Direct connection type shaft-free plate installing structure with safety limiting function

A direct-connected, shaftless technology, used in general parts of printing machinery, printing, printing machines, etc., can solve problems such as adjustment trouble, damage to cylinder components, deformation of printing plate rollers, etc., to prevent damage to cylinder components and increase products. The effect of life and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

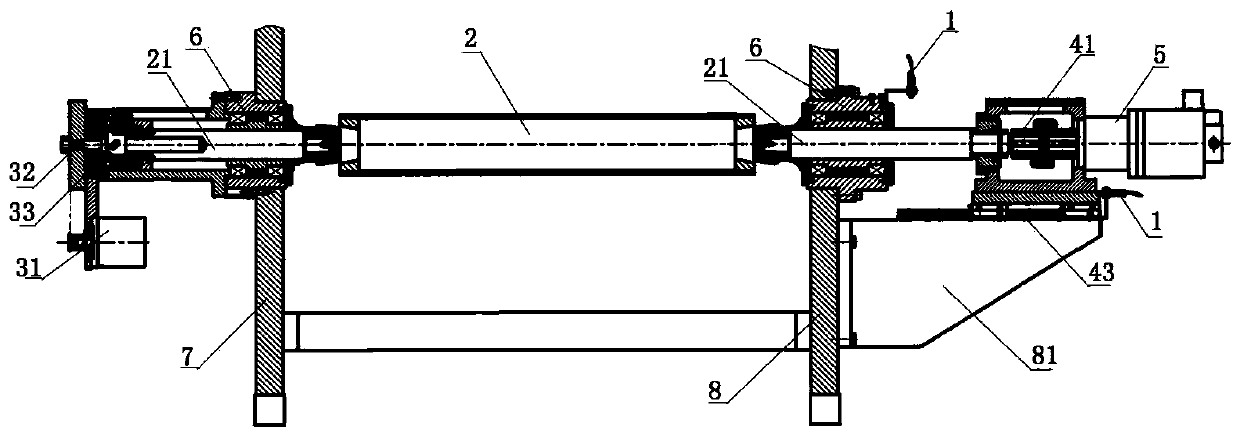

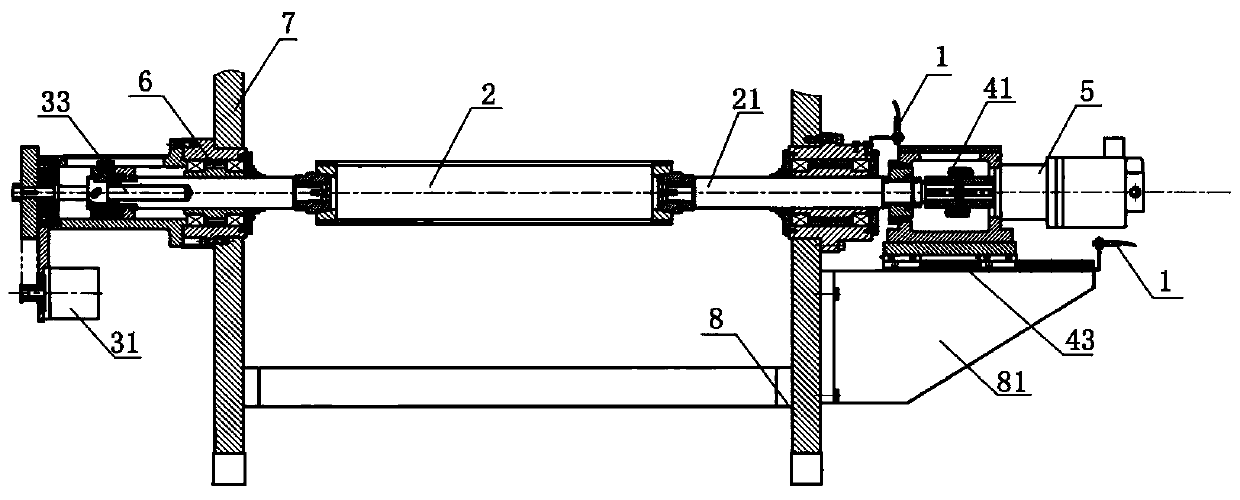

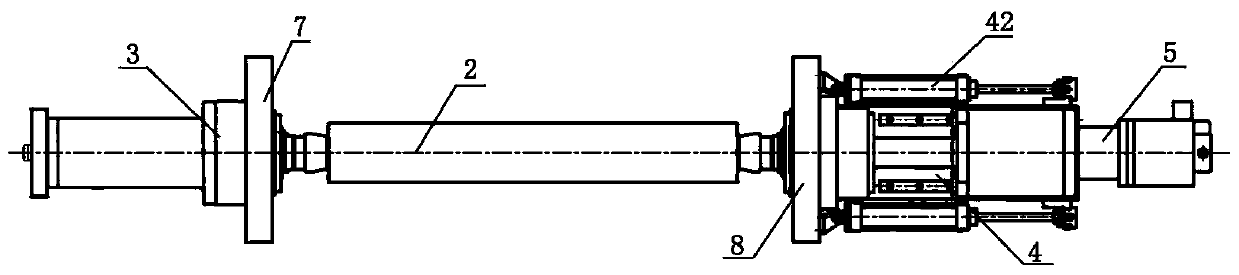

[0019] refer to Figure 1~3 , is a schematic structural view of the present invention. A direct-connected shaftless plate loading structure with a safety limit, comprising: a limit switch 1, a printing plate roller 2, a first pushing device 3 and a second pushing device 4, the two ends of the printing plate roller 2 They are respectively connected to the left push device 3 and the right push device 4 through the printing plate shaft 21, the described printing plate shaft 21 is installed on the operation surface wallboard 7 and the transmission surface wallboard 8 through the bearing seat 6, and the described limit switch 1 is installed on the first pushing device 3 and / or the second pushing device 4, and the limit switch 1 is respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com