Double-block sleeper appearance quality detection system and method based on machine vision

A technology of machine vision and appearance quality, which is applied in the high-precision appearance and dimension detection of double-block sleepers in high-speed railways, and in the field of double-block sleeper appearance quality inspection systems based on machine vision, which can solve the problem that the detection accuracy cannot fully meet the size detection error requirements, Problems such as low detection efficiency and failure to meet detection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

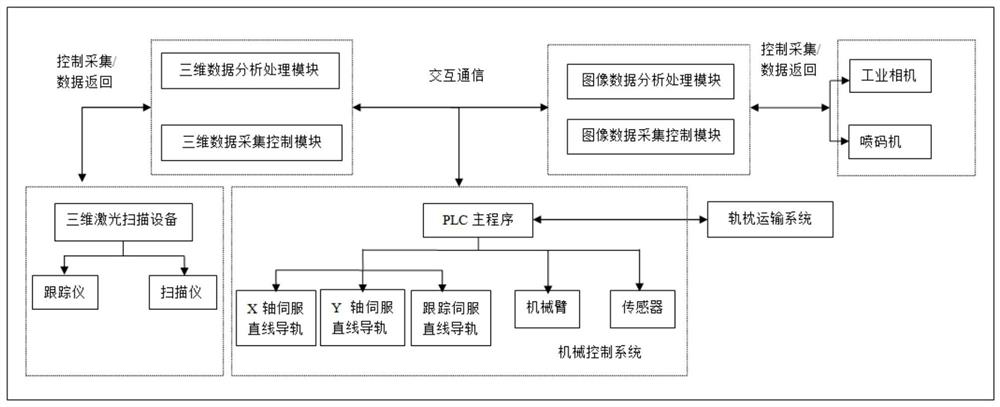

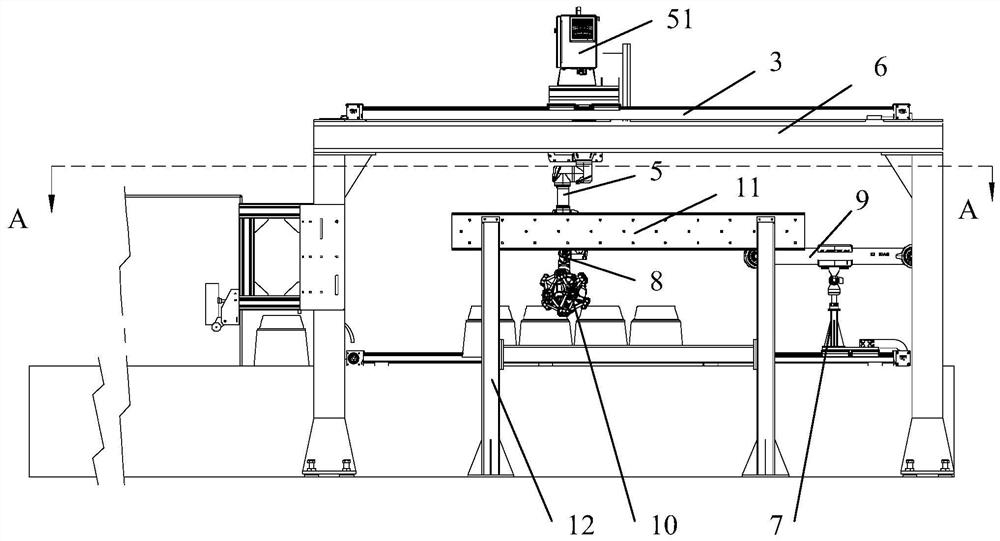

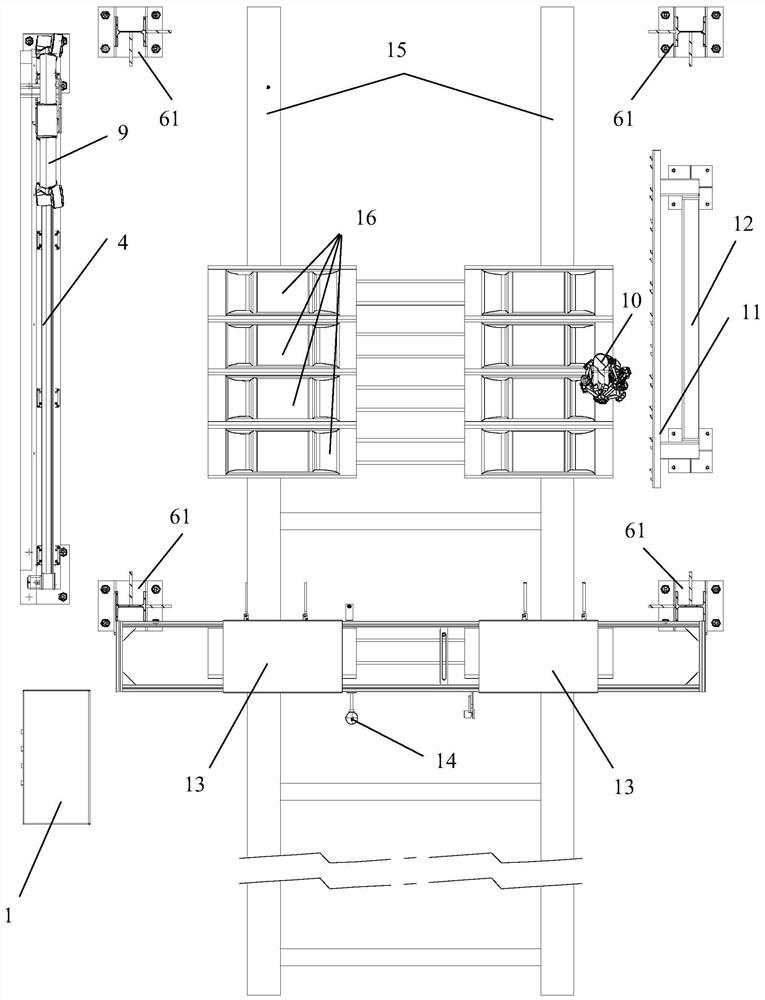

[0041] Example: see attached Figure 1-7 , a double-block sleeper appearance quality inspection system based on machine vision, including upper computer software interactively communicating with PLC main program, multi-axis servo linear guide rail, sleeper transportation system and installation frame; said upper computer software and PLC main program Installed in the control cabinet 1, the interior of the control cabinet 1 is also equipped with an industrial computer, a switch and a power supply, and the surface of the control cabinet 1 is operated through a touch screen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com