Patents

Literature

44results about How to "Repeat positioning is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

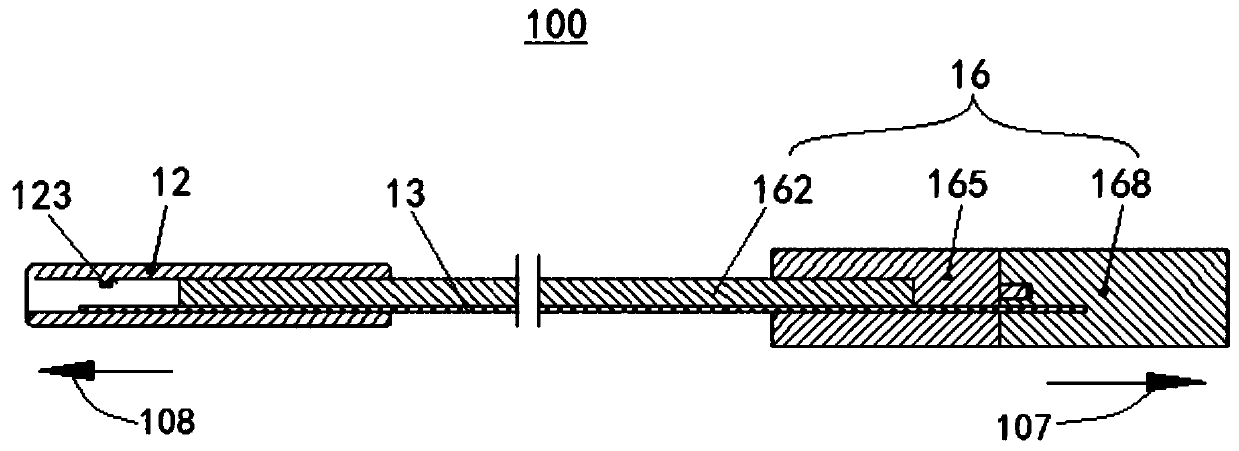

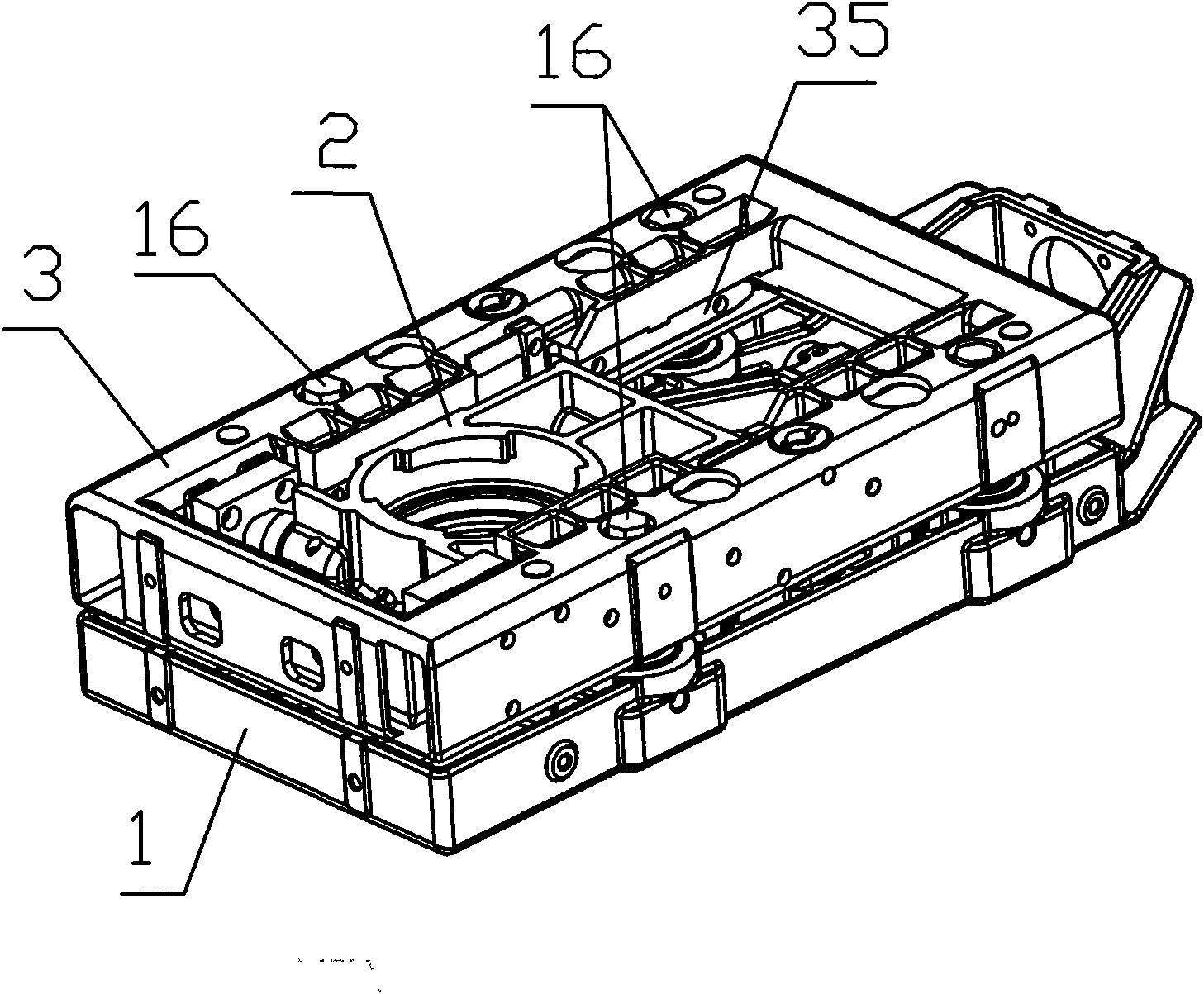

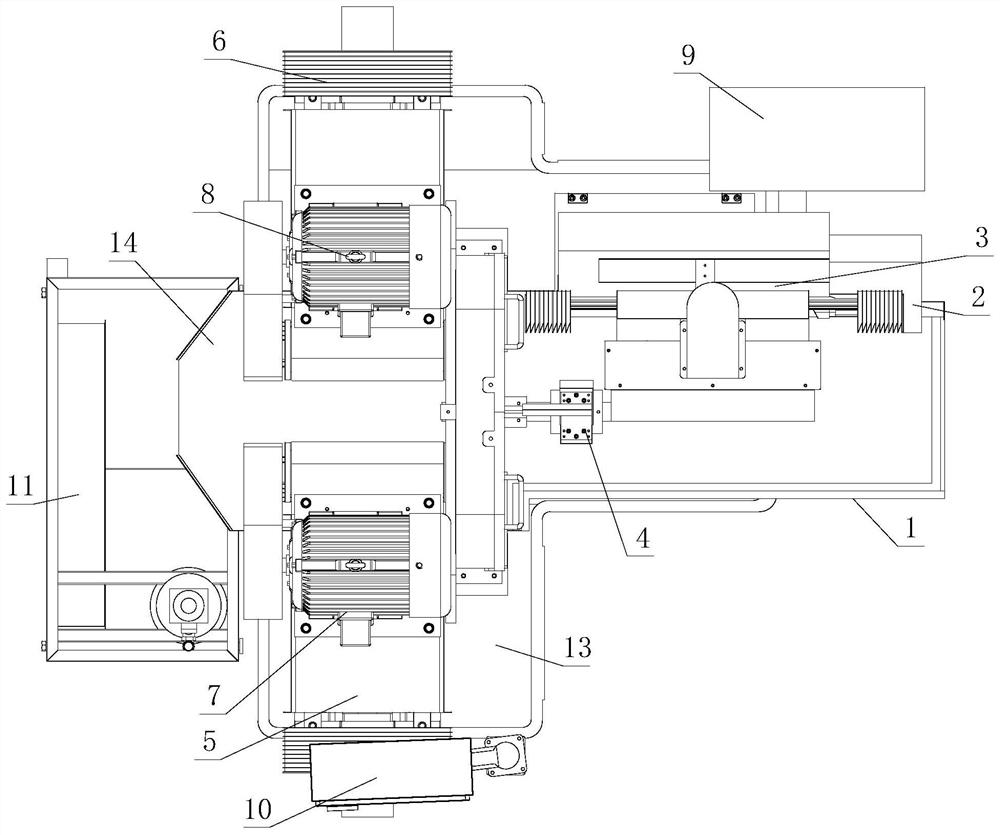

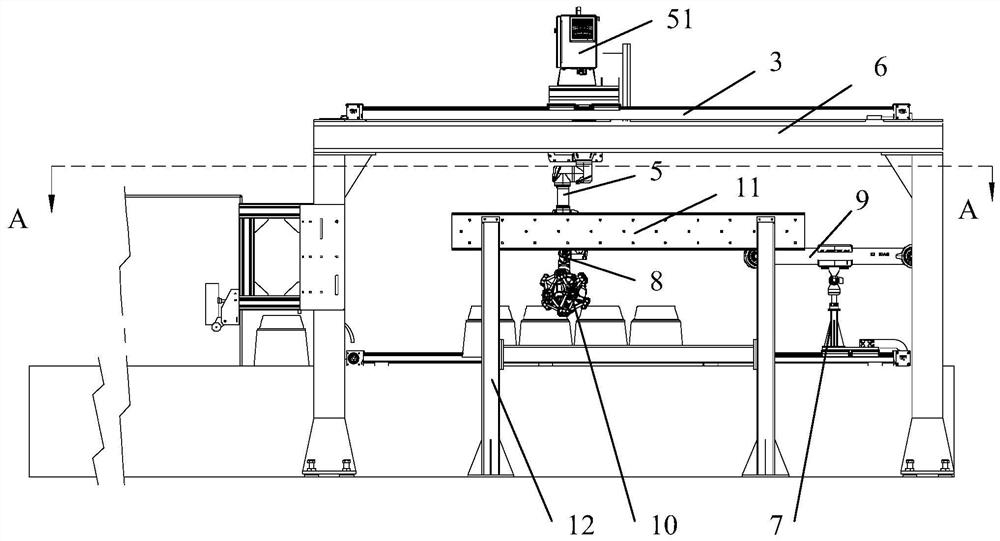

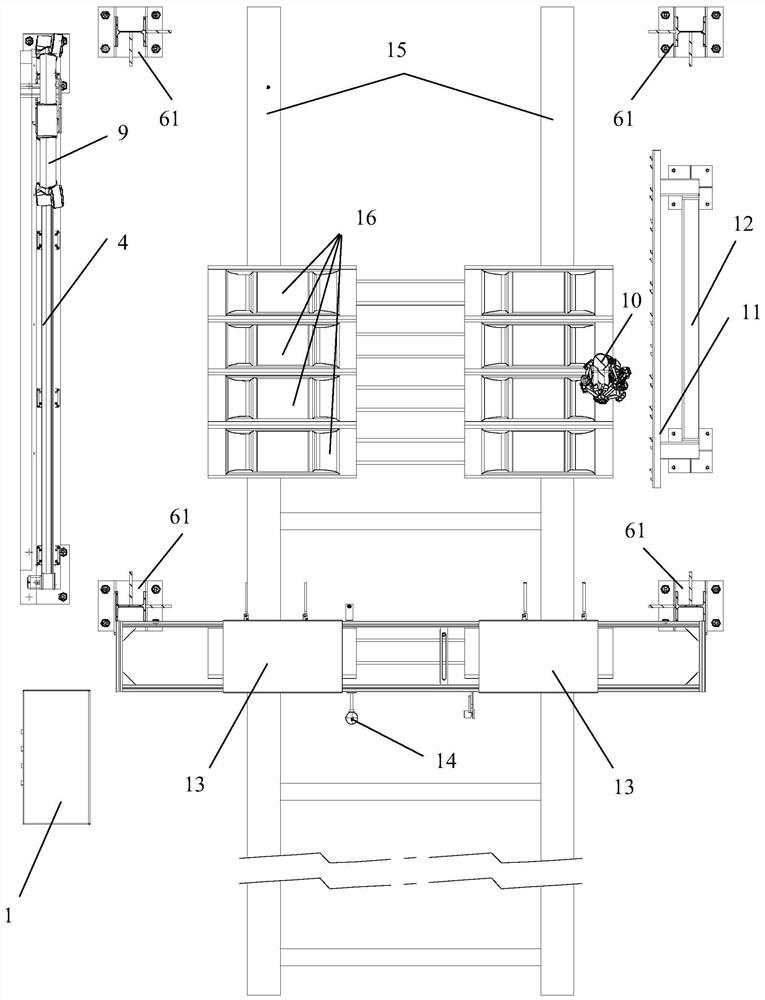

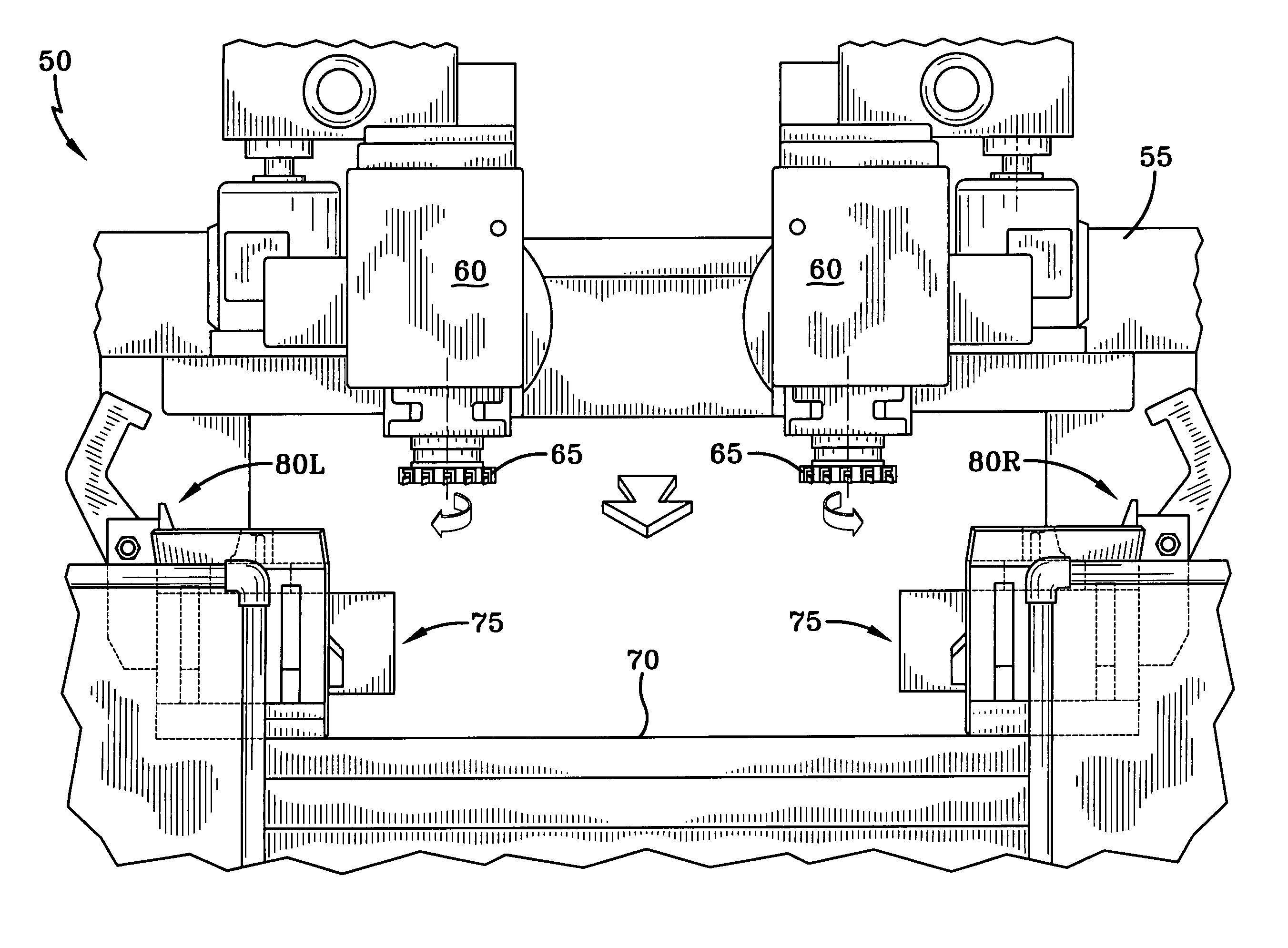

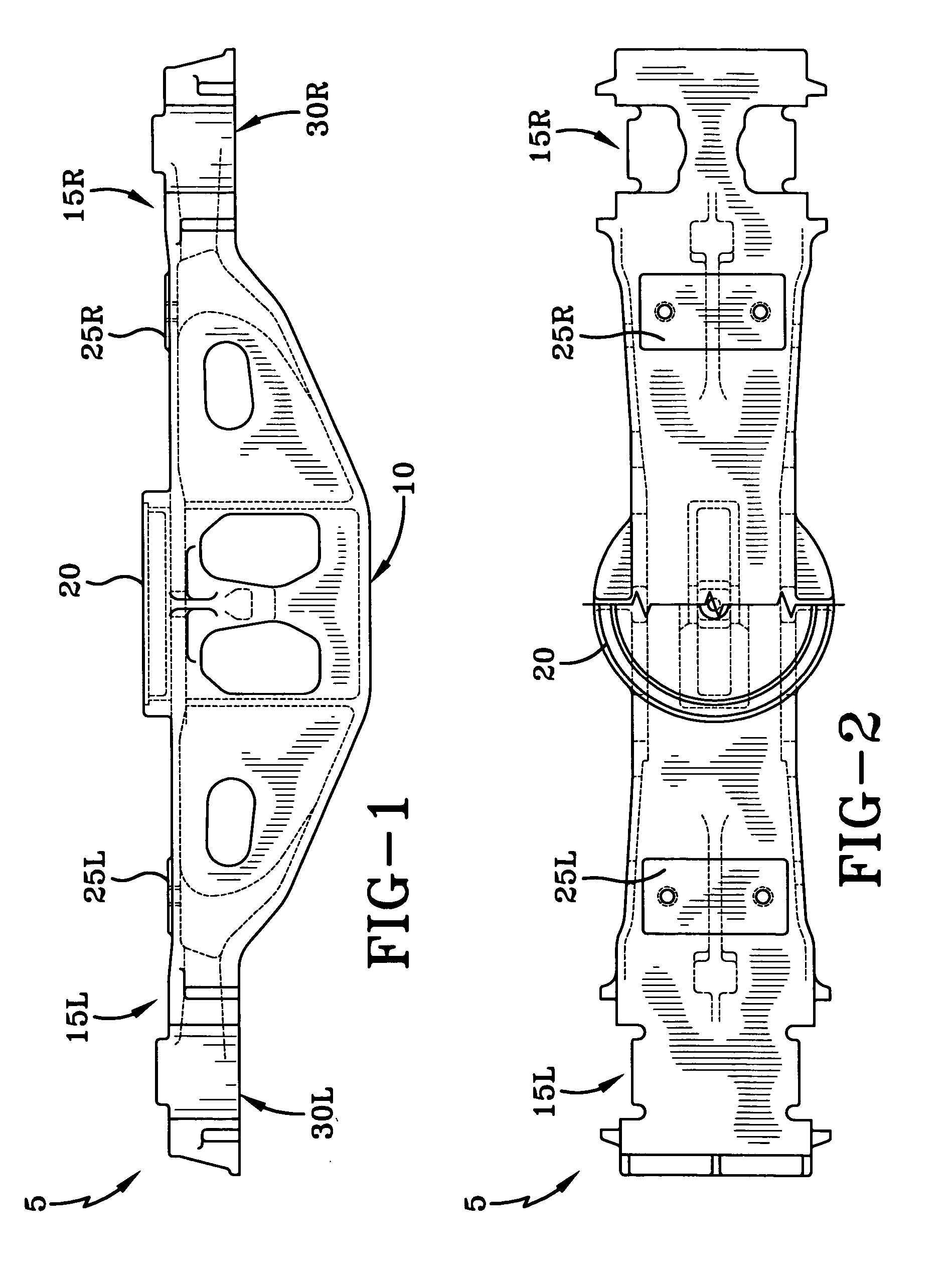

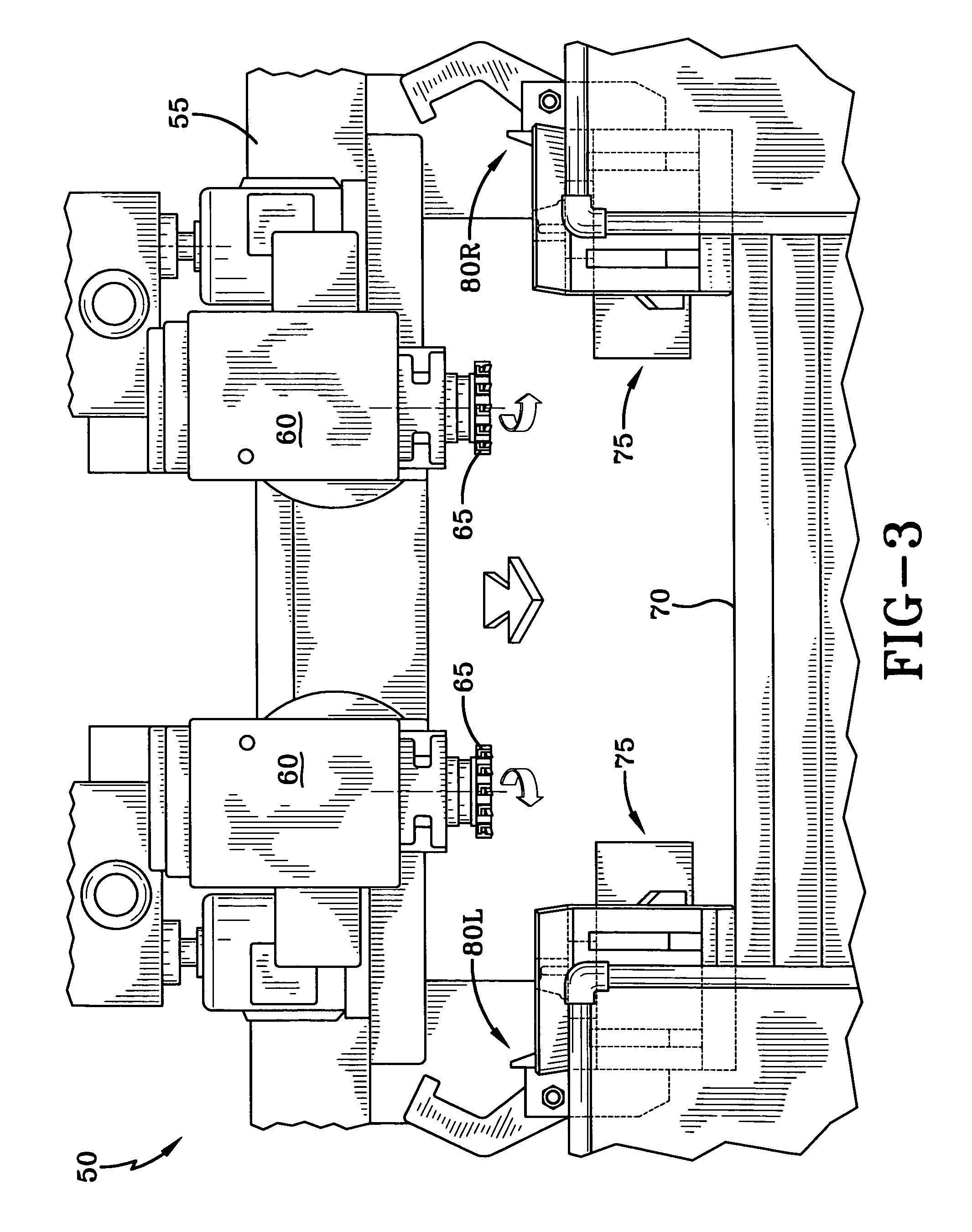

Railcar truck bolster side bearing mounting pad milling machine and method

InactiveUS7523535B2Repeat positioning is accuratePrecise and repeatable locatingPlaning/slotting machinesMilling machinesEngineeringTruck

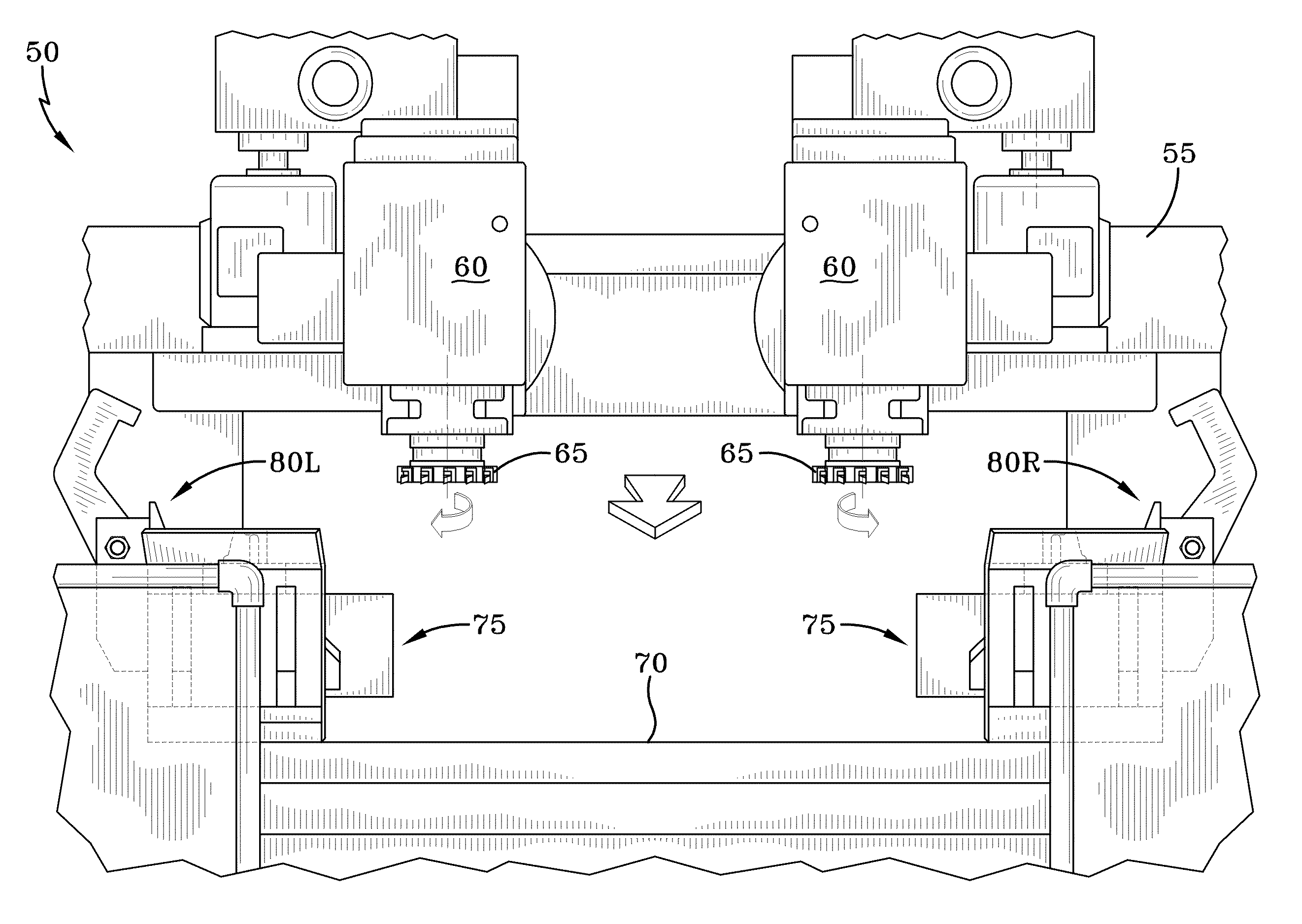

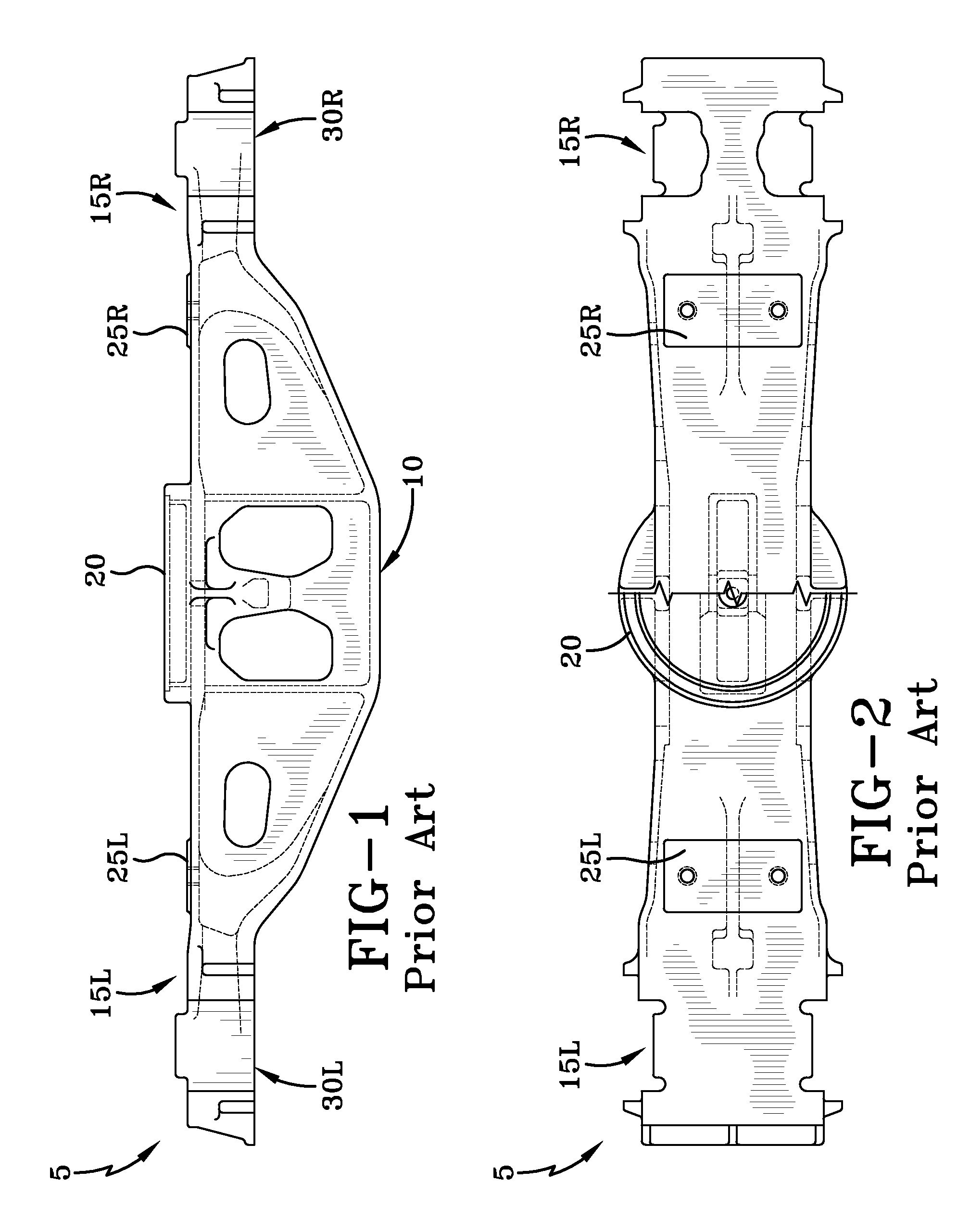

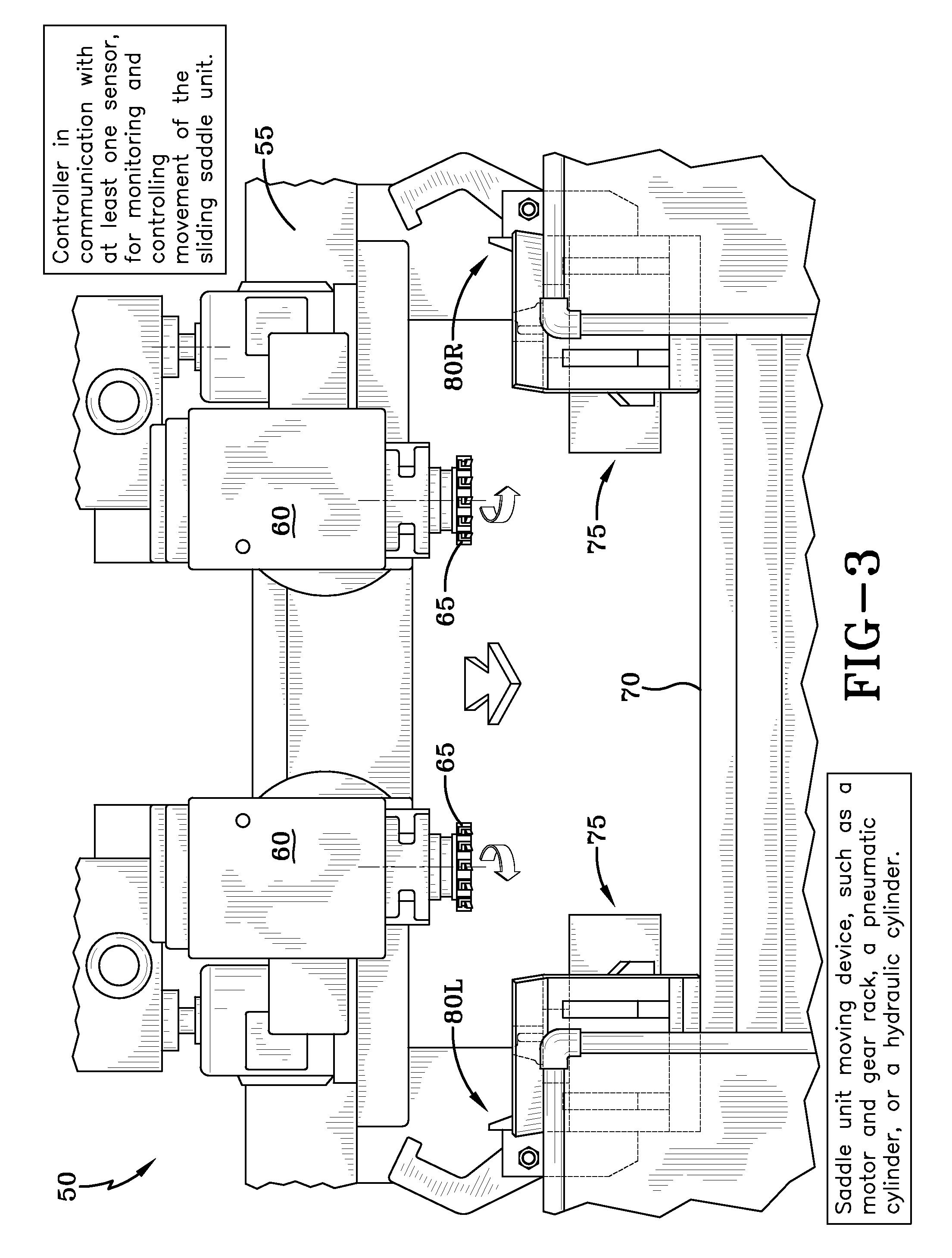

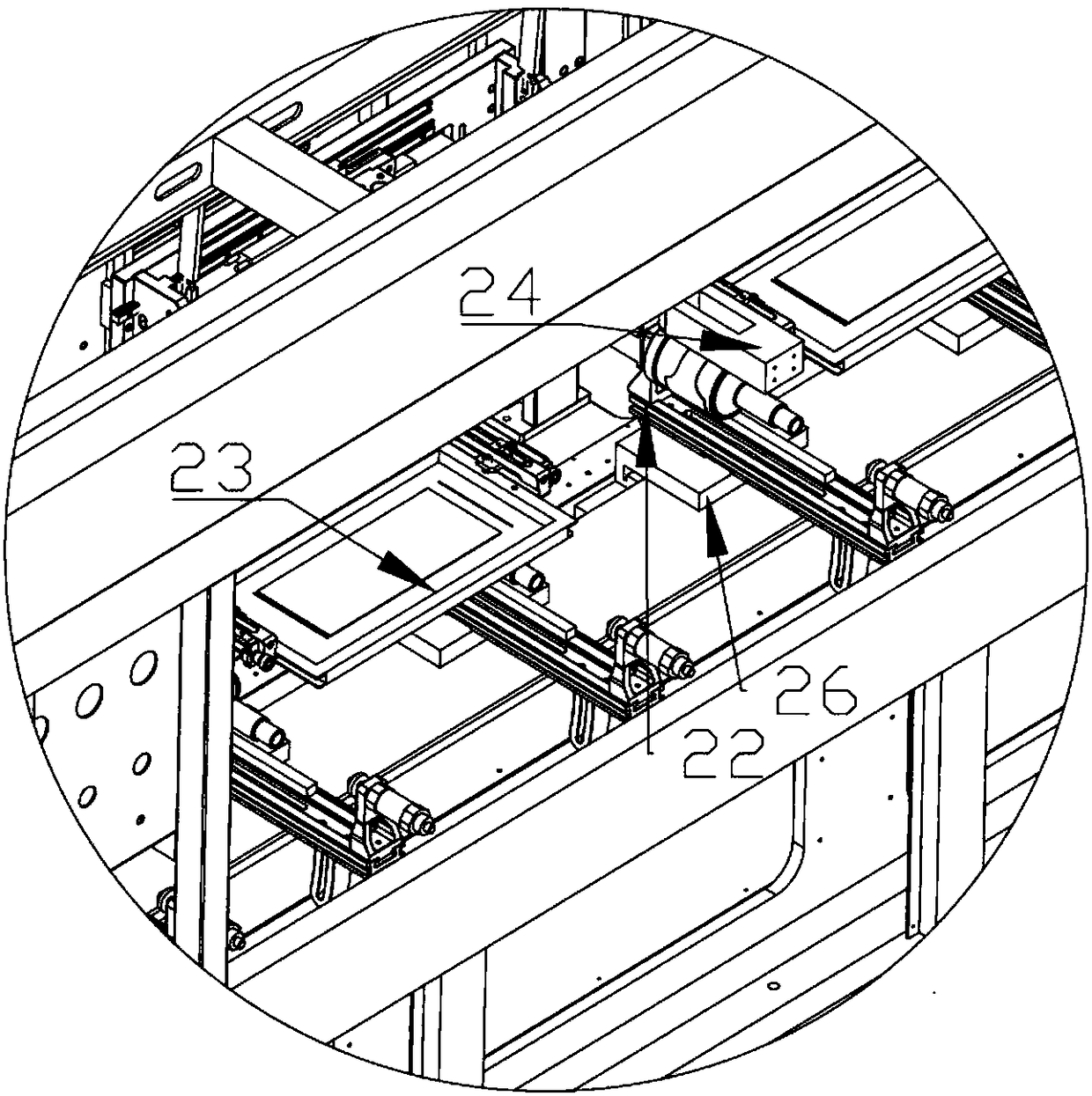

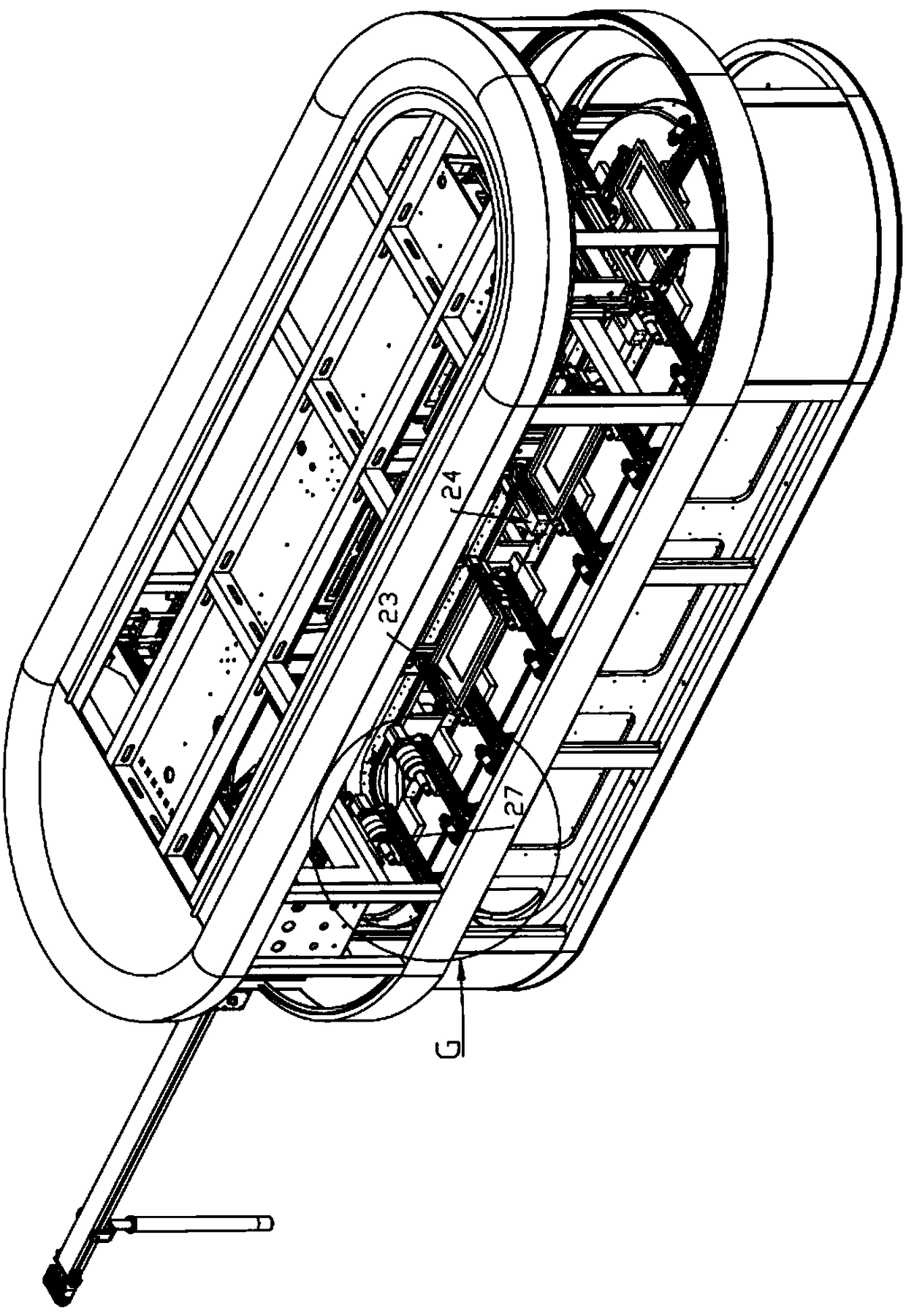

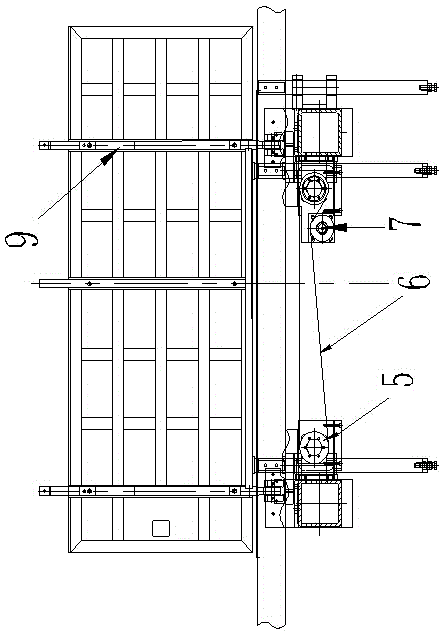

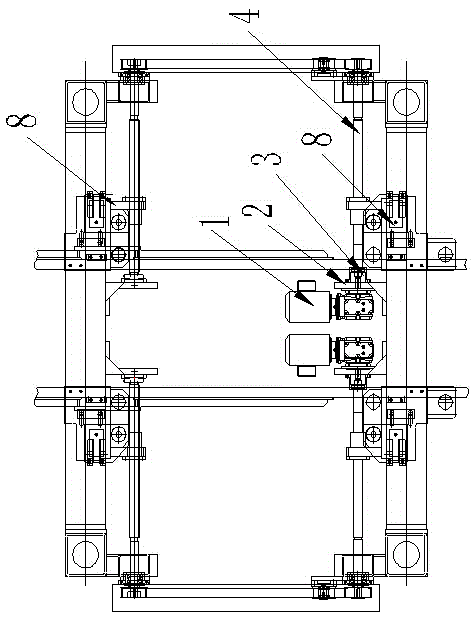

A railcar truck bolster side bearing mounting pad milling machine and method. A milling machine of the present invention includes a pair of milling heads and associated cutters suspended from an overhead frame member. A sliding saddle unit is provided for transporting the bolster into and out of a work envelope of the milling machine. At least one fixturing assembly is attached to the sliding saddle unit to support and fix the position of the bolster in three directions. The bolster is rigidly supported from its underside, thereby eliminating the risk that the bolster may move downward during machining. Since the vertical position of the bolster when presented to the cutters is fixed, thereby the need to raise the bolster into a working position is also eliminated.

Owner:COLUMBUS STEEL CASTINGS

High-precision automatic robot welding device and working method thereof

ActiveCN104999202AImprove securityImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesAutomatic controlAutomated control system

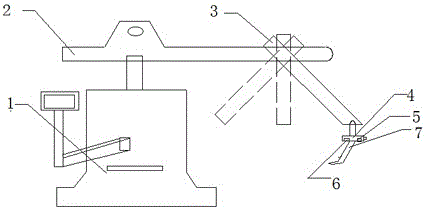

The invention discloses a high-precision automatic robot welding device, which comprises a fixing seat, a horizontal shaft, a first joint shaft, a second joint shaft, a first position sensor, a second position sensor, a welding gun and a control device, wherein the control device comprises a welding device, a sensor control module, an execution device, an alarming system and an automatic control system; the first position sensor and the second position sensor are arranged on the second joint shaft and are connected with the sensor control module; and the horizontal shaft, the first joint shaft and the second joint shaft form an arm of the robot. According to the high-precision automatic robot welding device, the first position sensor and the second position sensor are arranged on the arm of the robot, the position of a welding point is calculated via detection values of the two sensors, automatic calibration of the welding position is realized, accuracy of the welding gun position and the welding port position can be effectively ensured, accuracy of the welding position is greatly improved, and stability of the welding quality is ensured.

Owner:SUZHOU WST ROBOT AUTOMATION CO LTD

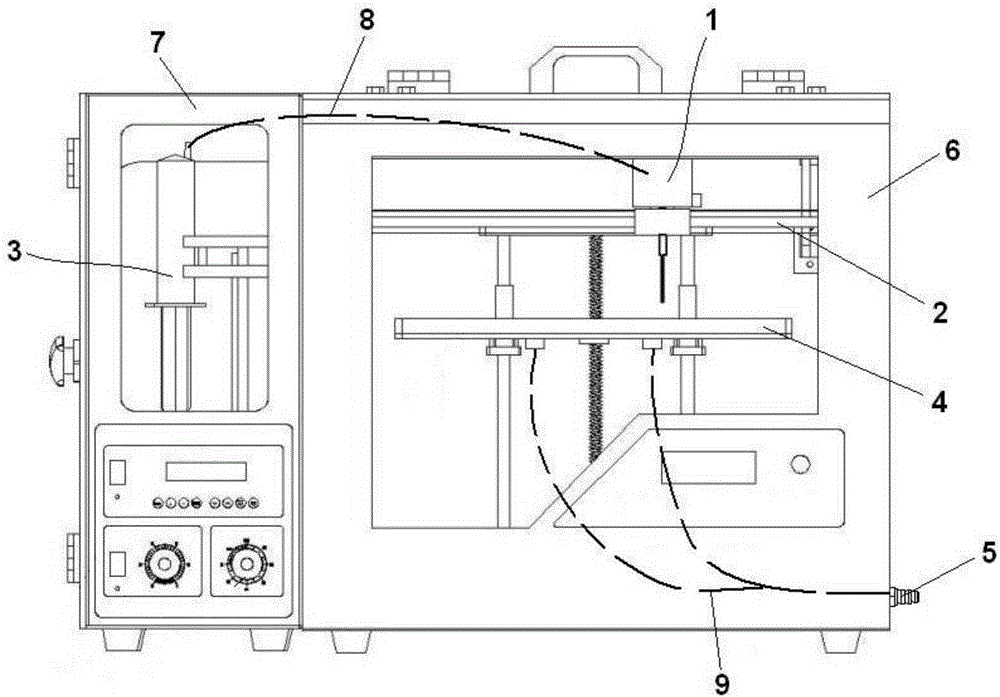

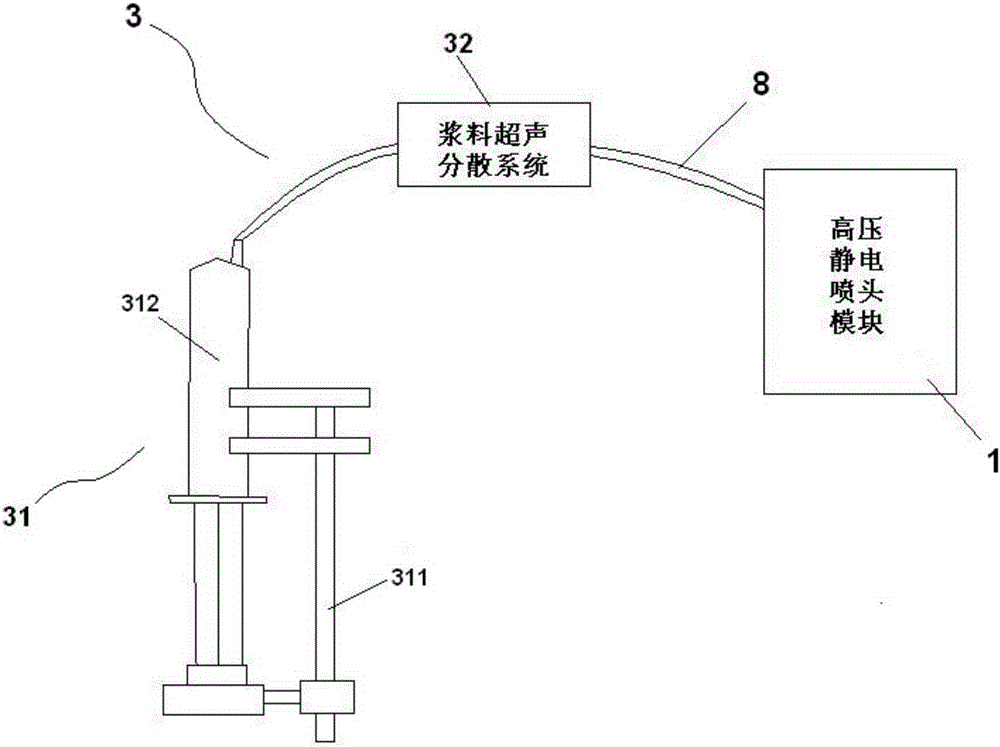

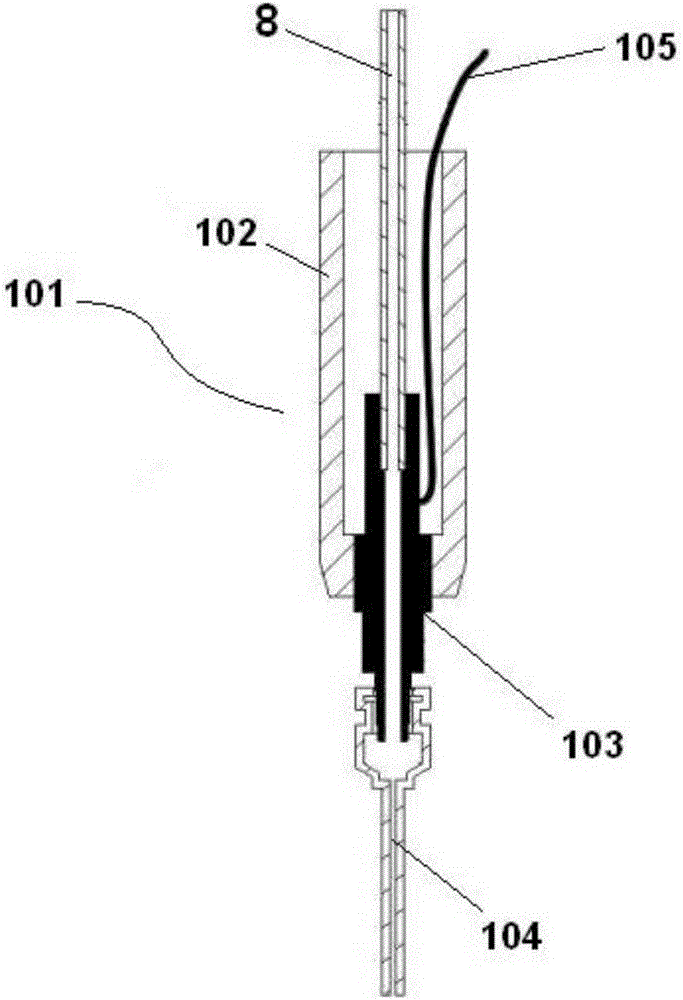

Programmed type electrostatic spraying device

ActiveCN105170359ASmooth slurry flow controlIncrease profitLiquid spraying plantsEngineeringHigh pressure

The invention provides a programmed type electrostatic spraying device. The programmed type electrostatic spraying device comprises a box, a control mainboard and a switching power supply. The programmed type electrostatic spraying device is characterized in that the programmed type electrostatic spraying device further comprises a high-voltage electrostatic spraying nozzle module, a spraying nozzle movement support, a slurry conveying system, an automatic lifting platform and an air connector; the box comprises a box chamber A and a box chamber B; the control mainboard, the switching power supply, the high-voltage electrostatic spraying nozzle module, the spraying nozzle movement support, the automatic lifting platform and the air connector are arranged in the box chamber A; the slurry conveying system is arranged in the box chamber B; the high-voltage electrostatic spraying nozzle module is arranged on the spraying nozzle movement support; the automatic lifting platform is arranged below the high-voltage electrostatic spraying nozzle module; the slurry conveying system is connected with the high-voltage electrostatic spraying nozzle module through a polytetrafluoroethylene tube; the air connector is arranged on the side wall of the box chamber A and connected with the automatic lifting platform through a hose. The programmed type electrostatic spraying device can remarkably increase the utilization rate of sprayed slurry and reduce the usage quantity of expensive slurry.

Owner:NANJING UNIV +2

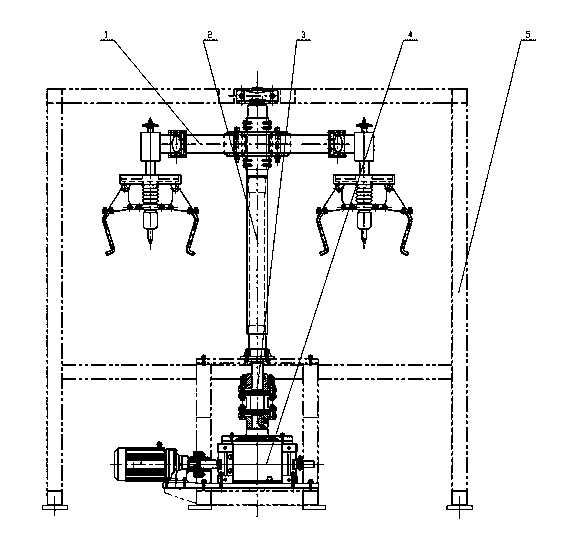

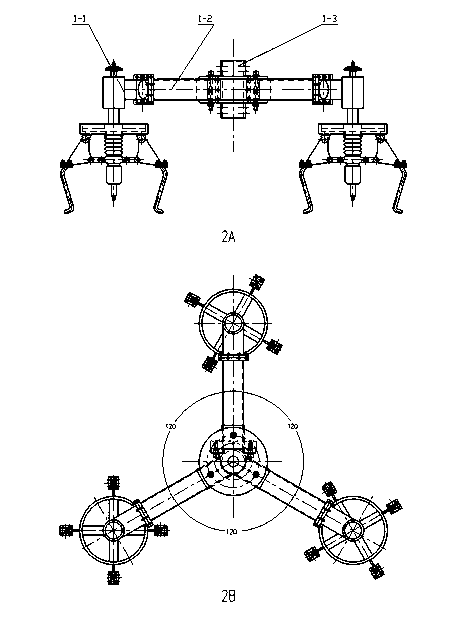

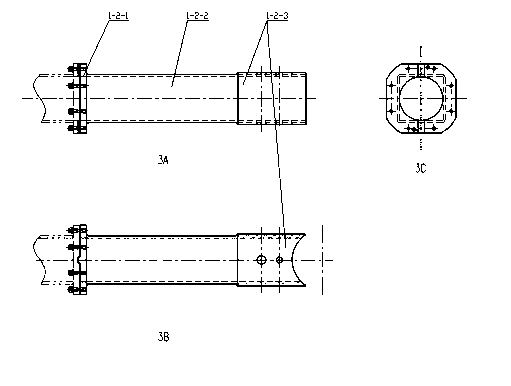

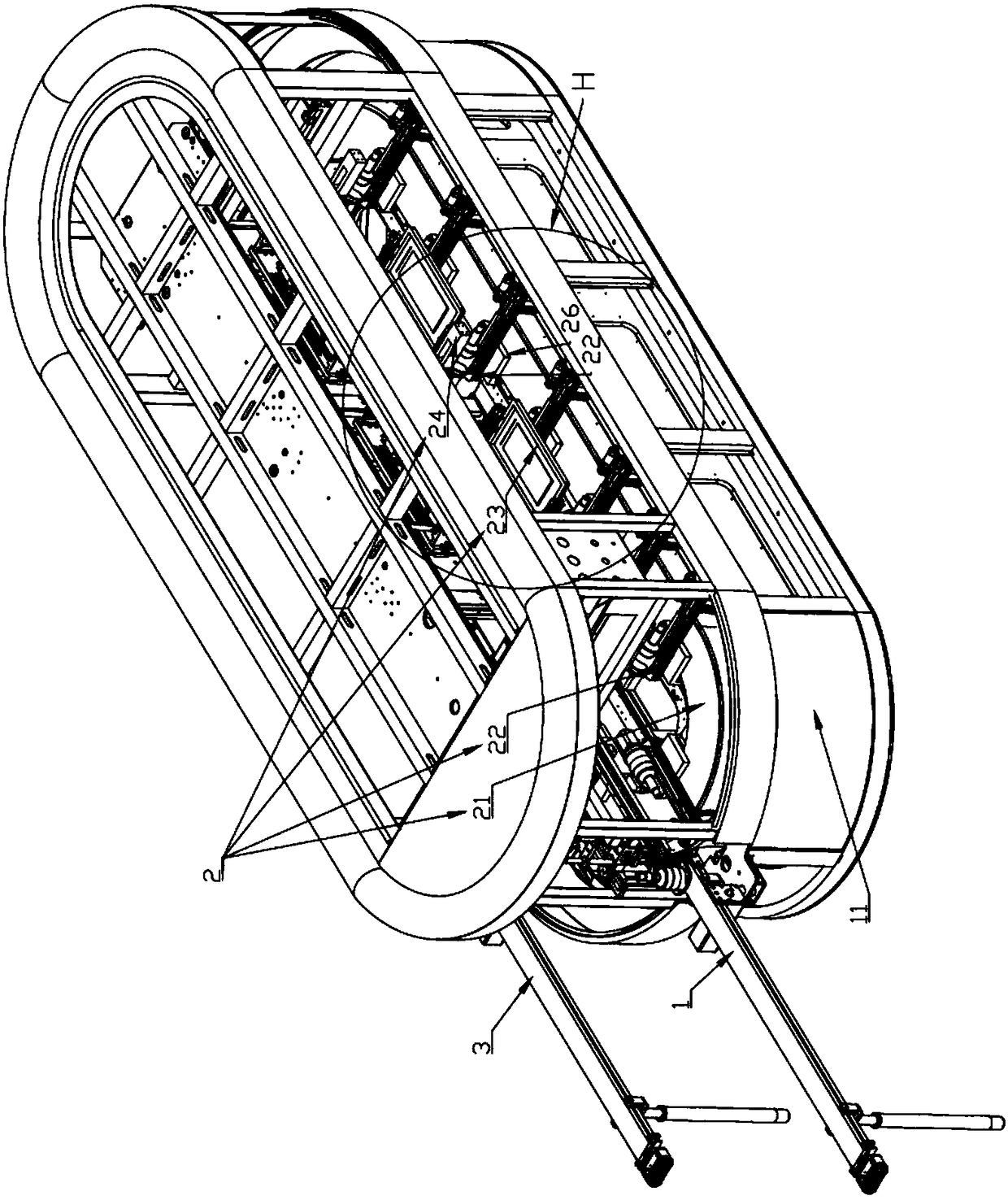

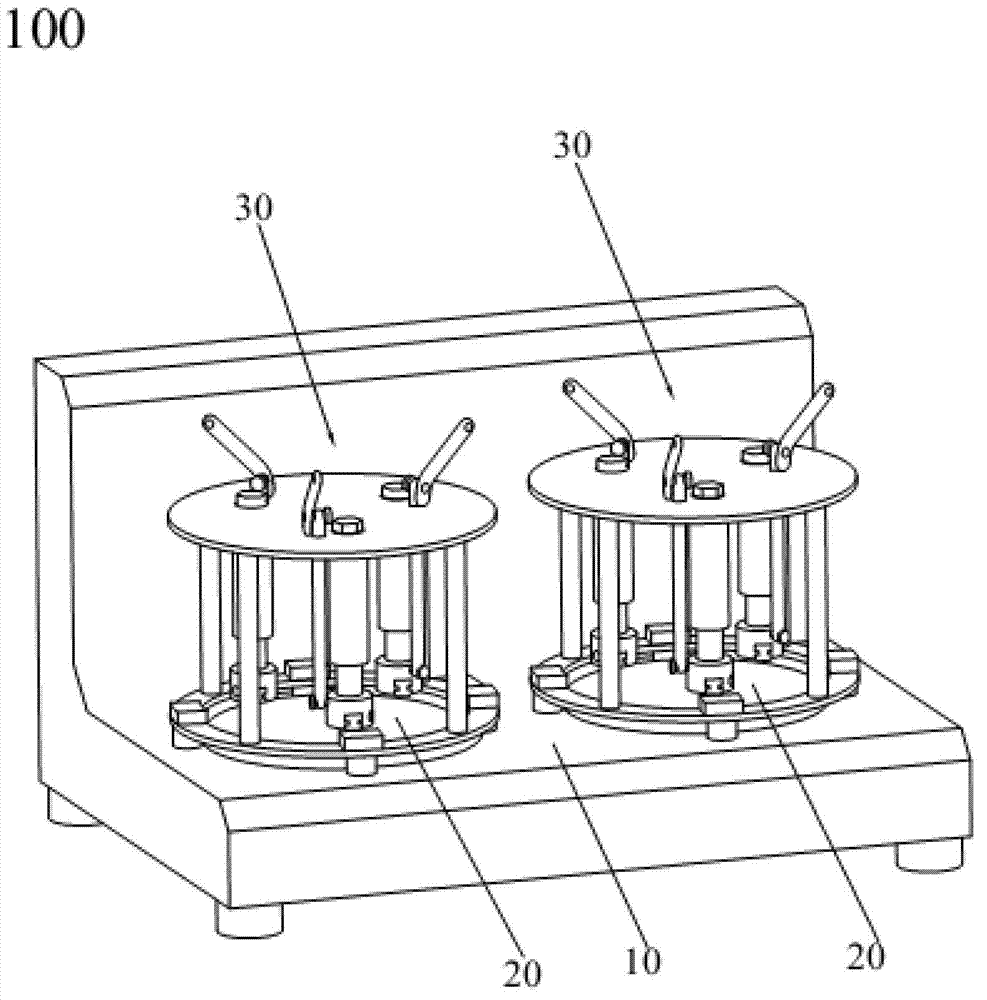

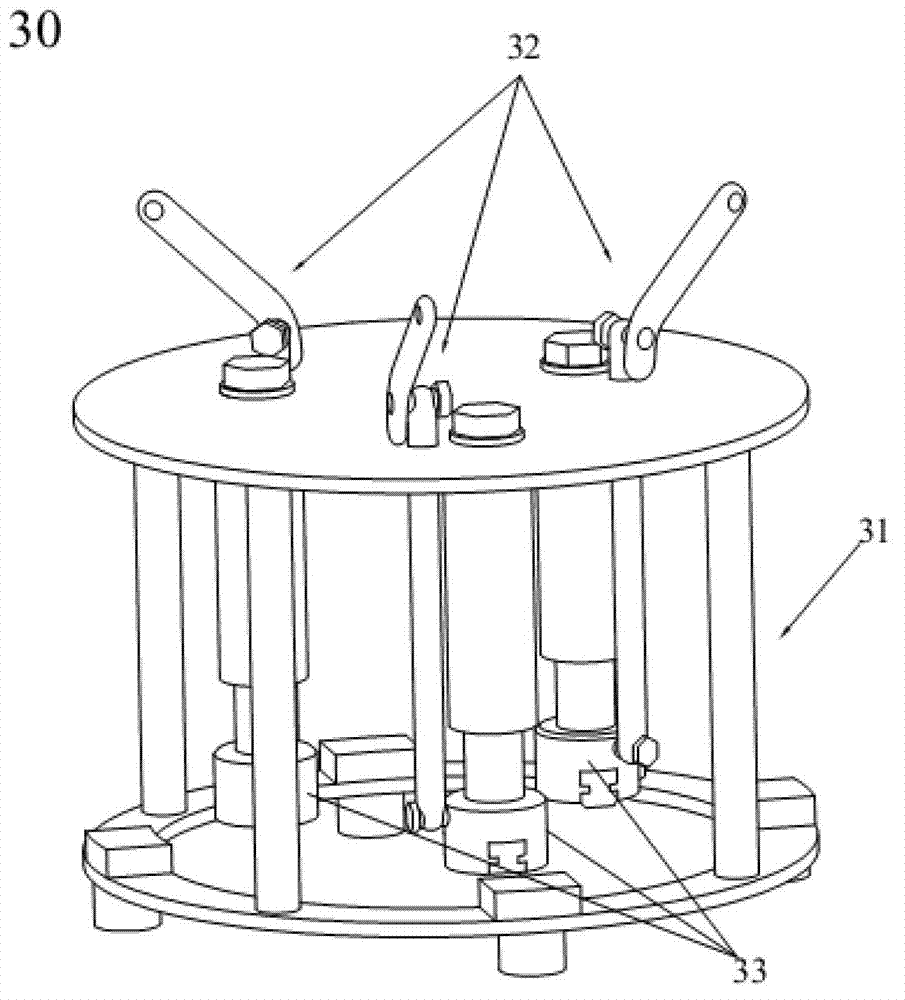

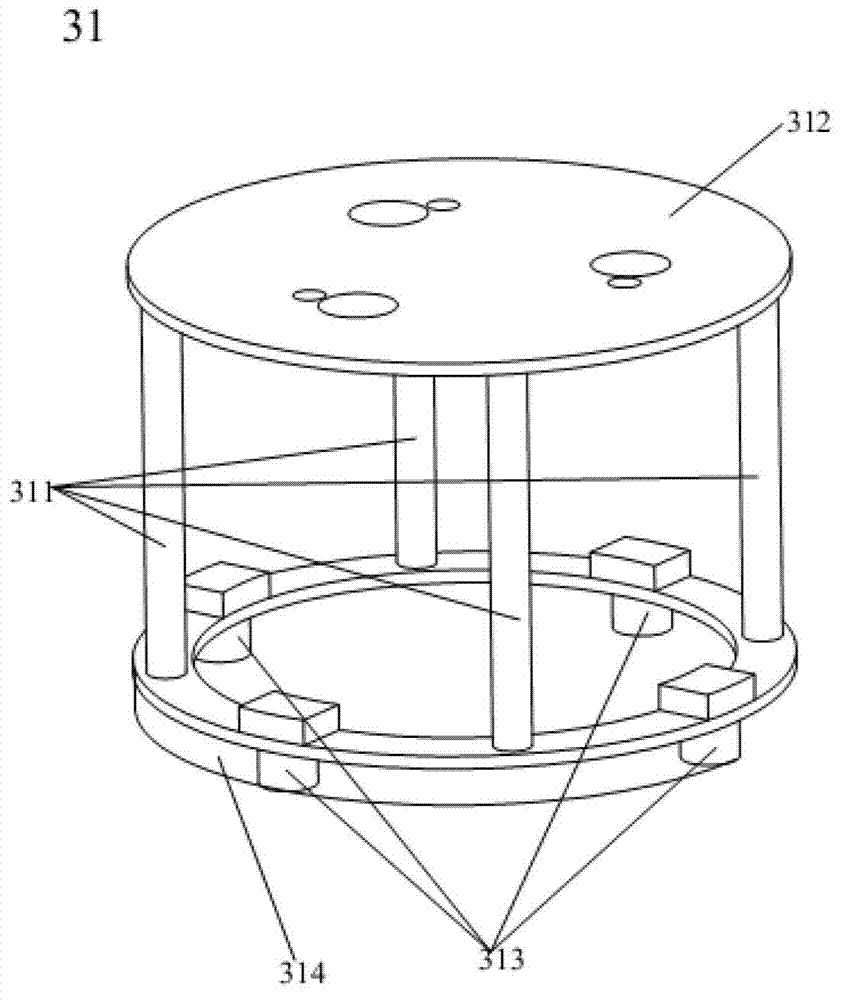

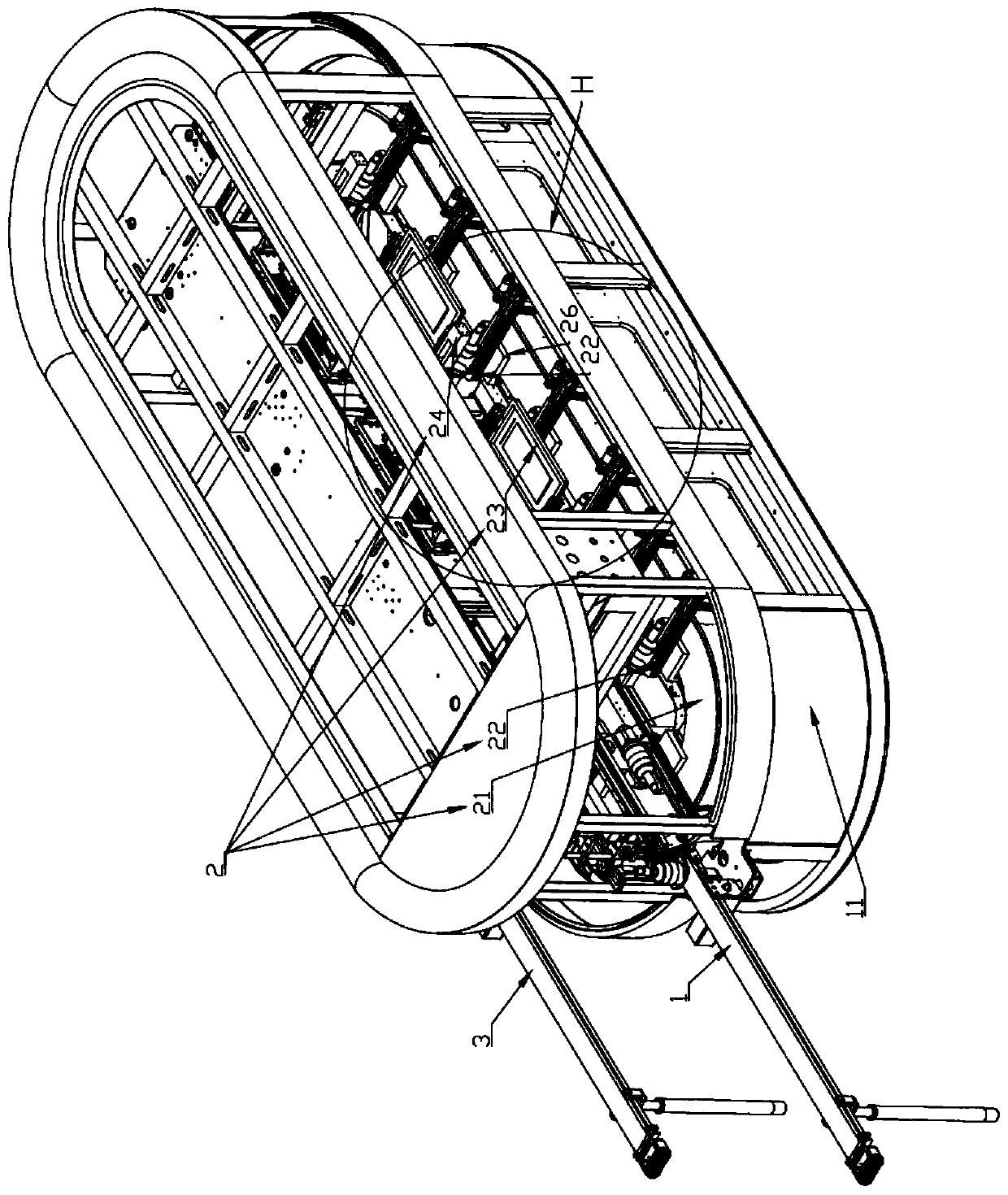

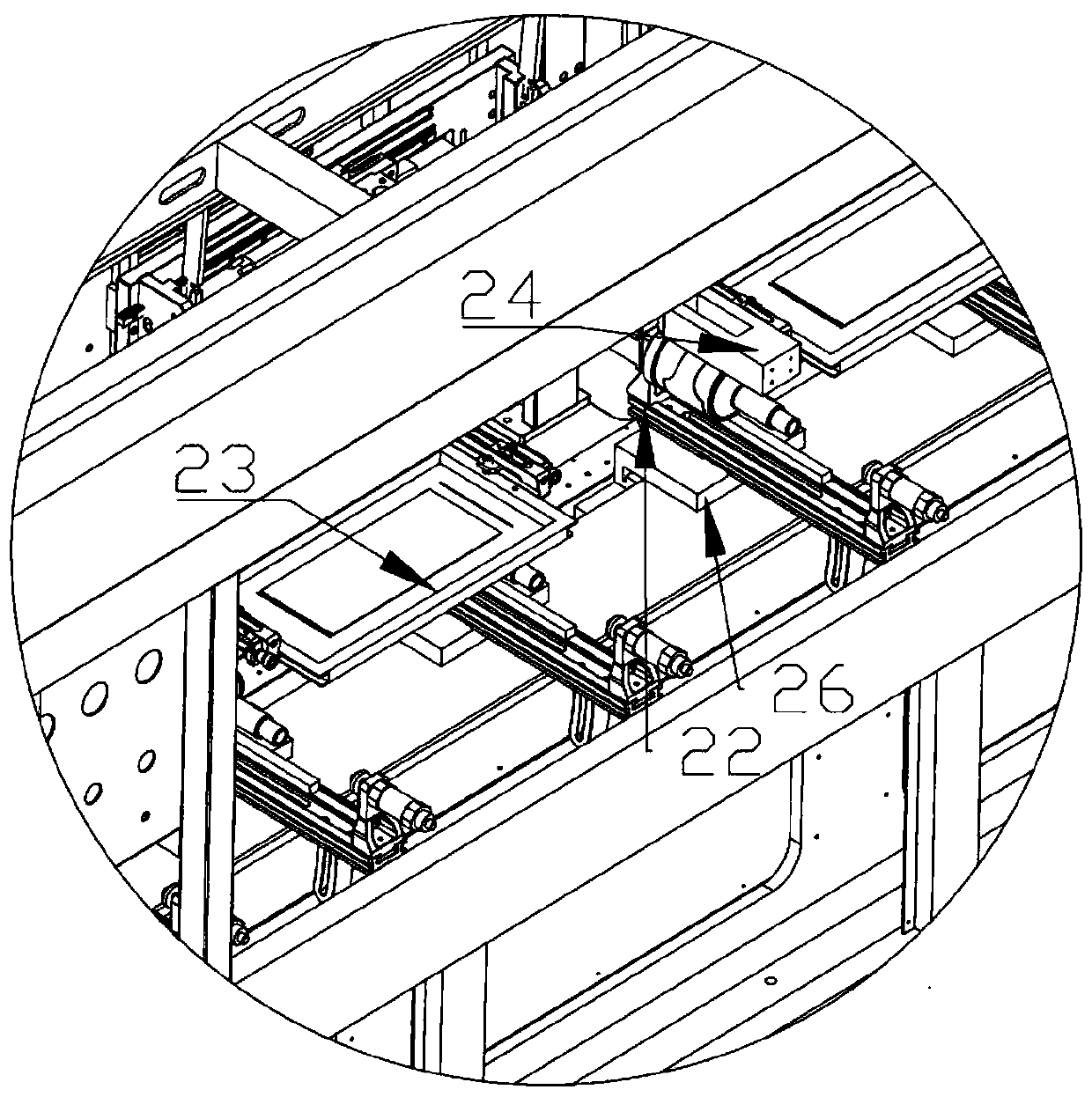

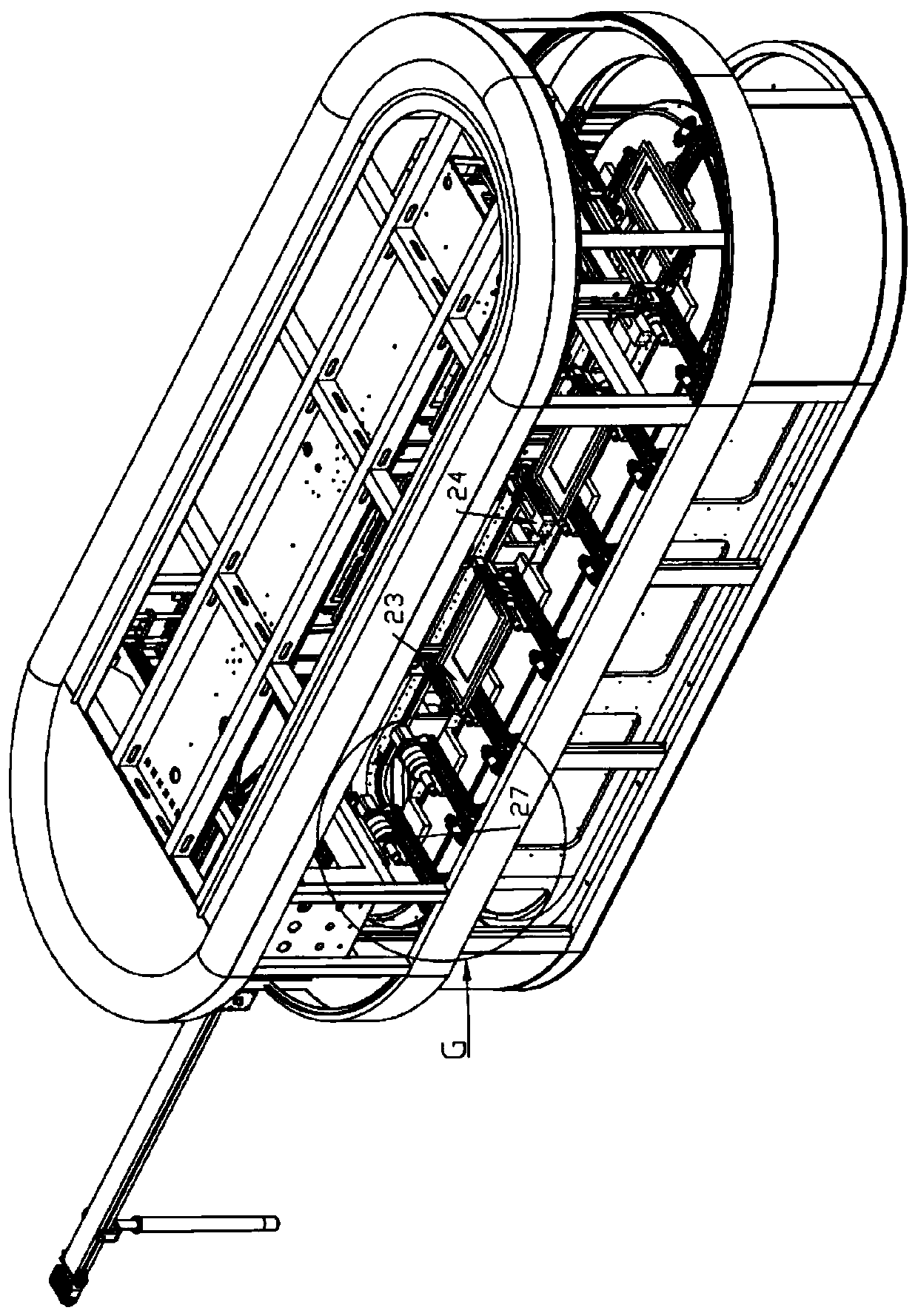

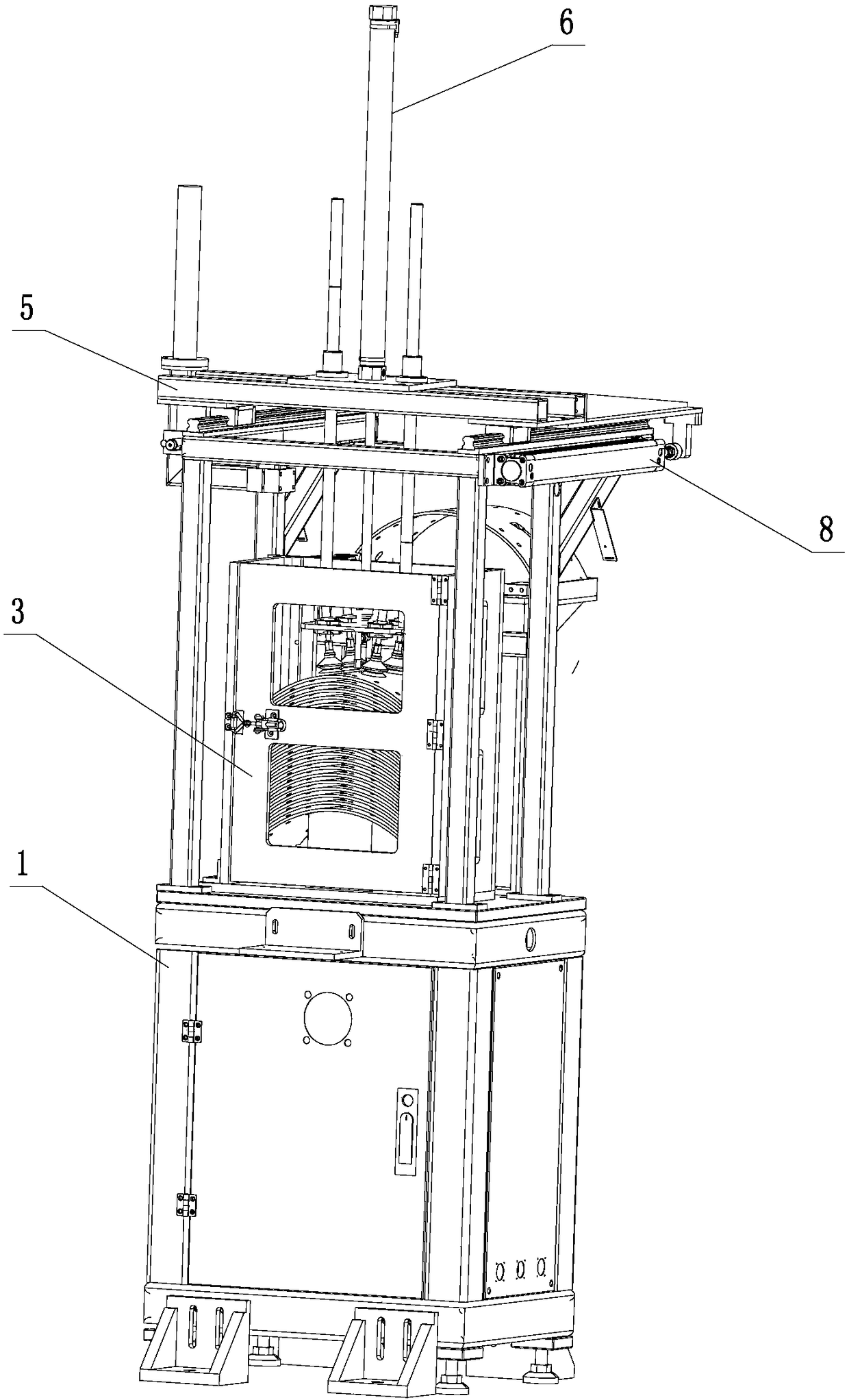

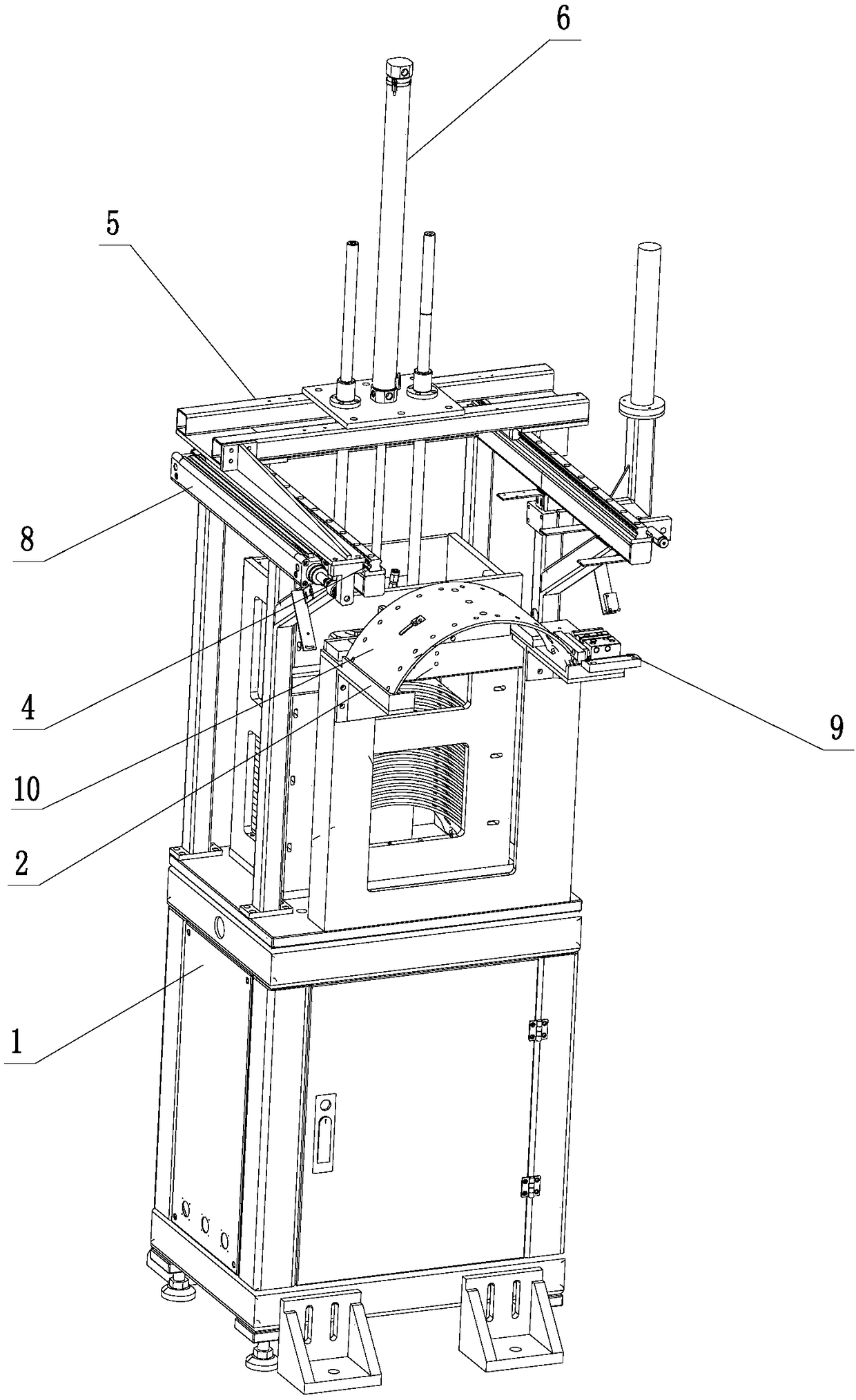

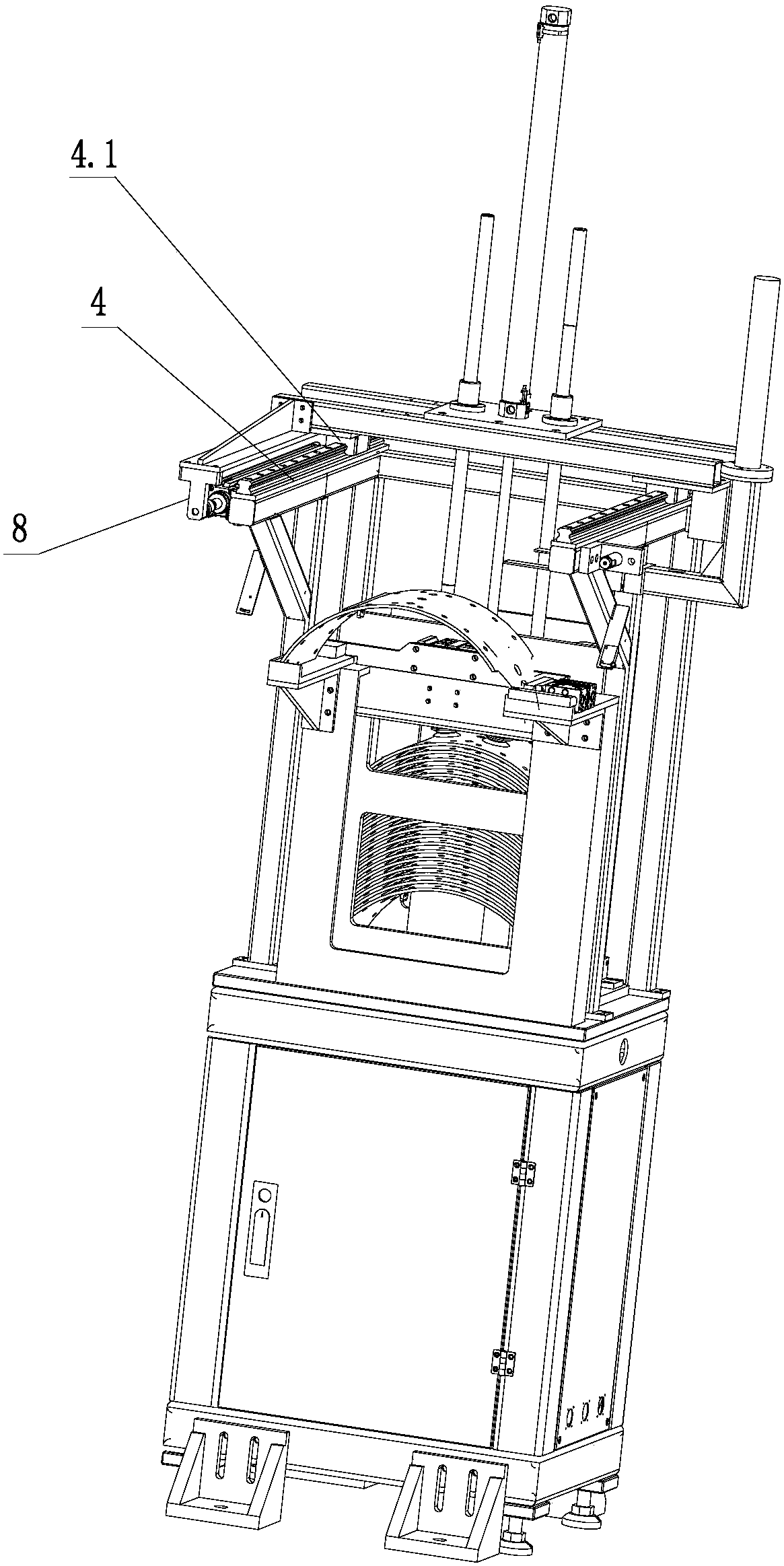

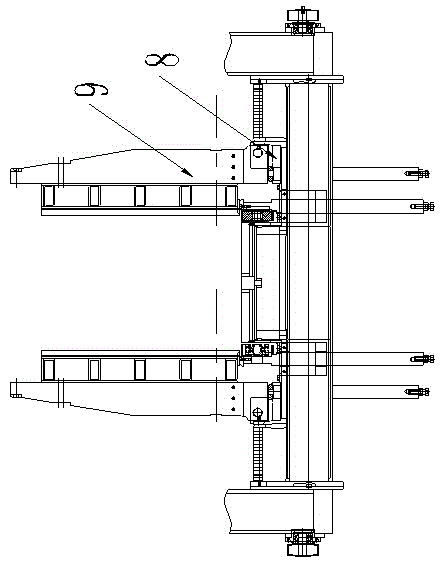

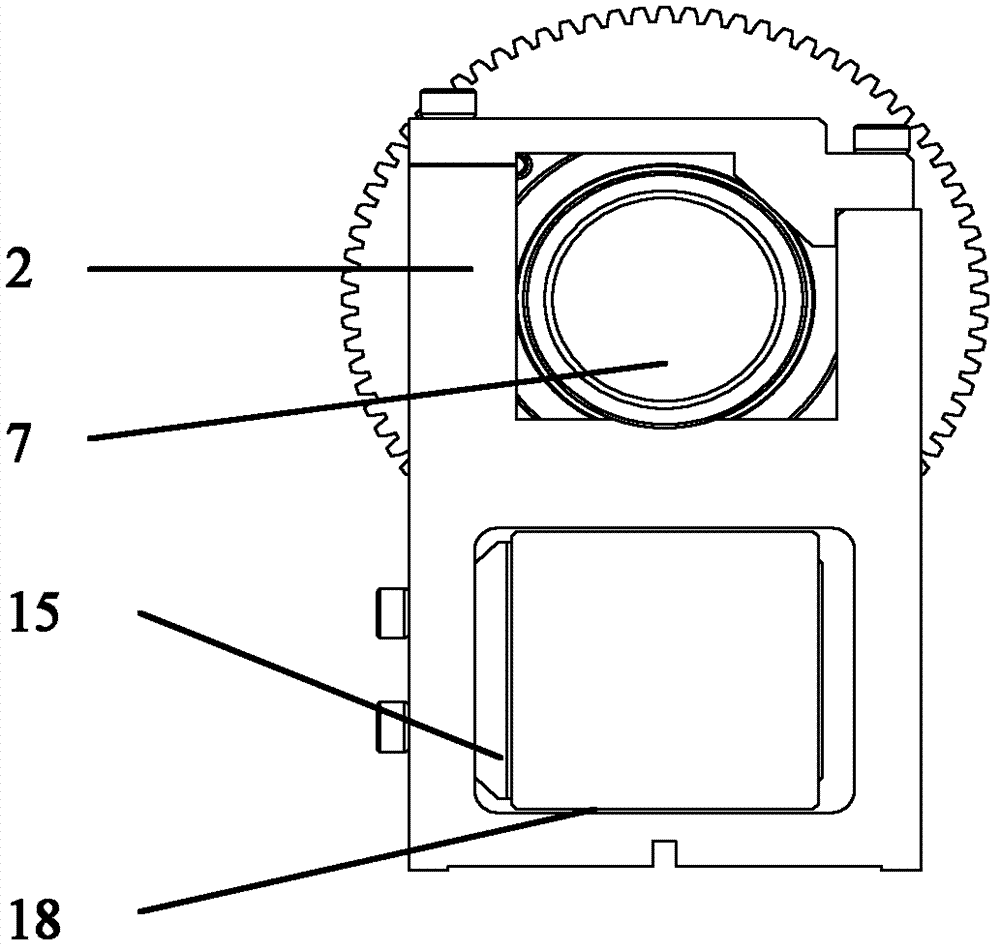

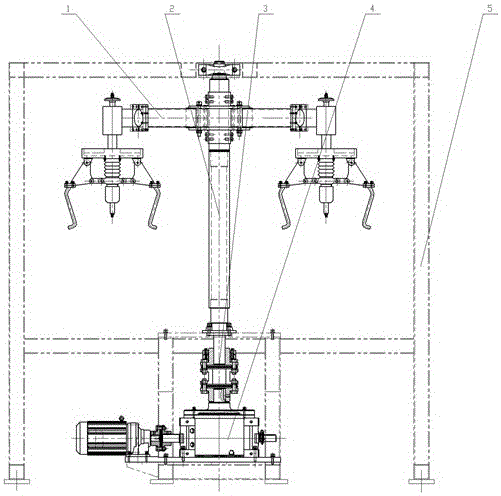

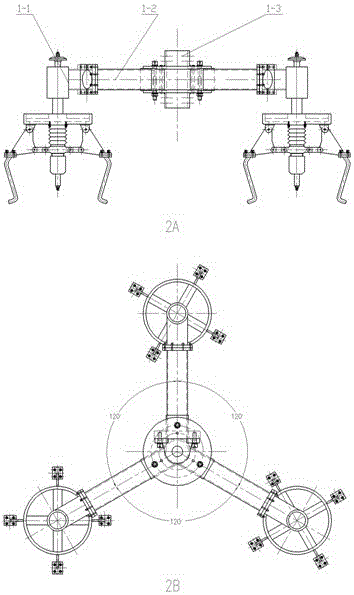

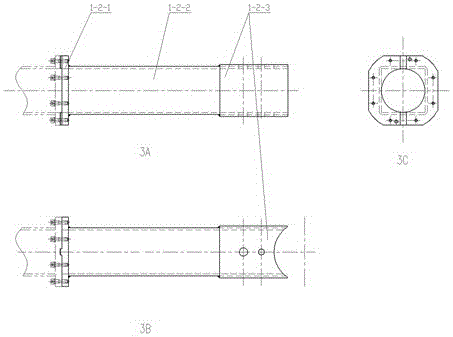

Multi-station tyre gripper rotating device of tyre spraying coater and a rotating manner thereof

ActiveCN103846200ASimple structureShorten spray cycleLiquid surface applicatorsSpraying apparatusControl engineeringElectric machinery

The invention discloses a multi-station tyre gripper rotating device of a tyre spraying coater and a rotating manner thereof. The device comprises a multi-station tyre gripper component, a vertical center rotating shaft component, a rotating drive component and a dual-node metal diaphragm coupler. The multi-station tyre gripper component forms a rib-shaped structure by no less than three groups of tyre grippers and corresponding connecting cross arms and connecting arm supports. The rib-shaped structure is fixedly connected to the upper part of the vertical center rotating shaft. The lower end of the vertical center rotating shaft is connected to the rotating drive component including a cam divider through the dual-node metal diaphragm coupler. When the device rotates, a vertical output end of the cam divider drives a vertical shaft connected to the vertical output end, and the multi-station tyre gripper component to rotate by driving a horizontal input end of the cam divider through a gear motor, so as to achieve actions of simultaneously rotating of the multi-station tyre grippers. The multi-station tyre gripper rotating device is simple in structure, high in rotating efficiency, and accurate to position; and the grippers and the connecting cross arms are simply installed and conveniently adjusted.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

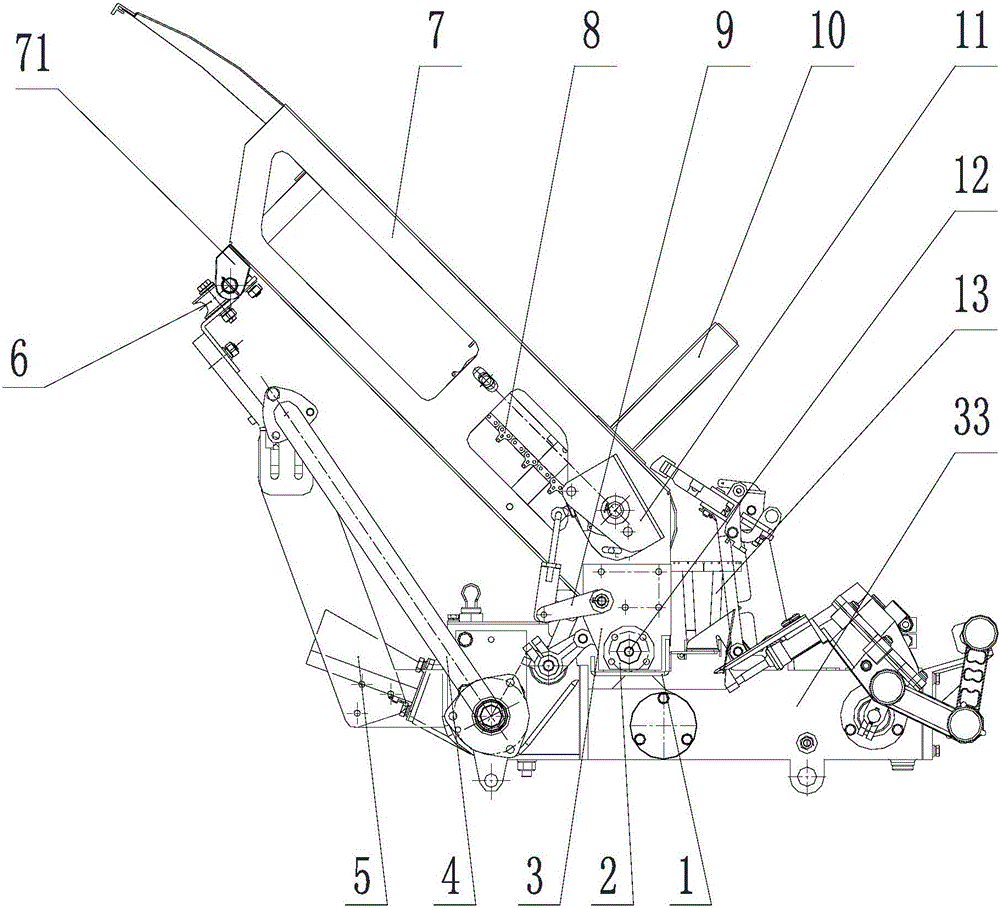

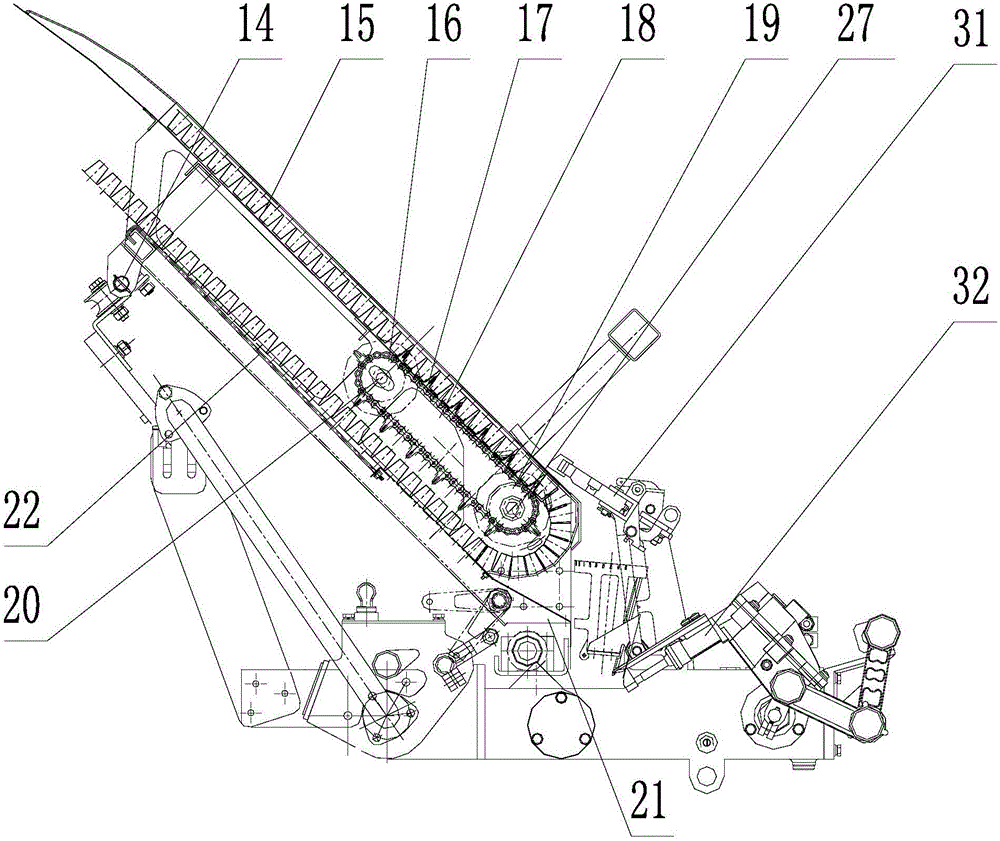

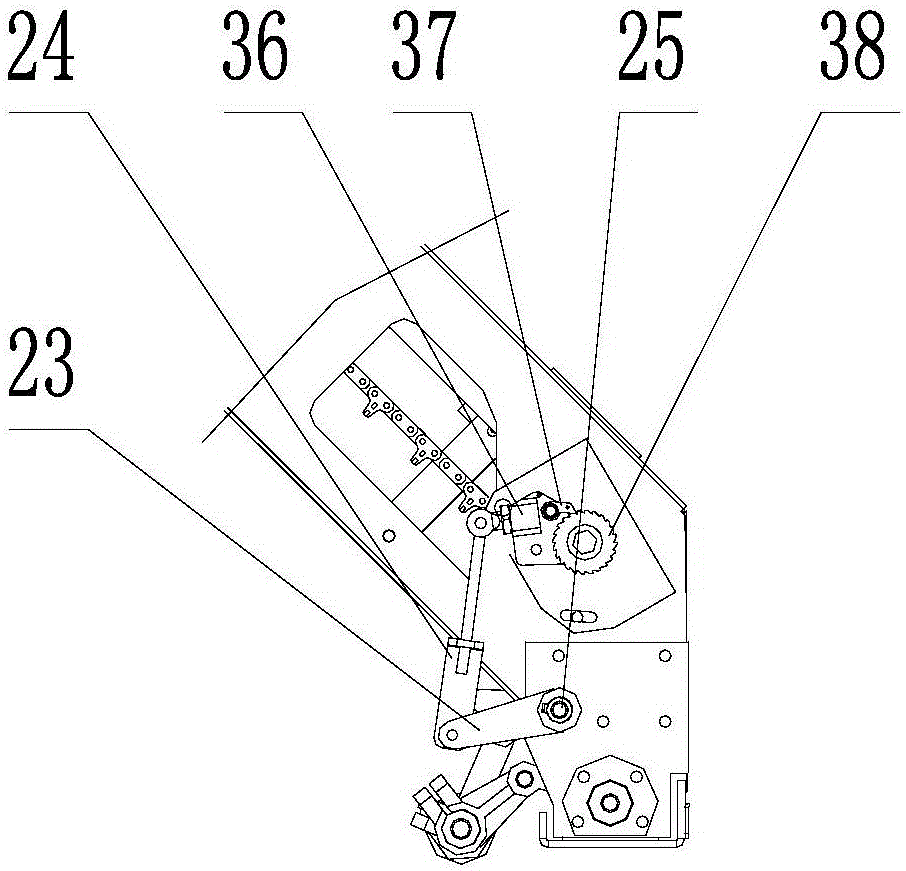

Seedling box structure of pot seedling transplanter

InactiveCN105850320AAccurate returnPrecise stepping seedling deliveryTransplantingManipulatorBiology

The invention discloses a seedling box structure of a pot seedling transplanter. The seedling box structure comprises a fixed guide rail base, a box shifting guide rail support base, box shifting guide rail brackets, a seedling box bracket, a seedling feeding chain mechanism, a seedling feeding swing rod mechanism, a seedling tray return bracket, a seedling feeding positioning mechanism, a box shifting guide rail and a chain box and the like, wherein the fixed guide rail base is arranged on the chain box; the box shifting guide rail support base is arranged on the fixed guide rail base; the left and right box shifting guide rail brackets are arranged on two side surfaces of the seedling box; the seedling feeding swing rod mechanism is arranged on the box shifting guide rail brackets; the lower end of the seedling box bracket is connected with the chain box and the upper end of the seedling box bracket is connected with a bracket support plate; a connection part is arranged at the upper end of the seedling box; and the lower end of the seedling box is fixed on the box shifting guide rail. The seedling box structure has the beneficial effects that accurate step-by-step seedling feeding, accurate repeated positioning, seedling tray return and accurate box shifting are achieved through operation of the seedling feeding swing rod mechanism, the seedling feeding positioning mechanism and the seedling feeding chain mechanism and the matching of a seedling take manipulator and a seedling transplanting support arm; and the seedling box structure has the characteristics of being simple in structure and convenient to use.

Owner:HUBEI YIXIN MACHINERY TECH CO LTD

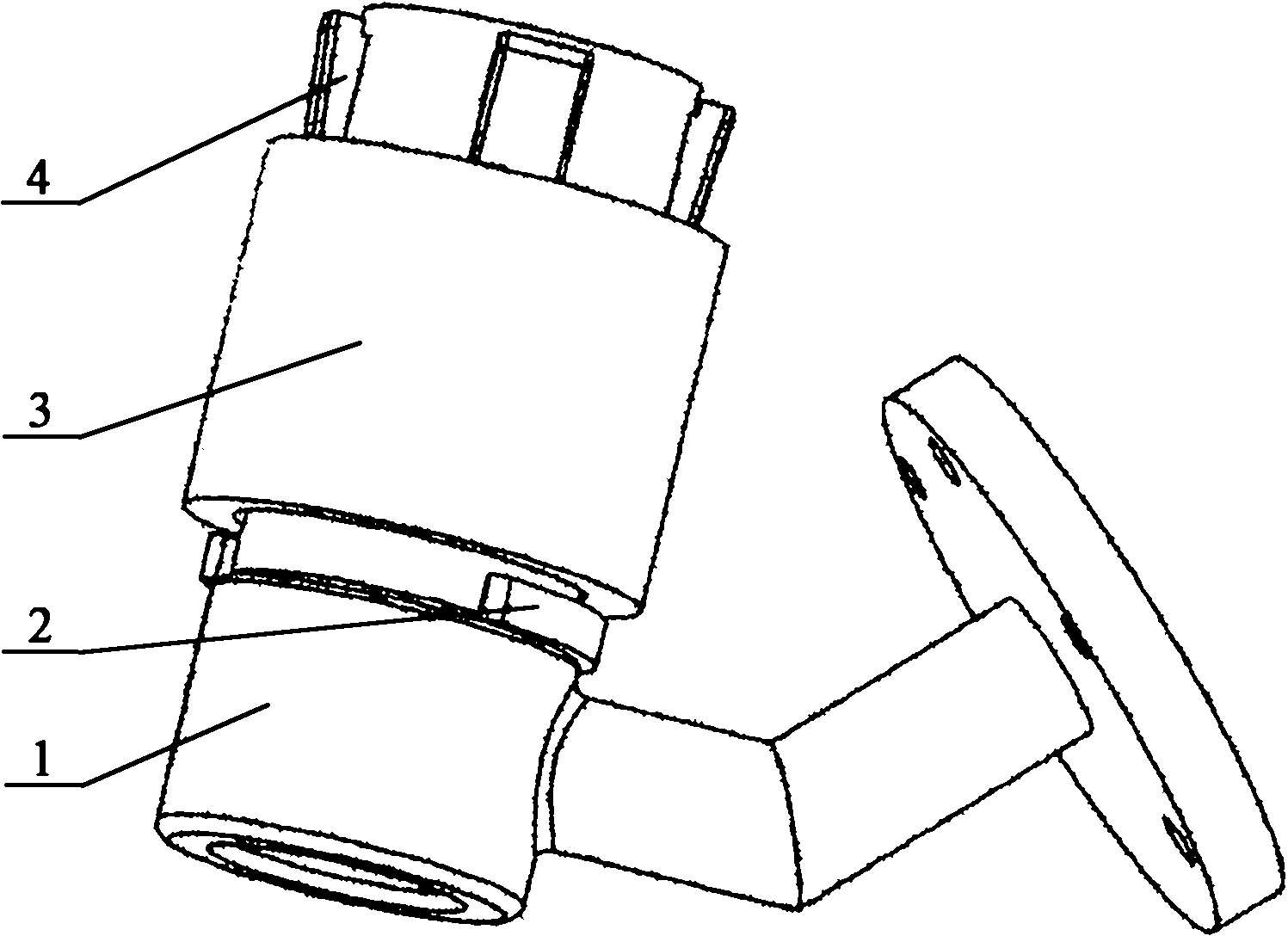

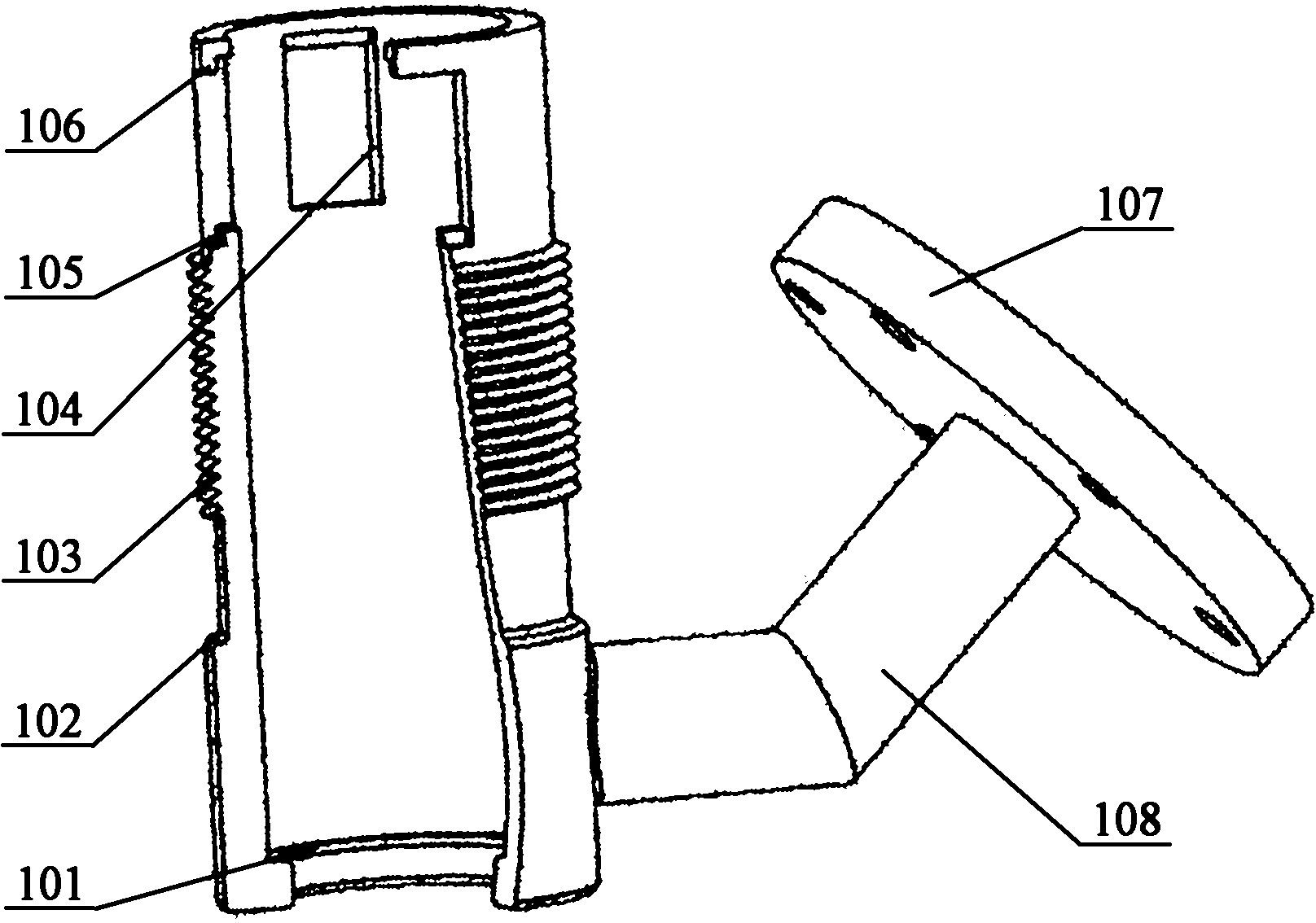

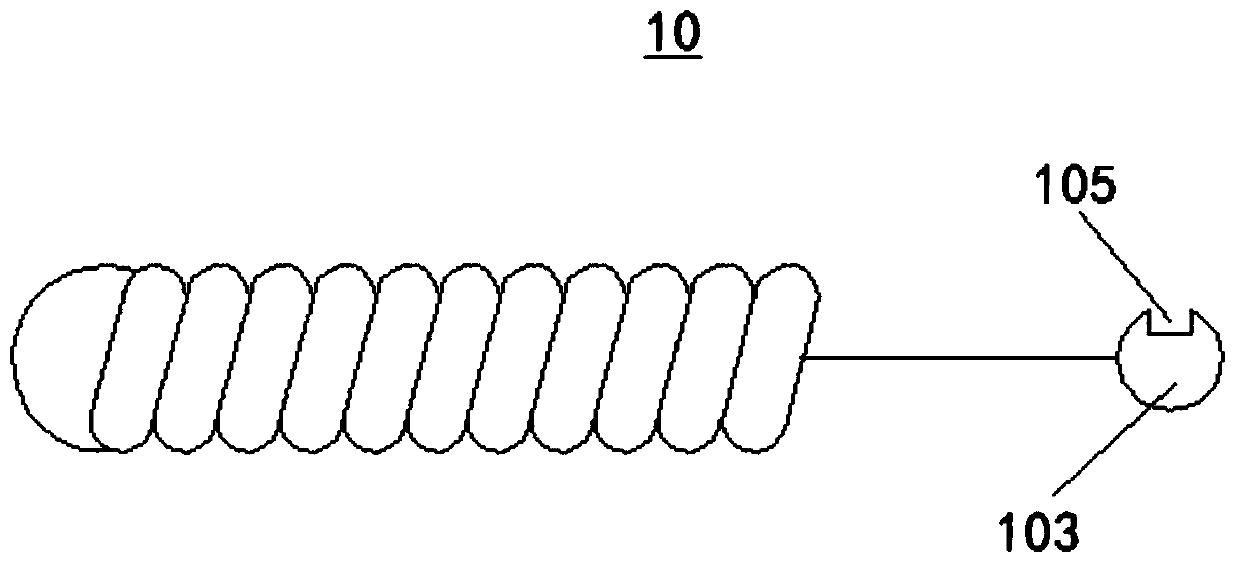

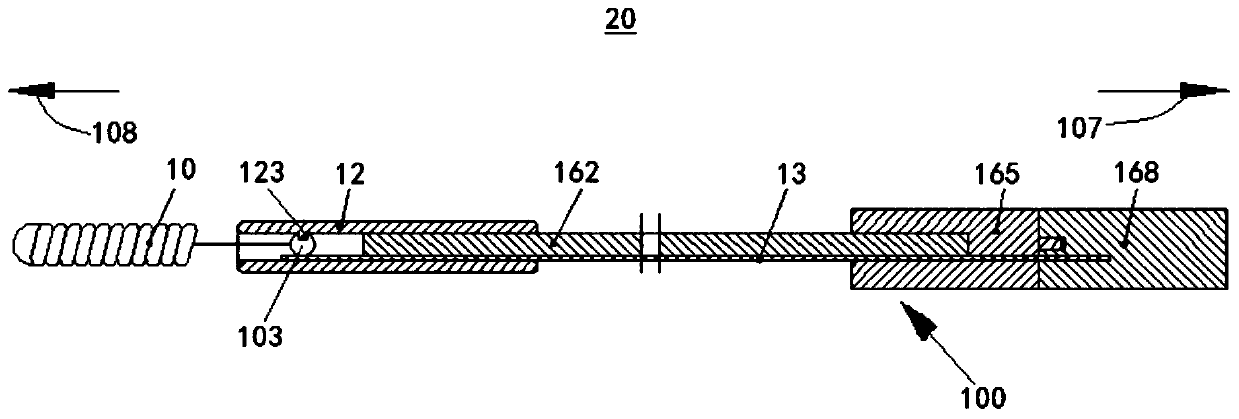

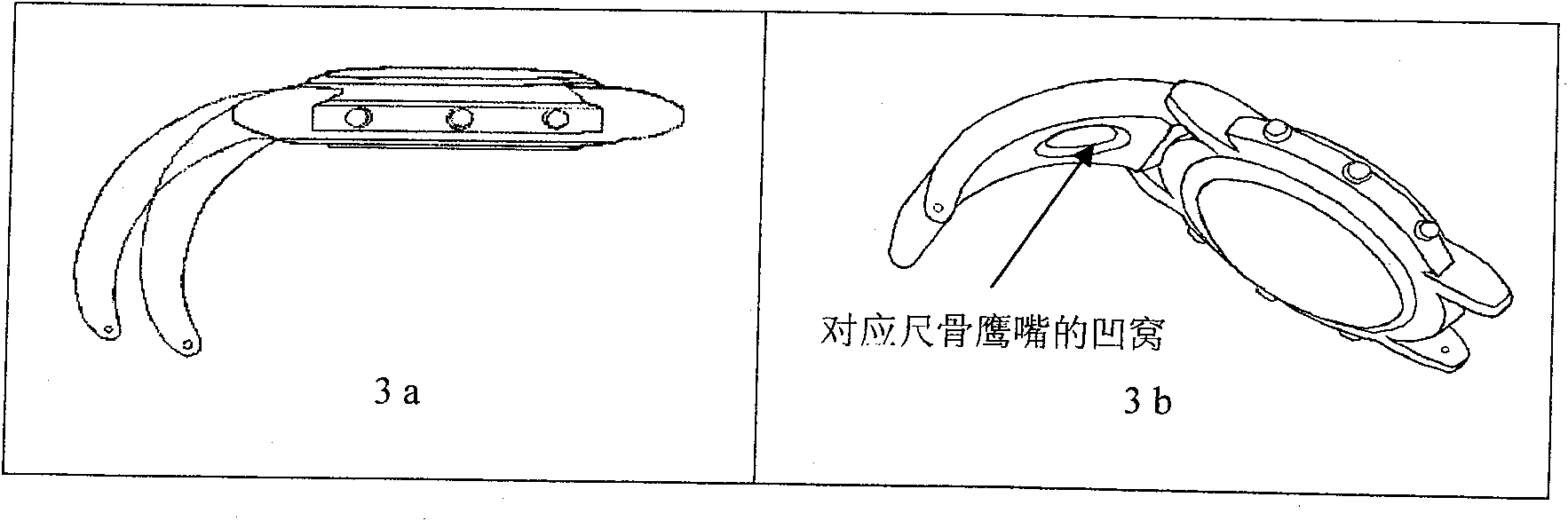

Tubular holder for holding tail end of mechanical arm of holding bone drill

ActiveCN102579105ARepeat positioning is accuratePrecise positioningGripping headsSurgeryDrillEngineering

The invention relates to a tubular holder for holding a tail end of a mechanical arm of a bone drill. The tubular holder comprises a main holding pipe, an opening snap ring, a locking sleeve and a plurality of cone-shaped holding blocks, wherein the holding pipe is arranged at the tail end of the mechanical arm; the opening snap ring is positioned in the middle outside the main holding pipe; the locking sleeve is sleeved at a tail end of the outer part of the main holding pipe, the plurality of cone-shaped holding blocks are respectively positioned in holding block holes arranged at the tail end of the outer part of the main holing pipe and are arranged in the locking sleeve. The tubular holder can not only have the positioning function along the axial line of the tubular holder, but alsoensure that the axial line of the bone drill is consistent with the axial line of the holder all the time, thereby realizing the accurate repeated positioning of the bone drill after disassembly and assembly at one time; in addition, the tubular holder also has the characteristics that the operation is simple, the structure is compact, the holding force is small, the holding is reliable, etc.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

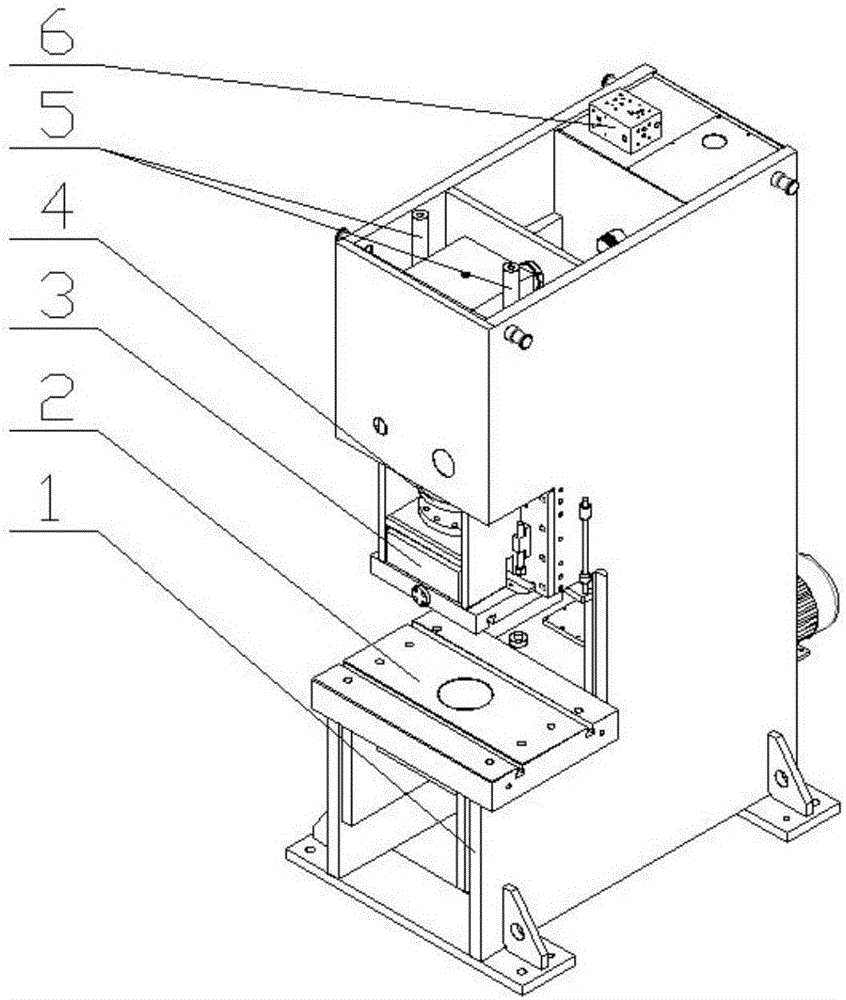

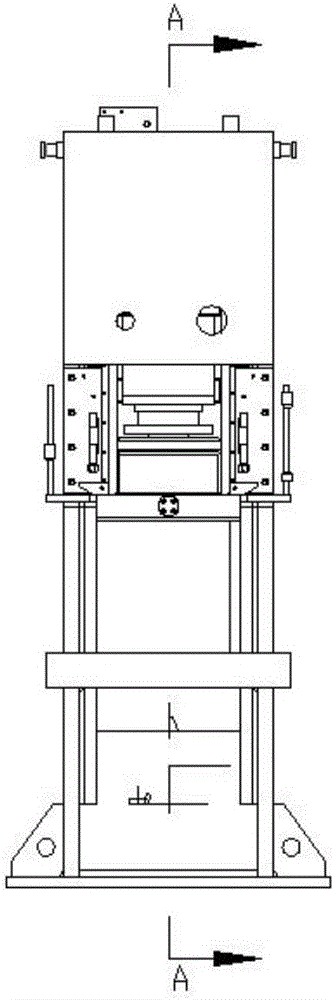

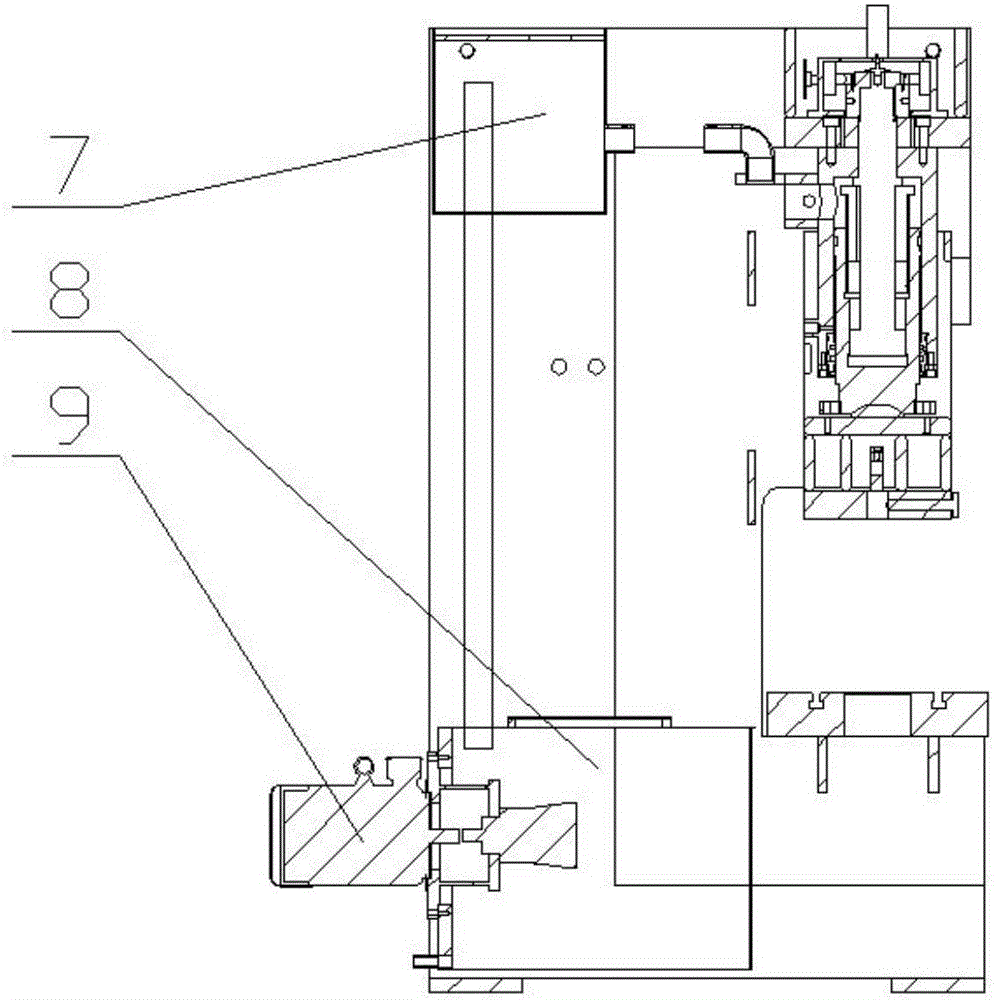

Stroke regulation built-in precise fast press machine, and oil cylinder and use method thereof

The invention discloses a stroke regulation built-in precise fast press machine, and an oil cylinder and a use method thereof, belongs to the field of a hydraulic press machine, and solves the problems of low production efficiency, high cost and complicated structure of a slide block regulating mechanism of the existing hydraulic press machine. The oil cylinder provided by the invention comprises a main cylinder piston rod and a main cylinder body, wherein one end of the main cylinder piston rod extends into the main cylinder body; one end extending into the main cylinder body is provided with a cavity; a regulating screw nut is arranged at the upper part of the inner wall of the cavity; the regulating screw nut and the inner wall of the cavity are connected through screw threads; a regulating screw rod is also arranged in the cavity; the lower end of the regulating screw rod extends into the cavity; the middle end passes through the regulating screw nut; the upper end extends out of the main cylinder body; the upper end, extending out of the main cylinder body, of the regulating screw rod is fixedly provided with a worm wheel; the middle end, penetrating through the regulating screw nut, of the regulating screw rod is provided with a key slot; a guide key is arranged on the corresponding regulating screw nut. The press machine, the oil cylinder and the use method have the advantages that the cost can be reduced; the production efficiency is improved; the applicability to various processing processes can be realized.

Owner:YANGZHOU ENG MACHINERY CO LTD

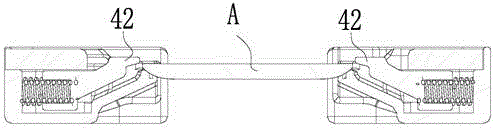

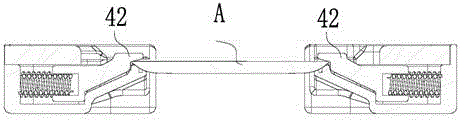

Mechanical release structure, implant and mechanical release instrument

The invention discloses a mechanical release structure, an implant and a mechanical release instrument and relates to the technical field of medical instruments. The mechanical release structure matches the proximal end of the implant and comprises a release tube and a release rod, a clamping portion is arranged at the proximal end of the implant, the release tube is used for holding the clampingportion, and the distal end of the release rod is used for extending into an inner cavity of the release tube and matching the clamping portion. When the release rod is supported on the clamping portion, the clamping portion clamps the release tube to be in a locked state; when the release rod is separated from the clamping portion, the clamping portion and the release tube are in the release state. The mechanical release structure is ingenious in design, simple in structure, stable in interlocking, reliable in release and convenient to operate, and can repeatedly position the implant in a blood vessel rapidly, stably and accurately.

Owner:苏州优医港科技有限公司

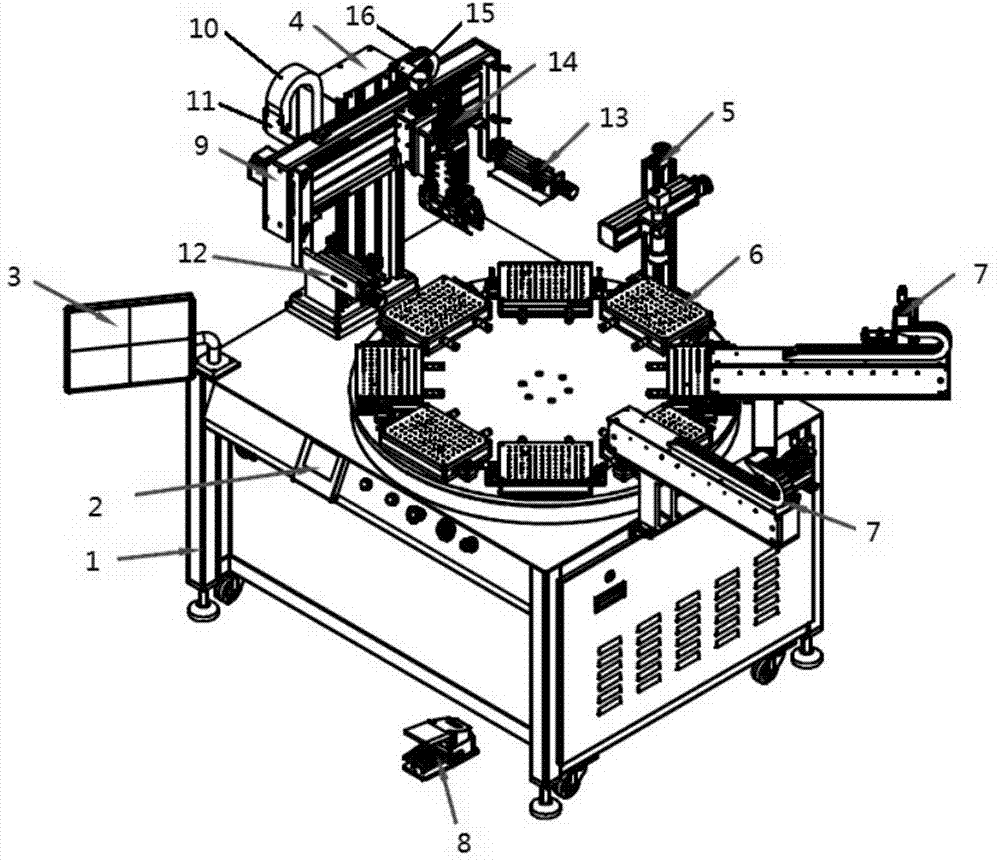

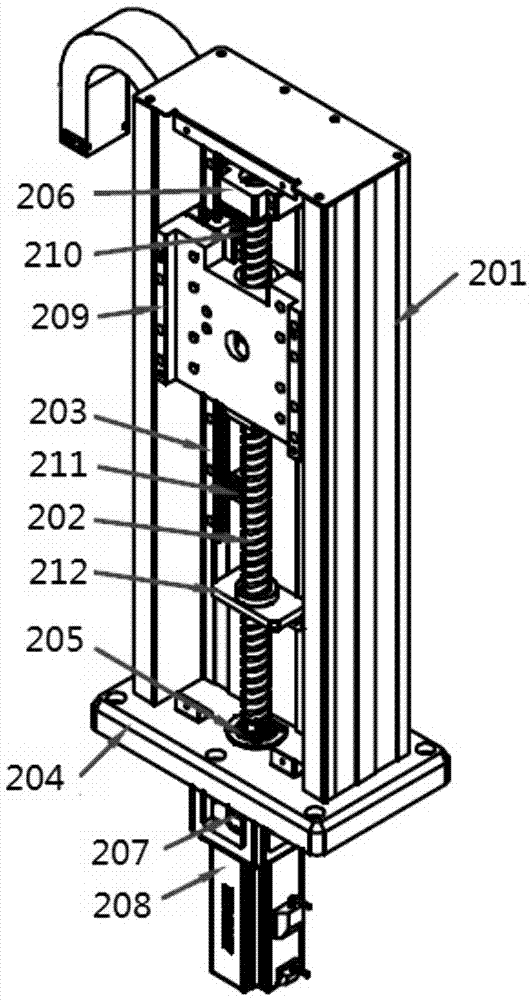

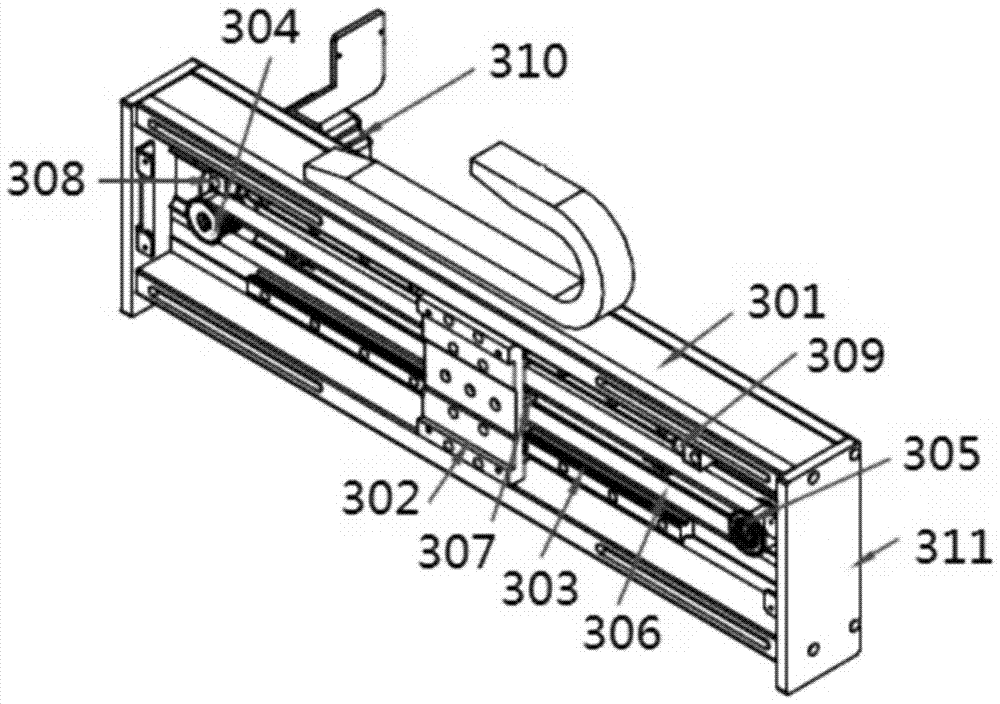

Bottle body automatic screen printing machine

ActiveCN108454224AOutstanding and Beneficial Technical EffectsFast transmissionScreen printersNon-mechanical conveyorsScreen printingUltraviolet

The invention discloses a bottle body automatic screen printing machine. The machine comprises a conveying and loading device, a circular conveying working line and an unloading device; a bottle bodycircular conveying working line comprises the circular conveying working line arranged on a stand; the circular conveying working line comprises an annular guide rail set, a linear motor magnetic suspension motion mechanism and a servo control system; the linear motor magnetic suspension motion mechanism is provided with a mover for circularly moving along annular guide rails; the mover is provided with a bottle body fixture; a screen plate and an ink curing device are arranged beside the linear motor magnetic suspension motion mechanism; a scraper is arranged on the screen plate; the screen plate and the ink curing device are both positioned above a motion trajectory of the bottle body fixture; and the ink curing device is positioned between an ink plate and the unloading device. The machine is precise in repeated positioning, safe, reliable and high in speed, improves the chromatography precision and the printing quality, adopts ultraviolet rays or electronic beams to cur ink on bottle bodies, and is suitable for printing of some glass bottles and cosmetic bottles with complicated shapes.

Owner:台州科迅印刷设备科技有限公司

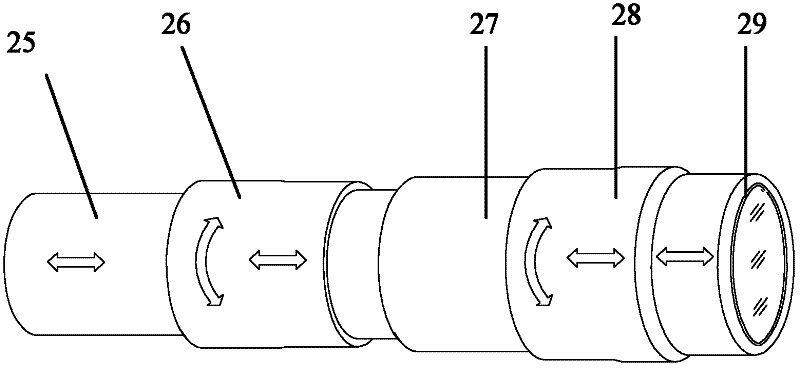

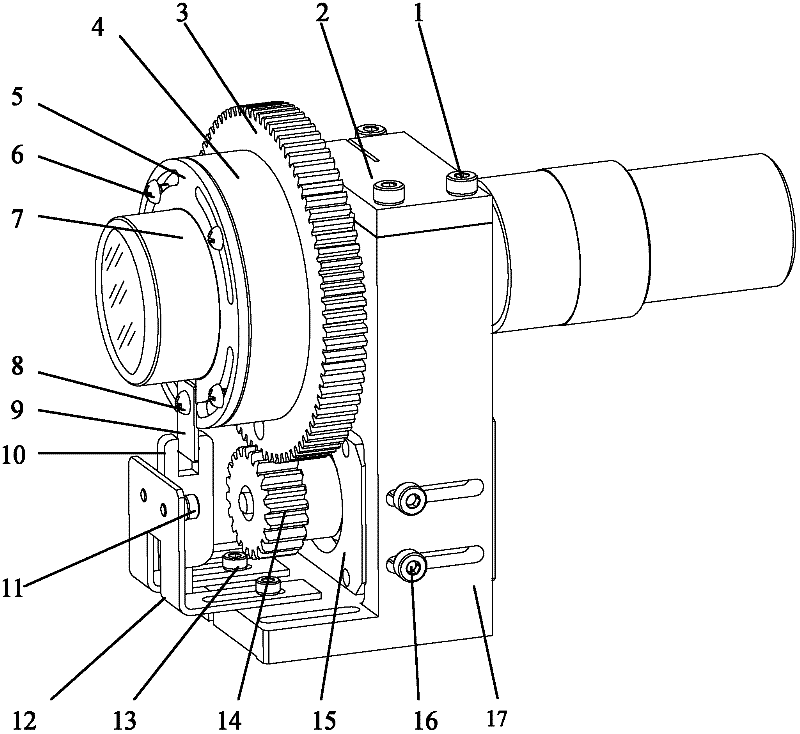

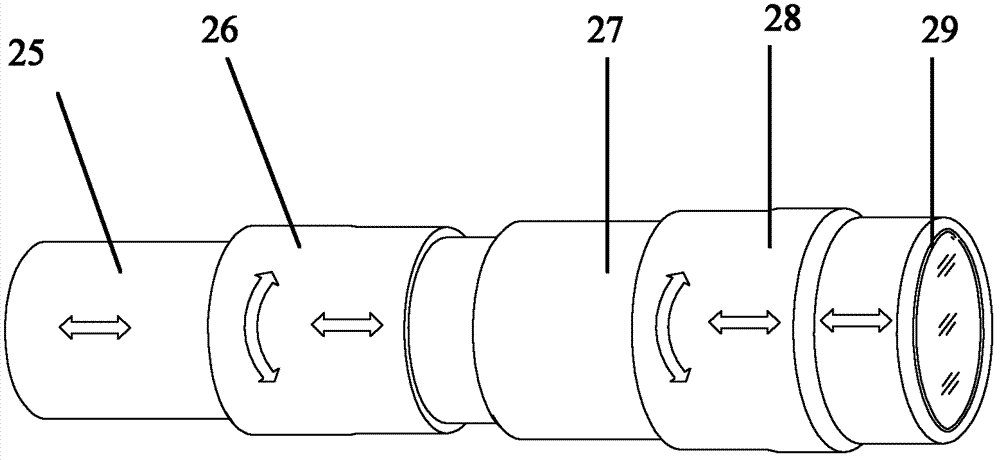

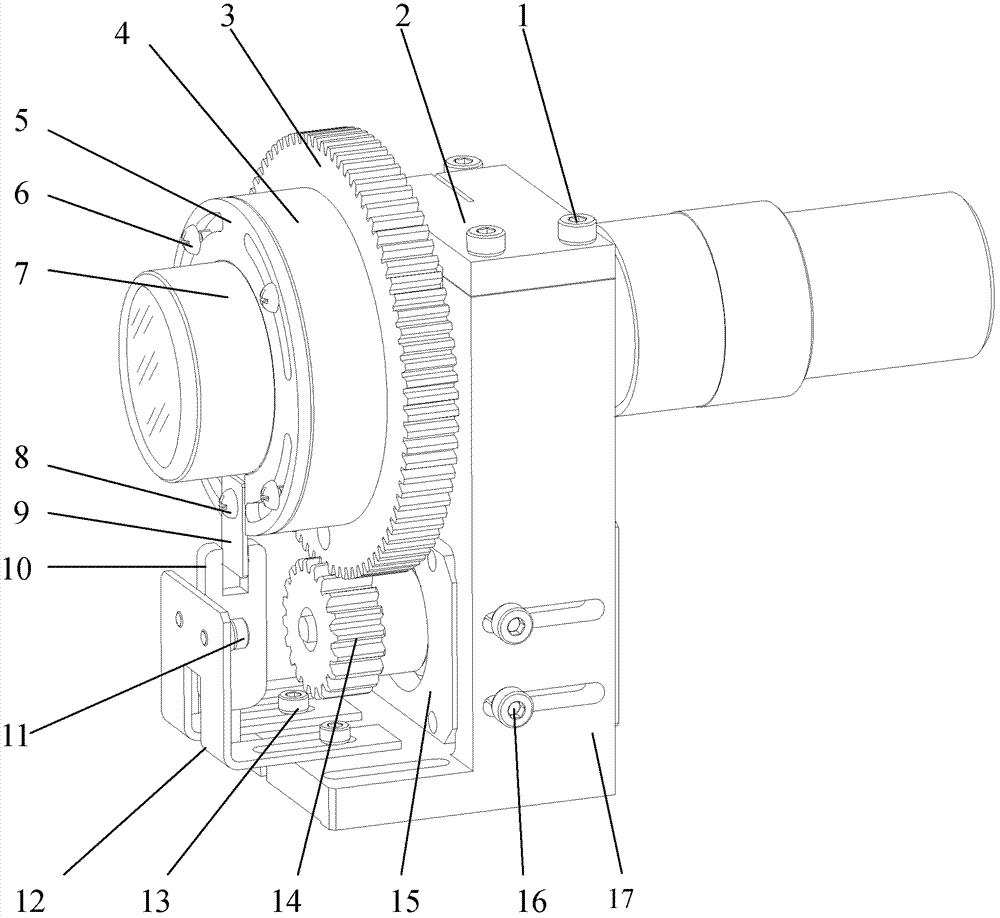

Gear-driven automatic precision focusing mechanism of beam expander

InactiveCN102331613ASave spaceRepeat positioning is accurateMountingsLaser beam welding apparatusPhysicsMotor shaft

The invention discloses a gear-driven automatic precision focusing mechanism of a beam expander. The gear-driven automatic precision focusing mechanism comprises a beam expander main body part and a beam expander seat, wherein a beam expander external fastening part is arranged on the beam expander seat. The gear-driven automatic precision focusing mechanism is characterized in that: a beam expander pressing plate is fastened at the upper end of the beam expander main body part; the beam expander pressing plate is pressed against the beam expander external fastening part from the side upper part; an outer ring of a beam expander rotary fastening sleeve fastens a bull gear; the interior of the beam expander rotary fastening sleeve is in coaxial fastening connection with a beam expander focusing part regulating sleeve; a stepping motor seat is fixed on the beam expander seat; a stepping motor is fixed on the stepping motor seat; a pinion is fixed on a stepping motor shaft; a triggering sheet is fixed on a sleeve fastening pressing ring; the triggering sheet is connected with the beam expander focusing part regulating sleeve; a photoelectric interrupter is fastened on a sensor seat; and the sensor seat is fastened on the beam expander seat. The gear-driven automatic precision focusing mechanism of the beam expander is simple and compact in structure, small in occupation space, accurate in repeated positioning and easy in adjustment and maintenance; and the operating safety environment of a laser operator is greatly improved.

Owner:江苏迈健生物科技发展股份有限公司

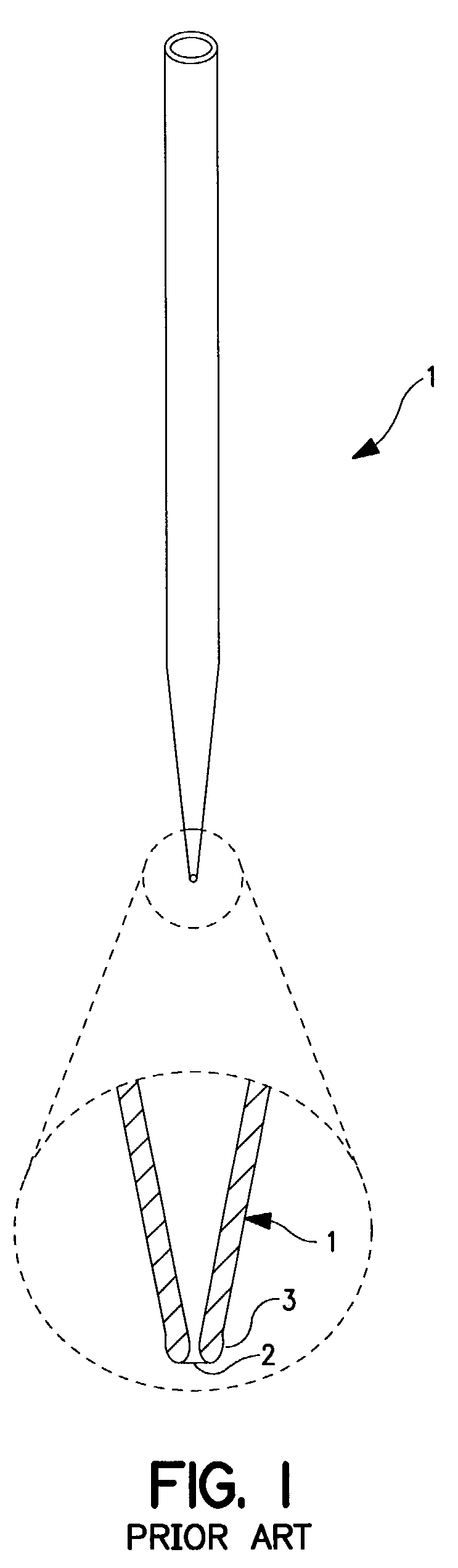

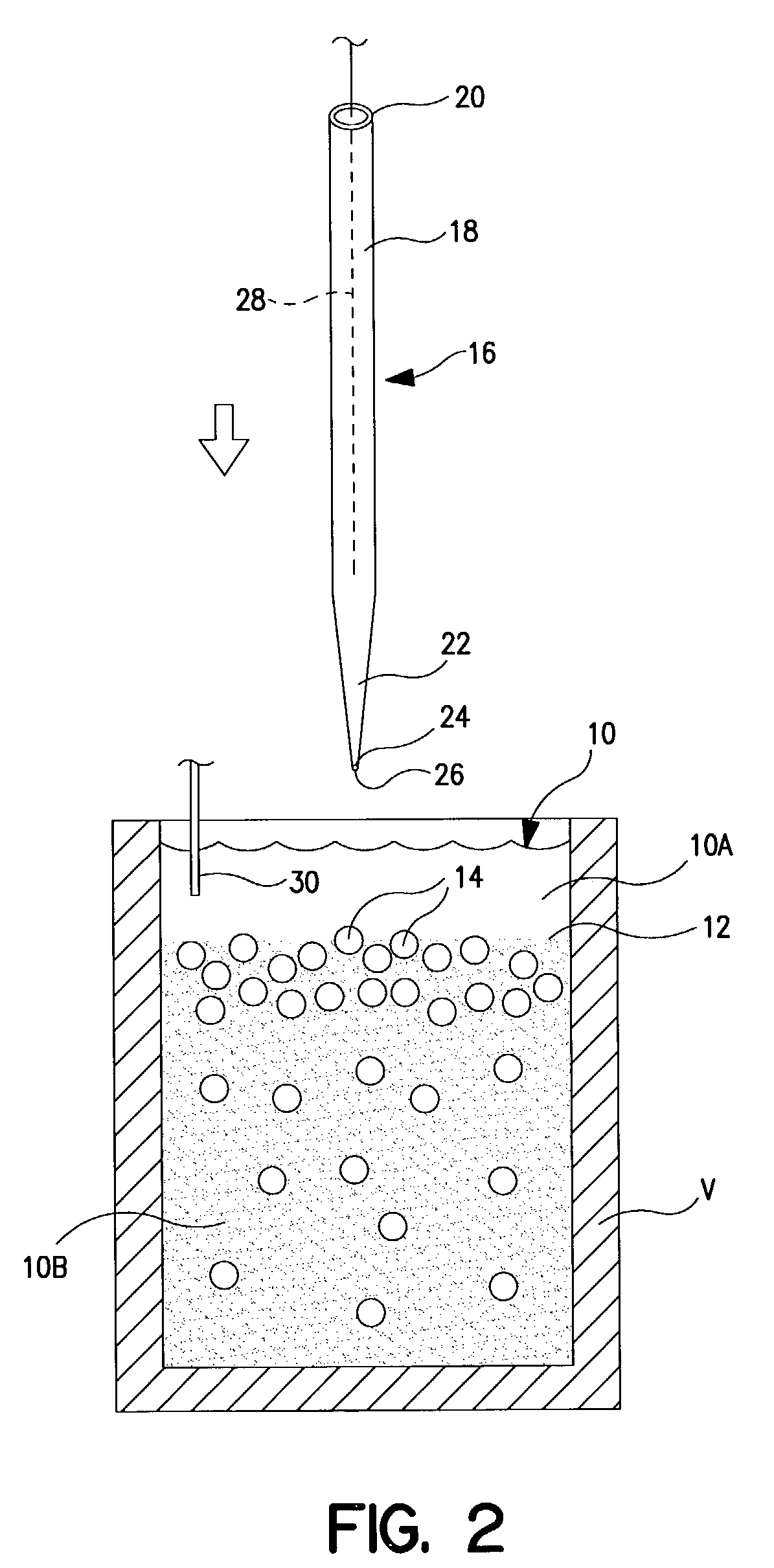

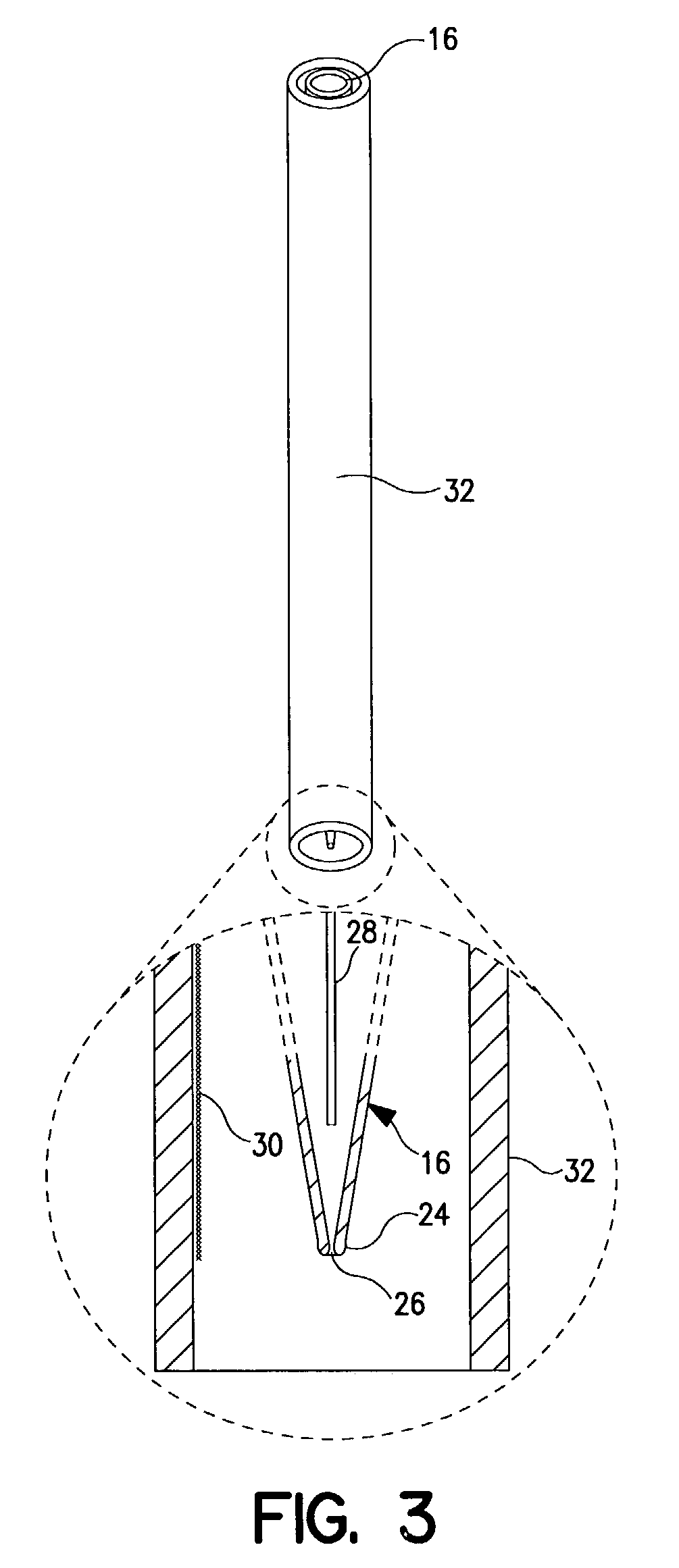

Liquid interface configurations for automated patch clamp recording

InactiveUS7241565B2Repeat positioning is accuratePromoting cell attachmentBioreactor/fermenter combinationsBiological substance pretreatmentsAutomated patch clampLiquid suspension

A method of automatically conducting patch clamp testing is provided wherein a liquid interface is utilized. The liquid interface is defined in a liquid suspension between layers of distinct densities such that cells introduced into the liquid suspension float towards the interface. Thus, the cells are locatable relative to the interface.

Owner:BRISTOL MYERS SQUIBB CO

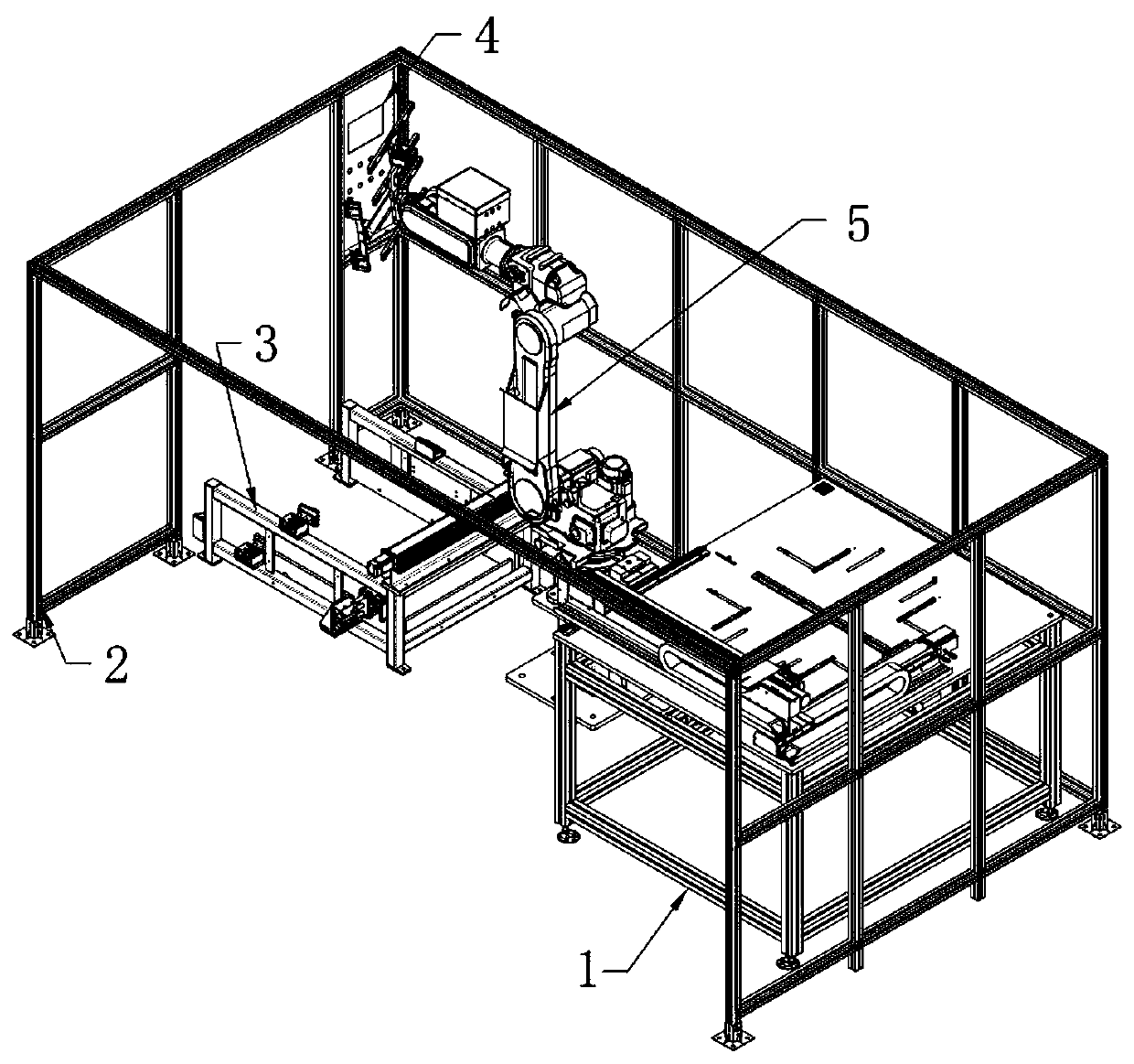

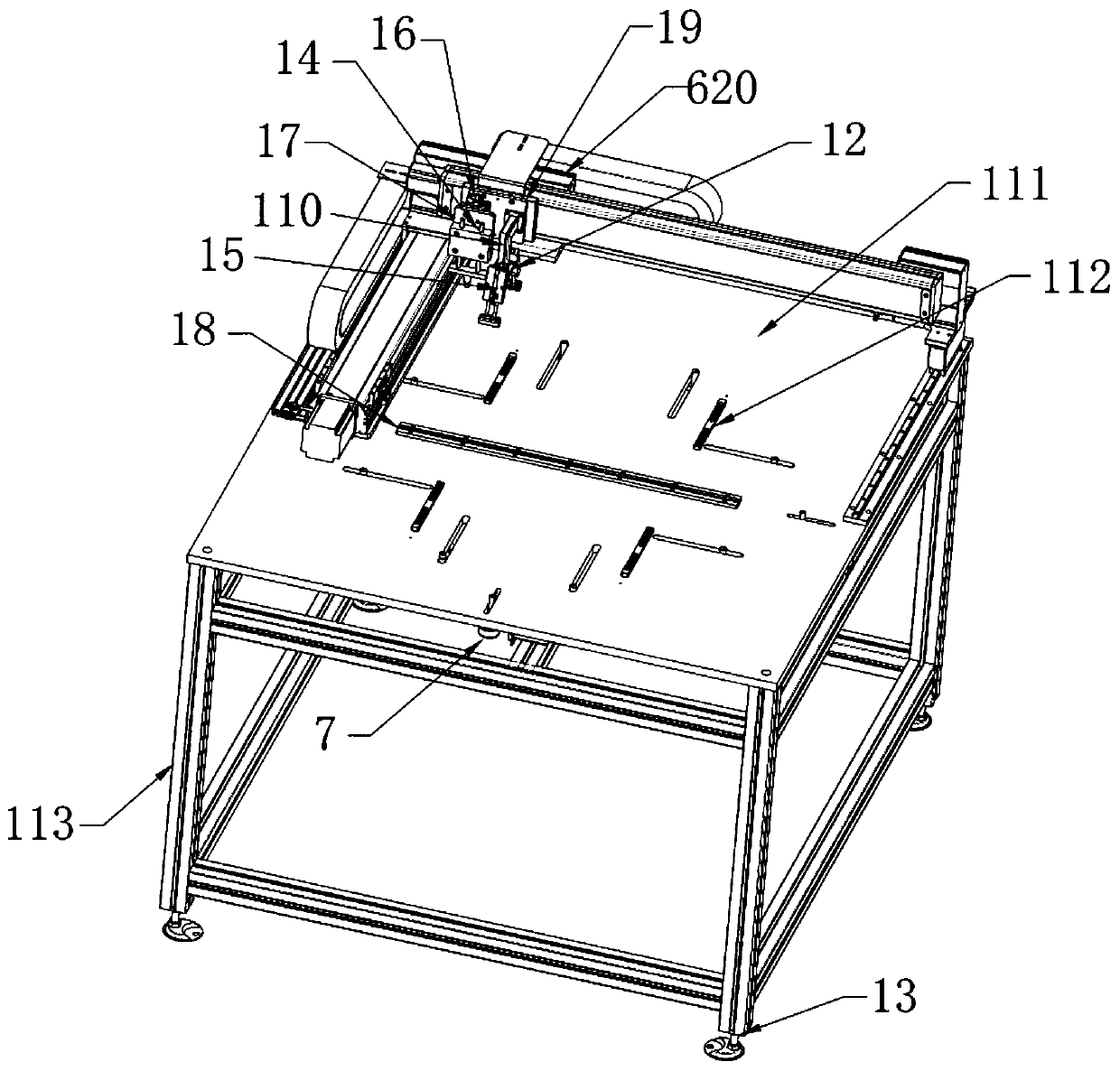

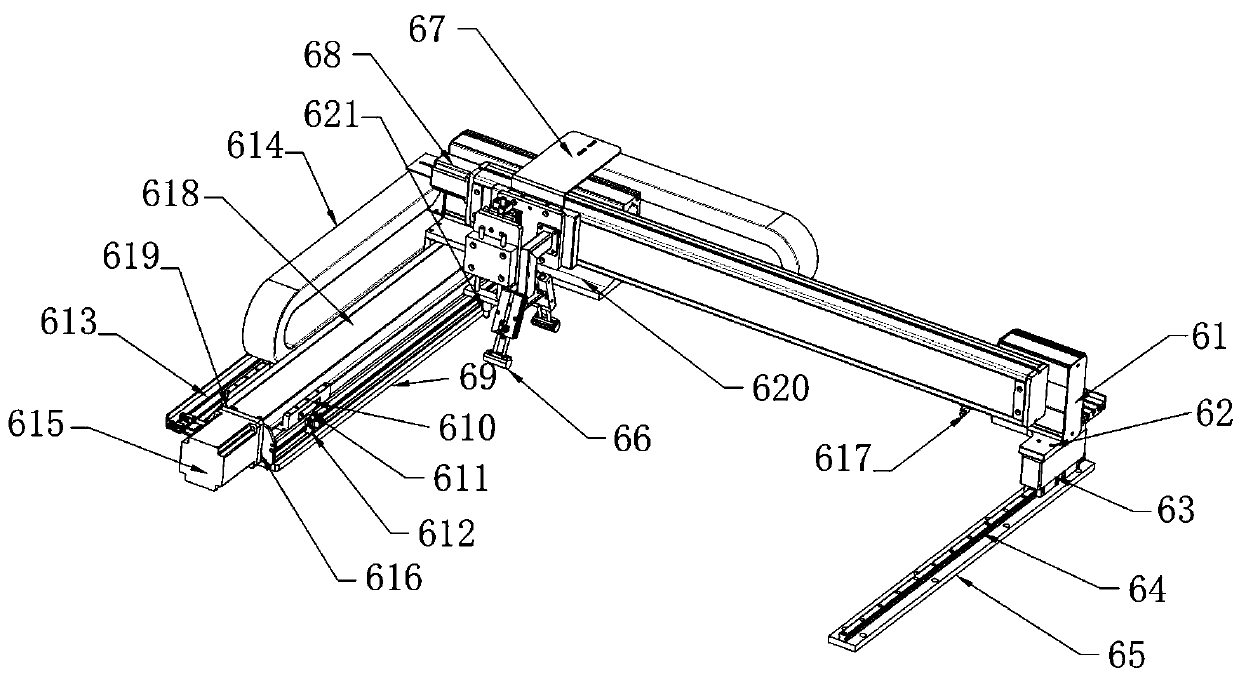

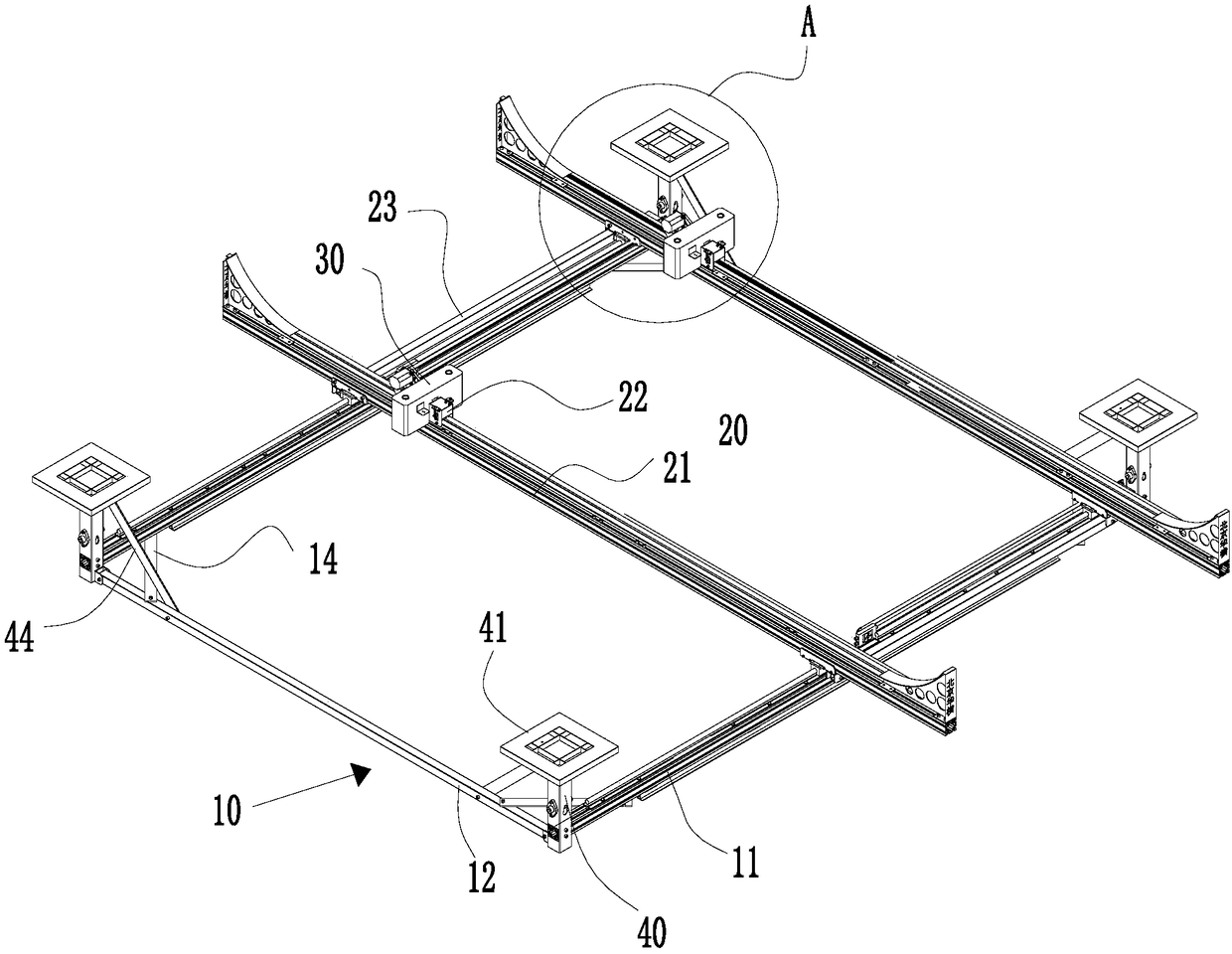

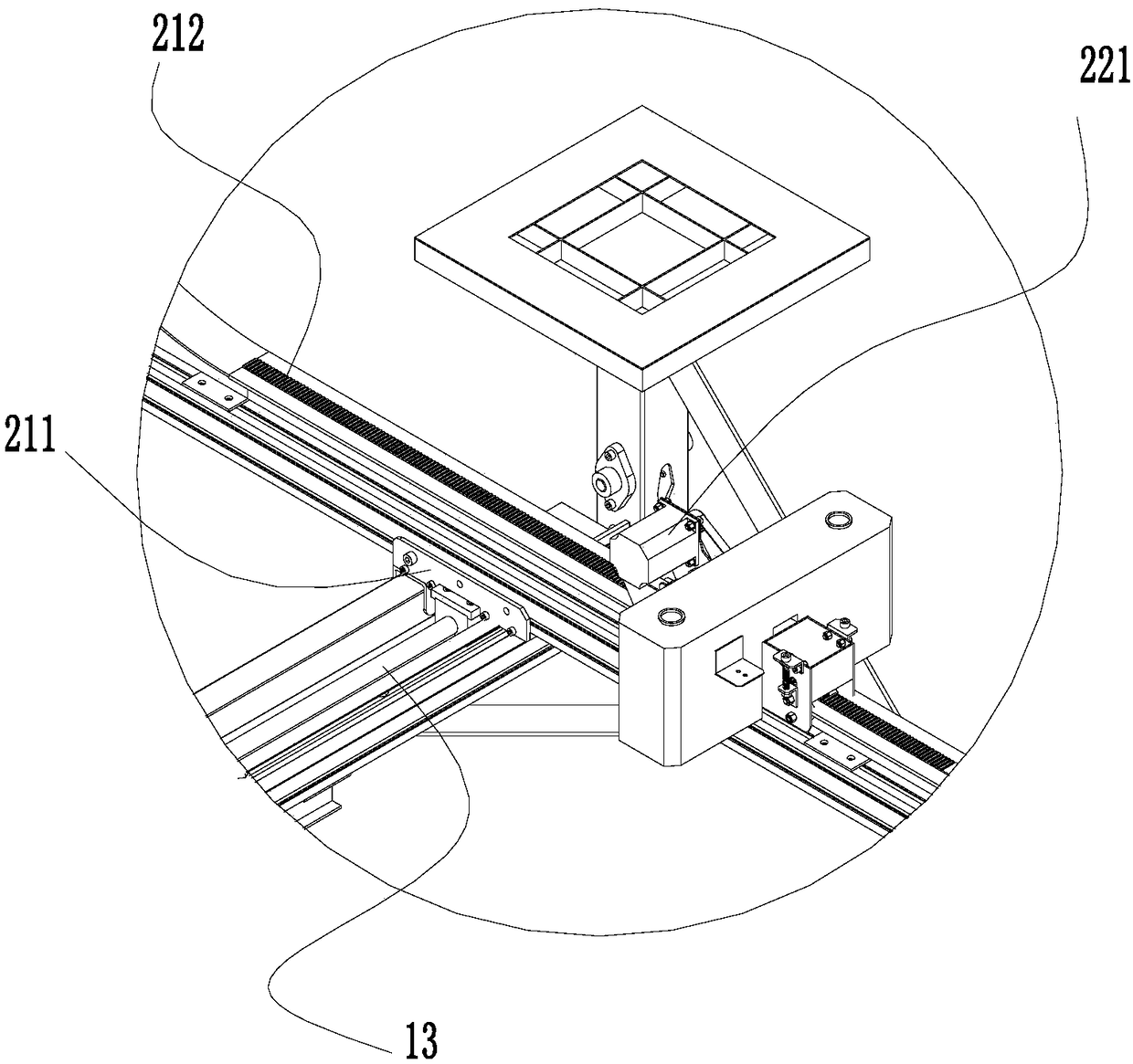

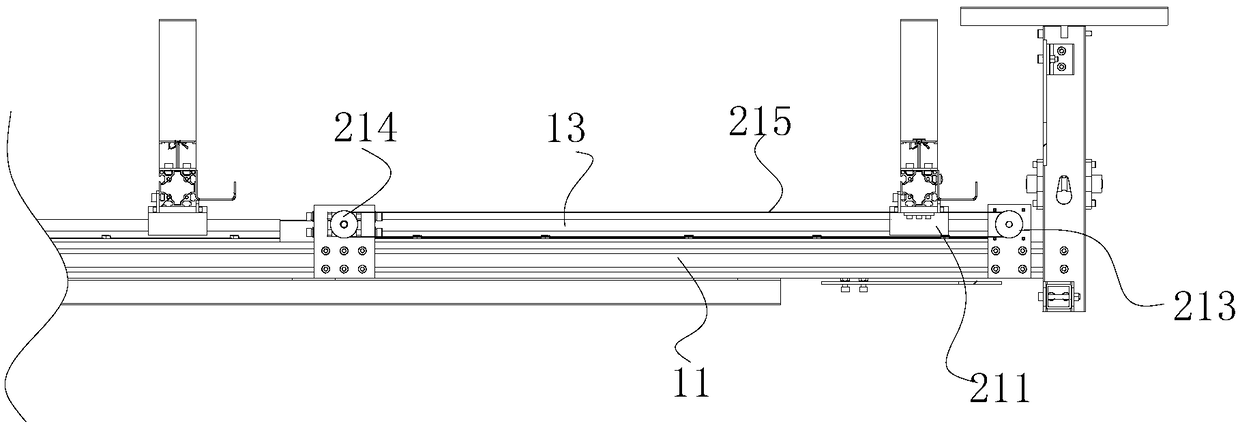

Automatic loading machine with glass cutting function

PendingCN109573612AIncrease flexibilityEasy to transportGlass severing apparatusConveyor partsGeneral assemblyHuman–machine interface

The invention relates to the technical field of glass raw material processing equipment, and discloses an automatic loading machine with a glass cutting function. A cutting table general assembly bodyis integrally mounted on the lower side of the right end portion of an aluminum profile frame, a loading system assembly body is mounted on the lower side of the left end of the aluminum profile frame, a human-machine interface control system is integrally mounted above the left end of the aluminum profile frame, and a robot general assembly body is integrally mounted below the middle portion ofthe aluminum profile frame; a transfer trolley loading manner is adopted, the flexibility is high, transportation is convenient, and repeated use can be achieved; and after positioning is completed, asignal is transmitted to a mechanical hand to take a material, a loading mechanical hand adopts a six-axis mechanical hand, the running speed is high, the precision is high, the sealing performance is good, and the size is small. Suction cup fixtures are composed of vacuum suction cups and clamps which cooperate with each other, the 16 suction cups have strong adsorption force, a cutting mechanism is composed of X, Y and two-axis precision modules and a lifting slide table cylinder to ensure the cutting precision and speed.

Owner:永州市亿达自动化机械有限公司

Bridge crack detecting device

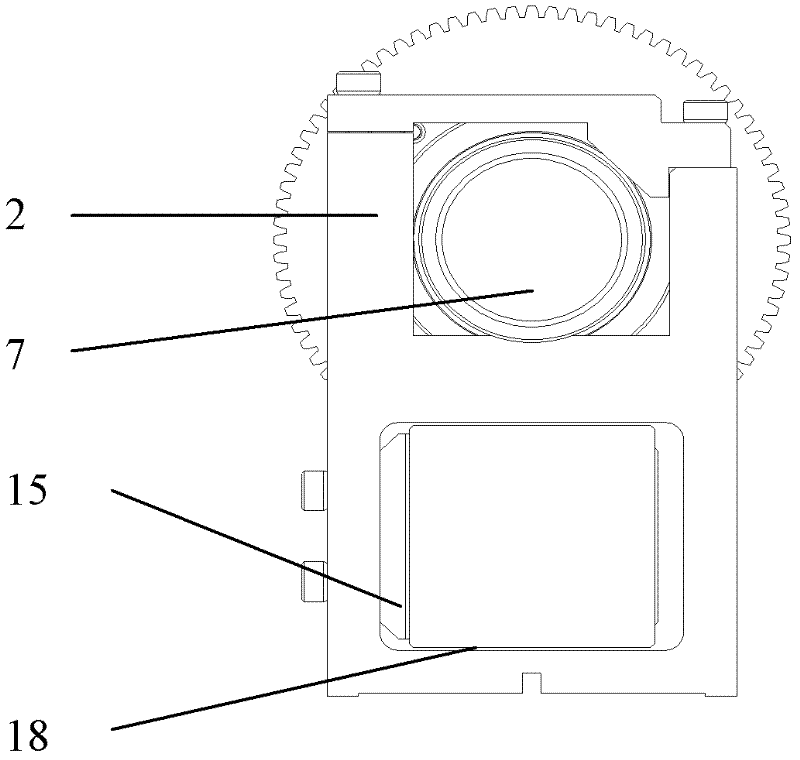

PendingCN108802061AImprove accuracySimple structureOptically investigating flaws/contaminationImage recordingComputer science

The invention discloses a bridge crack detecting device which comprises a support frame, a walking device and an image recording device, wherein the support frame can be detachably mounted on the bottom surface of a bridge; the image recording device is movably disposed on the support frame through the walking device; and the image recording device driven by the walking device is movable in at least one direction on the support frame. The image recording device performs image recording on the bottom surface of the bridge during the movement, and an inspector checks cracks at the bottom of thebridge according to the image recording. The device has the advantages of simple structure, convenient disassembly, high stability, accurate positioning and the like, and is capable of quickly and accurately detecting the cracks at the bottom of the bridge.

Owner:BEIJING HUAHENG NEW TECH DEV

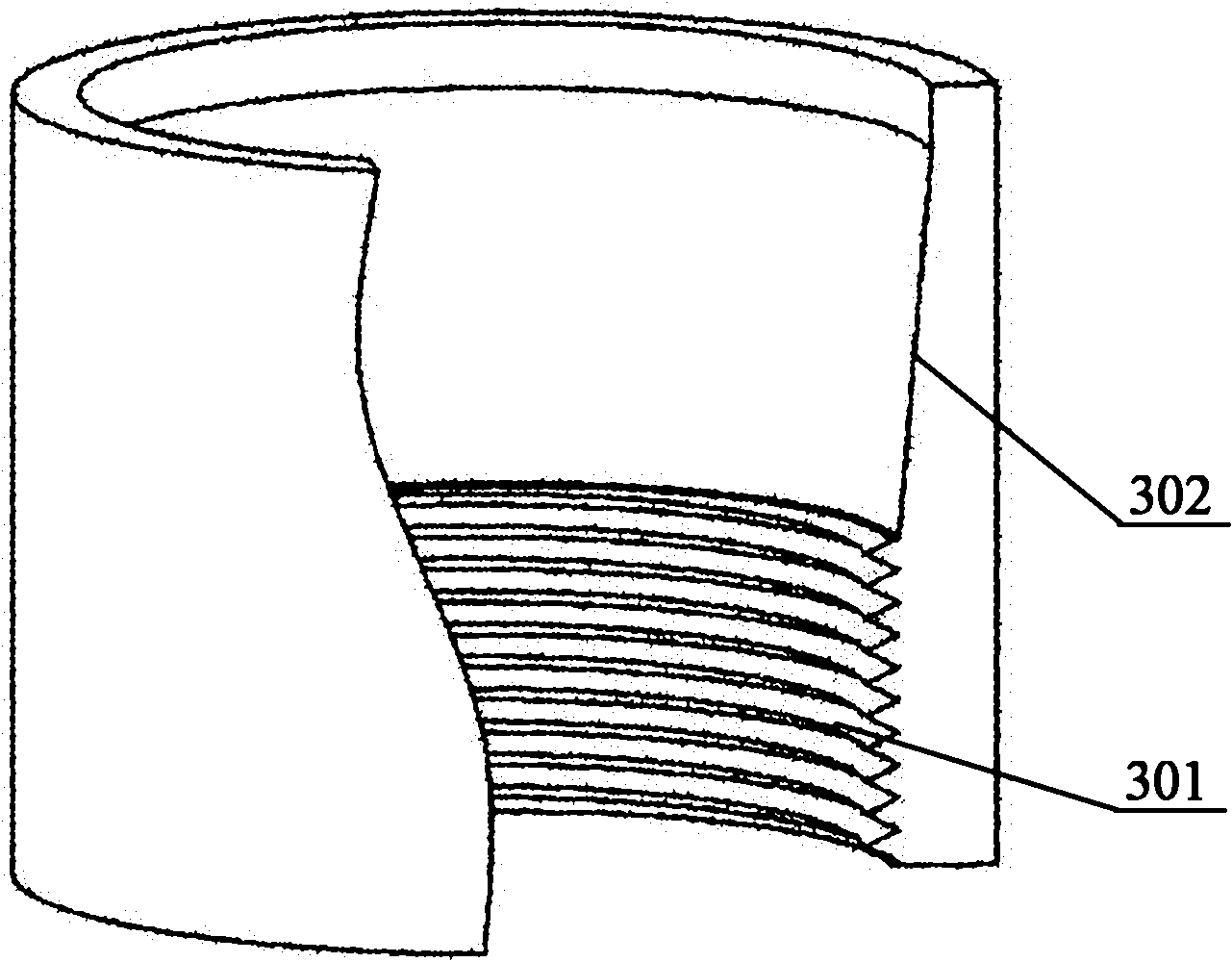

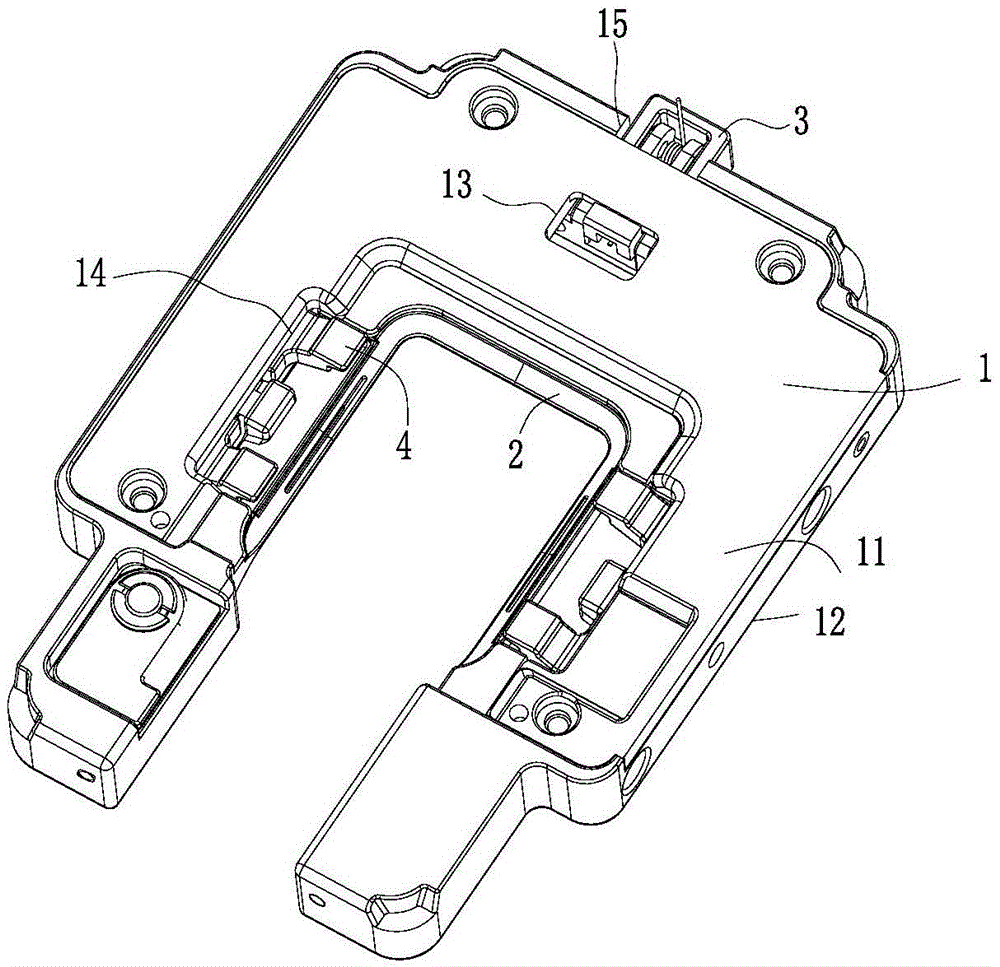

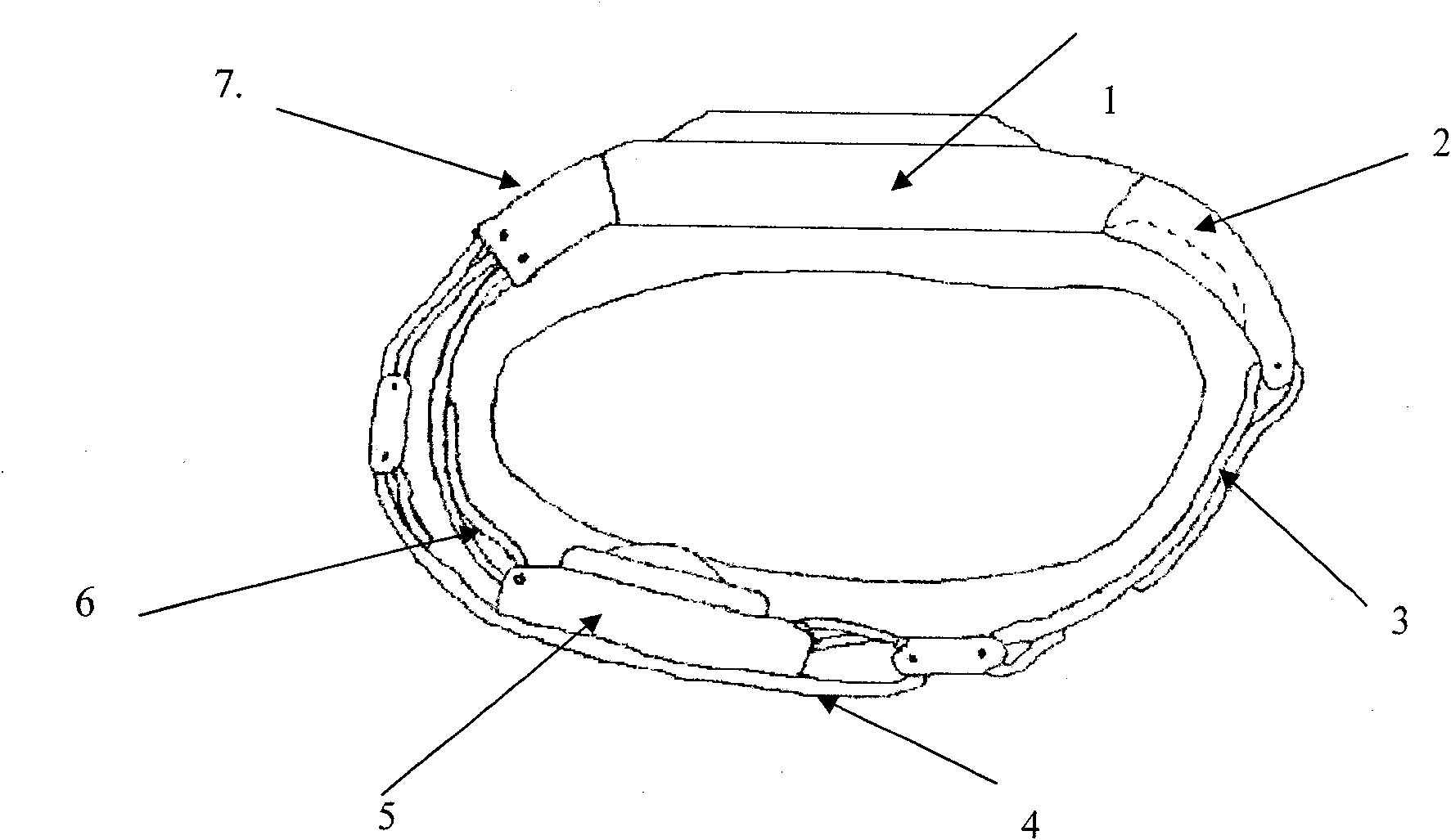

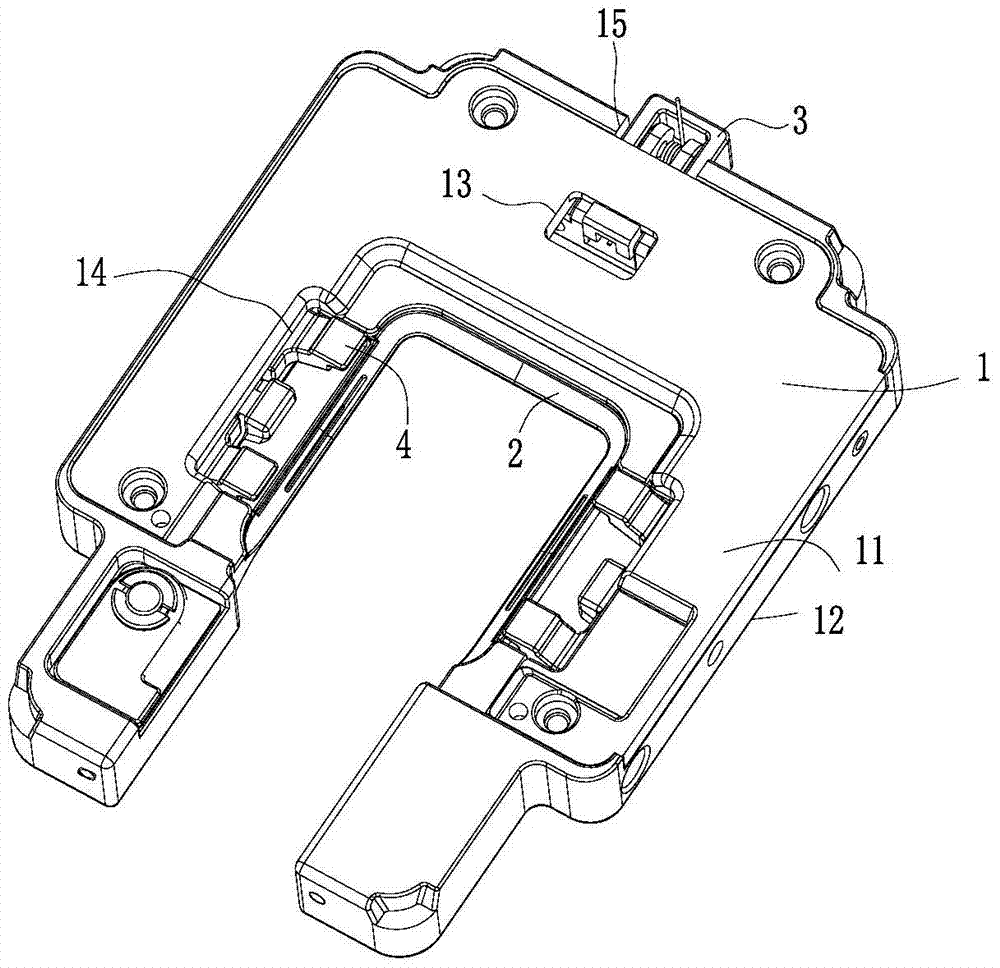

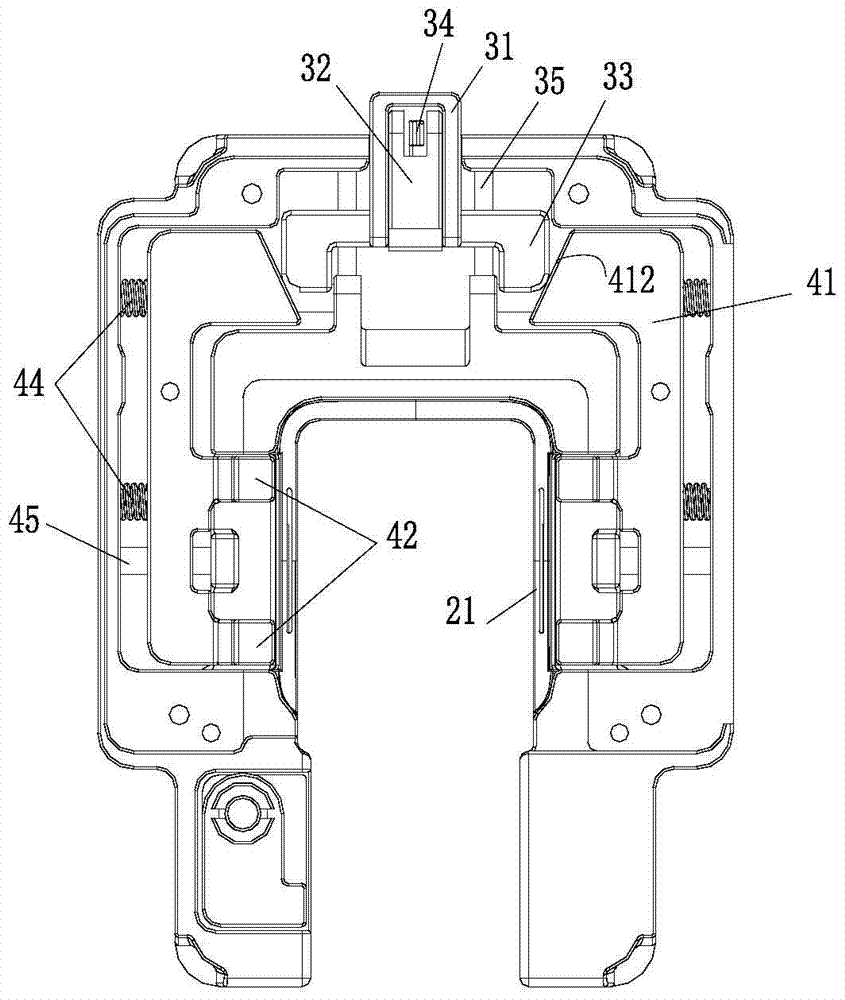

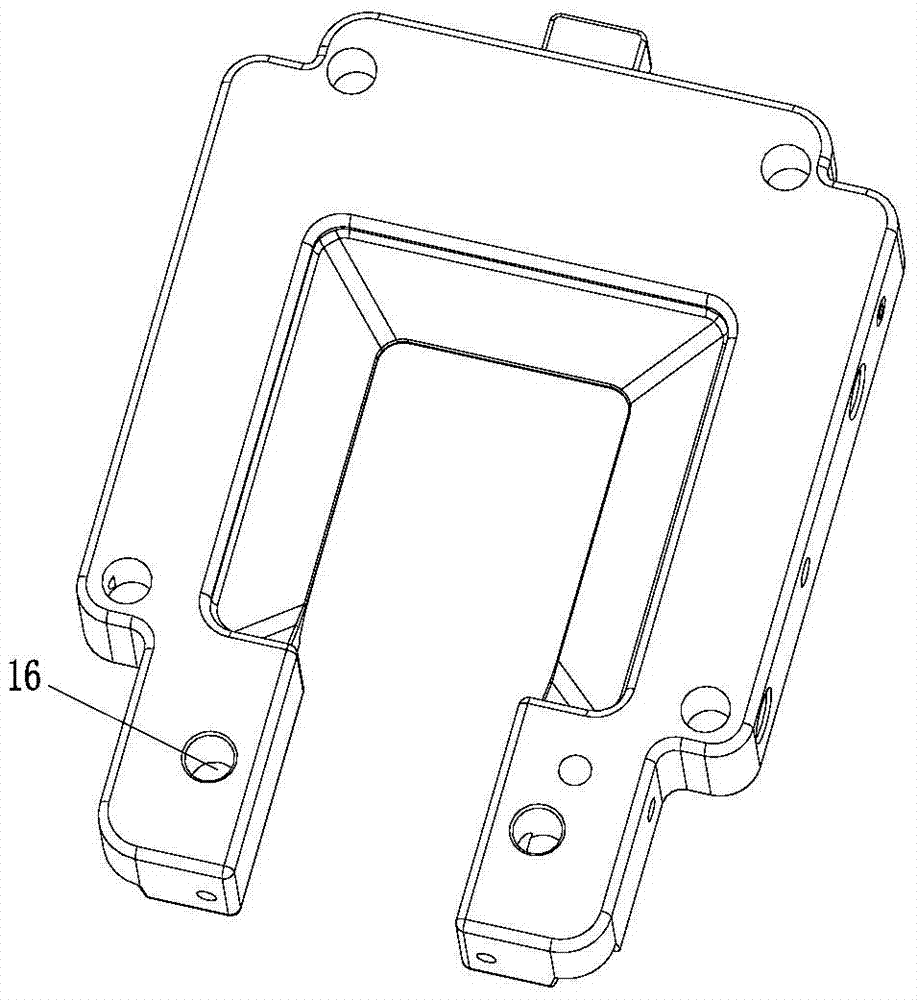

Positioning and clamping mechanism

InactiveCN105458797AGuaranteed flatnessWon't scratchPositioning apparatusMetal-working holdersProduction lineEngineering

The invention discloses a positioning and clamping mechanism. The positioning and clamping mechanism comprises an annular main body of which the interior is provided with a containing space, profiling faces fixed on the inner ring of the main body, a buckle switch assembly which is located in the containing space and partially stretches out of the main body and buckle parts; each buckle part comprises a buckle part main body, buckle claws extending out of the main body from the buckle part main body to the positions above the profiling faces and a buckle resetting part which is located between the main body and the buckle part main body and makes contact with the main body and the buckle part main body, and an oblique face upwards transiting from outside to inside is adopted as the lower surface of each buckle claw; the buckle switch assembly can drive the buckle part main bodies to compress the buckle resetting parts to enable the buckle claws to be far away from the profiling faces; the buckle resetting parts can push the buckle part main bodies to be close to the profiling faces. The positioning and clamping mechanism is applied to an automatic production line of thin products and can accurately position and fix workpieces to be machined and prevent damage to the workpieces due to clamping.

Owner:SHENZHEN ULMT TECH CO LTD

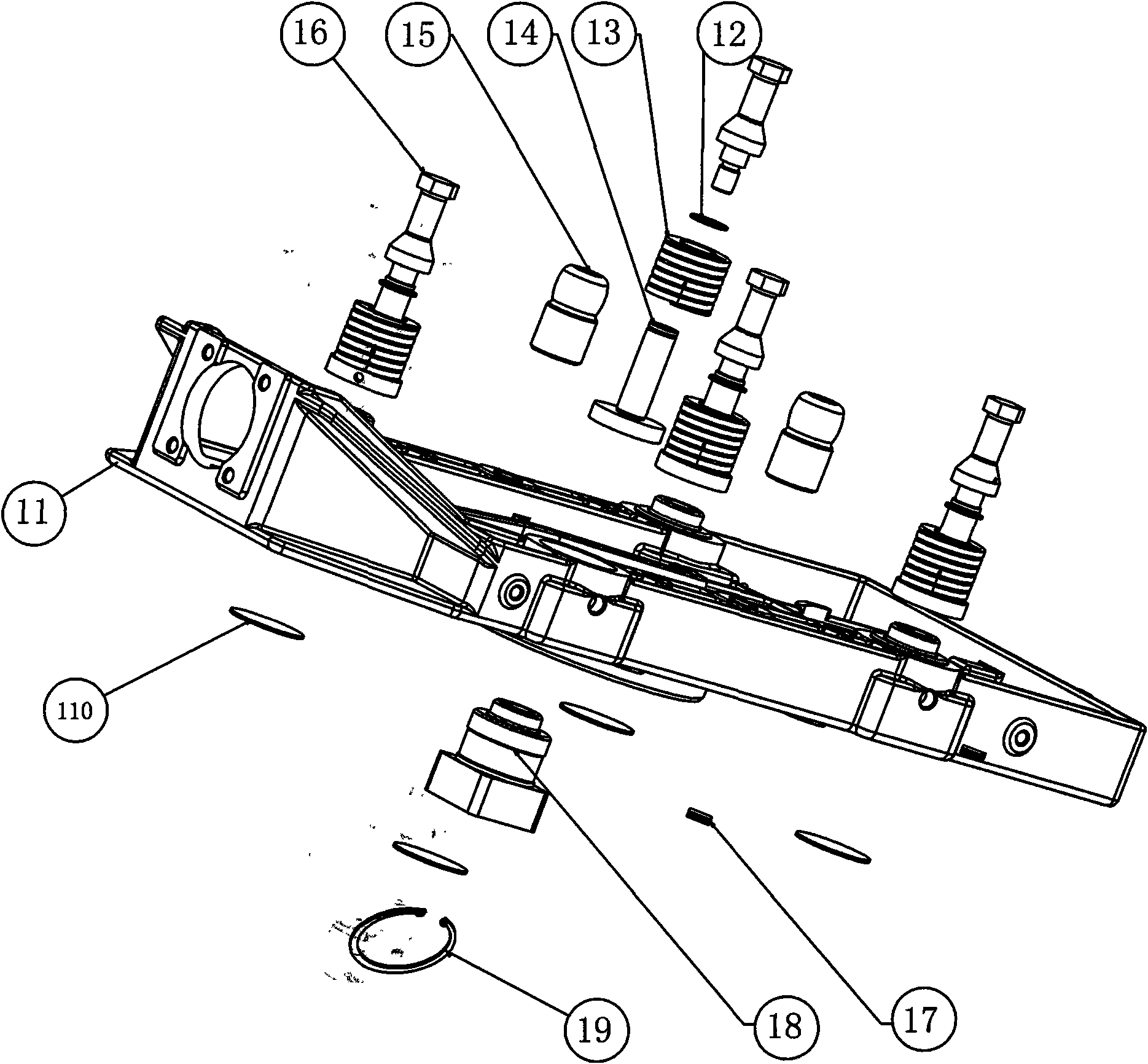

Sliding mechanism controlling ladle molten steel casting flow rate

InactiveCN101569928AEasy to useExtended service lifeMelt-holding vesselsHydraulic cylinderMechanical equipment

The invention relates to smelting mechanical equipment. A sliding mechanism controlling ladle molten steel casting flow rate comprises a main frame, a slide block and a support, wherein the slide block is matched with and slide-mounted in a slide block frame of the support on the lower end of the main frame; frame bodies on two sides of the splicing surface of the main frame and the support are respectively provided with positioning mechanism which are matched with each other; the main frame, the slide block and the support are connected into a whole through elastic tension elements; two sides inside the slide block frame of the support are symmetrically provided with two guide rails respectively; a pulley intermediate steel sheet is arranged in the middle of two guide rails on each side; one corresponding end of the guide rails on two sides is provided with a pulley stopper; after the pulley on the other end of the slide block pushed by a pushing rod of an external hydraulic cylinder drops on the position of the pulley stopper, the pulley on the end is just in the pulley intermediate steel sheet. The pin slide board can be changed and operated conveniently, is better matched with the requirement of ladle continuous casting, improves the safety use coefficient and service life of the sliding mechanism, and is beneficial to new technology of steel-making continuous casting.

Owner:河南省伯马股份有限公司

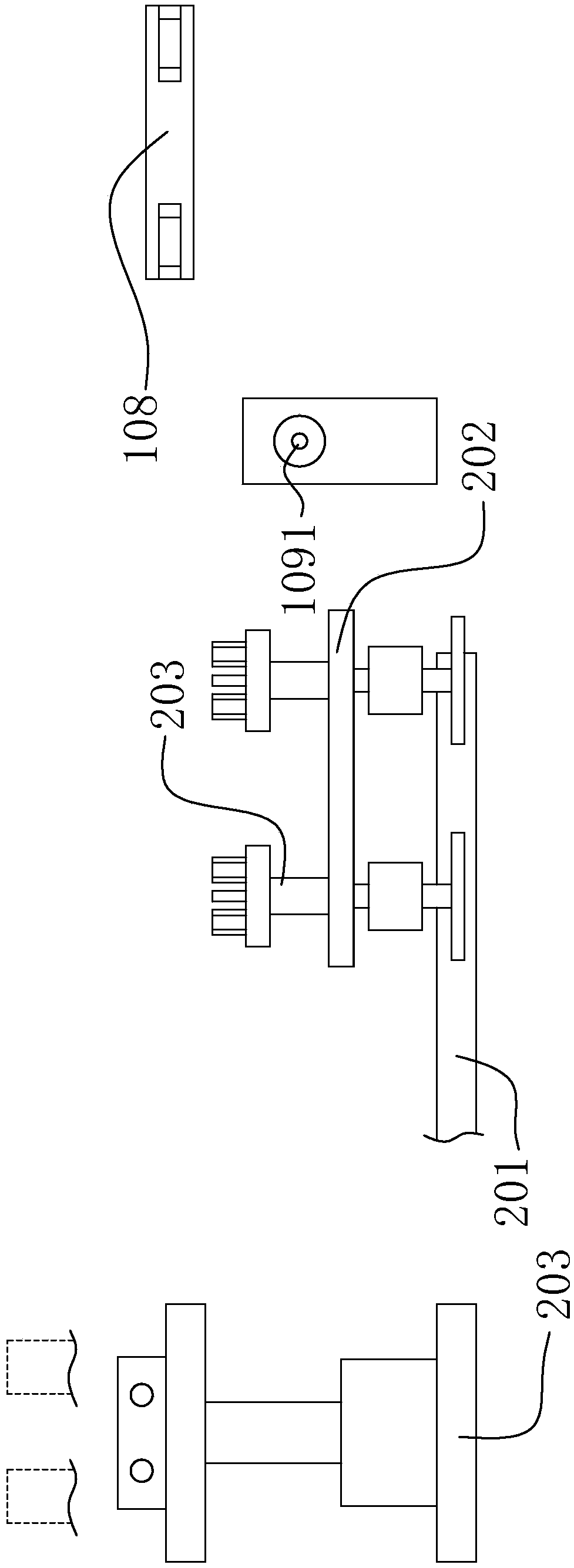

Motor shaft conveying line

InactiveCN108818100ARepeat positioning is accurateQuick clampingManufacturing dynamo-electric machinesMetal working apparatusEngineeringMotor shaft

The invention discloses a motor shaft conveying line. The motor shaft conveying line comprises a shaft grabbing robot, wherein a grabbing tool is arranged on the shaft grabbing robot, a conveying frame is arranged at the left side of the shaft grabbing robot, a conveying guide rail and a centering device are arranged on the conveying frame, and the centering device comprises a location cone and apush cone; and grabbing jaws are arranged on the grabbing tool, a walking device is arranged on the conveying guide rail, a transport lifting plate is arranged on the walking device, radial clamping devices are arranged on the transport lifting plate, double-station numerically-controlled machining equipment is arranged at the front side of the conveying guide rail, a transposing device is arranged at the rear side of the conveying guide rail, and the transposing device comprises two transposing clamps. The two plate transposing clamps form one-to-one correspondence with the two radial clamping devices separately, and the left-right positions of the two plate transposing clamps are not changed in the case that motor shafts are inserted into the radial clamping devices by the plate transposing clamps and in the case that the motor shafts are taken out from the radial clamping devices by the plate transposing clamps; and in this way, accurate repeated location for the plate transposing clamps can be conveniently realized by a simple mechanical structure. The motor shaft conveying line is used for machining for the motor shafts.

Owner:FOSHAN CITY NANHAI POPULA FAN

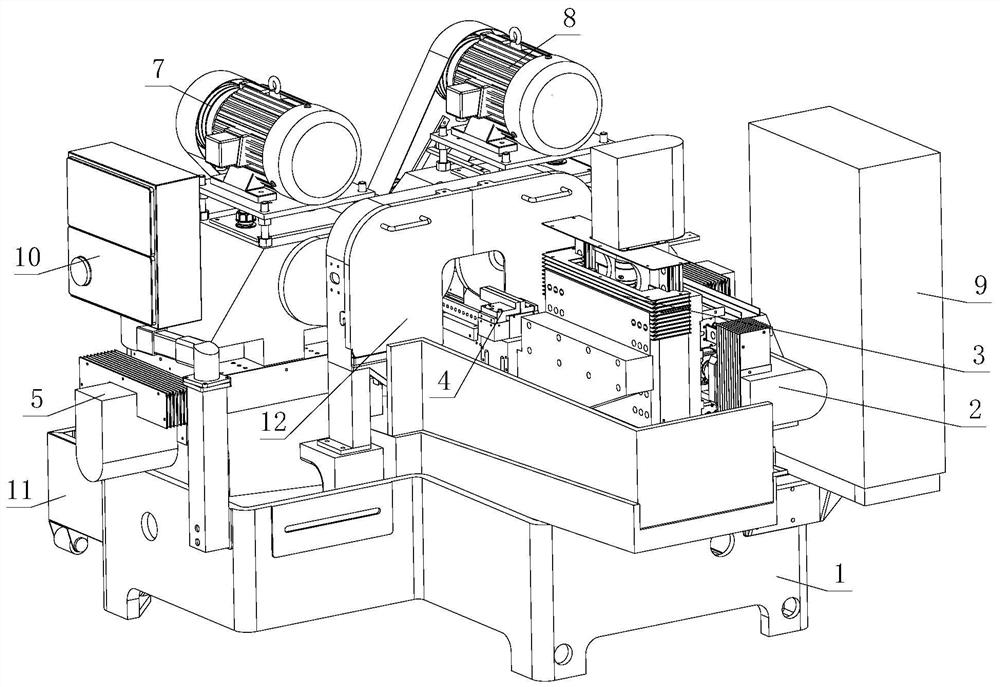

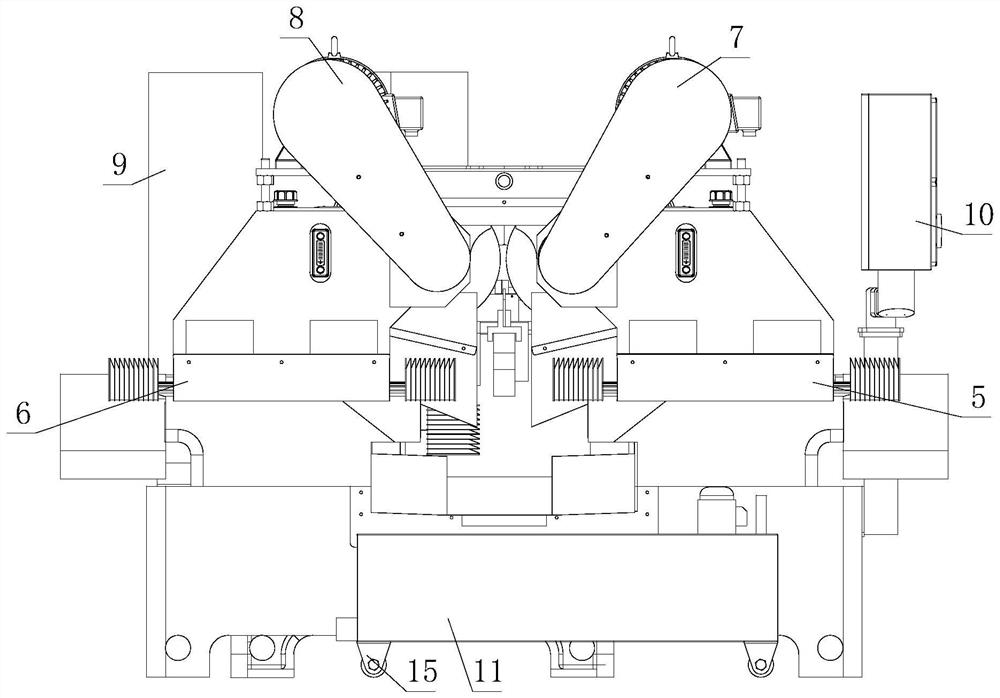

Numerical control double-sided grinding structure

PendingCN113478302AEasy to adjustRepeat positioning is accurateGrinding carriagesOther manufacturing equipments/toolsNumerical controlMachine

The invention discloses a numerical control double-sided grinding structure, and relates to the technical field of hardware cutter and shear machining equipment. The numerical control double-sided grinding structure comprises a lathe bed, an X-axis feeding assembly, a Y-axis feeding assembly, a clamp, a first cutter feeding assembly, a second cutter feeding assembly, a left axle box assembly, a right axle box assembly, an electric box, a numerical control operation panel and a water tank, wherein the X-axis feeding assembly is fixedly installed at the front end of the lathe bed, and the Y-axis feeding assembly is fixedly installed on a sliding table of the X-axis feeding assembly. According to the numerical control double-sided grinding structure, the X-axis feeding assembly and the Y-axis feeding assembly are controlled by a system to operate in a matched linkage mode, double-sided cutting edge track machining of a workpiece is completed under the synchronous feeding of the left axle box assembly and the right axle box assembly, an exquisite arc-shaped curved surface can be machined, the machining track of the workpiece can be conveniently completed, the defects of a traditional machine for manually manufacturing a mold are overcome, two spindle box assemblies are driven by a servo motor, repeated positioning is accurate and stable, action is flexible, the operation is convenient, the application range is wide, and efficiency is high.

Owner:阳江市阳东区国浩机械制造有限公司

Portable semi-automatic grinding and polishing equipment

InactiveCN102756327ADetachableSimple structureLapping machinesWork carriersTest sampleSemi automatic

The invention discloses portable semi-automatic grinding and polishing equipment which is used for carrying out grinding and polishing pretreatment on a test sample. The portable semi-automatic grinding and polishing equipment comprises a mounting base, a fixed device and a turnplate, wherein the turnplate is rotatably arranged on the mounting base, the fixed device consists of a stand, a manual regulating device and a clamping mechanism connected with the manual regulating device, the manual regulating device is arranged on the stand which is detachably arranged on the mounting base, the test sample is fixed by the clamping mechanism, the manual regulating device drives the clamping mechanism to drive the test sample to approach or be away from the turnplate, and the turnplate carries out grinding and polishing pretreatment on the test sample. the portable semi-automatic grinding and polishing equipment is simple in structure, simple and convenient to operate, small in occupied space, safe and stable, and capable of carrying out portable semi-automatic grinding and polishing, improves the test sample preparation efficiency and qualification, and increases the practicability.

Owner:CENT TESTING INT GRP CO LTD

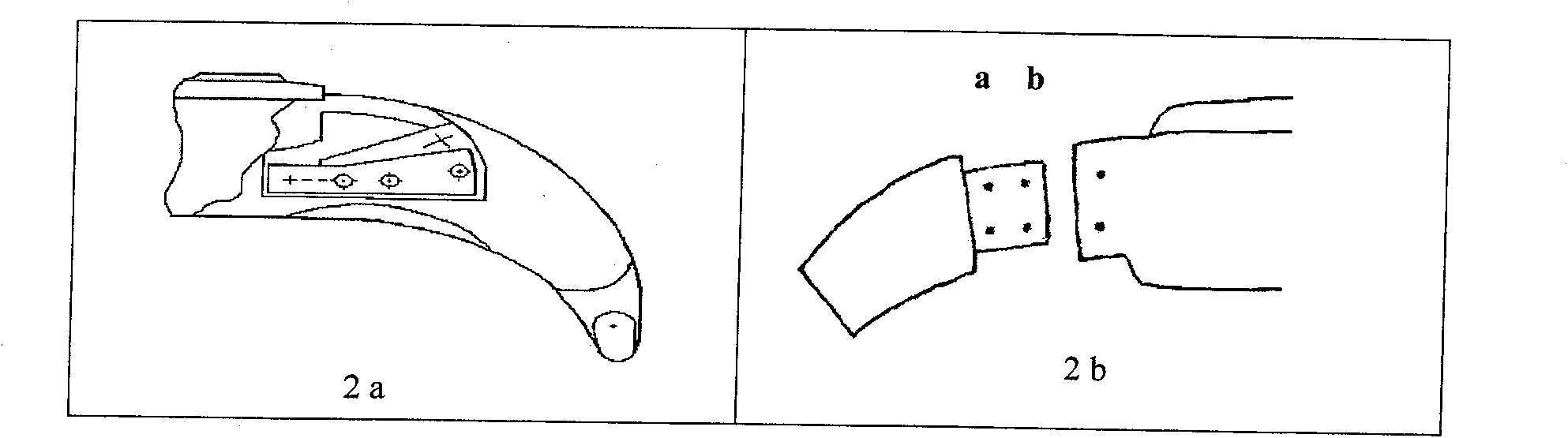

Watch strap human blood pressure non-invasive continuous detection device

InactiveCN100586366CConvenient and comfortable continuous blood pressure measurementEasy to wear and detectEvaluation of blood vesselsAngiographyElectricityHuman body

The invention belongs to general electronic blood pressure measuring apparatuses, aiming at providing a wristlet typed human body blood pressure trauma-free continuous checkout gear for realizing theconvenient and comfortable continuous blood pressure measurement. The technical scheme adopted by the invention is that the wristlet typed human body blood pressure trauma-free continuous checkout gear consists of two parts of a wristwatch and a human body pulse wave checkup gear, and the two parts are connected by a wristlet and an electric signal wire; the human body pulse wave checkup gear consists of a piezoresistive pulse wave sensor and a base of the pulse wave sensor; a pulse wave signal processor unit is attached to the inside of the wristwatch of the wristlet typed human body blood pressure continuous checkout gear; the wristlet consists of a pressing belt of the pulse wave sensor, a sensor location adjustment strip, a length size regulating mass used for regulating the length ofthe wristlet, a camber regulating mass used for regulating the measuring point locating relation between the wristlet and the pulse and a fastening belt. The checkout gear is mainly used for manufacturing blood pressure continuous monitoring and measuring apparatuses.

Owner:胡梦辰

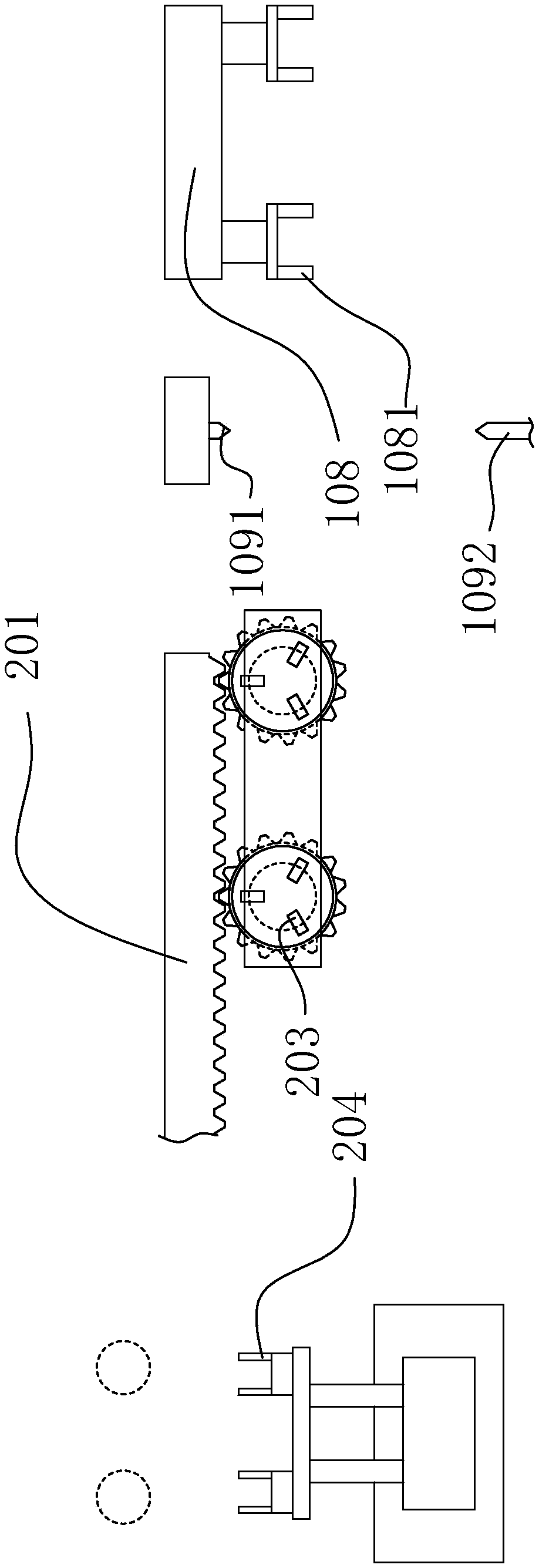

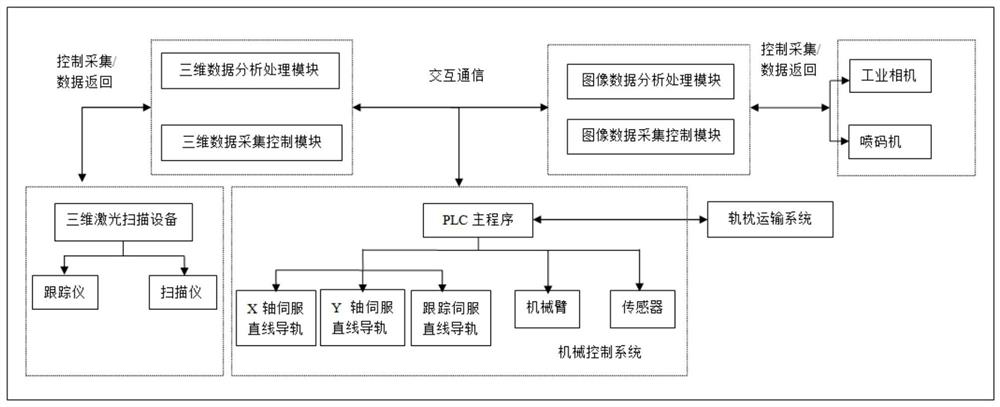

Double-block sleeper appearance quality detection system and method based on machine vision

PendingCN113405472AImprove automationHighly integratedMaterial analysis by optical meansUsing optical meansComputer hardwareTransit system

The invention relates to a double-block sleeper appearance quality detection system based on machine vision. The double-block sleeper appearance quality detection system comprises upper computer software in interactive communication with a PLC main program, a multi-axis servo linear guide rail, a sleeper transportation system and an installation frame. The upper computer software controls a scanner and a tracker through the three-dimensional data acquisition control module and the three-dimensional data analysis processing module, and controls an industrial camera and an ink-jet printer through the image data acquisition control module and the image data analysis processing module. The PLC main program controls the multi-axis servo linear guide rail and the mechanical arm to operate to drive the scanner and the tracker to carry out three-dimensional data acquisition, and the PLC main program is in interactive communication with the sleeper transportation system so that the system is compatible with the production takt of a production line. The invention further comprises a detection method using the system. The multi-index detection task of the sleeper can be completed in a highly automatic, streamlined, collaborative, efficient and high-precision mode, expansibility and universality are achieved, and the method can be applied to streamlined detection of other similar workpieces.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

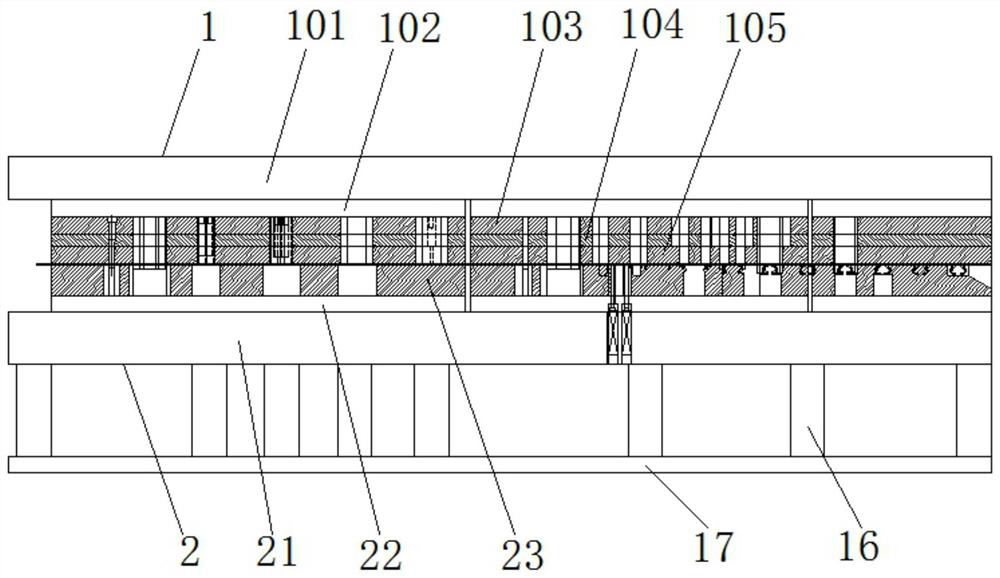

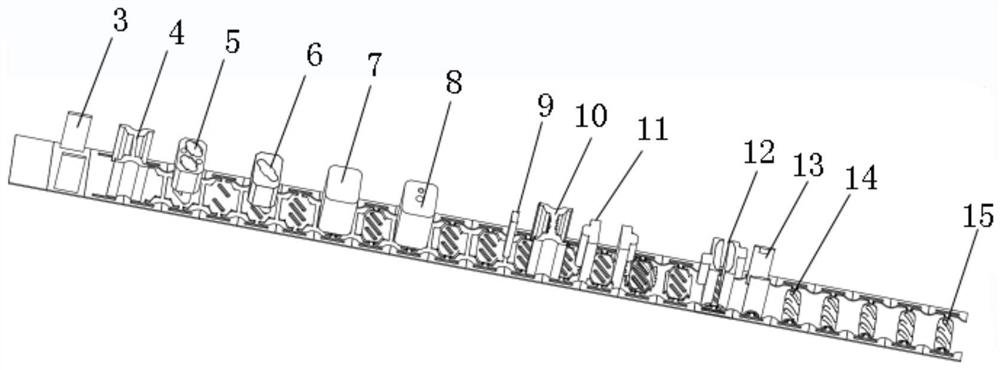

Railcar truck bolster side bearing mounting pad milling machine and method

InactiveUS20070110532A1Precise and repeatable locatingAccurate tolerancePlaning/slotting machinesMilling machinesBogieEngineering

A railcar truck bolster side bearing mounting pad milling machine and method. A milling machine of the present invention includes a pair of milling heads and associated cutters suspended from an overhead frame member. A sliding saddle unit is provided for transporting the bolster into and out of a work envelope of the milling machine. At least one fixturing assembly is attached to the sliding saddle unit to support and fix the position of the bolster in three directions. The bolster is rigidly supported from its underside, thereby eliminating the risk that the bolster may move downward during machining. Since the vertical position of the bolster when presented to the cutters is fixed, thereby the need to raise the bolster into a working position is also eliminated.

Owner:COLUMBUS STEEL CASTINGS

A bottle automatic screen printing machine

ActiveCN108454224BFast transmissionRepeat positioning is accurateScreen printersNon-mechanical conveyorsScreen printingControl system

The invention discloses a bottle body automatic screen printing machine. The machine comprises a conveying and loading device, a circular conveying working line and an unloading device; a bottle bodycircular conveying working line comprises the circular conveying working line arranged on a stand; the circular conveying working line comprises an annular guide rail set, a linear motor magnetic suspension motion mechanism and a servo control system; the linear motor magnetic suspension motion mechanism is provided with a mover for circularly moving along annular guide rails; the mover is provided with a bottle body fixture; a screen plate and an ink curing device are arranged beside the linear motor magnetic suspension motion mechanism; a scraper is arranged on the screen plate; the screen plate and the ink curing device are both positioned above a motion trajectory of the bottle body fixture; and the ink curing device is positioned between an ink plate and the unloading device. The machine is precise in repeated positioning, safe, reliable and high in speed, improves the chromatography precision and the printing quality, adopts ultraviolet rays or electronic beams to cur ink on bottle bodies, and is suitable for printing of some glass bottles and cosmetic bottles with complicated shapes.

Owner:台州科迅印刷设备科技有限公司

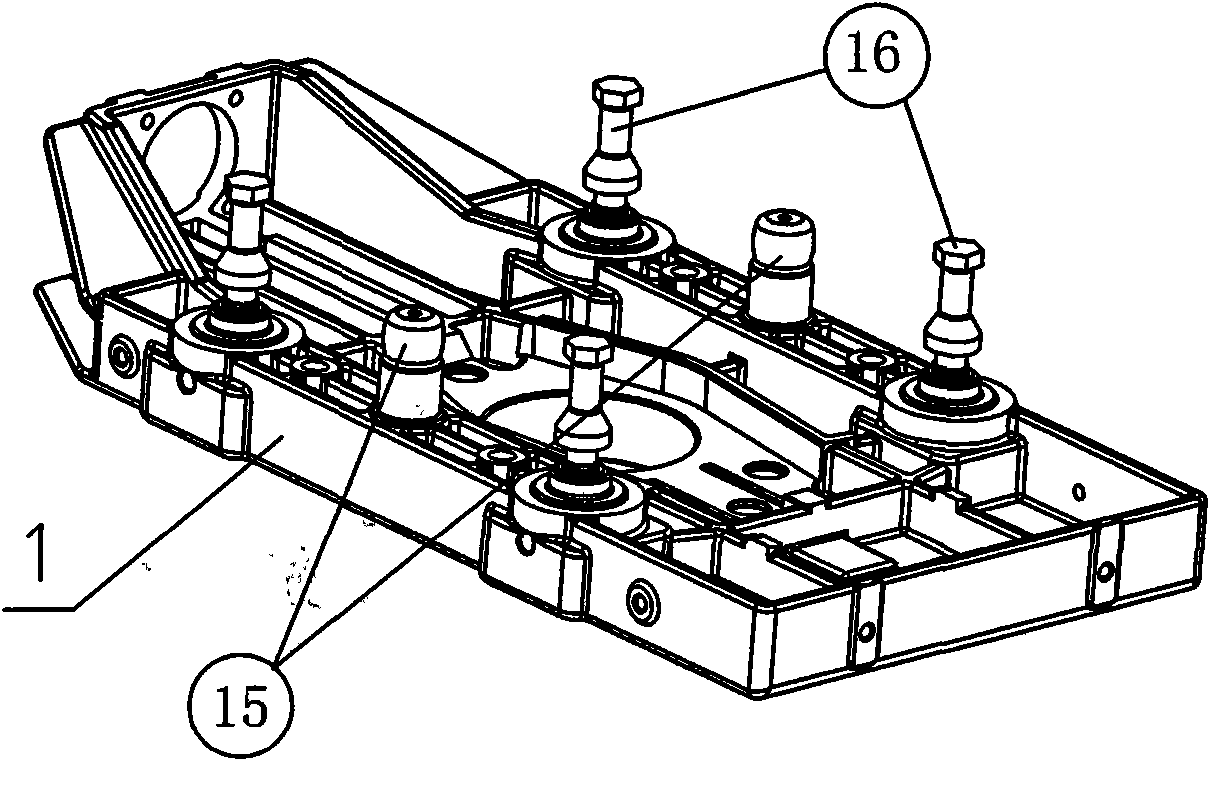

Base plate loading table for brake shoe welding and loading steps thereof

InactiveCN108581285AAvoid direct contactSave human effortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBrake shoe

The invention discloses a base plate loading table for brake shoe welding and loading steps thereof. The base plate loading table for brake shoe welding comprises a loading table body and a loading station; the loading table body is provided with a stacking groove; a slide rail is arranged above the stacking groove; a cross beam is erected on the slide rail; a lifting cylinder is arranged on the cross beam; the bottom of the lifting cylinder is connected with an absorbing mechanism; a front-back cylinder is on the outer side of the slide rail; the lifting cylinder drives the absorbing mechanism to move in the vertical direction; the front-back cylinder pushes the cross beam and the lifting cylinder to move in the direction of the slide rail, so that the lifting cylinder is aligned to the stacking groove or the loading station; and a positioning cylinder is arranged in the loading station. The loading table is mated with a robot automatic welding line, realizes whole system automatic production, improves the production efficiency, prevents manual operation uncertainty, saves the production cost to a certain extent, improves the working stability, and eliminates potential safety hazards.

Owner:GUANGDONG LXD ROBOTICS CO LTD

Hydraulic clamp side plate adjusting mechanism

The invention discloses a hydraulic clamp side plate adjusting mechanism, and belongs to the technical field of refrigerator foaming molds. The hydraulic clamp side plate adjusting mechanism comprises two side plates arranged in the vertical direction, horizontally placed sliding seats, motor mounting bases for mounting and fixing motors, servo motors mounted on the motor mounting bases, and shaft couplers connected with the servo motors, wherein the other ends of the shaft couplers are connected to trapezoidal lead screws; the trapezoidal lead screws are connected with the side plates through the sliding seats and perform driving adjustment; the servo motors output and drive synchronous pulleys; the speed transmission between the synchronous pulleys is performed by synchronous belts and adjusted by tensioning wheels; the synchronous pulleys, the synchronous belts and the tensioning wheels ensure that the front and rear points on the side plates are in synchronous displacement. The hydraulic clamp side plate adjusting mechanism disclosed by the invention has the following advantages: 1. the hydraulic clamp side plate adjusting mechanism is simple in structure, convenient to mount and free of repeated debugging; 2. the adjusting mechanism is driven by the servo motors, free of manual intervention, quick in adjustment and accurate in resetting; 3. the adjusting mechanism is adjusted by the trapezoidal lead screws and large in torque and people do not need to worry about that the load of the motor is too high; 4. the synchronous belts are used for transmission, so that the noise is low.

Owner:ANHUI XINMENG EQUIP CO LTD

Gear-driven automatic precision focusing mechanism of beam expander

InactiveCN102331613BSave spaceRepeat positioning is accurateMountingsLaser beam welding apparatusBeam expanderGear drive

The invention discloses a gear-driven automatic precision focusing mechanism of a beam expander. The gear-driven automatic precision focusing mechanism comprises a beam expander main body part and a beam expander seat, wherein a beam expander external fastening part is arranged on the beam expander seat. The gear-driven automatic precision focusing mechanism is characterized in that: a beam expander pressing plate is fastened at the upper end of the beam expander main body part; the beam expander pressing plate is pressed against the beam expander external fastening part from the side upper part; an outer ring of a beam expander rotary fastening sleeve fastens a bull gear; the interior of the beam expander rotary fastening sleeve is in coaxial fastening connection with a beam expander focusing part regulating sleeve; a stepping motor seat is fixed on the beam expander seat; a stepping motor is fixed on the stepping motor seat; a pinion is fixed on a stepping motor shaft; a triggering sheet is fixed on a sleeve fastening pressing ring; the triggering sheet is connected with the beam expander focusing part regulating sleeve; a photoelectric interrupter is fastened on a sensor seat; and the sensor seat is fastened on the beam expander seat. The gear-driven automatic precision focusing mechanism of the beam expander is simple and compact in structure, small in occupation space, accurate in repeated positioning and easy in adjustment and maintenance; and the operating safety environment of a laser operator is greatly improved.

Owner:江苏迈健生物科技发展股份有限公司

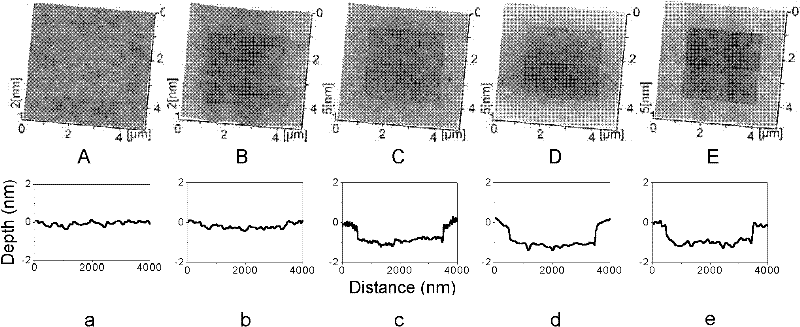

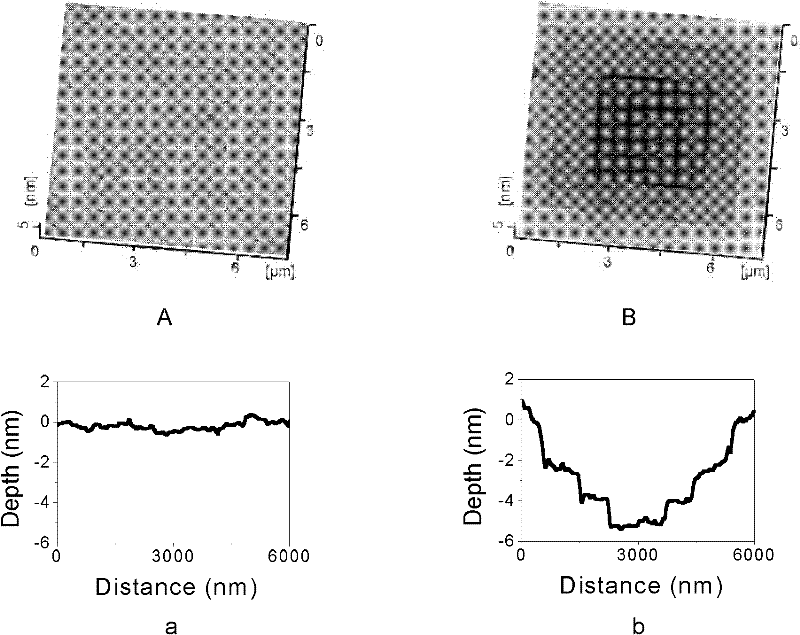

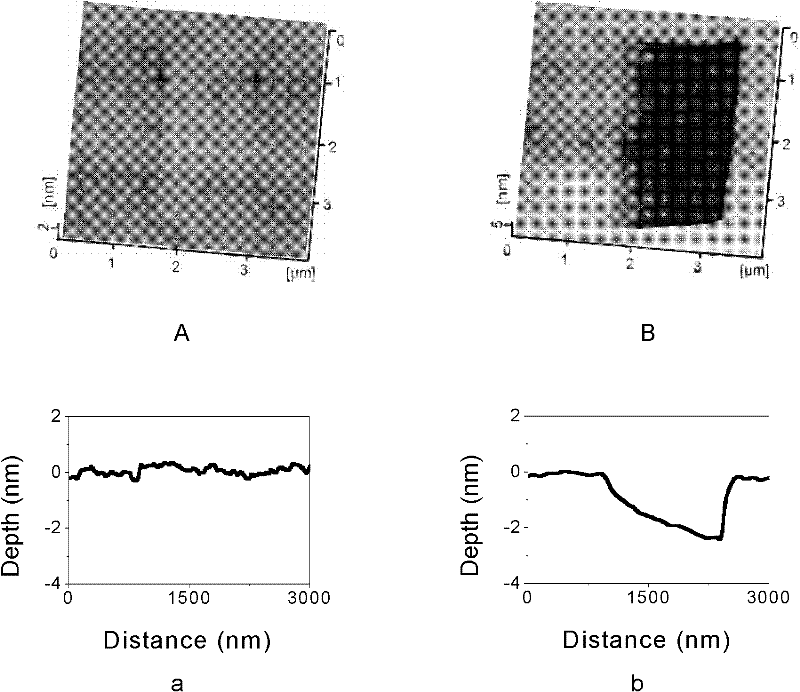

Friction induction-based single crystal quartz surface selective etching method

InactiveCN101973507BAvoid damageReduce wearDecorative surface effectsChemical vapor deposition coatingConstant loadTime critical

The invention discloses a friction induction-based single crystal quartz surface selective etching method. The method comprises the following steps of: arranging a probe with ball coronary tip on an atomic force microscope, fixing single crystal quartz on a sample platform, starting the atomic force microscope, and applying constant load F or variable load F' to the probe, wherein the value of the F or the variable range of the F' is 0.03 to 0.14 times critical load Fy of yield on the quartz surface; performing scanning on the surface of the single crystal quartz along the set track and cycletimes by the probe; and after scanning, corroding the single crystal quartz for over 2.5 hours by using 15 to 25 percent KOH solution. The method can effectively perform nano processing by combining scanning under extremely low load and subsequent corrosion, does not need a mask or repeated corrosion, and can process a multistage nano structure. The method does not damage or pollute the structureand the surface outside the processed area, and is a simple, accurate and clean nano quartz processing method.

Owner:SOUTHWEST JIAOTONG UNIV

Continuous forging and pressing die for safety belt guide ring

PendingCN112828226AImprove yield rateImprove production efficiencyShaping toolsForging/hammering/pressing machinesStructural engineeringManufacturing engineering

The invention discloses a continuous forging and pressing die for a safety belt guide ring. The continuous forging and pressing die comprises an upper die and a lower die, wherein the upper die is provided with punches, a die cavity corresponding to the punch is formed in the lower die, the punches comprise a first trimming punch, a second trimming punch, an outer groove forging and pressing punch, an intermediate groove forging and pressing punch, a first outer ring forging and pressing punch, a second outer ring forging and pressing punch, a third trimming punch, a fourth trimming punch, a bending punch, a first forming punch, a second forming punch, a shaping punch and a cutting punch which are sequentially arranged. According to the continuous forging and pressing die, two processes of forging and stamping are combined to be completed in one set of die, the manufacturing efficiency can be obviously improved, repeated positioning is accurate, friction and abrasion are reduced, and the part yield is improved.

Owner:竹田(无锡)汽配制造有限公司

positioning clamping mechanism

InactiveCN105458797BGuaranteed flatnessWon't scratchPositioning apparatusMetal-working holdersProduction lineEngineering

Owner:SHENZHEN ULMT TECH CO LTD

Automatic detection and automatic unloading sorting wire mesh machine

ActiveCN105172338BRun fastReduce noiseScreen printersPrinting press partsHuman–machine interfaceControl system

The invention discloses an automatic detection and automatic unloading and sorting wire mesh machine, which includes a frame, which is equipped with a man-machine interface control system, an image detection system, a lifting column assembly, a CCD lens assembly, a turntable workbench, and a blanking machine. The manipulator and foot switch, the lifting column assembly is provided with a beam that can move up and down along the lifting column assembly, the lifting column assembly is equipped with a lifting towline, the beam is equipped with a lifting towline buckle, and the lifting towline is connected to the lifting towline buckle , There are adjustable and fixed left net arm and right net arm on the crossbeam, there is a printing seat that can slide left and right along the crossbeam between the left net arm and the right net arm, there is a printing seat drag chain on the crossbeam, and a printing seat is set on the printing seat. There is a drag chain buckle of the printing seat, the drag chain of the printing seat is connected with the drag chain buckle of the printing seat, the image detection system is electrically connected with the CCD lens assembly, the turntable table is set on the CCD lens assembly, the unloading manipulator, the left mesh arm and the right mesh arm below.

Owner:广东恒锦智能装备有限公司

Multi-station tire gripper indexing device and its indexing method for tire spraying machine

ActiveCN103846200BSimple structureShorten spray cycleLiquid surface applicatorsSpraying apparatusSprayerCoupling

The invention discloses a multi-station tyre gripper rotating device of a tyre spraying coater and a rotating manner thereof. The device comprises a multi-station tyre gripper component, a vertical center rotating shaft component, a rotating drive component and a dual-node metal diaphragm coupler. The multi-station tyre gripper component forms a rib-shaped structure by no less than three groups of tyre grippers and corresponding connecting cross arms and connecting arm supports. The rib-shaped structure is fixedly connected to the upper part of the vertical center rotating shaft. The lower end of the vertical center rotating shaft is connected to the rotating drive component including a cam divider through the dual-node metal diaphragm coupler. When the device rotates, a vertical output end of the cam divider drives a vertical shaft connected to the vertical output end, and the multi-station tyre gripper component to rotate by driving a horizontal input end of the cam divider through a gear motor, so as to achieve actions of simultaneously rotating of the multi-station tyre grippers. The multi-station tyre gripper rotating device is simple in structure, high in rotating efficiency, and accurate to position; and the grippers and the connecting cross arms are simply installed and conveniently adjusted.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com