattern; overprinting the photo-curing ink layer on the second area, and performing jointing, light illumination and stripping on an ink layer which is not photo-cured and a holographic nickel plate or holographic film which is provided with a special edition pattern; and metallizing the surface of the base material on which the background pattern and the special edition pattern are copied or only the special edition pattern is copied to obtain a broad-width holographic mold pressing mother matrix consisting of the special edition pattern and the background pattern or a broad-width holographic mold pressing mother matrix consisting of the special edition pattern. By using the manufacturing method provided by the invention, the special edition pattern can be accurately set in the background pattern, and small-area special pattern plates can be assembled into a truly seamless large plate, which is suitable for production, through repeated assembling.

Owner:GUANGDONG XINRUI NEW MATERIAL TECH

Novel imprinting device

The invention discloses a novel imprinting device. The novel imprinting device comprises a vertical rack, a plate roller, a compression roller and a lifting driving device, wherein the two ends of the plate roller are arranged on the vertical rack; a left lifting plate and a right lifting plate are respectively arranged on the two sides of the vertical rack in a sliding manner; the two ends of the compression roller are respectively arranged on the left lifting plate and the right lifting plate; a synchronous lifting mechanism is arranged between the left lifting plate and the right lifting plate; and the synchronous lifting mechanism can drive the left lifting plate and the right lifting plate to synchronously rise, fall and move relative to the plate roller, so that the two ends of the compression roller are guaranteed to synchronously rise, fall and push, and the overprinting precision and printing quality of the imprinting device are improved.

Owner:ZHONGSHAN SOTECH PRINTING MACHINERY CO LTD

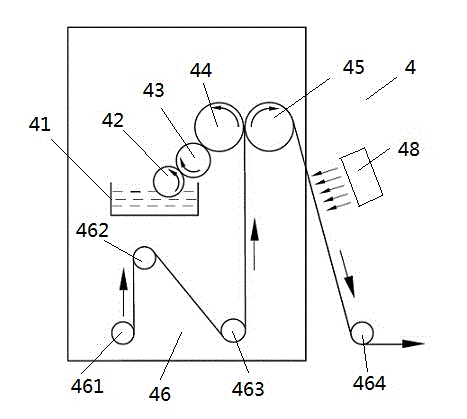

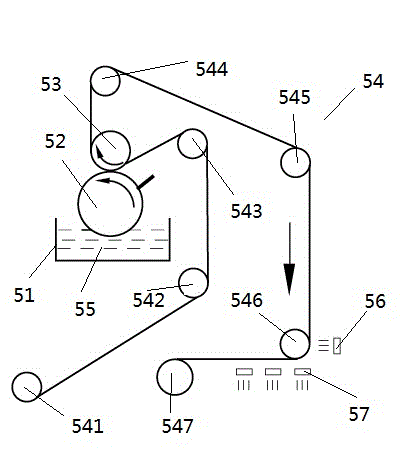

Manufacture process of ecological laminating composite food-grade BOPP laser membrane

InactiveCN105584180AReduce usageAddressing Pollution DefectsLamination ancillary operationsSynthetic resin layered productsIron powderColor printing

The invention discloses a manufacture process of an ecological laminating composite food-grade BOPP laser membrane. The BOPP laser membrane is composed of a laser imaging layer, a laminating layer, a color printing layer and a substrate layer. The manufacture process comprises the following steps: processing a polypropylene material with co-extrusion flat membrane manner two-way stretching production process to obtain the substrate layer; after action of surface tension, performing color printing with special printing ink of food packaging, thereby obtaining a substrate with the color printing layer; mixing polypropylene, high-density polyethylene, polystyrene, bentonite and iron powder, fusing and plasticizing the mixture in an extruder, laminating on the color printing layer of the substrate via a T type mold head to form a substrate with the laminating layer, and processing to obtain a BOPP membrane roll; and unreeling the BOPP membrane roll, coating the whole width or the specific part of the width of the surface of the laminating layer with the laser imaging layer, primarily curing, performing mold pressing, further curing, and reeling to obtain the food-grade BOPP laser membrane with environmental friendliness, low cost and high quality.

Owner:HAINING CHANGKUN PACKAGING

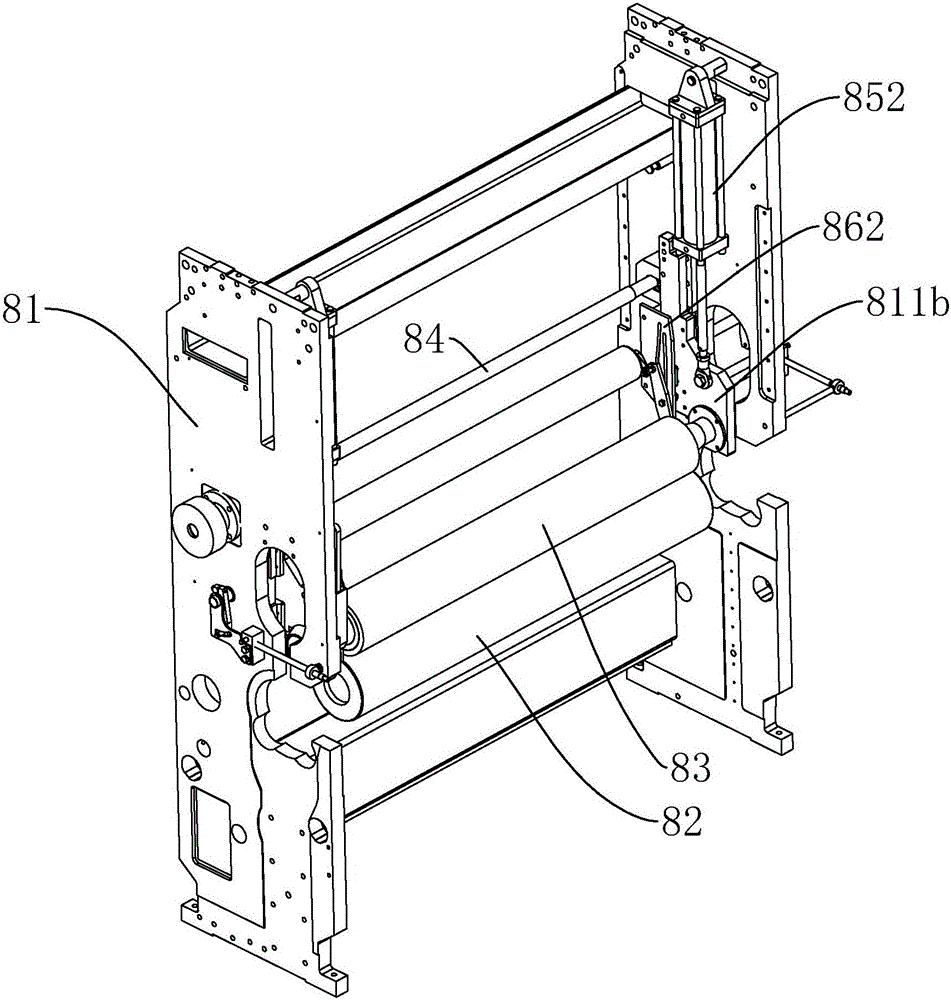

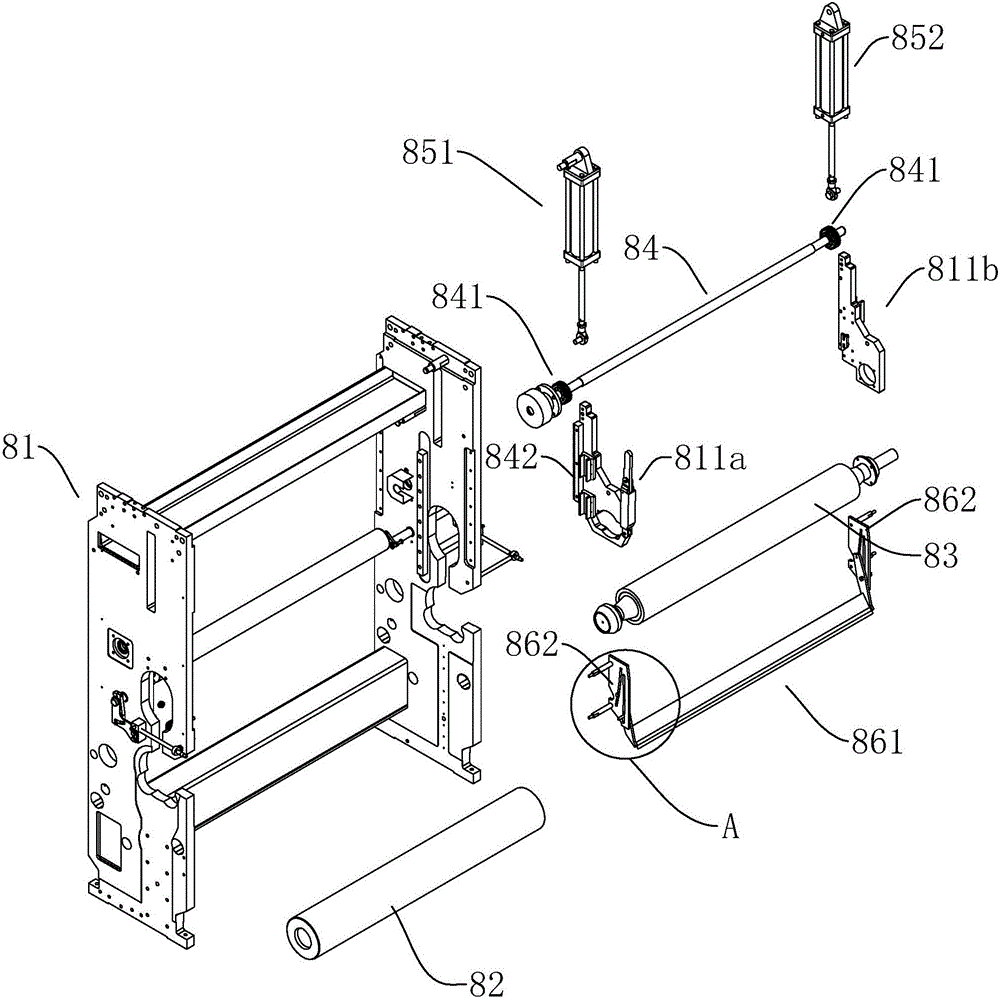

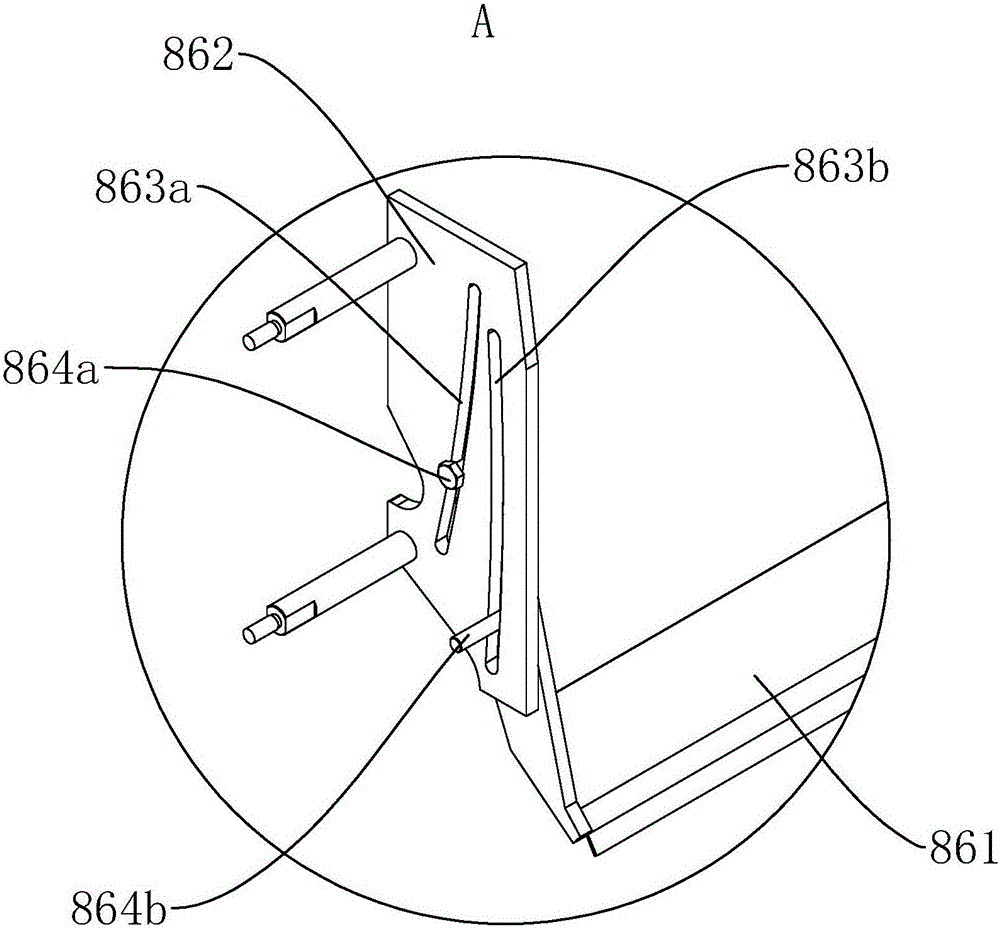

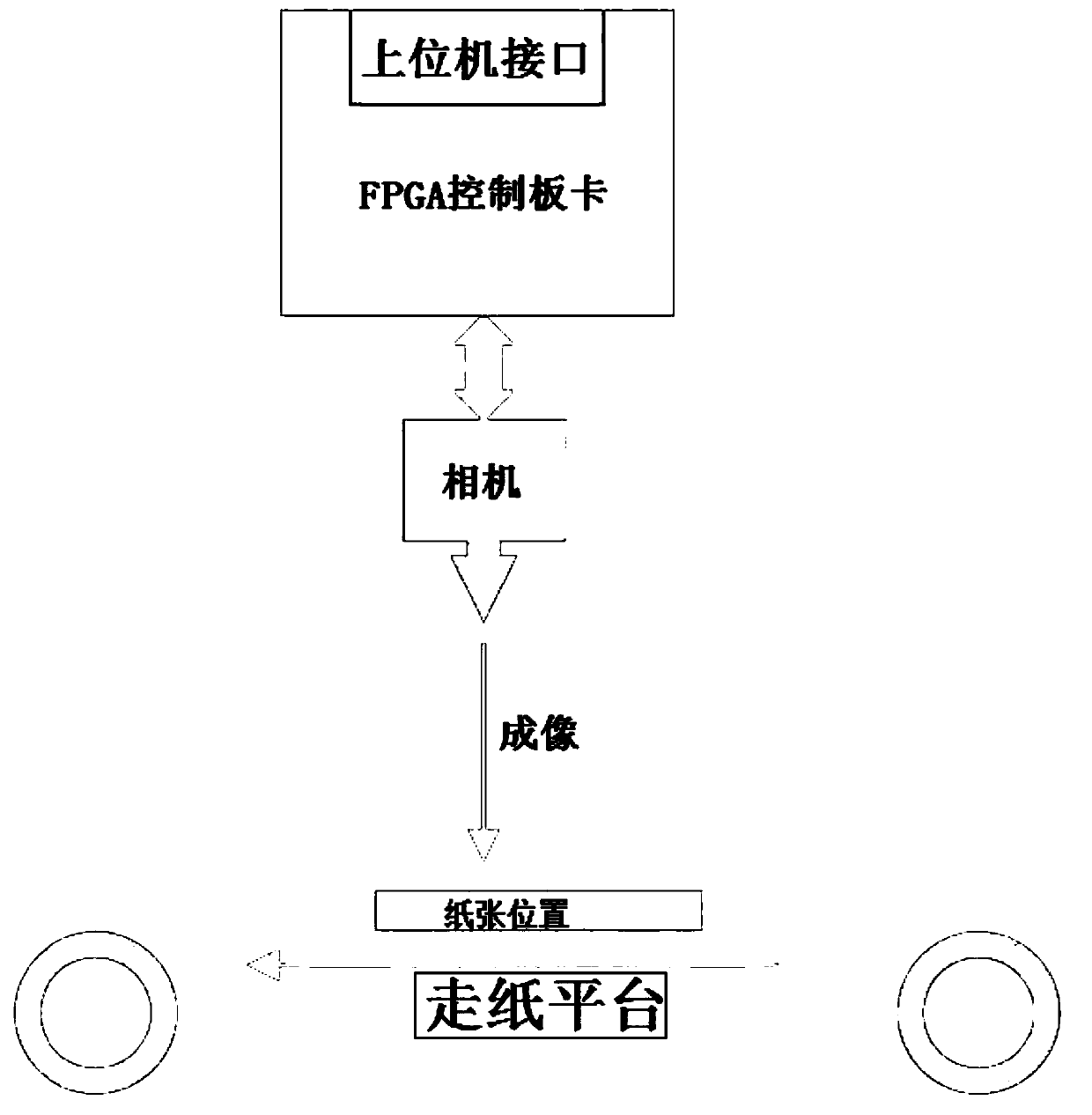

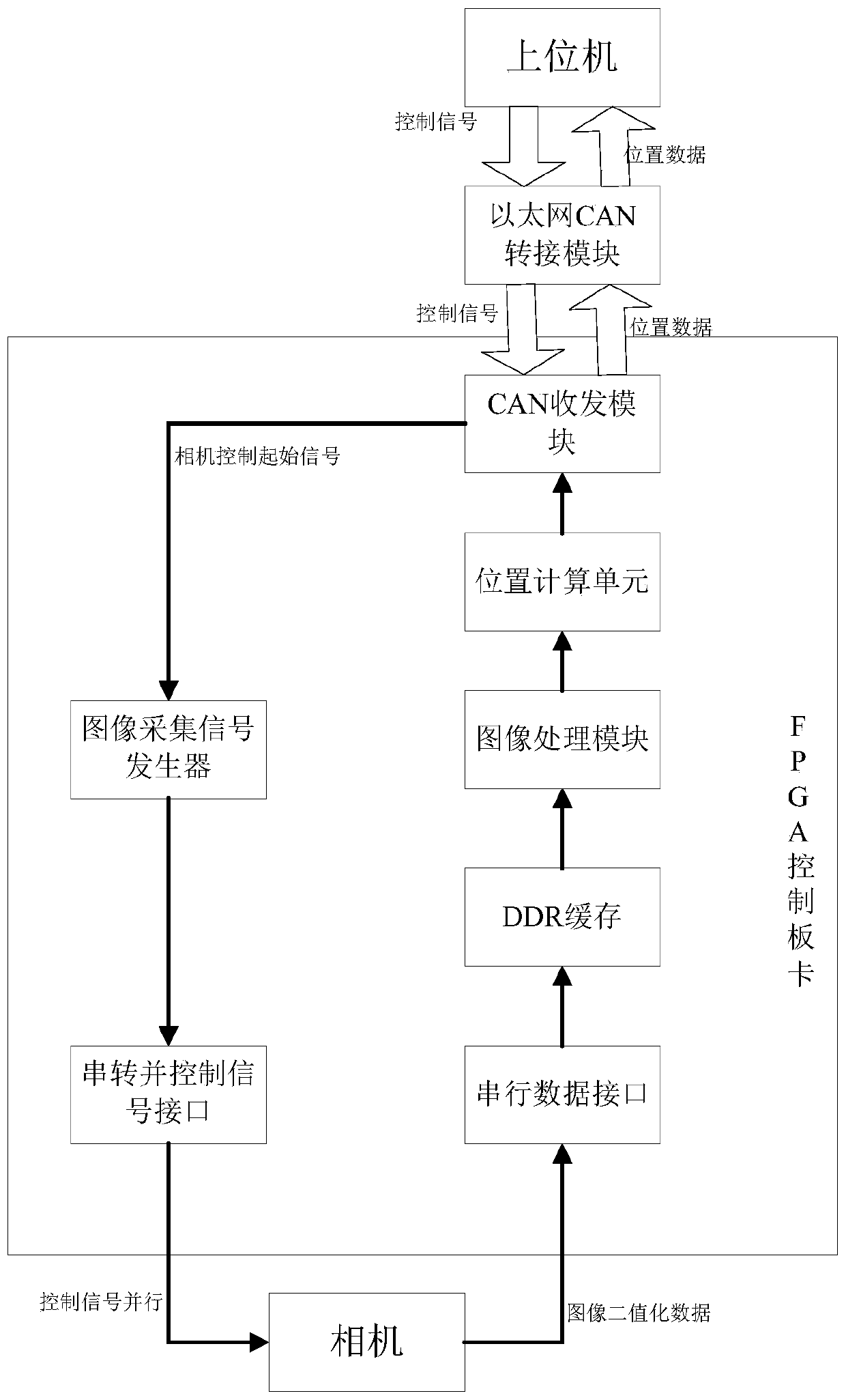

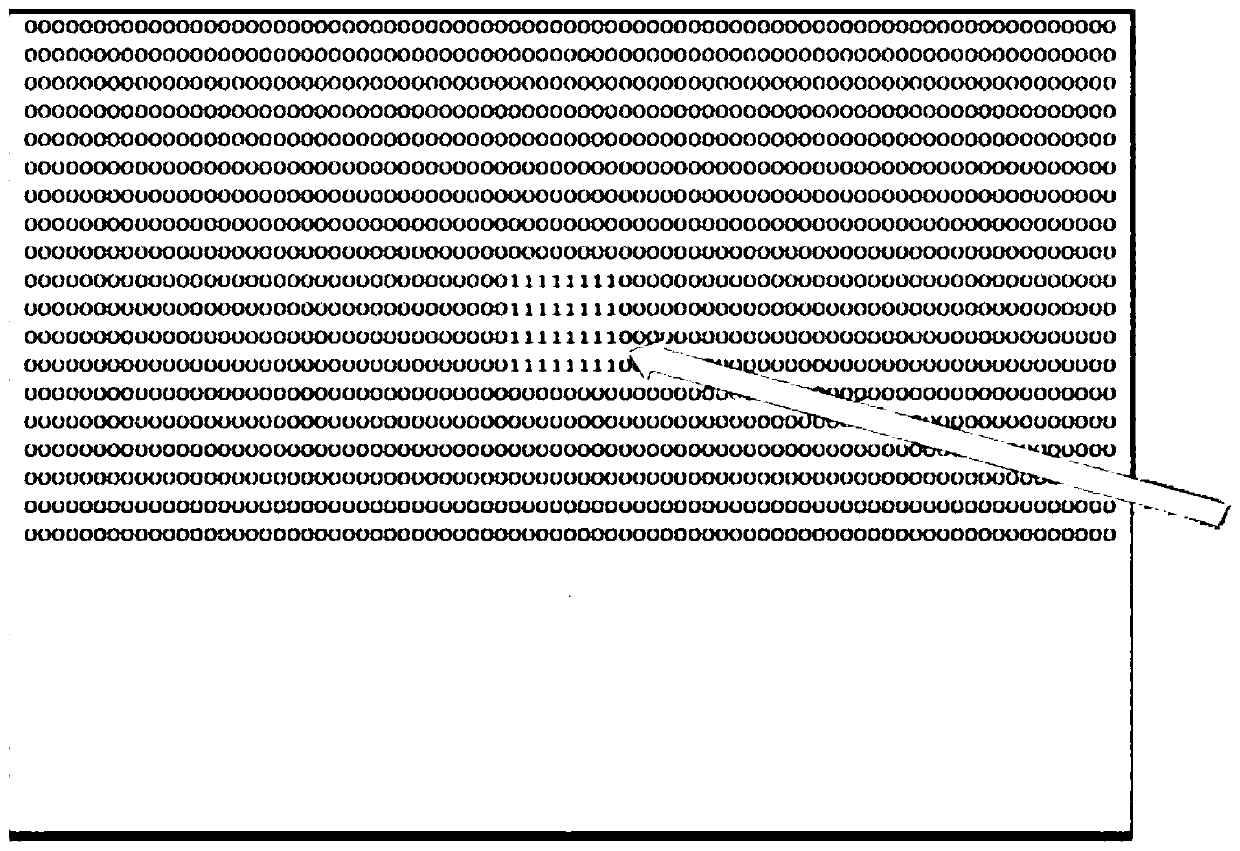

FPGA-based high-speed visual positioning system

InactiveCN111391503AIncrease diversityImprove adaptabilityTypewritersOther printing apparatusComputer hardwareImaging processing

The invention provides an FPGA-based high-speed visual positioning system. The FPGA-based high-speed visual positioning system comprises an upper computer, a linear CCD camera and an FPGA control board card; the FPGA control board card is provided with an upper computer interface and a linear CCD camera interface and is further provided with an image acquisition signal generator, an image processing module and a position calculation unit; the image processing module synthesizes a plane image according to sampling frequency; and the position calculation unit calculates the current position of paper and transmits the current position to the upper computer through the upper computer interface. The FPGA-based high-speed visual positioning system performs image acquisition by the linear CCD camera and performs intelligent image processing, and can adapt to more quantity and types of paper, thereby improving the diversity of printing products and the adaptability of the positioning system.

Owner:TIANJIN CHANGRONG DIGITAL TECH

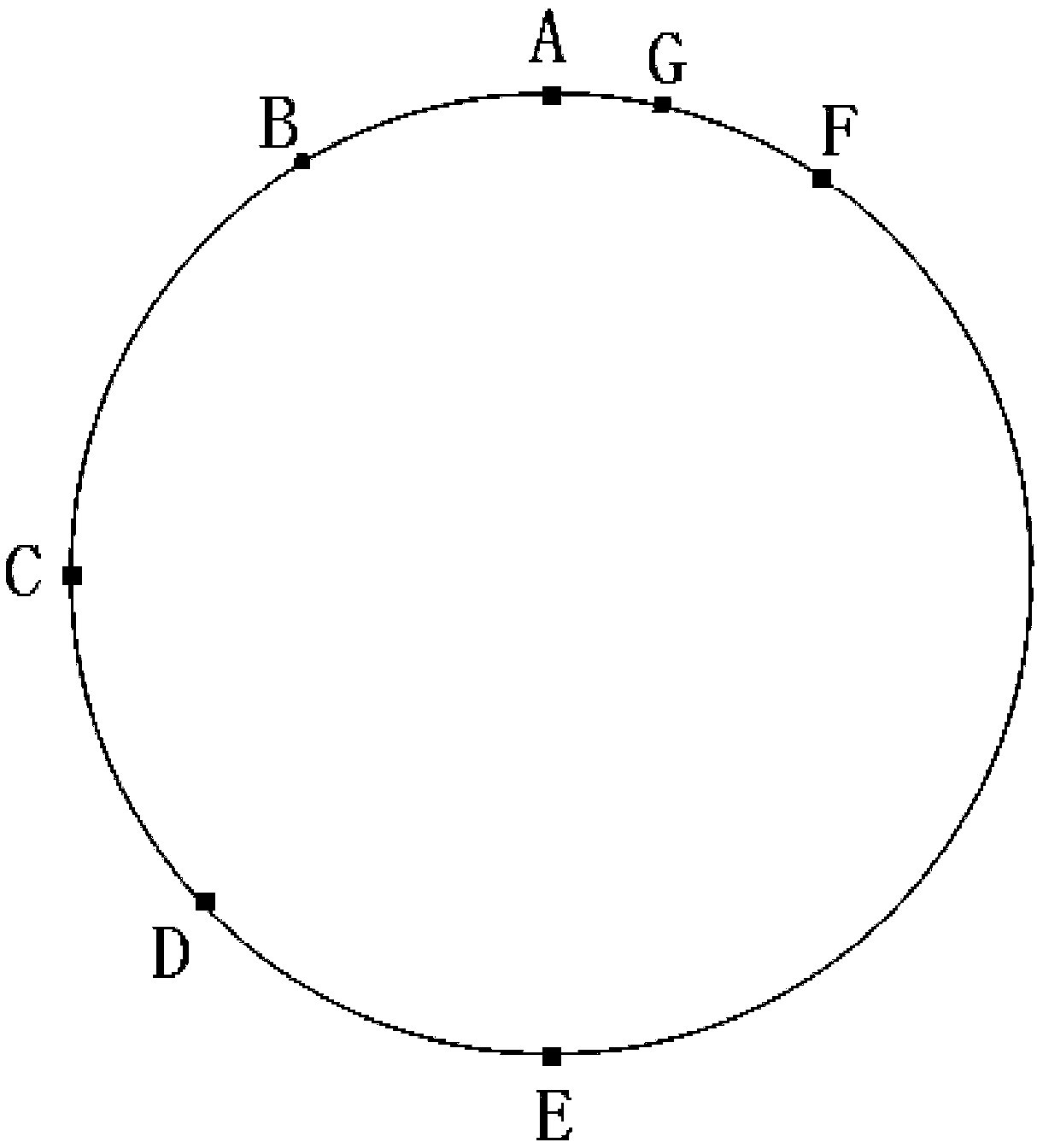

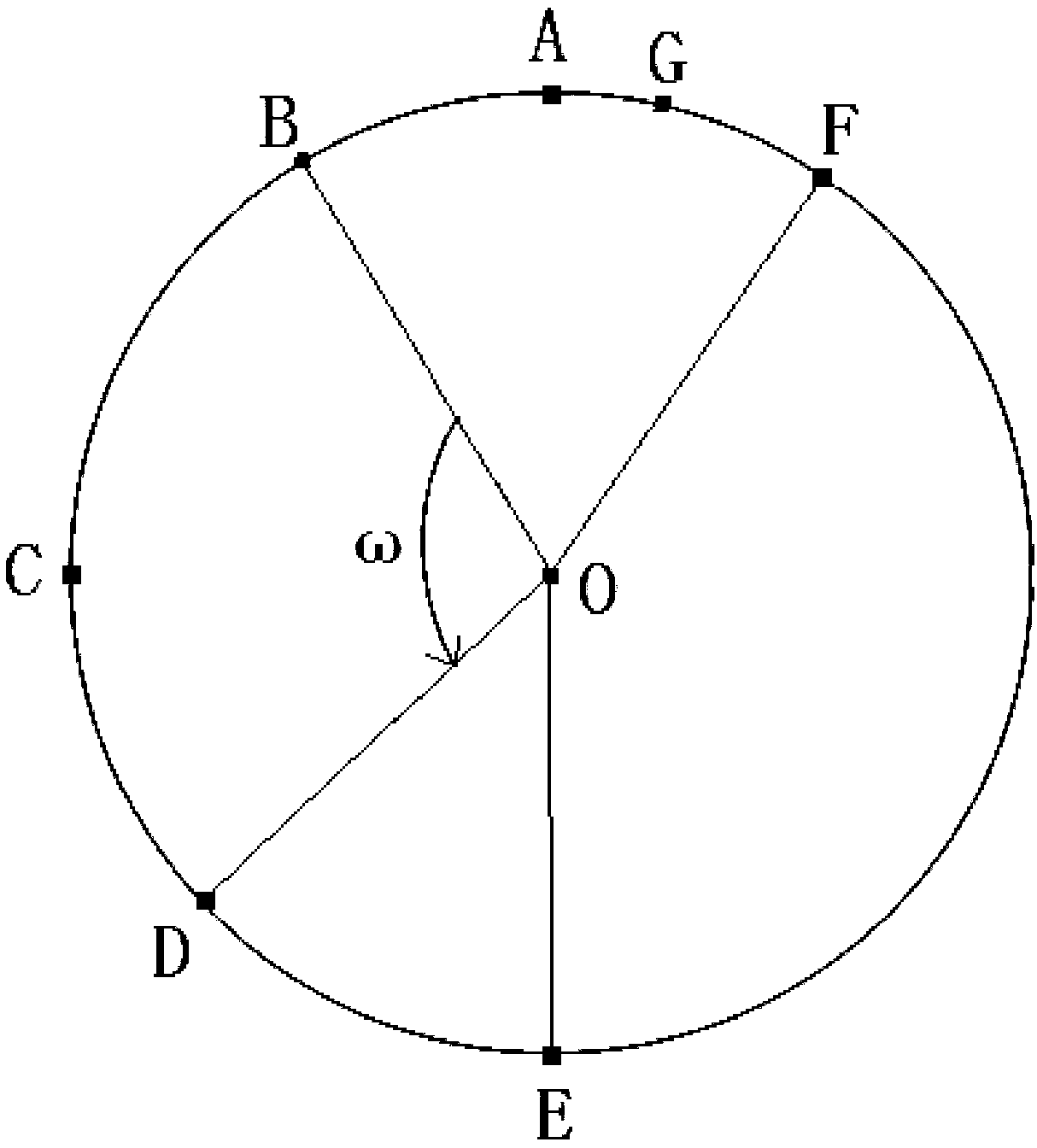

Marking method for circular tube printing object overprinting starting point

ActiveCN109304953APrecise positioningEasy to implementOther printing apparatusColor printingEngineering

The invention provides a marking method for a circular tube printing object overprinting starting point, and relates to a marking method for an overprinting starting point, and belongs to the technical field of color printing technology. The marking method for the circular tube printing object overprinting starting point comprises the following steps that when the first color printing is carried out on the circular tube printing object, annular detection is carried out by the aid of a sensor, and selecting one specific point from the detected point of the first color to serve as an overprinting starting point for marking; the selection mode of the specific fixed point is any one of the following steps a, selecting a starting point or an ending point of the maximum distance block; b, selecting a starting point or an ending point of the closest distance cell block; c, selecting a starting point or an ending point in the two points with the largest deviation angle; and d, and selecting astarting point or an ending point in the two points with the deviation angle omega. The marking method solve the problem that the overprinting precision of an existing circular tube colored printing object is low. The method can be applied to printing of circular tube colored printing object.

Owner:广东旭展科技有限公司

Chromatography system for printing machine

InactiveCN102211451AHigh sensitivityImprove accuracyPrinting press partsMachine controlControl system

The invention discloses a chromatography system for a printing machine, which consists of a chromatography control cabinet, a chromatography control box, a photoelectric scanning head and a photoelectric encoder, and is characterized in that: the color of a chromatography color mark is complementary with the colors of light rays emitted by a photocell eye of the photoelectric scanning head; the conventional two colors of white and blue of the light rays of the photocell eye are increased to seven luminous colors of red, green, orange, blue, yellow, purple and white; and in the printing process, according to a principle that the color of the color mark is complementary with the colors of the light rays of the photocell eye, the photocell eye capable of emitting the light rays in the seven colors is selected, and the color sensitivity and accuracy of the photocell eye are improved. The chromatography system belongs to the field of printing machine control systems.

Owner:WUHAN HUAMAO IND AUTOMATION

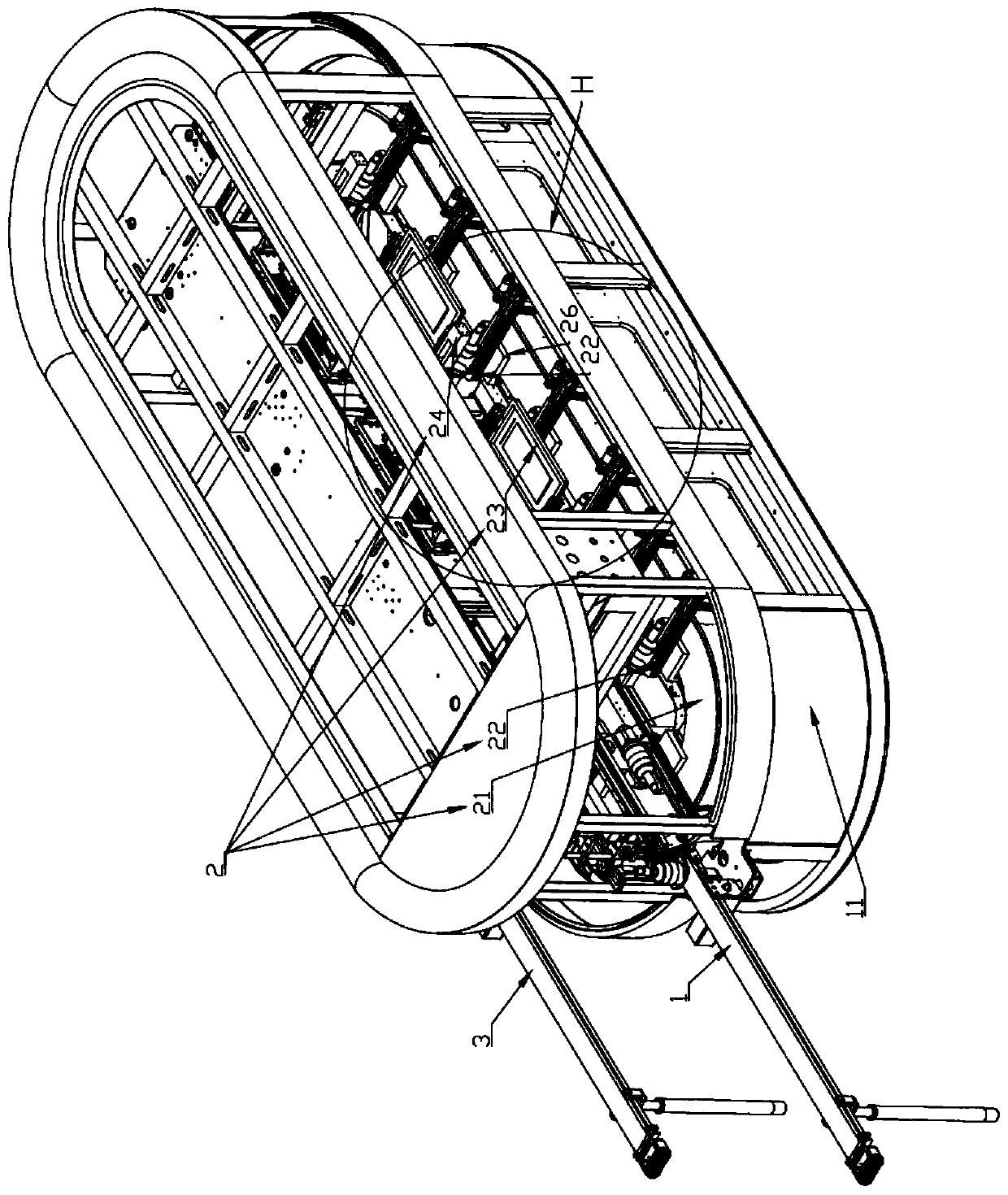

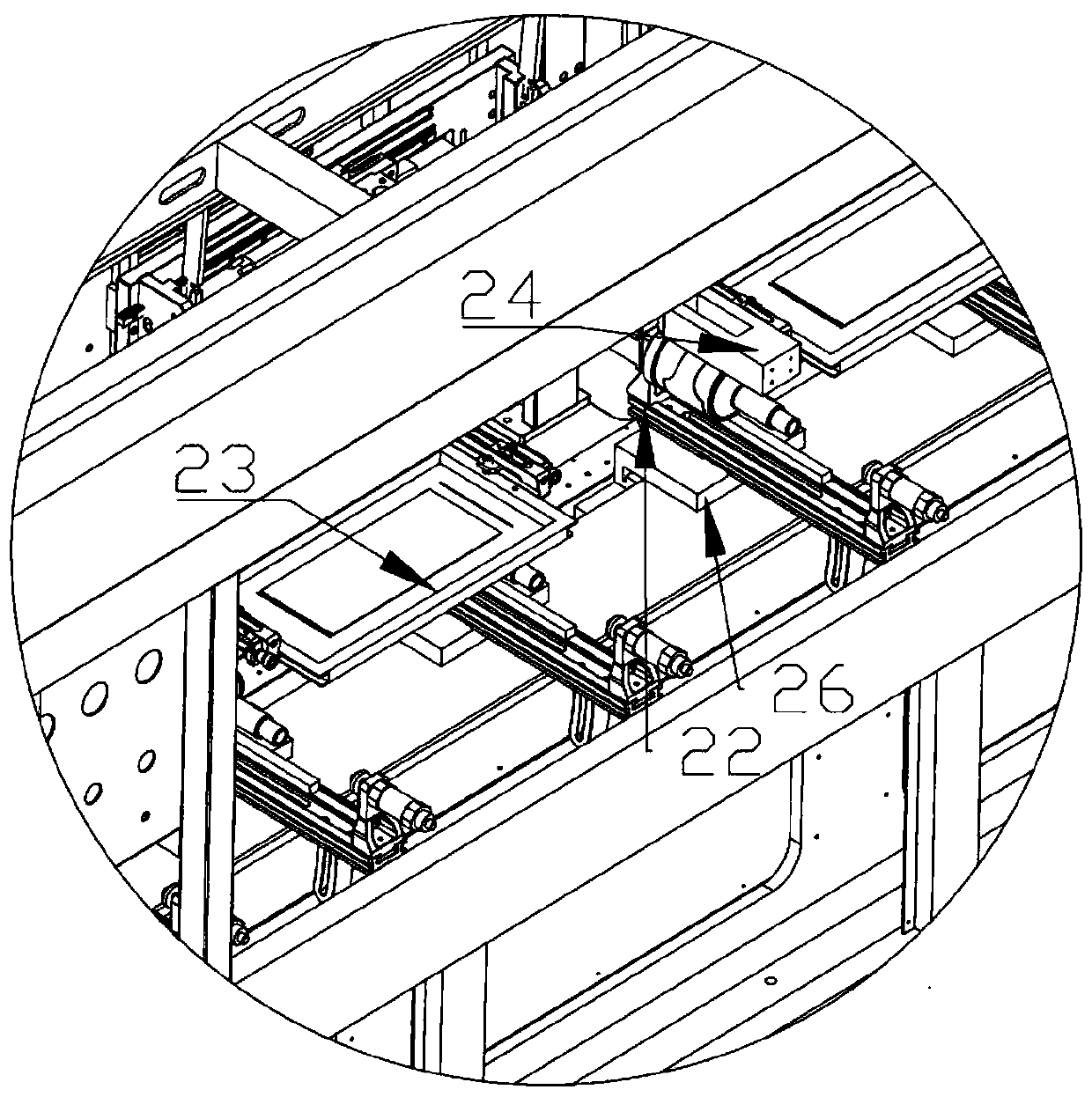

Satellite type flexo printing machine and technology for tipping paper printing

ActiveCN107901580AGuaranteed printing qualityReduce the risk of going off trackRotary letterpress machinesRelief printingPulp and paper industryWater cooling

Owner:HUBEI CHINA TOBACCO IND

Gravure printing machine

InactiveCN101698369BImprove appearance qualityImprove overprint accuracyRotary intaglio printing pressPrinting press partsDrive shaftThrough transmission

The invention discloses a gravure printing machine. The gravure printing machine comprises a winding group, a unwinding group and a middle color group, wherein the groups are connected together though cross beams and based which are fixed on wall boards of the groups, an operating corridor is arranged outside the wall boards, the winding group and the unwinding group are separately provided with a winding device and an unwinding device, the middle color group owns a plurality of groups, each color group is provided with a coining device and an oven heating device, and the coining devices of the color groups are connected together through transmission shafts in a synchronous manner. The gravure printing machine has good appearance and quality, compact structure and high installation precision, can ensure continuous roll-changing without stopping the machine, and is characterized by energy saving, high efficiency and low consumption.

Owner:WENZHOU GUOWEI PRINTING MACHINERY

A bottle automatic screen printing machine

ActiveCN108454224BFast transmissionRepeat positioning is accurateScreen printersNon-mechanical conveyorsScreen printingControl system

The invention discloses a bottle body automatic screen printing machine. The machine comprises a conveying and loading device, a circular conveying working line and an unloading device; a bottle bodycircular conveying working line comprises the circular conveying working line arranged on a stand; the circular conveying working line comprises an annular guide rail set, a linear motor magnetic suspension motion mechanism and a servo control system; the linear motor magnetic suspension motion mechanism is provided with a mover for circularly moving along annular guide rails; the mover is provided with a bottle body fixture; a screen plate and an ink curing device are arranged beside the linear motor magnetic suspension motion mechanism; a scraper is arranged on the screen plate; the screen plate and the ink curing device are both positioned above a motion trajectory of the bottle body fixture; and the ink curing device is positioned between an ink plate and the unloading device. The machine is precise in repeated positioning, safe, reliable and high in speed, improves the chromatography precision and the printing quality, adopts ultraviolet rays or electronic beams to cur ink on bottle bodies, and is suitable for printing of some glass bottles and cosmetic bottles with complicated shapes.

Owner:台州科迅印刷设备科技有限公司

Cooling flat-type bronzing machine with three colored tapes

PendingCN108501522AHot stamping effect is goodImprove bronzing speedRotary pressesHot stampingEngineering

The invention discloses a cooling flat-type bronzing machine with three colored tapes. An unwinding device, a winding device and a delivery roll between the unwinding device and the winding device arefixedly arranged on a main frame body. The delivery roll is driven by a motor for delivering the paper to be bronzed. Three bronzing parts and a cooling part are fixed sequentially on the main framebody in the direction of moving of the paper to be bronzed. Unwinding shafts and winding shafts are arranged on upper portion of the bronzing parts in parallel, and first separating rollers and secondseparating rollers are arranged on the lower portion of the bronzing parts, material drawing rollers are arranged under the winding shafts, and heating units and drying units are arranged in the bronzing parts. A hot stamping machine unit with three heating devices and one cooling device is adopted, the bronzing speed is accelerated, automatic moving marking function is achieved, the overprintingaccuracy is higher, and is generally 40-60 meters per minute, the number of bronzing paper is reduced, vibration is extremely small, and the noise is small. Because heat conduction, heat absorption and melting of a hot melt adhesive take a certain time, the hot stamping effect of flat-type bronzing machine is better than that of other machines, and the efficiency is improved.

Owner:DALIAN ALTMA IND CO LTD

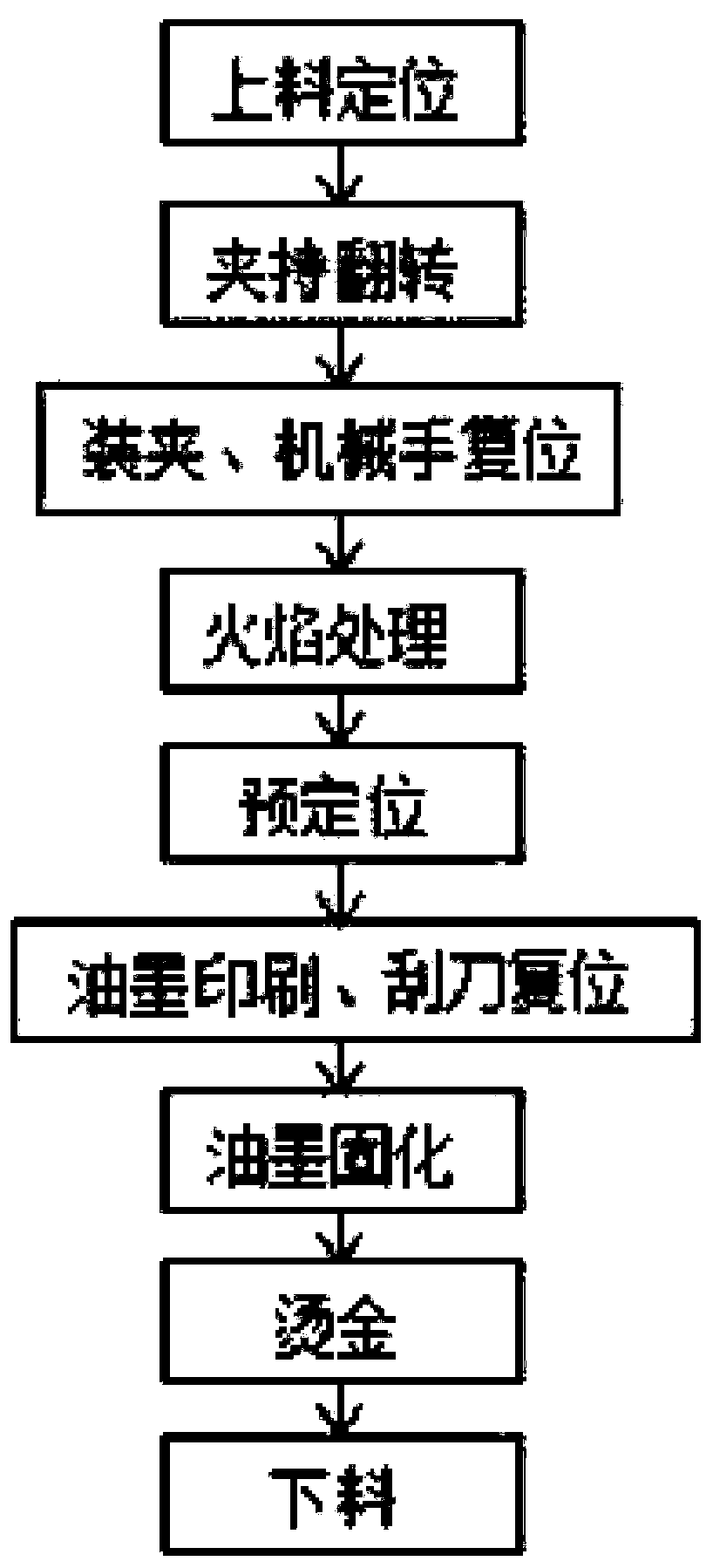

A bottle silk screen printing process using a circular conveying line

ActiveCN108621619BFast transmissionReduce noiseDuplicating/marking methodsOther printing apparatusScreen printingFlame treatment

The invention relates to a bottle body silk-screen process employing a cyclic conveying operating line. The process comprises the following steps: loading and positioning; clamping and overturning; clamping; resetting by a manipulator; flame treatment; pre-positioning; printing oil printing; scraper resetting; printing oil curing; gliding and unloading. According to the process provided by the invention, an intelligent cyclic line system is adopted when printed materials are conveyed. The intelligent cyclic line comprises a station cyclic conveying operating line and rotors; the transmission system is precise to position repeatedly (+ / -10 [mu]m). A clamp on each rotor clamps at one time till all printing flows are completed, then the clamp is released to wait for unloading or gliding to unload, and the plurality of rotors can be mounted on one station cyclic conveying operating line, so that the bottle body silk-screen process is safe, reliable and low in noise, improves the overprintprecision, the printing quality and the working efficiency. In addition, the failure rate is also relatively low. Printing oil on a bottle body is cured by adopting ultraviolet rays or electronic beams. During use, the printing oil is cured by using an LED lamp which is 300-400 watts. The LED lamp is turned on and off immediately: the LED lamp is turned on when the bottle is cured and the LED lampis turned off when the bottle is not available, so that the energy source is saved effectively.

Owner:台州科迅印刷设备科技有限公司

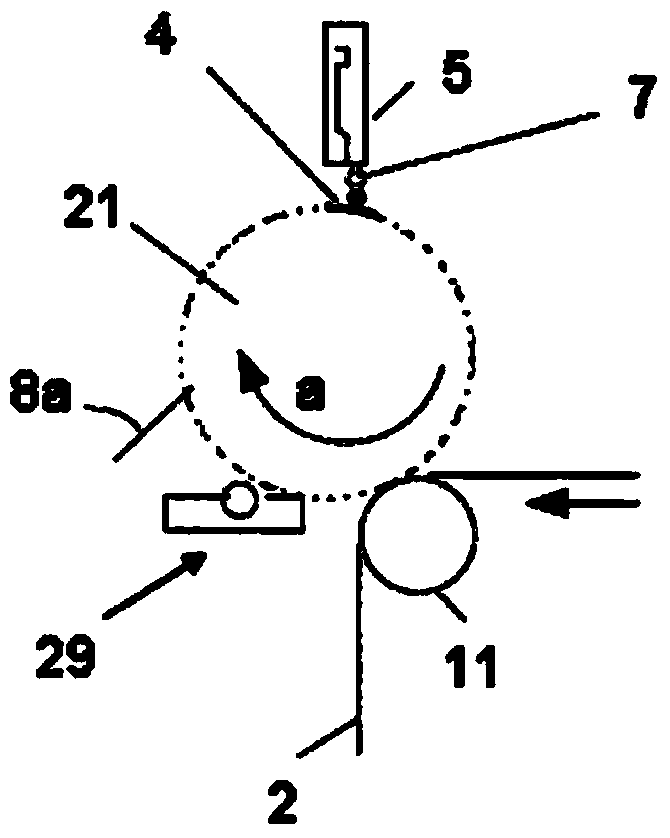

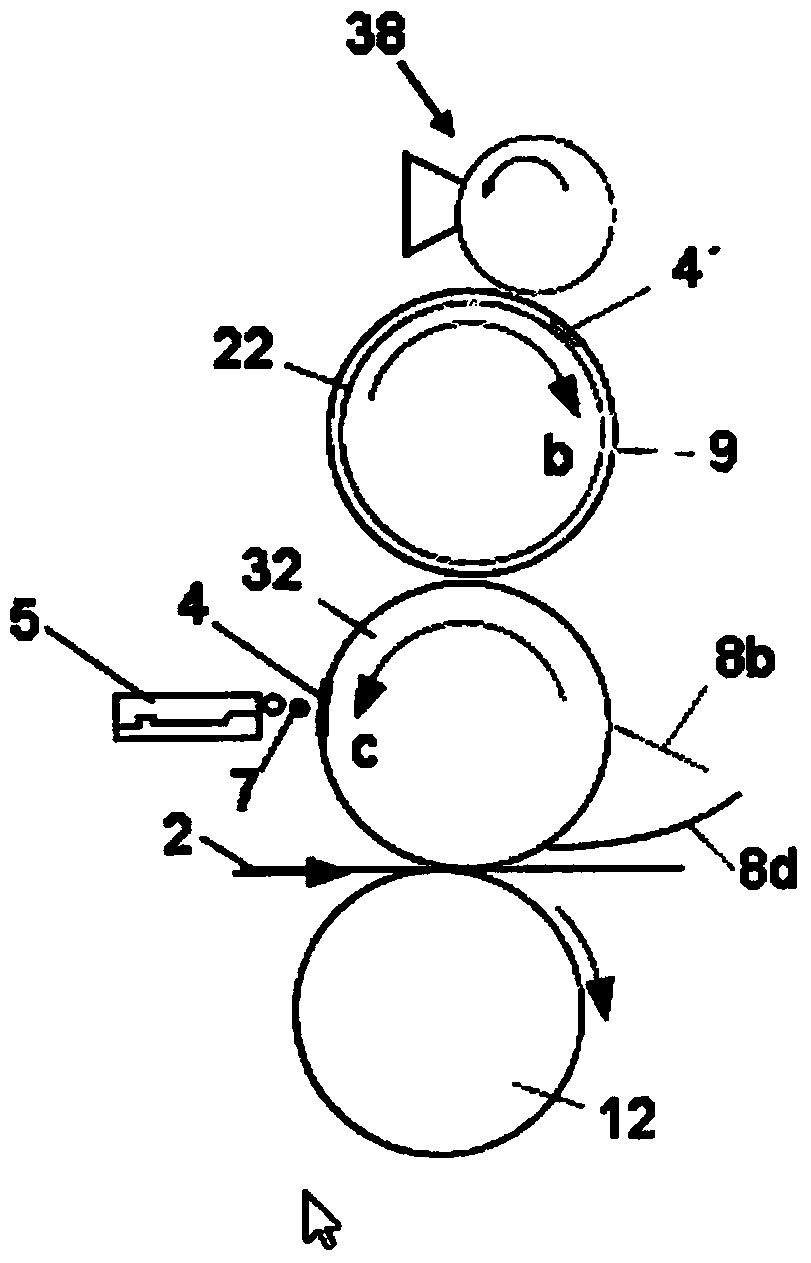

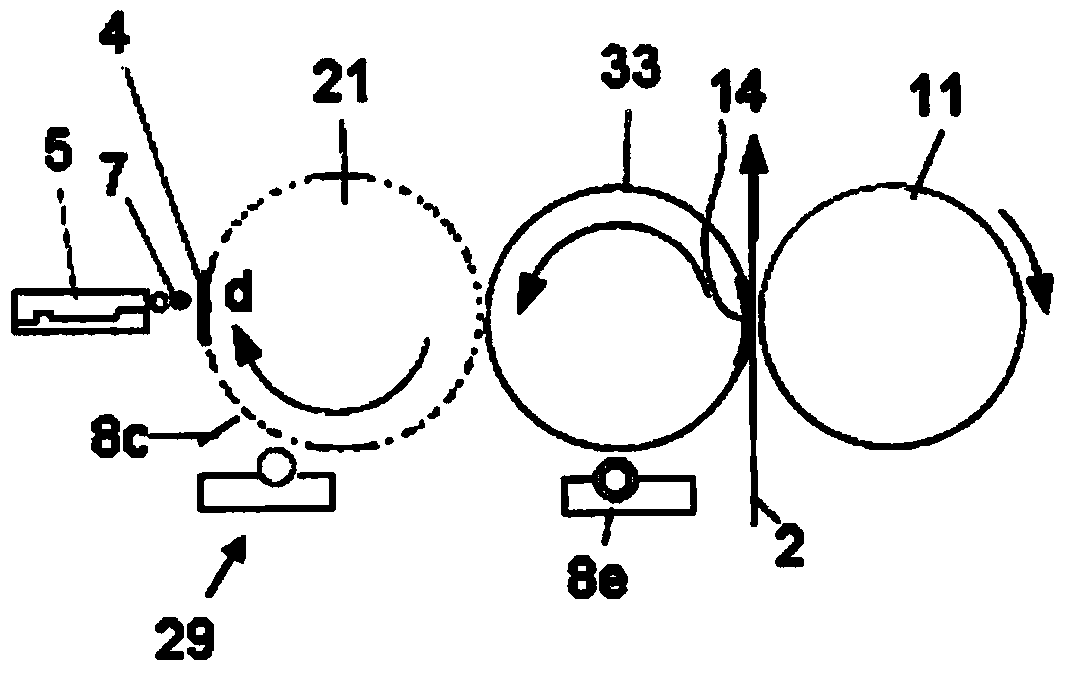

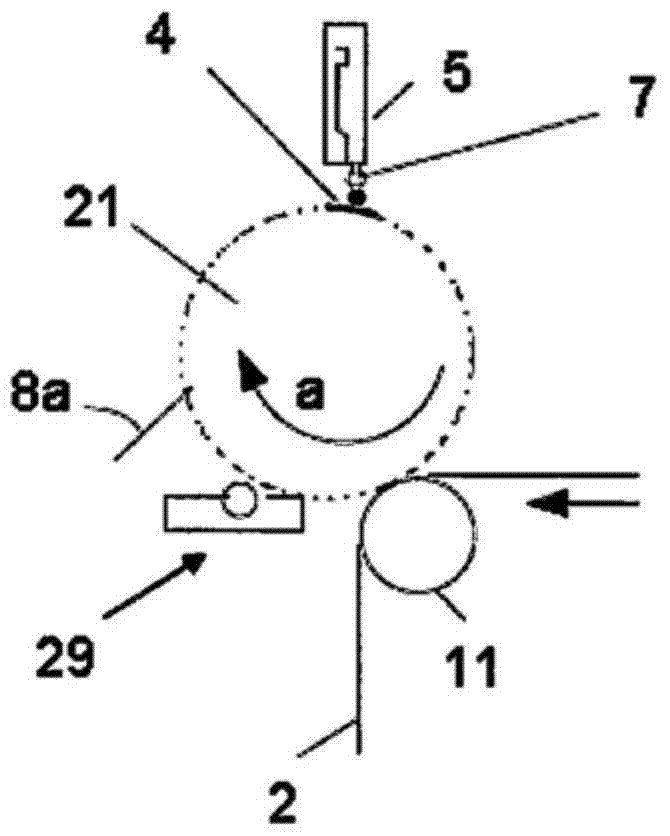

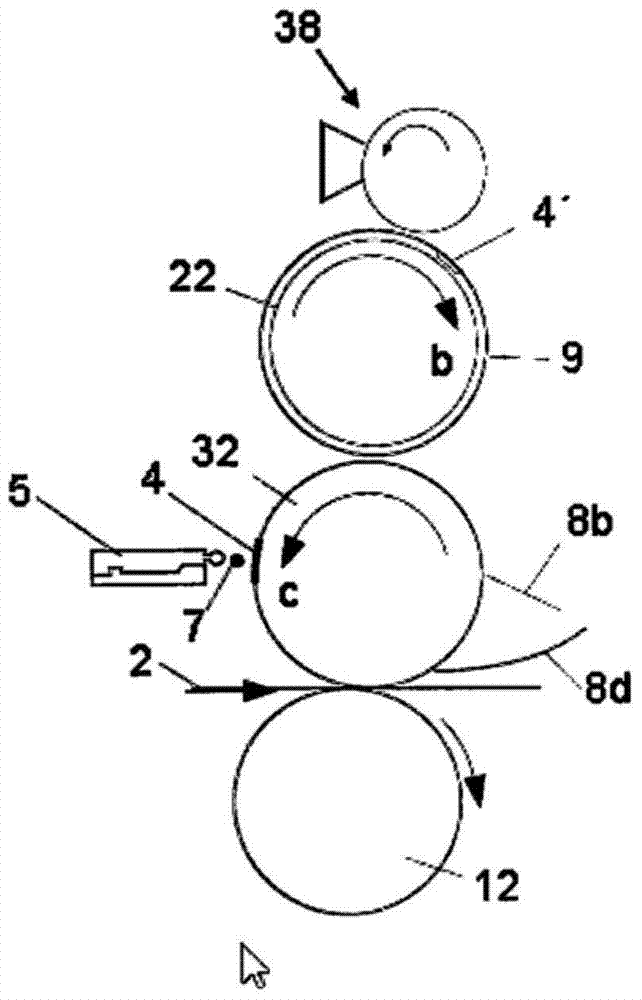

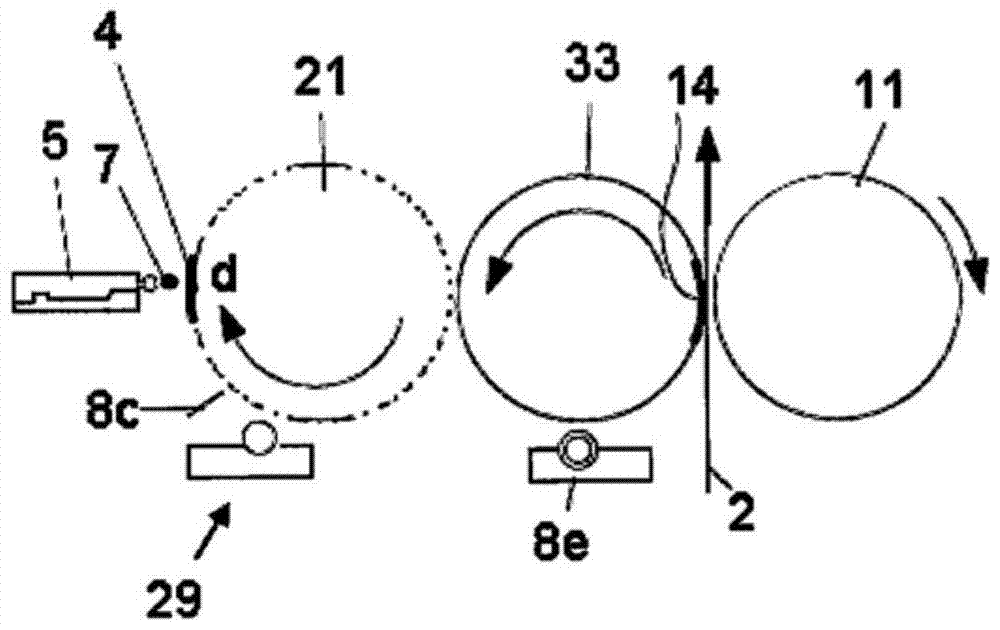

Method and device for printing substrates

InactiveCN103660650BQuality improvementImprove overprint accuracyRotary pressesOther printing apparatusPrinting inkPrinting press

The method involves applying an additional print image directly on a colorless peripheral section (4) of a gravure printing cylinder (21), a flexo-printing unit-transfer cylinder or gravure printing unit-transfer cylinder by an inkjet printing device (5), where the printing cylinder directly contacts a printed material (2). The print image is transferred from the printing cylinder to the material by the transfer cylinders. The applied print image is removed from the peripheral section by a cleaning device e.g. scraper (8a), during a production print operation of a rotary printing machine. The gravure printing cylinder is provided with a surface made of ceramic. An independent claim is also included for an arrangement for printing a printed material in a rotary printing machine.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Direct connection type shaftless lock up structure

InactiveCN107757113AEliminate transmission backlashImprove stabilityPrinting press partsConnection typeLow speed

The present invention relates to the field of printing plate roller plate loading structure, in particular to a direct-connected shaftless plate loading structure, comprising: a printing plate roller, a printing plate shaft and a printing plate driving motor, and the left and right ends of the printing plate roller are connected The printing plate shaft, the outer end of the left printing plate shaft is equipped with a correction motor unit, and the outer end of the right printing plate shaft is equipped with a cylinder, which drives the right printing plate shaft and the printing plate driving motor to move, and the correction motor unit and the cylinder cooperate with each other. Make the printing plate roller move back and forth laterally for adjustment. The beneficial effects of the present invention are: 1. The direct-connection shaftless plate loading structure adopts only one coupling between the printing plate shaft and the printing plate driving motor, and the printing plate driving motor adopts a low-speed high-torque servo motor, eliminating The transmission backlash inherent in the intermediate deceleration part; 2. The printing plate roller is adjusted by the cooperation of the motor unit and the cylinder so that it can move back and forth laterally, and the cylinder drives the printing plate drive motor and coupling to move along the linear guide rail , The direction and position of the combined force of the cylinder are consistent with the axis of the printing plate, and no additional torque will be generated during operation, thereby improving the stability of the printing operation of the equipment, overprinting accuracy and printing speed, and also increasing the service life of the product.

Owner:广东汕樟轻工股份有限公司

Direct connection type shaft-free plate installing structure with safety limiting function

InactiveCN107757112AAvoid sheddingAvoid extrusion deformationPrinting press partsConnection typePower flow

The invention relates to the field of printing plate roller plate loading structure, in particular to a direct-connected shaftless plate loading structure with safety limit. The limit switch mainly includes: a limit switch, a printing plate roller, a first pushing device and a second pushing device, and the two ends of the printing plate roller are respectively connected to the left pushing device and the right pushing device through the printing plate shaft, so The above-mentioned printing plate shaft is installed on the operation surface wallboard and the transmission surface wallboard through the bearing seat, and the above-mentioned limit switch is installed on the first pushing device and / or the second pushing device. The shaftless and shaftless plate loading structure increases the limit switch for printing plate safety, which can not only limit the displacement of the printing plate shaft and the printing plate roller, avoid the occurrence of the printing plate roller falling off, but also effectively prevent the damage of the cylinder assembly and the printing plate The roller is deformed by extrusion, and the transverse correction motor is damaged due to current overload.

Owner:广东汕樟轻工股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com