Mechanical release structure, implant and mechanical release instrument

An implant and mechanical technology, applied in the field of medical devices, can solve problems such as difficult and reliable release, and achieve the effect of reliable release, convenient operation, and stable interlocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

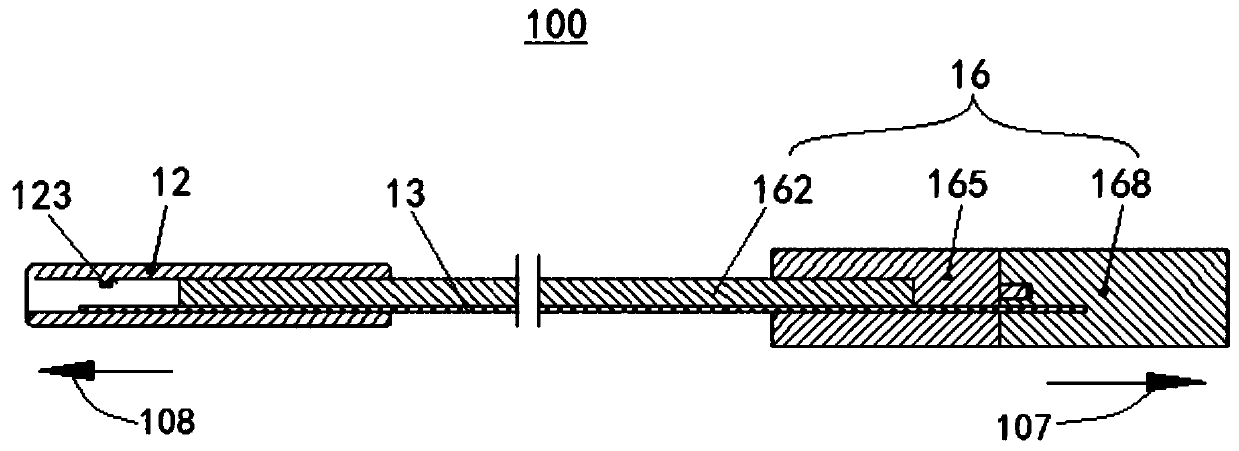

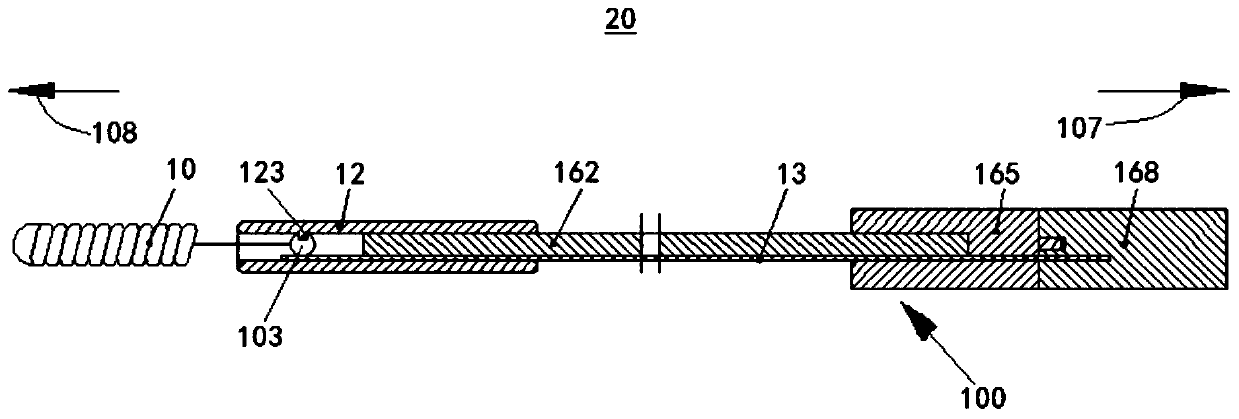

[0038] figure 1 A cross-sectional view of the mechanical release structure 100 provided in this embodiment, figure 2 is a schematic diagram of an implant 10 cooperating with a mechanical release structure 100, image 3 For the assembled sectional view of the mechanical release structure 100 and the implant 10, please refer to figure 1 , figure 2 and image 3 shown.

[0039] The mechanical release structure 100 provided in this embodiment 1 includes a release tube 12 and a release rod 13, the inner wall of the release tube 12 is provided with a protrusion, and the proximal end of the implant 10 is provided with a clamping part 103, and the clamping part 103 extends into the release tube 12, the notch 105 of the clamping part 103 cooperates with the protrusion on the inner wall of the release tube 12, and under the support of the release rod 13, the implant 10 and the release tube 12 are clamped and locked, and the release rod 13 is locked. After being pulled away from be...

Embodiment 2

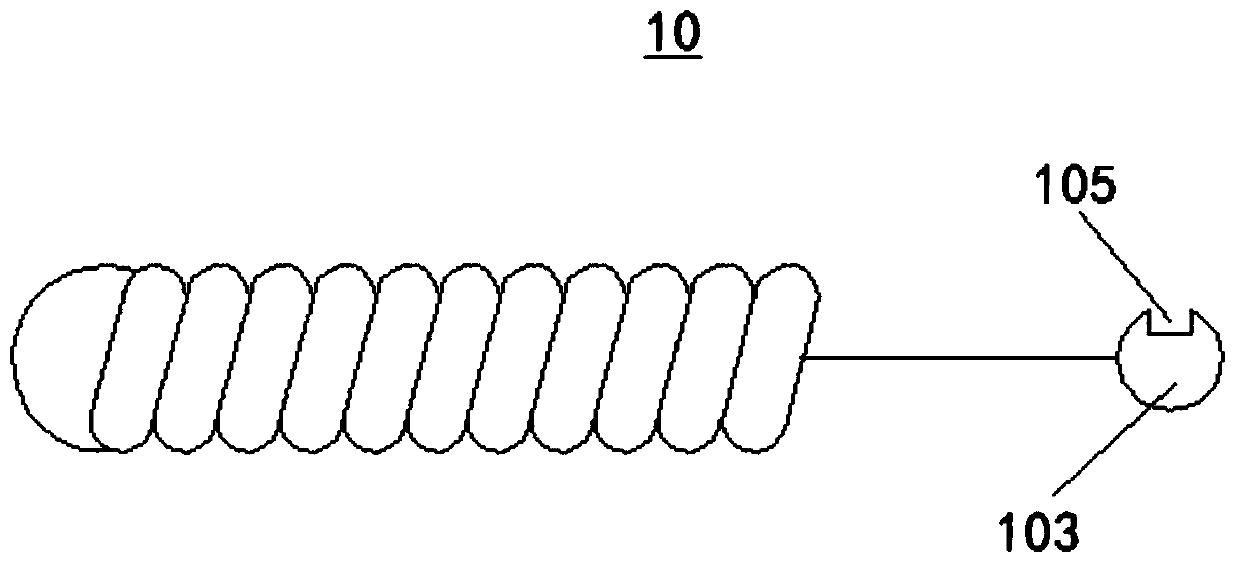

[0070] This embodiment provides an implant 10 configured to cooperate with a mechanical release structure 100, please refer to figure 2 As shown, the specific description is as follows.

[0071] The implant 10 is generally made of materials that are opaque to X-rays and have good biocompatibility, commonly used are platinum, tungsten, nickel-titanium or other alloy materials. When treating vascular diseases, the usual operation method is to insert the microcatheter into the blood vessel along the guide wire and reach the designated target area. After the microcatheter is in place, the implant 10 at the distal end of the delivery system can be pushed to the target area through the lumen of the microcatheter. After the position of the implant 10 is determined under the imaging technique, the implant 10 can be released from the delivery system so that it can be placed in the designated position.

[0072] The proximal end of the implant 10 is provided with a locking part 103 , ...

Embodiment 3

[0078]This embodiment provides a mechanical release device 20, including the implant 10 and the mechanical release structure 100 provided in Embodiment 1 above, please refer to image 3 As shown, the specific description is as follows:

[0079] The proximal end of the implant 10 is provided with a clamping portion 103, the clamping portion 103 is provided with a notch 105, the inner wall of the release tube 12 is protrudingly provided with a pin 123, the clamping portion 103 extends into the inner cavity of the release tube 12, and the concave The opening 105 can cooperate with the pin 123 , under the support of the release lever 13 , the clamping part 103 is lifted and can be clamped and locked with the release tube 12 .

[0080] When the release rod 13 is pulled under the action of an external force to separate the release rod 13 from the clamping portion 103, the notch 105 and the pin 123 of the release tube 12 are in a release state, thereby realizing the implant 10 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com