Multi-station tyre gripper rotating device of tyre spraying coater and a rotating manner thereof

A multi-station, spraying machine technology, applied in spraying devices, devices for coating liquid on the surface, coating, etc., can solve the problem of lengthening the spraying cycle of a single wheel tire, high difficulty in processing large-diameter gears, and reducing indexing efficiency and other problems, to achieve the effect of shortening the spraying cycle, simple structure and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

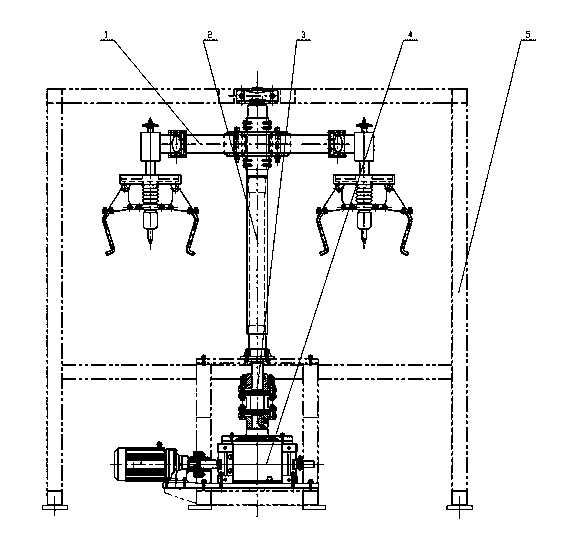

[0037] Example: An indexing device for a three-station tire gripper of a tire spraying machine (see attached figure 1 ), consisting of a three-station tire gripper assembly (1), a vertical center shaft assembly (2), an indexing drive assembly (4) and a double-section metal diaphragm coupling (3).

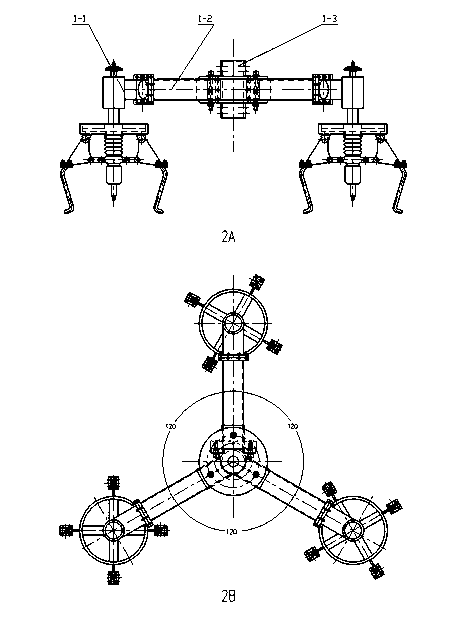

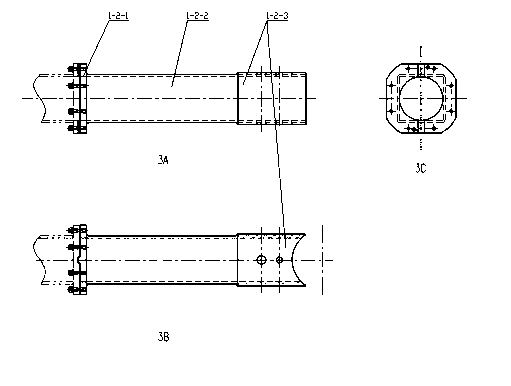

[0038] Three-station tire gripper assembly (1) (see attached figure 2 ) is composed of three sets of tire grippers (1-1) and their respective connecting cross arms (1-2) and connecting arm supports (1-3). One end of the connecting cross arm (1-2) is connected to the tire The device (1-1) is fixed with a flange, and the other end is connected with the connecting arm support (1-3) in a mortise and tenon type. The distance between the center of each tire gripper (1-1) and the connecting arm support (1-3 ) center lengths are equal, the three sets of connecting cross arms (1-2) are connected with the connecting arm supports (1-3) in the shape of umbrella ribs, and the angle between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com