A bottle automatic screen printing machine

A screen printing machine and bottle body technology, which is applied to screen printing machines, printing machines, rotary printing machines, etc., can solve problems such as low work efficiency, transmission errors, and loud noises, and improve overprinting accuracy, safety, reliability, and noise. The effect of printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following specific examples are used to further select and describe the present invention:

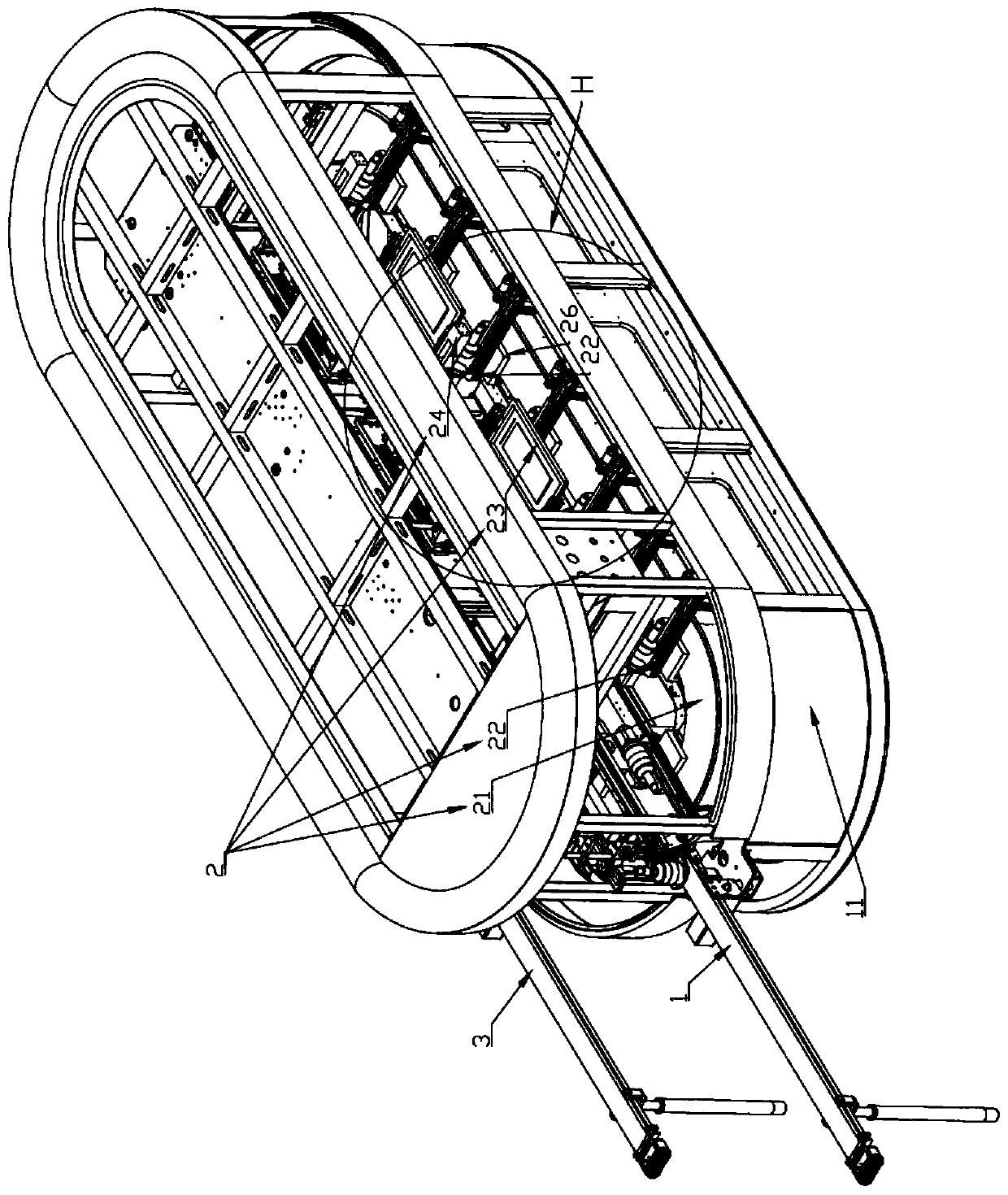

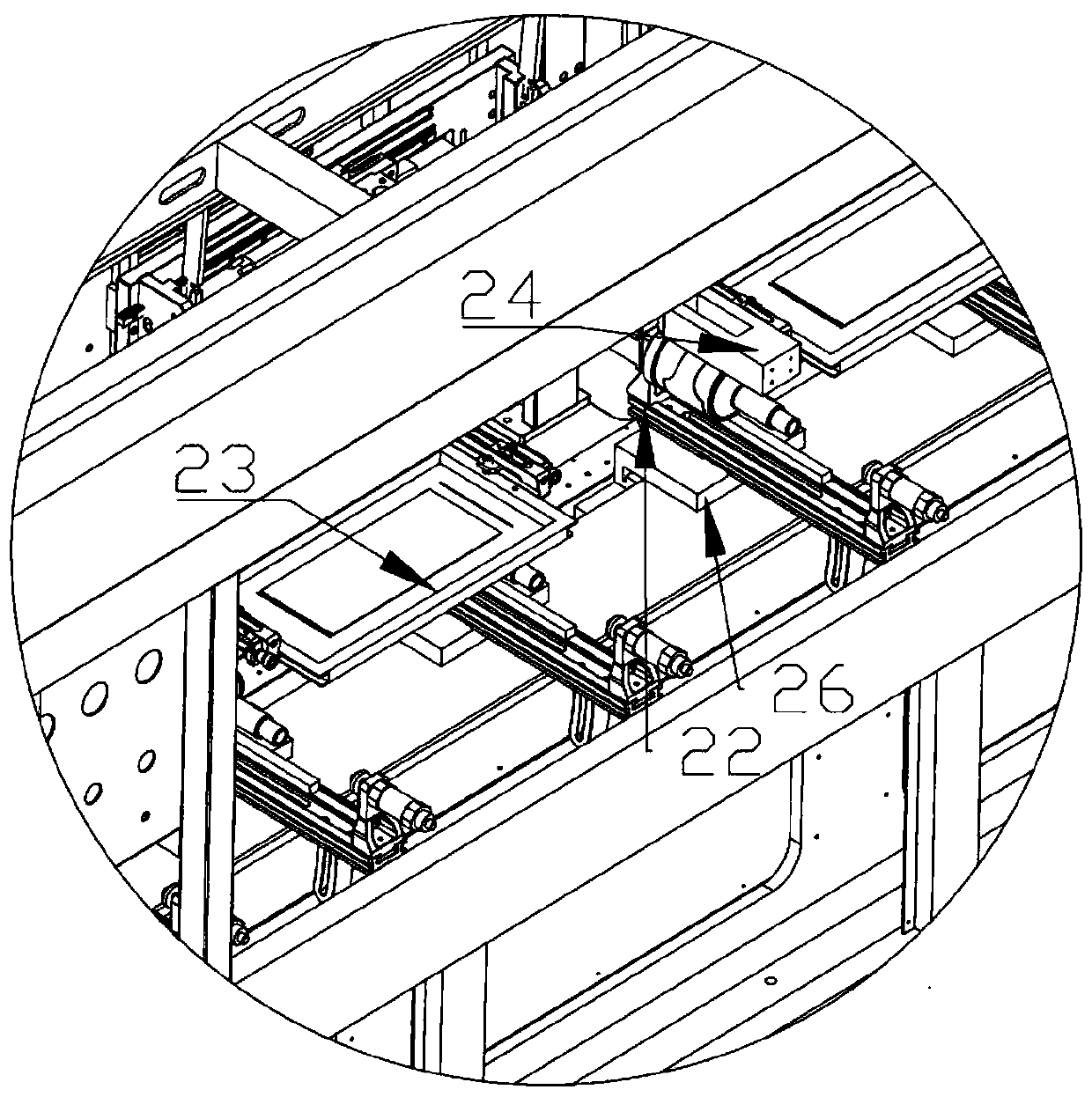

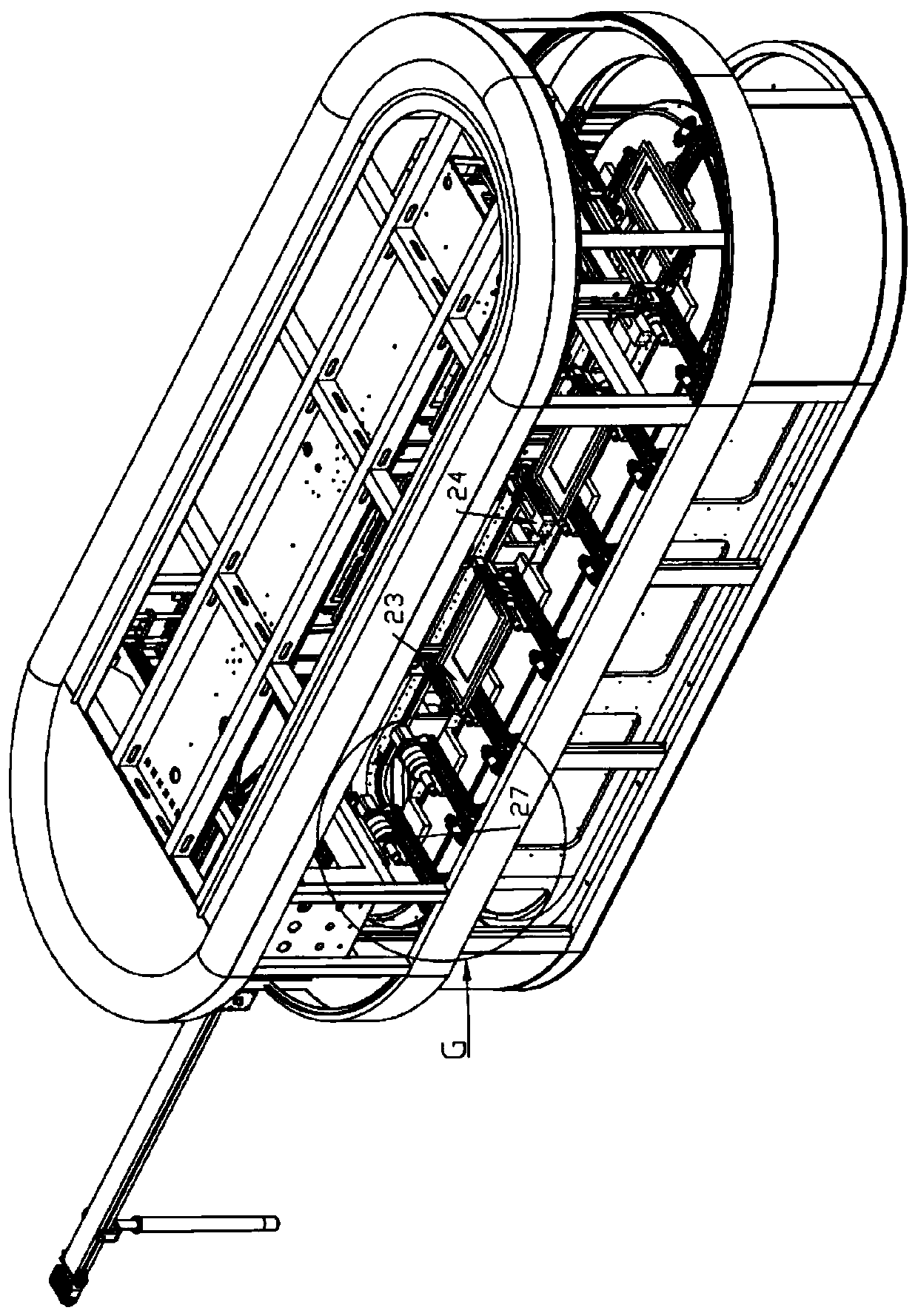

[0031] See Figure 1-Figure 7 As shown, a bottle body automatic screen printing machine includes a conveying and loading device 1, a bottle body circulating conveying work line, and a feeding device 3. The bottle body circulating conveying work line includes: a linear motor magnetic levitation movement mechanism 2 arranged on a machine table 11. The linear motor magnetic levitation movement mechanism 2 includes an annular guide rail group 21. A linear motor magnetic levitation movement mechanism is arranged on the annular guide rail group 21, and at least one bottle that moves cyclically along the annular guide group is arranged on the mover of the linear motor magnetic levitation movement mechanism. The body clamp 22 is provided with at least one screen printing plate 23 and an ink curing device 24 on the side of the linear motor magnetic levitation movement mechanism, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com