positioning clamping mechanism

A technology for positioning, clamping and resetting parts, applied in positioning devices, clamping, metal processing mechanical parts, etc., can solve the problems of workpiece damage, affecting production efficiency, cumbersome steps, etc., to achieve accurate repeated positioning, high production efficiency, and operation. Quick and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

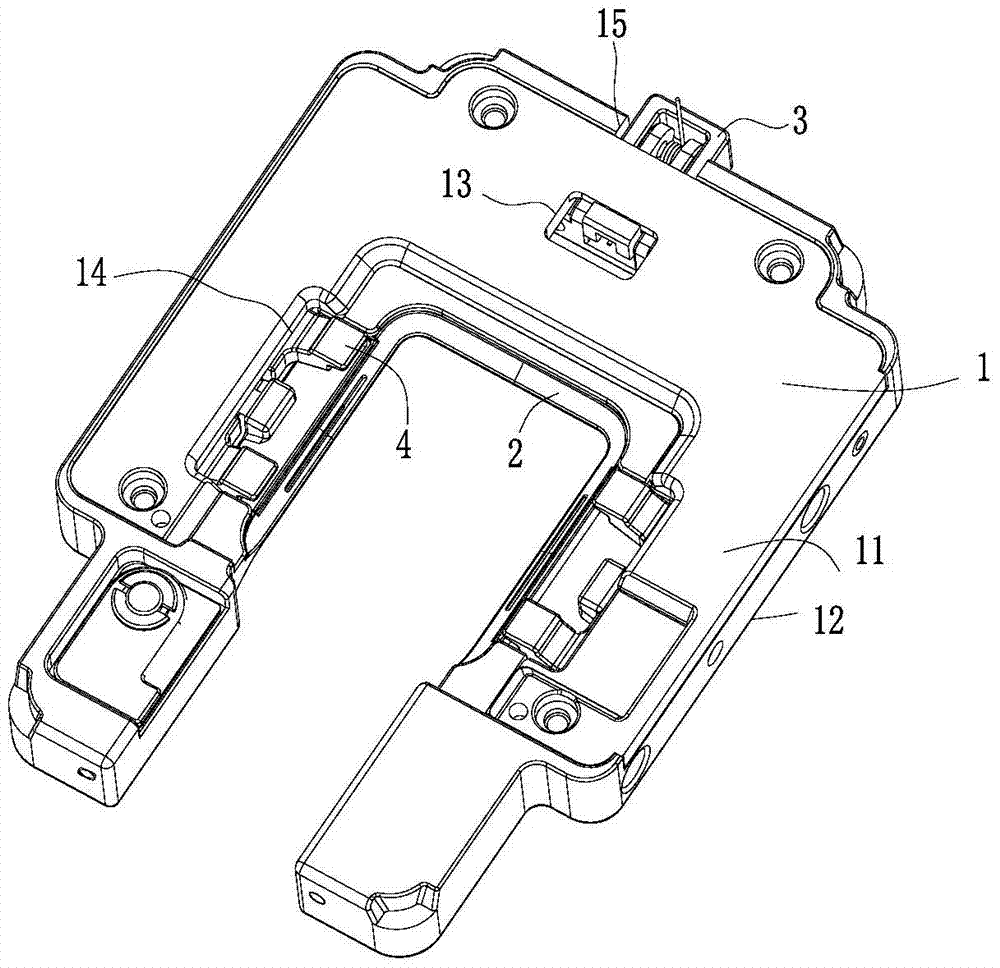

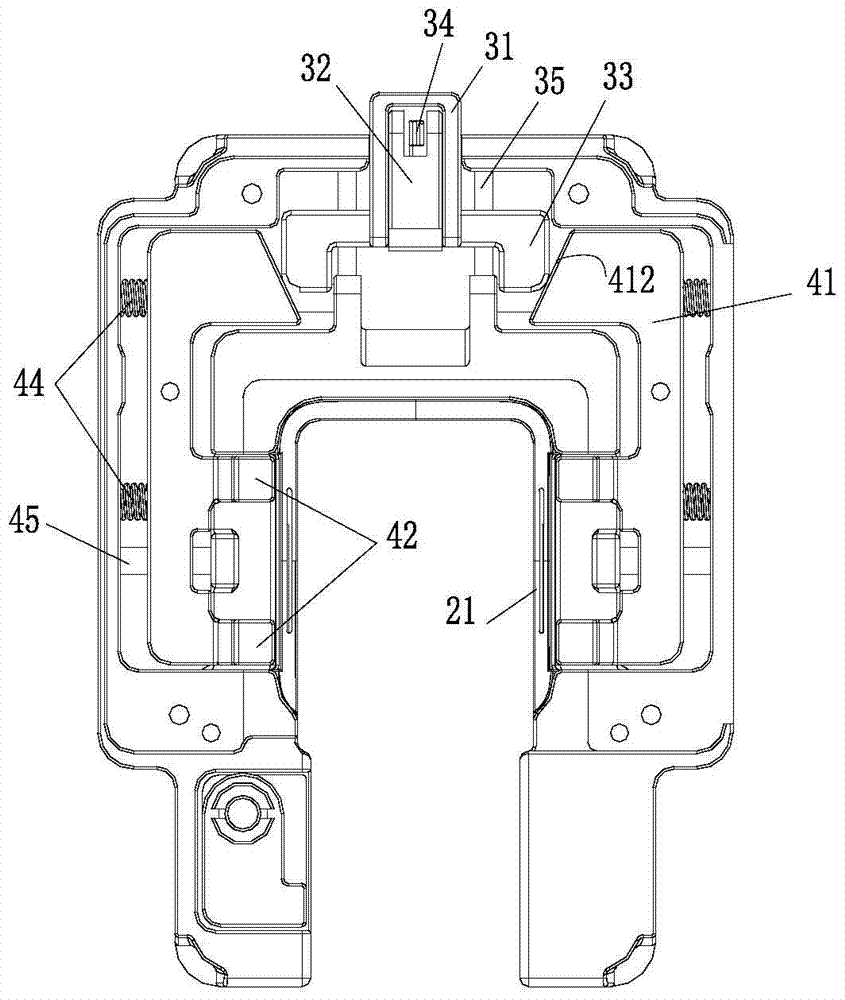

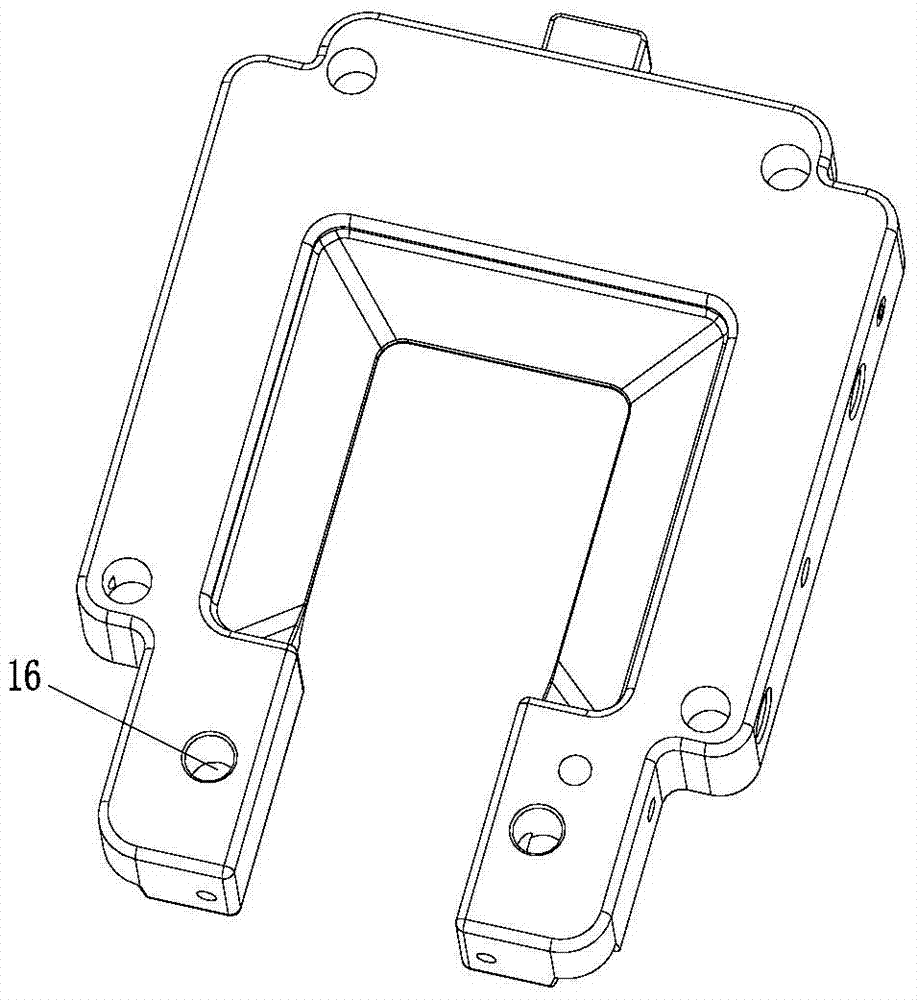

[0056] The invention discloses a positioning and clamping mechanism. The profiling surface is used for positioning, and the buckle is controlled by the buckle switch assembly to perform line contact and fixation on the edge of the workpiece to be processed.

[0057] If the shape of the workpiece to be processed is a regular figure, as in the present invention Figure 5A In the rectangular recessed mobile phone back cover, the buckles can be arranged symmetrically on both sides of the workpiece to be processed. The left and right buckles are controlled by a buckle switch assembly, and the workpiece A to be processed is fixed at the same time.

[0058] For convenience of description, the figure 1 The opening direction of the main body in the figure is called "front", the direction corresponding to the opening is called "back", the left side of the figure is called "left", the right side of the figure is called "right", and the direction of the center of the profiling surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com